Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

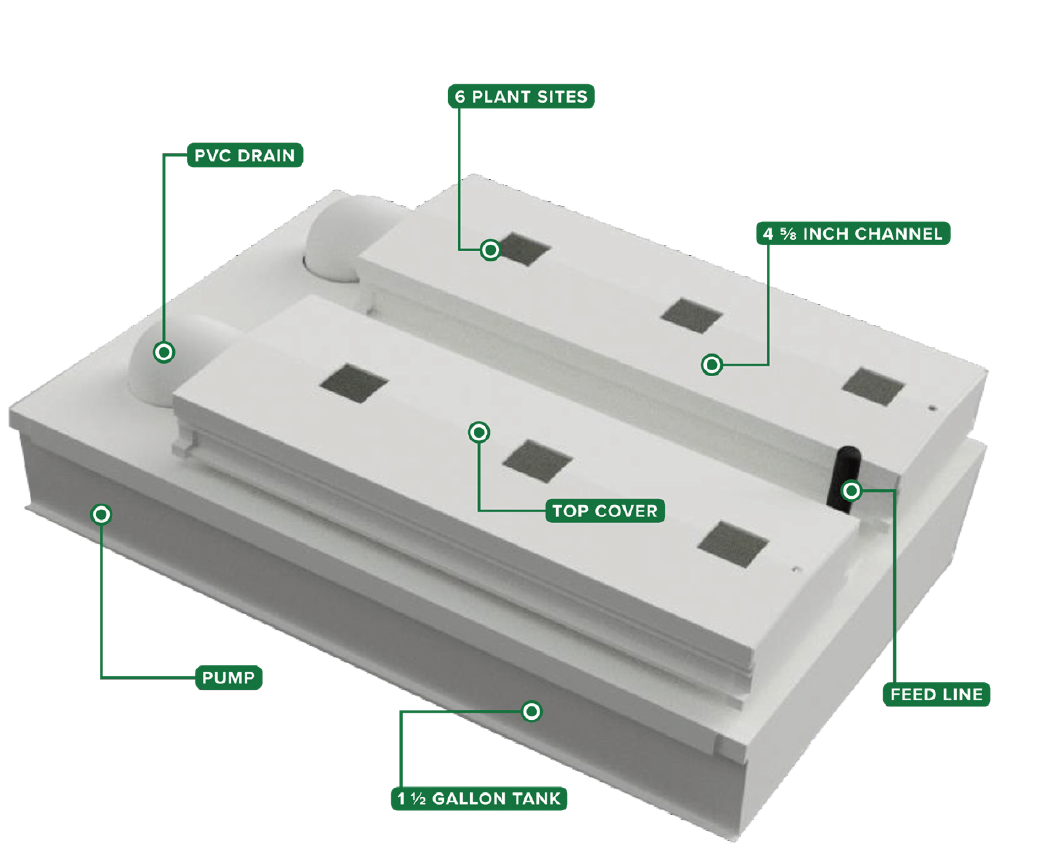

Desktop NFT System

Grow fresh, high-quality leafy greens on your desktop or kitchen counter.

Our unique hydroponic desktop NFT system has all the capabilities of a traditional sized NFT system allowing you to grow fresh, high-quality leafy greens on your desktop or kitchen counter. Perfect for schools, hobby growers and anyone looking for fresh produce year-round!

This system features:

• A removable top cap (lid) makes the channels easy to use and easy to clean.

• End caps on both ends of the channel, keeping light out & preventing algae growth.

• Constructed of non-toxic, food grade, UV-stabilized plastic.

• A standard electric plug – no additional power source required.

• Square top cap holes that are made for 1" seedling cubes.

Specs:

• Measures 16'L x 11'W x 4'H

• Weighs 3.5 lbs when the tank is empty & 12 lbs when it’s full.

System Includes:

• (2) 1' x 4 ⅝' grow channels

• 6 plant sites

• Pump

• Feed line

• 1 ½ gal tank

• Fertilizer & Rockwool cubes

$49.95

Get yours today by calling 330-302-4203!

*volume and educational discounts available

CropKing.com

Tips On Designing The Best Hydroponics System

November 1, 2018

To design the best hydroponics system, one must look at the host of factors contributing to plant growth, roughly these are the environment, temperature, nutrient delivery and protection from damaging agents.

Hydroponics farming in India looks to the use of Greenhouses as a solution to manage these factors. Greenhouses are large structures built over tracts of flat land to accommodate the protected farming techniques, that use climate control methods and such to grow seasonal crops in unseasonal weather. In hydroponics, an additional technology used is water chillers as a cool root zone promotes aeration and root health.

For ambient temperature fan and pad cooling systems are effective in dry and hot weather. The system works by drawing air in through a cellulose pad placed all along one side of the polyhouse structure, water is trickled through this cellulose pad to provide the evaporative cooling effect. The air is sucked in by large fans and blown out of the greenhouse.

The material a greenhouse is made of can also greatly help with removing trapped heat from the structure, commonly used material is polycarbonate which, while being significantly more expensive than a poly sheet, it has the best heat transfer ability and hence is the best for climate control. Polycarbonate is also more durable but can be tough to work with due to its rigidity. The ultimate in greenhouse material technology is Glass greenhouses, both the most expensive and the best to control temperature and climate. A Glass greenhouse would ultimately require less frequent maintenance than any other type of greenhouse material. A glass greenhouse would be ideal for doing hydroponics in Gurgaon or Delhi which have very varying climates.

When looking at doing large scale hydroponics in India it is important to remember that we undergo usually intense summers followed by pleasant winters. Heating is not a necessary concern except in very extreme cold climates, but these climate zones are restricted to a few pockets and usually, the market for hydroponics is not present in these areas. This, however, should not discourage potential hydroponic farmers as the colder climates help with growing high-value exotics. These have great export and commercial value in urban areas.

Automation is a key aspect of designing any hydroponics system, water is reactive and transpiration and evaporation can change key water parameters of ph and EC and hence it is necessary standing monitor systems like the Bluelab Guardian monitor. When looking at automatic dosing the requirement stems from the need to reduce labor and time spent on maintaining the system thereby freeing up labor for harvest, maintenance, and packaging of the produce. Automation can be achieved through master controllers and peristaltic pump dosers.

These control panels like the Bluelab Pro Controller are very efficient at monitoring and controlling dosing pumps such as the Bluelab Peripod to maintain the all-important parameters of pH and EC. The Bluelab connect software is a remote monitoring and control software that helps growers record data and control their dosing remotely.

The Pro controller is a versatile device that can control up to 12, 3 or 4 pump dosing units and can be used to do up to 3 nutrients and one pH solution, this has great application for automating fruiting vegetable crop production. The Pro controller can set an individual on/off times for each of the pumps thus enabling the grower to maintain the right NPK mix for his crops throughout the growing cycle.

The Hydroponics system itself should be designed according to the crop to maximize efficiency and space. For example, Tomatoes need larger root spaces with changes to their NPK ratios during flowering but lettuce can be grown close together on pipes with very little nutrient use.

Thus we use different hydroponic techniques for these plants, tomatoes are grown on DWC rafts or BATO bucket systems and NFT systems are used to grow leafy greens and herbs. The type of crop dictates the type of vessel the crop is grown in. While cheap and cost-effective, DWC trays may be cumbersome to maintain and flimsy meaning frequent repairs and upgrades. NFT and BATO systems are easier to maintain and dose, they also use water and space more efficiently.

One important factor of the use of all these technologies is the ability to monitor the factors affecting crop growth and thus giving us the necessary data to improve our crop growing process to produce better yields and more quality crops.

The use of technology could help us mitigate the damage that factory farming over vast tracts of land has done to our environment. The introduction of a data-based A+B= C formula is only possible with careful data monitoring and interpretation to make a replicable plant growing formula for great yields and quality produce.

FutureFarms Pvt. Ltd

4/640, 12th Link, 3rd Cross Street

Nehru Nagar, Venkateswara Colony

Perungudi, Chennai, India 600 096

An H-E-B-Owned Central Market Location In Dallas Sells Store-Grown Produce

Fresh Starts On The Perimeter

By Carolyn Schierhorn - 2018

Whether in a rural area or an urban hub, grocery retailers today are leveraging their fresh departments to differentiate their overall brand and their individual private brands from the competition. Across all generations of consumers, but especially among millennials, fresh food has an aura of healthfulness and excitement that far surpasses the packaged food products in the center store.

