Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

US (WV): Good Hot, Dry Weather Helpful in Aquaponics Facility's Construction

The recent hot, dry summer weather has been good as the project moves forward.

Construction work is underway on the aquaponics facility which will be located at Kermit. The recent hot, dry summer weather has been good as the project moves forward. The facility is located on the old Burning Creek Mine property inside the Kermit City limits.

Leasha Johnson, executive director for the Mingo County Redevelopment Authority, said, "With the delivery of the greenhouse expected in early July, we're getting more and more excited about the completion of the aquaponics project. Barring any unforeseen delays, we expect the facility to be completed by late August or early September."

"Sprouting Farms, our operating partner, is starting to put together job descriptions. Together with Sprouting Farms, we've engaged a marketing consultant to create a brand identity, logo and core messaging for the facility in order to expand the market that it will serve and to establish the facility's role in the community. We've gotten excellent cooperation and assistance from Mayor (Charles) Sparks and the Town of Kermit, and we're looking forward to the start of an innovative economic development and agriculture project in their community," Johnson added.

The multi-million-dollar project is to be developed on abandoned mine land just in northern Mingo County. When completed it is initially projected to employ about 12 people. The project was originally announced in 2016. It is part of the Abandoned Mine Lands (AML) Pilot Program and the W.Va. DEP.

When operational, the aquaponics facility and training center will provide 150 kilowatts of solar power, provide healthy and fresh food for local and regional consumers, and represent a model that can be implemented in other coalfield communities, according to Johnson.

Source: Williamson Daily News (Kyle Lovern)

Publication date: 7/1/2019

Cannabidiol Is A Powerful New Antibiotic

New research has found that Cannnabidiol is active against Gram-positive bacteria, including those responsible for many serious infections (such as Staphyloccocus aureus and Streptococcus pneumoniae), with a potency similar to that of established antibiotics such as vancomycin or daptomycin

June 28, 2019

Summary: Cannabidiol (CBD), a non-psychoactive compound extract of marijuana, has the potential to be used as an antibiotic. Researchers found CBD was remarkably effective at killing a wide range of Gram-positive bacteria, including bacteria that are resistant to common antibiotics. Additionally, CBD does not lose its effectiveness after extended treatment.

Source: ASM

New research has found that Cannnabidiol is active against Gram-positive bacteria, including those responsible for many serious infections (such as Staphyloccocus aureus and Streptococcus pneumoniae), with a potency similar to that of established antibiotics such as vancomycin or daptomycin. The research is presented at ASM Microbe, the annual meeting of the American Society for Microbiology.

Cannabidiol, the main non-psychoactive chemical compound extracted from cannabis and hemp plants, has been approved by FDA for the treatment of a form of epilepsy and is being investigated for a number of other medical conditions, including, anxiety, pain and inflammation. While there is limited data to suggest Cannabidiol can kill bacteria, the drug has not been thoroughly investigated for its potential as an antibiotic.

Work led by Dr Mark Blaskovich at The University of Queensland’s Institute for Molecular Bioscience’s Centre for Superbug Solutions, in collaboration with Botanix Pharmaceuticals Ltd, an early stage drug discovery company investigating topical uses of synthetic cannabidiol for a range of skin conditions, found that Cannabidiol was remarkably effective at killing a wide range of Gram-positive bacteria, including bacteria that have become resistant to other antibiotics, and did not lose effectiveness after extended treatment.