But “fresh” today doesn’t just refer to the produce, deli, “grocerant,” meat, seafood, bakery and dairy departments, according to Nicole Peranick, Stamford, Conn.-based Daymon’s senior director for culinary thought leadership, who shared her insights during Store Brands’ “Power of Private Brands” webinar series last year. “Fresh has taken on an expanded meaning, and solving for this new interpretation is really imperative to capture and retain customers,” she says.

As the Daymon white paper “From Shopper to Advocate: The Power of Participation” makes clear, fresh has become “the gateway to shopper loyalty.” To win consumers’ trust, grocery retailers must succeed in engaging customers at multiple touchpoints on the store perimeter and even before they walk into store — delighting shoppers with delicious samples, a cornucopia of colors and fragrances, high-energy food prep and cooking demonstrations, access to community resources such as representatives from local businesses or nonprofits, opportunities for “co-creation” and “personalization,” and more.

Under this broader definition, fresh could apply to a health & beauty section that allows shoppers to sample various botanical skincare products and aromatherapy oils, a wellness department coordinated by a registered dietitian nutritionist (RDN) who can help customers navigate the store and shop for their unique dietary needs, an in-store exhibition showcasing the work of local artists and craftspeople, or even a 3-D printer that lets shoppers scan photos and create ceramic figurines of themselves and loved ones (available at several Asda stores in the United Kingdom).

As West Des Moines, Iowa-based Hy-Vee demonstrates, fresh can also be a portal to a company’s values. For example, customers who shop at the Midwestern chain’s more than 245 stores are assured that the sushi in the retailer’s Nori Sushi bars is 100 percent responsibly sourced as are the many species of fish, mollusks and crustaceans sold in the fresh seafood department, from barramundi to Alaskan king crab legs to oysters. Indeed, Greenpeace ranks Hy-Vee among the top grocery retailers for seafood sustainability. Going the extra mile to ensure quality and safety, Hy-Vee also voluntarily employs a full-time U.S. Department of Commerce seafood inspector at its wholly owned Perishable Distributors of Iowa (PDI) subsidiary in Ankeny, Iowa.

Hy-Vee’s produce department also reflects the company’s commitment to environmental sustainability, specifically food waste reduction. The retailer has earned recognition, including a 2017 award from Store Brands for “Best Store Brand Merchandising Idea,” for the way it champions The Misfits, cosmetically challenged produce supplied by Eden Prairie, Minn.-based Robinson Fresh, which brought the Misfits concept and brand to the United States. (The brand originated with Redhat Co-operative in Alberta, Canada.)

Hy-Vee, which has sold nearly 2 million pounds of the misshapen, off-size or slightly discolored but otherwise delicious fruits and vegetables, “is a good example of a company that has embraced the program holistically, from sustainability to a consistent eating experience,” says Craig Arneson, general manager of Robinson Fresh. “It is paramount to the success of the Misfits program to have collaboration at all levels of the organization.”

Approximately 20 SKUs of The Misfits are available at any time, with the specific choices depending on the season. “Much of the product was left in the field or destroyed in the past, so the Misfits program provides a sustainable outlet for a wider range of production,” Arneson explains. In addition, to reducing waste and providing customers with affordable produce, the program helps support growers financially.

Meeting consumer demand

Winning over shoppers in the fresh realm requires meeting consumer demand for both healthful products and on-the-go convenience, notes Jeff Oberman, vice president of trade relations for the Washington, D.C.-based United Fresh Produce Association. One retailer that excels in this domain is Lowes Foods in Winston-Salem, N.C. The retailer’s stores have a “Pick & Prep” station, allowing shoppers to select their own fresh fruits and vegetables and then drop them off for customized cutting.

“So if you want to purchase a mango but don’t know how to cut it, you can bring it to the Pick & Prep station, and a trained produce professional will cut it for you,” Oberman says. Many customers also use the service to save time while they continue to shop, specifying whether they want an item, be it an onion or a watermelon, diced, sliced or chopped. Consumers can even order this service for produce purchased online from Lowes via Instacart.

Besides convenience, contemporary consumers, especially millennials, are demanding transparency and, when feasible depending on the season and type of product, local sourcing, Oberman points out. “Consumers want to know how these products are produced and how they’re grown. They want to know that the people who harvest the crops are ethically treated,” he says. “And it’s not just with produce; it’s with everything in the store.”

Consumers, moreover, increasingly expect to find organic offerings, but the demand for organic varies widely, depending on the region and shoppers’ income levels.

In southwestern Indiana, for example, where Baesler’s Market operates three stores — in Terre Haute, Linton and Sullivan — shoppers do ask for organic items but demand is not robust, says Bob Baesler, the company’s president. Nevertheless, he maintains a 12-foot section of organic produce in the less-rural Terre Haute store, which is in a small city of approximately 61,000 people.

“We don’t sell a lot of it, but there are people who want it, so we try to have it for them,” Baesler says, noting that Baesler’s Market’s commitment to delighting customers in the fresh arena is one way the retailer differentiates itself from Dollar General, which has several stores in the communities Baesler serves.

In a rural locale with many farms, consumers are more apt to prioritize local sourcing because of the positive impact on the area’s economy; it’s not simply a trendy millennial-driven preference.

Baesler’s Market carries local corn, carrots and watermelons. “We attempt to do as much local as we can, but there is a limit to what we can do,” Baesler says. Not only does Indiana have a limited growing season, but also local producers can’t meet the retailer’s need for many items during the warmer months.

“Outside of the three mentioned items, [local farms] don’t have enough quantity to where we can just depend on them all summer for tomatoes or all summer for cucumbers,” he elaborates. Still, customers appreciate the retailer’s efforts to sell local produce, and Baesler diligently works with the area’s farmers to bring more locally grown items into the three stores. For example, Baesler’s this year partnered with a Terre Haute organic farm called The Pickery, where customers normally go to pick their own vegetables. “On a regular basis, [the owner] would bring us eggplants and other items. But the supply was such that it only lasted a couple of days,” Baesler says.

Local sourcing is a challenge everywhere, and some larger supermarket chains are helping to defray farmers’ production costs to ensure a supply of fresh products that can meet rising consumer demand, Oberman adds.

Though still in the experimental phase and not a solution to the local supply challenge, an emerging trend among grocery retailers is “hyperlocal” store-grown produce. Retailers are beginning to grow their own leafy greens and herbs in rooftop greenhouses, on the sides of stores in hydroponic vertical gardens, and — as H-E-B-owned Central Market is doing — in a mobile container just outside of a store that could be moved from one location to another.

Behind one of Central Market’s Dallas stores, a 53-foot custom-built Growtainer, made from a recycled shipping container, provides 480 square feet of climate-controlled vertical production space. The miniature farm features proprietary technology for ebb-and-flow irrigation, a water-monitoring system, and energy-efficient light-emitting diode (LED) production modules specifically designed for multilayer cultivation, according to Glenn Behrman, president of Dallas-based Controlled Environment Agriculture (CEA) Advisors, which developed the Growtainer specifically for Central Market.

Behrman points out that the Growtainer has been a highly successful “innovation project” for the retailer. “They can’t keep up with the demand,” he says.

The hydroponically grown leafy greens are merchandised in the store’s produce department on an attractive mobile “Store Grown Produce” display made of wood. The greens are wrapped in plastic with a label branding the product as “Central Market Store Grown Lettuces,” with 10 varieties of lettuce listed and the specific type of lettuce in the package indicated with a checkmark.

For the Growtainer to work, “you need a fast-turnover, shallow-root kind of crop” and substantial commitment from the retailer, Berhman says.

Foraying into fresh-prepared

Addressing customers’ need for convenience and their growing enthusiasm for ethnic foods, grocery retailers across the country are expanding their deli departments into “grocerants,” establishing hot bars, salad bars, signature dishes, made-to-order stations and even fast-casual and full-service restaurants.

Hy-Vee has significantly ramped up its foodservice options at its new Minnesota stores. But smaller chains are also favorably impressing customers with expanded fresh-prepared offerings. For example, since KFC left the area, Baesler’s Market has developed a big fan base for its signature fried chicken, Baesler says.

The Indiana retailer also emphasizes quality and consistency in its deli meats and salads. “Some retailers will switch suppliers, but customers get tired of things not tasting the same,” Baesler notes. “We’ve been selling the same slaw for 20-some years and the same potato salad.”

The company does take risks, though it may tread more cautiously than urban and college town grocers with a younger population base. For example, when the retailer first added a hot bar in 2015, a number of customers complained because they didn’t like the change. But the hot bar has done “exceptionally well in sales,” according to Baesler, who notes that he has expanded the number of soup wells from three to six because soup is so popular with his customers, even during the summer. The hot bar offerings at Baesler’s include Mexican, Italian and Chinese dishes as well as American comfort food such as meatloaf.

Customized convenience seems to be the watchword of another supermarket chain, Skogen’s Festival Foods, which owns 31 stores in Wisconsin. In addition to a rotating hot bar menu featuring BBQ Monday, Taco Tuesday, Stir Fry Wednesday, Italian Thursday and Supper Club Friday, the De Pere, Wis.-based chain offers a “Daily Deli Deal.”

“For instance, on Mondays we offer four large pieces of lasagna and a loaf of Italian bread for $10,” says Lars Batzel, fresh department senior director at Festival Foods. “On Tuesday, we have $6 rotisserie chickens. On Wednesday, we have $5 sushi.”

Festival Foods also provides heat-and-eat prepared meals. Shoppers can choose a protein-based entrée and one or two side dishes at different price points. “These have done very well for us,” Batzel says.

Additionally, the retailer is venturing into own-brand meal kits, which are being rolled out to more than 75 percent of the retailer’s stores. What’s more, Festival Foods is considering adding made-to-order stations at some locations, beyond the well-equipped deli service counters. “There are a lot of logistical and equipment challenges that go into this, so we’re trying to figure out the right approach for us,” Batzel says.

Find a niche

In highly competitive markets, retailers need to find a niche in fresh where they can outshine rivals. This could be a bakery department that is the go-to place for birthday cakes, holiday pastries and even wedding cakes. Or perhaps the bakery is situated near the front of the store so shoppers can enjoy the aroma of fresh-baked bread as they walk in.

The often unsung dairy department also provides opportunities for differentiation, notes Julie Quick, Plano, Texas-based Shoptology’s senior vice president for insights and strategy. Retailers can use sampling to drive trial of flavored milks, newfangled non-dairy milks, new cheeses and yogurts. Supermarkets should also tell the stories of the farms that supply the store brand milk and other products in the dairy case, she suggests.

“Dairy has to actively managed and credentialed as a fresh department,” Quick emphasizes. “Retailers need to work harder to ensure freshness and share the origins of the product. The wholesomeness and goodness of the product needs to be merchandised.”

Consumers are looking for products with protein, so buzz can be built around milk’s naturally high protein content, adds Susan Stege, senior director of category and shopper insights for Dallas-based Dean Foods. Milk is also a natural product, ideal for modern consumers who are gravitating toward less-processed foods, she says, noting that positive dairy messaging can be established through the retailer’s website and social media channels.

As Stege puts it, “You can’t get any more ‘clean label’ than milk.”

Schierhorn, the managing editor of Store Brands, can be reached at cschierhorn@ensembleiq.com.

How A 3.5-Mile-Long Irrigation canal Used by 23 Farms Caused The E. coli Outbreak Linked To Romaine Lettuce

Flickr / Ken LundFDA offers its first assessment of what happened in Yuma, Arizona.

November 1st, 2018

by Joe Fassler

The Food and Drug Administration (FDA) on Thursday offered its first thorough postmortem of the recent E. coli outbreak linked to romaine lettuce. We last heard from the agency on this topic in June, when it announced that canal water in Yuma County, Arizona—the winter lettuce capital of the world—contained the same strain of E. coli found to be sickening people, and noted that the investigation was ongoing. Thursday’s release helps illustrate the full scale of the outbreak, provides new clues about what went wrong, and suggests the incident may permanently alter the federal government’s relationship to bagged salad.

To start, FDA’s “environmental assessment” provides the most recent update of the outbreak’s massive scale. Sickening 210 people across 36 states, sending nearly 100 to the hospital, and killing five, it was the largest outbreak of E. coli 0157:H7 in this country since 2006. Those numbers—including the five deaths—are similar to what was already known in June, so the human toll of the outbreak hasn’t turned out to be much larger than we knew. What is new, though, is a sense of how many farms were involved.

Until now, it hasn’t been known whether the outbreak was linked to just one producer, or if there was some kind of more systemic problem. Thursday’s report paints a clearer picture. An investigation by FDA and the Centers for Disease Control (CDC) found that 36 fields on 23 different Yuma County farms supplied lettuce that was potentially contaminated with the rare strain of E. coli implicated in the outbreak. The culprit? A 3.5-mile-long irrigation canal near Wellton, Arizona, which the farms each relied on for water.

“The commingling of romaine lettuce from various farm growing fields complicated traceback efforts.”

The agencies don’t know exactly how the water became contaminated in the first place, though they note it had an animal, not human, source—likely some form of domesticated livestock or wildlife. But all those plots relied on the affected water at some point. The FDA says that the most plausible ways the water reached the crops were through direct application, or when it was used to dilute pesticides sprayed on the fields. It also notes that a late season freeze—in early February—may have weakened the plants and made them more susceptible to contamination.

A compounding factor, though—and one reason why such a huge volume of lettuce was potentially impacted—was the way local processing plants mixed together romaine from multiple producers, complicating the investigation and potentially cross-contaminating product. Though the agencies only found the E. coli in question on a single farm, the 36 fields affected shared infrastructure, greatly muddying the picture.

Related: Could Yuma, Arizona’s trained falcons prevent the next E. coli outbreak

“The commingling of romaine lettuce from various farm growing fields at fresh-cut produce manufacturing/processing facilities complicated traceback efforts and made it impossible for FDA to definitively determine which farm or farms identified in the traceback supplied romaine lettuce contaminated with the E. coli O157:H7 outbreak strain,” said the report.

It’s that scenario that the agencies will work harder to prevent. Though FDA and CDC found no specific “deficiencies” at packing plants in the area, they signaled that they are exploring actions that would prevent a similar outbreak in the future.

For now, Gottlieb said, more action is needed “on all fronts.”

“Going forward, both FDA and industry need to explore better ways to standardize record keeping and determine whether the use of additional tools on product packaging could improve traceability,” FDA Commissioner Scott Gottlieb wrote, in a statement.

That will likely include more aggressive safety testing on the ground. “The FDA plans to collect and analyze romaine lettuce samples through a new special surveillance sampling assignment for contamination with human pathogens,” Gottlieb wrote. “This will help us determine whether products are safe to enter the U.S. marketplace.” As of now, it’s unclear exactly what kind of system would be put into place, though the Commissioner suggested whole-genome sequencing could be an option back in June.

For now, Gottlieb wrote, more action is needed “on all fronts”—the private and public sector will need to work harder, and work together, if they are to prevent another Yuma.

Pure Flavor® Breaks Ground on New Georgia Distribution Center

Georgia greenhouse, Pure Flavor® announced recently that they have broken ground on a new 60,000 sq. ft distribution center just 10 minutes away from their new greenhouse facility off of I-75 in Peach County, GA.

Fort Valley, GA - November 1st, 2018

With fresh tomatoes coming to life in its new Fort Valley, Georgia greenhouse, Pure Flavor® announced recently that they have broken ground on a new 60,000 sq. ft distribution center just 10 minutes away from their new greenhouse facility off of I-75 in Peach County, GA.

“We are strategically growing our business across North America and in doing so, need to support this growth with regional facilities that reduce food miles for our greenhouse grown vegetables. Our new distribution center in Peach County will allow us to better serve our retail & foodservice customers throughout the southeast year-round”, said Jamie Moracci, President. As a vertically integrated vegetable company, Pure Flavor®’s family of growers produce greenhouse tomatoes, peppers, cucumbers, eggplants and a wide variety of USDA certified Organic items at farms in Canada, USA, and Mexico.

The new Georgia distribution center will serve as a consolidation point which will provide an opportunity for a greater assortment of Pure Flavor® greenhouse grown vegetables to retailers & foodservice partners in the southeastern US region starting in early 2019. Pure Flavor® operates distribution centers in Leamington, ON, Romulus, MI, and San Antonio, TX to support its vast network of growers throughout North America.

A little over 14 months ago, Pure Flavor® broke ground on a 75-acre, $105 million-dollar greenhouse facility in Fort Valley, GA. Phase 1 of 25 acres is now complete with the first crop of Georgia Grown tomatoes to be picked in a few weeks’ time. Pure Flavor®’s Long English & Mini Cucumber crop will also be ready for picking in November.

“Our team has been hard at work building a state of the art, high tech greenhouse facility in Georgia. What has been accomplished in the past year has been remarkable”, said Moracci. “Our goal to grow greenhouse tomatoes & cucumbers in Georgia is becoming a reality, we look forward to promoting Georgia Grown vegetables this winter”, said Jamie Moracci.

To learn more about Pure Flavor®’s Georgia greenhouse project and to see photos of the construction of both projects, visit GeorgiaGrownFlavor.com.

Pure Flavor® is a family of greenhouse vegetable growers who share a commitment to bringing A Life of Pure Flavor™ to communities everywhere. Our passion for sustainable greenhouse growing, strong support for our retail & foodservice customers, and focus on engaging consumers is built on a foundation drawn from generations of growing expertise.

SOURCE: Chris Veillon | chris@pure-flavor.com

Chief Marketing Officer | Pure Flavor®

T: 519 326 8444

Experience From the Field

10/30/2018 | by Nick Greens, Horticulturist/Consultant

You’re a solid grower with great ideas, but you may feel like you don’t have enough experience in the field. You may need to be patient and research your ideas, but then again, maybe it’s not that. Maybe your ideas are missing something. There are extra factors with hydroponics that may cause things in the field to fail, here’s our tips for troubleshooting possible problems and finding potential solutions.

Timing

Expert growers have seen some herb seeds take up to a month to germinate but these are extreme cases. Mostly, growers see germinating over a three day period or sometimes up to a week. After a week without germinating we are in uncharted territory. If you don't achieve germination by the middle of the second week then you should reconsider the germination technique being used. You should also consider germinating a new batch so as not to delay your grow over non-viable seeds.

Germination Spraying

If you have a problem with over watering or using too much water at this stage, spraying is a viable and safe way to regulate water. It is far easier to spray a medium to make it moist than to otherwise water a medium to make moist. Get a spray bottle. If you still have a problem with over watering, consider adding perlite to the bottom of your tray next time. This will help absorb excess liquids in almost any growing method.

Air

Air is something your plants need all the time, even in the germination stage. Stale air results in a change in the ratio of gases that comprise it and the accumulation of new ones. Over watering can be a huge problem from the day you start to germinate your seeds because it locks out air. There is never a need to turn your growing medium into a swamp.

Germination and Darkness

Seeds should be germinated in the dark. If you use humidity domes, make sure the domes have top vents and that you cover properly without forcing the dome on. Even if the seeds are covered with a humidity dome, make sure your tray are in darkness because the seeds still need to be kept away from light. As soon as the seeds open, it is necessary that the tray receives the proper amount of light.

Room Temperature Water

Never use water directly from tap. Always let it reach room temperature. Cold water can shock plant roots because it quickly reduces the environment temperature of the growing medium. The same goes for seed germination, don't stick seeds in cold water and don't moisten seeds with cold water. Even when you feed your plants you should let the water reach room temperature. It’s also important to check your own water supply to determine its quality. In most cases chlorine in water won't cause issues with your plants but if your water isn't very clean or pure then you can't expect your plants to use it well. In either case, boiling water and letting it cool to room temperature can help to generate cleaner water.

The Agbioscience Rising Stars: A Discussion With A Legend

Science: “Used and Abused” in the World of Food – Food Evolution

Register Now! 2018 Indiana Agbioscience Innovation Summit Nov. 29

Moderator Scott Dorsey talks ingenuity, business smarts, and grit with some up-and-coming agbioscience executives.

Vijay Harrell | CEO, TradeLanes

Scott Massey | CEO, Heliponix

Ellie Symes | CEO, The Bee Corp

Andrew Uden | Co-Founder of Quantified Ag, Co-Founder, and President of AgVision International

Registration Table Opens

White River Ballroom

—— 9:00 a.m.

Welcome and Opening Comments

Beth Bechdol | President + CEO, AgriNovus Indiana

—— 9:15 a.m.

Investing in Tomorrow’s Food and Agriculture

Aaron Rudberg | Managing Director, S2G Ventures

—— 9:45 a.m.

Lessons from a Seasoned Entrepreneur

Scott Dorsey | Managing Partner, High Alpha

Introduced by: Mitch Frazier | CEO, Reynolds Farm Equipment

—— 10:05 a.m.

The Agbioscience Rising Stars: A Discussion with a Legend

Moderator Scott Dorsey talks ingenuity, business smarts, and grit with some up-and-coming agbioscience executives.

– Ellie Symes | CEO, The Bee Corp

– Scott Massey | CEO, Heliponix

– Vijay Harrell | CEO, TradeLanes

– Andrew Uden | Co-Founder of Quantified Ag, Co-Founder, and President of AgVision International

—— 10:50 a.m.

BREAK

—— 11:10 a.m.

Science and Technology Meets Food and the Consumer

Science and technology have always been inextricably linked to our food and agricultural system and its products. Yet, today, more than ever, there seems to be a growing movement to disconnect them.

Moderator: Jayson Lusk | Distinguished Professor and Head of the Department of Agricultural Economics, Purdue University

– Robert Colangelo | Founding Farmer and CEO, Green Sense Farms

– Sonia Nofziger Dasgupta | Vice President Commercial Strategy, EnviroKure

– Sue McCloskey | Co-Founder, fairlife

– Bob Krouse | President, Midwest Poultry Services

—— 12:00 p.m.

LUNCH

—— 12:20 p.m.

Science: “Used and Abused” in the World of Food – Food Evolution

“Food Evolution explores all the ways science has been used and abused in public discourse surrounding the genetic engineering of food. In a world of misinformation and disinformation, nothing can be more timely.” – Neil deGrasse Tyson

– Scott Hamilton Kennedy | Director + Producer + Writer, Food Evolution

—— 1:00 p.m.

BREAK

—— 1:20 p.m.

The Global Reach of Indiana’s Agbiosciences

Jim Collins | Chief Executive Officer, Corteva Agriscience, Agriculture Division of DowDuPont

—— 1:45 p.m.

Converging Sectors Create Unique Solutions

Moderator: David Johnson | CEO, Central IN Corporate Partnership

– Wayne Eckerle | VP of Research and Technology, Cummins Inc.

– Jack Phillips | President + CEO, Roche Diagnostics North America

– Aaron Schacht | Executive Vice President of Innovation, Regulatory & Business Development, Elanco

– Dr. Sue Ellspermann| President, Ivy Tech Community College

– Jim Collins | CEO, Corteva Agriscience, Agriculture Division of DowDuPont

—— 2:45 p.m.

BREAK

—— 3:15 p.m.

Investing AND Making a Difference in the World

David Rubenstein | Co-founder + Co-executive chairman, The Carlyle Group

—— 3:40 p.m.

A Thought Leaders Conversation: Why the Agbiosciences Matter to All of Us

Bloomberg interviewer David Rubenstein talks big global challenges, cutting-edge research and 21st-century talent priorities with two agbioscience leaders.

– Beth Ford | CEO, Land O’Lakes, Inc.

– Dr. Gebisa Ejeta | Director, Purdue Center for Global Food Security + World Food Prize Winner (2009)

—— 4:20 p.m.

It IS Happening Here… Seriously.

Indiana has a global reputation in pooling localized civic, educational and industry resources to make the region the gold standard in collaboration.

– Joseph Parilla | Fellow, Metropolitan Policy Program, Brookings Institution

—— 4:50 p.m.

Closing Comments

– Elaine Bedel | President, Indiana Economic Development Corporation

– Beth Bechdol | President + CEO, AgriNovus Indiana

—— 5:00 p.m. – 6:30 p.m.

Networking Reception

Guests are invited to stay for a cocktail and networking reception following the conference.

Seven-Figure Order for Ultra-Wide Spectrum Cannabis LEDs

As a company specialized in fine tuned spectra development, Valoya has independently tested and optimized Valoya Canna+ through a series of trials.

Earlier this month, Valoya, manufacturer of high end LED grow light solutions, introduced Valoya Canna+ to the market – a line of LED luminaires with an ultra-wide spectrum designed for professional cultivation of cannabis. As a company specialized in fine tuned spectra development, Valoya has independently tested and optimized Valoya Canna+ through a series of trials. The result is a balanced spectrum for consistent yields and cannabinoid expressions inside state-of-the-art LED luminaires. Valoya says its Canna+ is the widest spectrum available on the market at the moment covering the range from 380nm (UV-A) to 780nm (Far red) thus resulting in superior cannabinoid profiles.

The order is of 6400 pieces of Valoya Canna+ 120 fixtures which are high intensity, 4’ (120 cm) long bars that with 132 W produce a total output of 320 µmols. Delivery of this order is due before the year end.

“This 7 figure order comes less than a month after the product launch giving a good signal about the value the Valoya Canna+ line brings to the cannabis market. As the cannabis market is developing so are growers’ needs for solutions enabling them to bring superior offerings to the market. Cannabis growers are looking for high yields with superior secondary metabolite and terpene compositions with fixtures that do not consume much energy and are reliable.” – Mr. Rabbe Ringbom, VP Sales and Marketing at Valoya.

The order is realized through Innovative Growers Equipment (IGE), Valoya’s North American distributor for the cannabis market. IGE is an equipment supplier to commercial growers in North America. Their products include ebb and flow and expanded metal benches, Valoya’s LED grow lights, plant support systems, automated fertilizer injectors etc.

For more information:

Valoya Oy, Finland

Tel: +358 10 2350300

sales@valoya.com

www.valoya.com

Innovative Growers Equipment

+1 (815) 991-5010

sales@innovativegrowersequipment.com

www.innovativegrowersequipment.com

Could the Future of Farming be Vertical?

Vertical farming is greener and more efficient than traditional agriculture, writes Natalie Mouyal

Photo: BrightAgrotech, Pixabay

Vertical farming promises a more sustainable future for growing fruit and vegetables. Instead of planting a single layer of crops over a large land area, stacks of crops grow without soil or sunlight.

The nascent technology enables farmers to grow more food on less land. Among the benefits, it reduces the environmental impact of transportation by moving production from the countryside to the cities, where most people live.

Dilapidated warehouses and factories around the globe are being transformed into urban farms to grow salads and other leafy greens at a rate that surpasses traditional farming techniques. LEDs provide the lighting plants need to grow, while sensors measure temperature and humidity levels. Robots harvest and package produce.

At one vertical farm in Japan, lettuce can be harvested within 40 days of seed being sown. And within two towers measuring 900 m2 each (actual cultivation area of 10 800 m2 and 14 400 m2), the factory can produce 21 000 heads of lettuce each day.

Indoor farming is not a new concept, as greenhouses have long demonstrated. It has existed since Roman times and can be found in various parts of the world.

Greenhouses are described in a historic Korean text on husbandry dating from the 15th century and were popular in Europe during the 17th century. In modern times they have enabled the Netherlands to become the world’s second largest food exporter.

Vertical farming offers a new take on indoor farming. Popularized by the academic Dickson Despommier, its proponents believe that vertical farming can feed millions of people while reducing some of the negative aspects associated with current agricultural practices: carbon-emitting transportation, deforestation and an over-reliance on chemical fertilizers.

Vertical farming is defined as the production of food in vertically stacked layers within a building, such as a skyscraper or warehouse in a city, without using any natural light or soil. Produce is grown in a controlled environment where elements including light, humidity, and temperature are carefully monitored.

The result provides urban dwellers with year-round access to fresh vegetables since they can be grown regardless of weather conditions, without the need for pesticides and have only a short distance to cover, from farm to plate.

Initially conceived by Despommier with his graduate students as a solution to the challenge of feeding the residents of New York City, vertical farming has since taken off around the world, most notably in the United States and Japan. According to the research company Statista, the vertical farming market is expected to be worth USD 6,4 billion by 2023.

High-tech farming

According to the UN Food and Agriculture Organization, food production worldwide will need to increase by 70% by 2050 to feed a projected global population of 9,1 billion. Vertical farming seeks to address the dual challenges of feeding a growing population that, increasingly, will live in urban centres.

By repurposing warehouses and skyscrapers, these ‘high-tech’ greenhouses reuse existing infrastructure to maximize plant density and production. One vertical farm in the United States claims that it can achieve yields up to 350 times greater than from open fields but using just one percent of the water traditional techniques require.

In general, two methods for vertical farming are used: aeroponics and hydroponics.

Both are water-based with plants either sprayed with water and nutrients (aeroponics) or grown in a nutrient-rich basin of water (hydroponics). Both exhibit a reliance on advanced technology to ensure that growing conditions are ideal for maximizing production.

So as to produce a harvest every month, vertical farms need to control the elements that affect plant growth. These include temperature, requisite nutrients, humidity, oxygen levels, airflow and water.

The intensity and frequency of the LED lights can be adjusted according to the needs of the plant. A network of sensors and cameras collects data with detailed information about the plants at specific points in their lifecycle as well as the environment in which they grow.

This data is not only monitored but also analyzed to enable decisions to be taken that will improve plant health, growth and yield. Data sets sent to scientists in charge of the growing environment enable decisions to be made in real-time, whether they are onsite or at a remote location.

Automation can take care of tasks such as raising seedlings, replanting and harvesting. It can also be used to provide real-time adjustments to plant care. One factory plans to automate its analytical process with machine learning algorithms so that real-time quality control can take into account a diverse range of data sets.

While each of these farms will implement varying levels of technology, it can be expected that as these technologies become more widespread, their adoption will increase. The use of artificial intelligence and cloud computing is not yet extensive but is likely to become increasingly important to ensure production yields remain high.

Growing pains

Despite the enthusiasm for vertical farming, its business model is not yet proven. The initial investment needed to launch a vertical farm and the electricity required to power the 24-hour lights, sensors and other technologies can be costly.

Depending on the source of the electricity used to run the equipment, it may not necessarily prove environmentally cleaner than traditional farming techniques. For this reason, a shift towards renewable energy sources could support the claim that these farms have a positive environmental impact.

At this stage, vertical farms are used primarily for growing crops that attract high market prices, such as herbs, medicinal plants and baby greens. They have not been used to grow the wheat, beans, corn or rice which feed much of the world. Its scale is not yet sufficient to meet food demands.

Vertical farming is still in its infancy. No large scale studies have yet been completed to allow a full comparison with traditional farming techniques. Despite this, it has generated much enthusiasm and, more recently, significant financial support, which may enable vertical farming to create a niche market for the supply of fresh produce to city dwellers.

Box Greens Hydroponics Brings Farm-In-A-Box Concept To Miami

WENDY RHODES | October 29, 2018

Imagine growing 500 heads of lettuce every week in a space smaller than your backyard. That's what sisters Lisa Merkle and Cheryl Arnold of Box Greens are doing with hydroponics.

But instead of growing greens inside stationary buildings like most hydroponic farmers do, they use portable 40-by-eight-foot shipping containers that can be placed near where the produce will be consumed.

“Climate change is a major issue, and one of the main contributors is CO2 from transporting food,” Merkle says. “Most of the produce we eat comes from very far away, like Chile, South Africa, and New Zealand. Most of the lettuce at Whole Foods comes from California.”

Box Greens is a Miami-based company that retrofits shipping containers into portable hydroponic farms that grow non-GMO produce using sustainable, environmentally friendly methods with no pesticides or herbicides.

“We have the ability to grow an abundance of fresh, nutrient-dense food without an impact on the environment like traditional produce,” Merkle says of the company’s hydroponic, farm-in-a-box concept.

“It’s really surprising because we live in one of the most beautiful and lush places, but there are very few things we eat regularly that are actually grown in South Florida,” Merkle says. “Produce is picked before it's ripe, then it sits in containers for weeks or months where it’s sprayed with gases to preserve it."

Each container produces the equivalent of 1.5 acres of land, and Merkle says that herbs, microgreens, lettuces, kale, and collards flourish the best in hydroponic environments. Unlike traditional soil farming, hydroponics use no dirt. Nutrients are injected into the plant’s root systems through the water.

“With climate change, there is not the ability to farm like people used to, but the idea of bringing farming indoors allows production 365 days a year,” Merkle says. “And that’s groundbreaking.”

Nutrients from soil are critical to optimal health, and Merkle says that while hydroponics are healthy, they are best consumed in conjunction with traditionally farmed produce. But hydroponics can help us avoid the problems associated with long-distance food transport.

“We can’t live in a bubble just growing hydroponics under lights with filtered water and nutrients,” she says. “The future of food is eating hydroponics and things that are locally grown.”

Box Greens expects to have its first containers producing by December. The containers can be placed in schools to teach children about nutrition and urban farming, or near restaurants to provide greens so fresh that they can be consumed the same day they are picked.

Merkle also hopes to place containers in some of Miami’s food deserts where people have little access to fresh produce.

“We will give on-the-job training,” she says about hiring locals to learn about hydroponic farming. “We pay fair wages and will host onsite community dinners to bring together the community in public places where people can learn about healthier eating.”

Wendy Rhodes is a lover of rock 'n' roll and all things vegan. She has witnessed a green flash, kissed a live shark, and stood atop an active volcano. She is always open to new story ideas.

United States and Israel Collaborative Research: Safe Recycle of Aquaponics and Hydroponics Water

Scientists from the University of Illinois and Agricultural Research Organization, Israel are collaborating to reduce the use of water in aquaponics and hydroponics.

USA.- Scientists from the University of Illinois and Agricultural Research Organization, Israel are collaborating to reduce the use of water in aquaponics and hydroponics. To prevent plant pathogens from spreading in these soilless environments, water disinfection is required.

The researchers found that disinfection with ozone created lower toxic effects than with chlorine. They also found that lower concentration of disinfectants over a longer exposure time created lower toxicity in the recycled water. The results were presented to aquaponics and hydroponics producers in Illinois.

Never Heard of Indoor Farming? That's About To Change

October 30, 2018

Cincinnati-based 80 Acres Farms is in the middle of an expansion that will triple the size of its current Spring Grove location on Este Avenue and potentially revolutionize farming.

"It's going to be a fully automated farm," said Mike Zelkind, CEO of 80 Acres Farms. The company plans to open two new locations in Hamilton during the first half of 2019.

The indoor farming facilities will be the first of their kind to use robotics in the farming process.

"(It) will essentially allow us to automate the process from seeding all the way to harvesting," Zelkind said.

Zelkind and president Tisha Livingston started 80 Acres Farms in 2015. They took the company's name from the fact that the Este Avenue building is able to produce 80 acres worth of produce despite being located on just a quarter of an acre.

The company also boasts the world's first completely indoor, in-building vine crop room, where workers are able to grow tomatoes, cucumbers, peppers and strawberries.

The idea is to grow the produce cleanly and quickly so that when it is harvested, they are able to deliver to restaurants and grocery stores within 24 hours.

"It's a lot fresher than anything else you'll see," said Robert Norris, head grower for 80 Acres Farms.

"Most of the other produce that is on the produce shelves gets shipped from California or Florida," Norris said.

That time on the road, or what he calls "food miles," degrades the food quality, shortens the shelf life and leads to food waste, according to operations supervisor Samantha Bergman.

"You're going get something freshly picked," she said. "And, you're going to get at least two weeks out of it."

The company currently provides produce to local restaurants and grocery stores like Jungle Jim's, Whole Foods and Clifton Market. It also provides produce to Dorothy Lane Market in the Dayton area.

"Our goal is to provide the cleanest, healthiest food to our local communities, grown in the most sustainable way possible," Zelkind said.

They use a process called precision agriculture, which includes using LED lighting to promote photosynthesis and using filtered air and water that is piped to the plants with nutrients. The delicate plant roots are protected by controlling the temperature with water chillers. It's all done with very little waste.

"We're a hydroponic farm," Bergman said. "One of the really cool things is we have 97 percent less water waste than traditional farming."

"All of the evaporation gets captured back into the system and is put back into our nutrient solution," Norris said. "So, everything goes back to the plant."

They've seen success with their process based on a demand for produce. Two shipping containers on the side of their current location are used for additional growing space. Bergman said there's been a big demand for kale.

"We were totally sold out and people really, really wanted kale," she said. "We were getting phone calls, 'Please give us more kale.'"

Zelkind said they don't label their produce organic, even though they don't use pesticides. He said the indoor growing process they use is cleaner that traditional farming, and the opposite of genetically modified organisms.

"What you do with GMOs is you take the original genetics of the plant and you try to modify it to survive in a specific environment," he said. "We create a perfect environment for those genetics to succeed and to thrive."

"We are the future of farming," Bergman said.

Vegetable Towers to Rise in Parisian Suburbs

The country has seen a boom in urban farming over the last couple of years.

The French sure like their cities green. The country has seen a boom in urban farming over the last couple of years. In various projects both the government and various private parties have been launching ideas and concepts, and building farms to grow vegetables in the cities. The latest project to be launched is nearby Paris. In the suburb Romainville, two vegetable towers will comprise an acreage of 1000 m2 to supply inhabitants with freshly grown vegetables.

© : Poltred Studio / Ilimelgo and Secousses architects

"Talking about urban farming, the French market is a very promising market, since the French value their food highly", Corenthin (Felix) Chassouant with CMF confirms. CMF is specialized in high-tech greenhouses and buildings and has been working for several years on a proposal for urban farming greenhouses all around the world. In France they're participating in the new project as well.

La Cite Maraichere

This urban agriculture building is to be realized as part of a city renovation program. "All floors above the ground floor will be dedicated to local production", Corenthin shows. "As for the subsurface, it will be intended to produce mushrooms. The building will consist of 2 wings of 7 m wide each, the eastern greenhouse on the 6th floor and the western greenhouse on the 3rd floor (the first vegetable towers in Europe)."

© : Poltred Studio / Ilimelgo and Secousses architects

© : Poltred Studio / Ilimelgo and Secousses architects

The building will also meet the latest environmental standards and will comply with public safety regulations. According to Corenthin though, the major challenge of this project was to combine aesthetics and technicality.

The project is to deliver a harvest of up to twelve tonnes per year. That consists of carrots, tomatoes and other products, all grown grown in circular economy substrates, mixing local compost, grinded green waste, coffee grounds. The vegetables are to be sold for small prices to local inhabitants and will also be used in the cafeteria on the ground floor.

© : Poltred Studio / Ilimelgo and Secousses architects

Residence with greenhouses

The new Parisian project isn't the only urban farming project in France being realized currently. Various projects are mushrooming. One of them is "5 ponts" in Nantes, Corenthin shows. "This residence will integrate two urban farming greenhouses (6th floor and 4th floor) as well as two private winter gardens built by CMF. These greenhouses will be equipped with shading screens, heating systems and climate control. "This ambitious and innovative project entails various constraints: occupant safety, climate management of glazed spaces, and cohabitation with agricultural activity in urban areas", Corenthin shows.

©Samo / TETRARC Nantes Project manager and architect

The project is proposed by “Les Eaux Vives" Association. It is supported by the City of Nantes, Nantes Métropole and the European Union as part of the UIA project (Urban Innovative Action).

"It is really cool to be a part of this", Corenthin confirms. "With CMF we've always supplied the traditional market - which is also interesting - but now we see we have the capability to imagine and develop innovative solutions that combine our greenhouse knowhow as a climate builder with architectural concepts, to meet the specific situation of an urban farmer."

For more information:

CMF

BP 10 001 - Varades

44370 Loireauxence

Tél. : +33 (0)2 40 98 34 00

Fax. : +33 (0)2 40 98 34 94

www.cmf-groupe.com

Publication date : 10/29/2018

Author: Arlette Sijmonsma

© HortiDaily.com

The Age Of Hemp: Global Advanced Industrial Applications

The Age Of Hemp: Global Advanced Industrial Applications

Giadha De Carcer is Founder/CEO of New Frontier Data, an independent, tech-driven analytics company specializing in global cannabis markets.

Getty

Hemp, the non-psychoactive variety of the cannabis sativa plant, is already being integrated into several mature markets such as food, textiles, construction, personal care and nutraceuticals. This relatively quiet cannabis relative is emerging as a potential commodity ripe to not only impact, but possibly revolutionize, tech-driven markets and economies around the world.

In 2014, I founded New Frontier Data, an analytics and business intelligence reporting group dedicated to the global cannabis industry, after more than 20 years in finance, industry analytics, intelligence reporting and emerging markets. As such, I have had the privilege of following hemp’s emergence and evolution. Half a decade later, this robust, environmentally friendly, low -cost-to-produce plant has become one of the most diversely applied and globally significant natural resources in the world. Here is a look at its applications across several mature industries:

Automotive

In 2013, BMW announced its newest electric car, the i3. Using low-weight hemp in its interior, the i3 weighs 800 pounds less than its market competitors. The Kestrel, created by Canadian Motive Industries, uses polymer resin-infused hemp stalks to replace fiberglass in the body of the vehicle. From this replacement, consumers can expect a dramatic reduction in weight, improved efficiency and the appeal of an ecologically sustainable vehicle.

Supercapacitors

The challenge to find lighter and longer-lasting energy storage devices (e.g., batteries) can be found in almost every sector. Hemp could prove to revolutionize battery life by aiding in the development of faster, smaller and cheaper supercapacitors. A supercapacitor is an energy storage device that can discharge powerful infusions of energy, needed only in small bursts. Such powerful discharges are used in braking systems of electric vehicles, the powering on of computers and new technologies such as rapid phone charging or cordless tools.

The current top-performing supercapacitors use graphene. However, in 2004, Dr. David Mitlin of Clarkson University and researchers at the National Institute for Nanotechnology (NINT), discovered that hemp-based supercapacitors outperformed graphene supercapacitors in energy storage by nearly 200%.

The downsides of graphene are its dwindling sources and costly process to mine and import from rural areas in China and India. Hemp, however, can be grown in almost any terrain or country, and produces hemp bast, the key material used to replace graphene, as a waste byproduct of hemp processing. According to Mitlin’s research, hemp processing is 1,000 times cheaper than graphene processing.

Soil Regeneration

Hemp has the ability to mitigate the toxin transfer from contaminated soil into food products. This process uses phytoremediation, an organic process where toxins are absorbed by plant roots and then stored in the cellulose for disposal. Hemp phytoremediation became more well-known after the Chernobyl disaster for its use in helping grow crops that are safe for consumption.

Challenges

Hemp’s greatest obstacle is its association with psychoactive cannabis, despite the important distinction that hemp contains only nominal amounts (no more than 0.3%) of the psychoactive ingredient, tetrahydrocannabinol (THC). Although the U.S. is the largest importer of hemp products according to the Hemp Business Journal (a New Frontier Data subsidiary), hemp itself has struggled to gain social acceptance in the country and elsewhere. For instance, current U.S. legislation only permits universities and states performing agricultural or academic research to cultivate hemp. However, the 2018 Farm Bill currently in Congress would grant hemp full legalization across the nation. Passage of this bill would be a key step in promoting public acceptance in the U.S. and elsewhere, allowing the country to participate in the rapidly growing global hemp market.

Africa And China: The Rise Of Global Hemp Markets

Hemp is legally cultivated in countries around the world, and China is leading the way. As detailed in a High Times article, China produces approximately 44,000 tons annually, almost 40% of the world’s total. According to that same article, Chile is South America’s largest producer, and France is Europe’s most proliferate producer.

China is also positioning itself to become the world’s leading semiconductor and microchip producer. Under an initiative called Made in China 2025, the country announced its intention to dominate technologies such as industrial robots and software, electromobility and more.

The way I see it, the marriage of China’s position as the world’s supplier of hemp -- and its burgeoning semiconductor industry -- could be the key to China’s hegemony over the microchip industry. Semiconductors are traditionally made using silicon. Graphene semiconductors, however, could one day lead to computers that are a thousand times faster, consume significantly less power and are smaller than silicon semiconductors used in computer transistors. In application, graphene’s dwindling supply and costly manufacturing issues would still exist. Putting this all together, Mitlin’s research has sparked interest in the potential for hemp to create the next-generation semiconductor.

Approximately 65% of sub-Saharan Africa’s agricultural land is degraded, according to data collected in 2015, resulting in food insecurity and a declining economy in a region where the agricultural industry employs more than half of the total labor force. Hemp’s soil nutrient replenishing properties could be the key to reviving crop production, providing a novel food source (hemp seeds) and boosting the agro-based economies of South Africa and other hemp-cultivating sub-Saharan countries.

The U.S. hemp-derived CBD market alone is projected to reach $450 million by 2020, and China's cannabis market could grow to 100 billion yuan by 2022 (approximately $14.5 billion). Hemp is already interwoven into the futures of the automotive, construction, energy, environmental mediation and technology industries. Once fully utilized and legal, this plant could impact the global economic positionings of North America, China and Africa.

Forbes Technology Council is an invitation-only community for world-class CIOs, CTOs and technology executives. Do I qualify?

Giadha De Carcer is Founder/CEO of New Frontier Data, an independent, tech-driven analytics company specializing in global cannabis markets.

Growing Microgreens With LED Grow Lights In Sonora, Mexico

Written by, admin

Urban grower Karla Garcia is proud to announce the creation of her new company, Microgreens FLN based in Sonora, Mexico. Karla is a recent graduate with honors and a master's degree in plant science from the University of Arizona. She is proud of her company's commitment to specializing in microgreens production using an indoor vertical farming strategy. Microgreens are an emerging class of specialty leafy greens and herbs. The crops are harvested when the cotyledons are fully developed and in some cases when the young plants have one true leaf.

Studies have shown that microgreens are an excellent source of vitamins (Sun et al., 2013; Xiao et al., 2012) that offer a variety of flavors, textures and colors. For this reason they are quickly gaining in popularity among foodies, salad lovers and top chefs around the world. Karla and Microgreens FLN are currently focused on producing a wide variety of microgreens, including broccoli, mustard, coriander, beetroot and radish.

Creating the proper growing environment

Climate management is key in allowing Karla and her team to grow consistently and year round. Their specifically designed grow room enables them to maintain production throughout the year regardless of the outside temperature. The room is conditioned with fans and a cooling system to maintain seedlings at an average temperature of 21 ° C (70 ° F). Growracks are used to stack the crops and maximize the square foot production area.

Microgreens FLN is also working with Hort Americas to create the proper light intensity and light spectrum with ARIZE LED grow lights from GE in combination with white fluorescent lamps . This combination enables the company to provide at least one daily light integral DLI of 12 mol / m / d in order to maintain quality, predict growth and reduce energy costs.

How-to tips

For growers interested in trying to grow microgreens, Karla offers the following tips.

1. Ensure a clean area by disinfecting trays, seeds (in case they need it) and shelves.

2. Germinate seed by keeping trays in dark and humid conditions for the first three days.

3. After germination, place seedlings under grow lights for about two weeks and then harvest.

Harvesting techniques

Microgreens FLN has two different harvesting techniques. Some customers request that their microgreens be delivered live, still growing in trays filled with substrate which provides a longer shelf life. Other customers prefer that the crop be harvested with sterilized scissors and packaged in a plastic clam shell. The delivered product is protected ready to be washed and served.

Microgreens FLN's goal is simple: offer a fresh, healthy, environmentally-friendly product that is nutritious and flavorful.

"Take care of your body, take care of the planet, eat microgreens!" Said Karla.

Urban farmer Karla Garcia is proud to announce the creation of her new company, Microgreens FLN in Sonora, Mexico. Karla (recently graduated with honors and a Masters in Plant Sciences from the University of Arizona) is proud of her company which is committed to specializing in the production of shoots using vertical farms as a strategy. For those who do not know the term buds. The shoots are a new class of vegetable product, which consists of edible seedlings grown from vegetable seeds or herbs, which are harvested at the end of the development of tender leaves called cotyledons.

Studies have shown that shoots are an excellent source of vitamins (Sun et al., 2013; Xiao et al., 2012), also offering a range of colors, flavors and textures. Reason why this product has quickly gained interest in consumers of vegetable products, salad lovers and top chefs around the world. Karla and Microgreens FLN are currently focused on the production of different types of shoots such as: Mustard, broccoli, radish, beet and cilantro.

Creating the right environment to grow

The control of the environment is the cornerstone that allows Karla and her team to grow shoots throughout the year. This team has been dedicated to design a quarter of growth to maintain its production during the year regardless of the outside temperature. The room is conditioned with fans and cooling system to maintain seedlings around 21 ° C on average. They use a shelf system to maximize production per area. Microgreens FLN also collaborates with Hort Americas to create the right lighting environment using GE "Arize LED" lights for plant growth with a combination of fluorescent bulbs. This combination allows Karla and her team to maintain quality, predict growth (Managing at least one DLI of 12 mol m -2 d -1 ) and in turn to reduce energy costs.

Tips to grow

For those wondering how they can do shoots at home, Karla gives the following tips:

The first step for the production of shoots is to ensure a clean area, by disinfection of trays, seeds (if necessary) and shelves. Second, induce germination by keeping the trays in a dark and humid place. After germination, the seedlings are placed under the growth lights for two weeks and then harvested.

Harvesting techniques

Microgreens FLN has two different harvesting methods. Some consumers demand to keep their buds alive, growing on the substrate, which generates a longer shelf life. Other consumers prefer that Microgreens FLN harvest the product, by cutting with sterile scissors, being packed in plastic containers. The delivered product is then ready to be washed and consumed.

The goal of Karla and Microgreens FLN is simple, to offer a product full of nutrients and flavor that is fresh, healthy and friendly to the environment. Quoting Karla: "Take care of your body, take care of your planet, consume Microgreens FLN!"

Tagged

Edenworks Touts Results From Growing With Ecology Instead Of Chemicals

Oct 30, 2018

Edenworks Touts Results From Growing With Ecology Instead Of Chemicals

Edenworks micro kale. Leafy greens are grown in a proprietary growing media designed to host a wide range of beneficial bacteria, improving plant health from the roots up. Plants are fertilized from under their roots with fertilizer from fish. Plants are grown in a controlled environment, lit by energy efficient LEDs.EDENWORKS

Jason Green, the aptly named CEO of Edenworks, says too many articles on the growth of the indoor farming industry are missing its "most exciting aspect." That is, the ability to achieve new levels of plant health through ecology rather than chemicals.

Edenworks grows produce and fish in aquaponic ecosystems. The company is based in Brooklyn, New York. When Forbes caught up with Green in 2017 for a "30 Under 30" feature, he and cofounder Matt LaRosa had plans to expand by the end of 2018, moving to a space 40 times larger while rolling out five more product lines across the New York City area.

Those type of plans are still in the works, but the company has been growing in other ways during the past year: Shifting its focus from the plant to the microbe after a bout with root rot fungus. And Green says they've unlocked ways to virtually eliminate diseases in plants while increasing yields and using less fertilizer.

Edenworks cofounders. From left: Ben Silverman, Matt LaRosa, Jason Green. Behind them is a vertical farming system. Plants are grown in vertically stacked shelves.HEIDI LEE

Edenworks supplies greens to Whole Foods and other select grocers in Brooklyn. The plants are grown with nutrients provided by the waste from farmed fish. Edenworks has plans to commercially sell the fish, striped bass, later on, followed by shrimp and salmon.

Tackling the Food Crisis with a Borderless Collaboration

At Omron, opportunities to engage with new challenges are abundant

After graduating from university in London, Kassim Okara joined the largest specialist distributor of control and automation products in the UK, where he worked on numerous large-scale projects. He decided to leave however, to join Omron Electronics as field sales engineer in 2015, as he had always felt that he wanted to contribute to society from a business development standpoint.

At Omron, opportunities to engage with new challenges are abundant; the varying projects involve not only control equipment but also healthcare and mobility as well as initiatives to actively employ disabled persons.

At that time, Intelligent Growth Solutions (IGS) had begun working on automated vertical farming to optimize crop production. Based at the James Hutton Institute in Scotland a leading crop science and research institute, the opportunity to collaborate was one of the key considerations in this location. To advance the efforts to practical application level, IGS needed an automation solutions provider.

In search of a suitable provider, IGS found Omron. In addition to its solutions, Omron's commitment to social responsibility attracted them into collaboration.

With the addition of Omron's automation technology to the expertise and knowledge of the two organizations, the first-ever UK project for automated vertical farming using IoT was initiated. Kassim was assigned as project leader on Omron's side. His passion for his work increased by the day as he deepened his understanding of his partners' enthusiasm toward the project.

In the beginning, developing an understanding of the project was particularly challenging, as it was unprecedented so that previous case studies could not be found. Despite this, Kassim took on the project, led by his determination to respond to social needs through business.

Publication date : 10/29/2018

Kimbal Musk Is Reinventing Food One Shipping Container At A Time

Interesting dresser, marketing pro, rich dude, brother to the most famous man in tech: Musk is changing food production, one shipping container at a time. And it's starting to work.

By Kevin Dupzyk

Oct 24, 2018

DAVID SCOTT HOLLOWAY

The low-slung building on Evans Avenue with the greenhouse roof blends into the surroundings in an uninspiring stretch of Denver, all nondescript retail and pockets of ranch homes. It’s a hydroponic farm, run by partners Jake Olson and Lauren Brettschneider. The produce is all on tables at waist height, and the plumbing is subtle and minimalist. There is no soil anywhere. From the street it’s easy to miss Rebel Farm; inside, it looks like an Apple Store hosting a farmer’s market.

One afternoon this summer, Kimbal Musk, a tall, lanky man in a cowboy hat, ducked in through the front door. He was here to see about the produce for his Denver-area restaurants. Unlike, perhaps, the average restaurateur, he’d brought a couple of assistants, who used smartphones to photograph his entrance, and his greeting with Olson and Brettschneider, and the huge smile he put on when he surveyed the farm. He’d never been to Rebel Farm before, but the operation was already providing him gem lettuce, a trendy green, and now he wanted to see what else it might offer. Olson and Brettschneider start walking him up and down the aisles. The building’s southern exposure is a heat-exchanging wall, and they start there, in the cool-climate crops.

“We just can’t get spinach to grow,” the Rebel guys say.

“Really?” Musk asks. “What about kale?”

Arugula’s easy. “The gateway green,” they all agree.

Musk surveys the farm and talks hydroponic technology in the manner you expect his older brother, Elon Musk, might approach a tour of NASA’s Jet Propulsion Laboratory. Like his brother, Musk is a billionaire entrepreneur, but since 2004 he’s made his living in food.

Musk tastes hydroponically-grown greens at Rebel Farm, an urban farm in Denver, CO.

DAVID SCOTT HOLLOWAY

At each new crop, Olson and Brettschneider tear off a few leaves for Musk to try, and he takes each bouquet, contemplates it, smells it deeply, eyes closed, takes a bite, and stares off into the middle distance. For a moment it’s like he is absorbing the simple life of the leaf, just sun, soil, and water, the way cannibals eat the hearts of others to imbibe their essence.

Of course, this also makes for good photos. And Instagram Live opportunities. He asks Olson and Brettschneider to do a short live video with him, and they oblige him behind a planting of sunflower sprouts on a sheet of geometric growing foam called Horticubes. An assistant gets in position with her smartphone, and as soon as they start recording, Musk comes to life, a perfect host, asking leading questions and making sure that the brands’ audience gets to know Olson and Brettschneider and their strange urban farm of delicious hydroponic crops.

Video over, tour back on, and Musk quickly turns to logistics. “Do you know how much production you do?” he asks.

Musk has a particular interest in this farm that goes beyond his restaurant chains, The Kitchen and Next Door. Musk also cofounded an urban farming startup based in Brooklyn, called Square Roots. Square Roots develops hydroponic farms housed in shipping containers that use high-tech lighting systems and offer precise, scientific control of light and every other relevant variable, like water and nutrients. Then it teaches a new breed of farmer—think Brooklyn hipster with a back-to-the-land mentality—to use them.

“Well, this is 15,000 square feet,” says Olson.

“Right, so that’s about one third of an acre,” Musk says. “At Square Roots we’re able to take a shipping container and get two acres of productivity out of it.”

“That’s some big shipping container,” Brettschneider says, not quite getting what Musk’s driving at. Musk is speaking entrepreneur, but Olson and Brettschneider are just two people who left pretty good day jobs to work the land. (As it were.)

Sprouts on a low-water growth medium. DAVID SCOTT HOLLOWAY

Musk’s goal isn’t just to produce food, or just to produce food that’s good. It’s to produce what he calls “real food”—“food you can trust to nourish your body, trust to nourish the farm, and trust to nourish the planet”—as efficiently as possible. The way he sees it, the last few decades have seen two food movements, opposites, both misguided. There’s the precious food movement, which aims to set the table only with food grown in the immediate community. The problem with that is that it’s pretty much restricted to wealthy people in fertile places.

Then there’s the feed-the-world movement, which produces more food than we need, most of it processed, unhealthy, and untasty, leading to health problems like diabetes and obesity. Musk is trying to shoot the gap, and unlike the cornucopia of restaurateurs in most midsize or larger cities these days offering local kale, he has the background and resources to implement a grander vision. Kimbal opened The Kitchen, a fine-dining restaurant, in 2004 before conceiving of Next Door, which sources ingredients with the same principles but offers food with a tad less pretention and a bit more fun, at prices—generally under $15 an entrée—that most Americans can afford. And Musk has ancillary enterprises that lay the groundwork. He founded a nonprofit, Big Green, that installs learning gardens in schools to educate kids about real food. Then there’s Square Roots. Musk points out that with shipping-container farms, which lock out all the traditional encumbrances of farming—drought, locusts, 24-hour cycles of day and night—optimization of food is possible. Unlike a traditional farmer, who may work his land for 50 years and in that time get only 50 growing seasons to experiment with, a Square Roots farmer can iterate endlessly until: spinach.

As we’re getting ready to leave, Olson and Brettschneider ask if they can show off some of their more specialized crops, and we make our way to the hot north end of the farm. They take us to a rack covered with huge serrated leaves and tangles of thick stalks. Brettschneider pulls some of the tangle away and points at a smooth purple ball from which the stalks emanate.

“What is that?!” Musk asks.