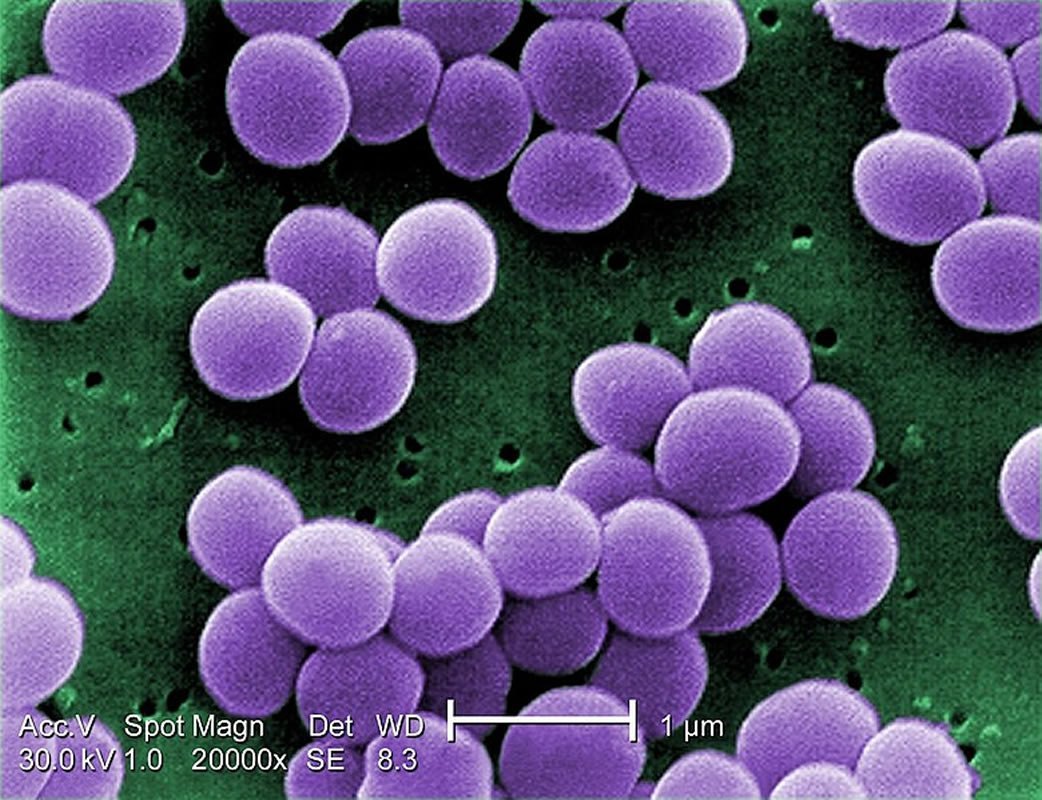

Importantly, the drug retained its activity against bacteria that have become highly resistant to other common antibiotics. Under a very high magnification of 20,000x, this scanning electron micrograph (SEM) shows a strain of Staphylococcus aureus bacteria taken from a vancomycin intermediate resistant culture (VISA). The image is credited to the CDC.

“Given cannabidiol’s documented anti-inflammatory effects, existing safety data in humans, and potential for varied delivery routes, it is a promising new antibiotic worth further investigation,” said Dr. Blaskovich.

“The combination of inherent antimicrobial activity and potential to reduce damage caused by the inflammatory response to infections is particularly attractive.”

Importantly, the drug retained its activity against bacteria that have become highly resistant to other common antibiotics. Under extended exposure conditions that lead to resistance against vancomycin or daptomycin, Cannabidiol did not lose effectiveness. Cannabidiol was also effective at disrupting biofilms, a physical form of bacteria growth that leads to difficult-to-treat infections.

The project was co-funded by Botanix and Innovation Connections, an Australian government grant scheme to commercialize new products, processes and services. The paper will be presented on Sunday June 23rd from 11am-1 pm at the annual conference of the American Society for Microbiology, ASM Microbe 2019, at the Moscone Convention Center in San Francisco.

ABOUT THIS NEUROSCIENCE RESEARCH ARTICLE

Source:

ASM

Media Contacts:

Aleea Khan – ASM

Image Source:

The image is credited to the CDC and is in the public domain.

Original Research: The findings were presented at ASM Microbe 2019 in San Fancisco, California.

Conference Theme Announcement: Putting Out Fruits

This year’s Aquaponics Association Annual Conference theme is “Putting Out Fruits”. Putting Out Fruits will take place in Frankfort, Kentucky at Kentucky State University on September 20 – 22nd, 2019

This year’s Aquaponics Association Annual Conference theme is “Putting Out Fruits”. Putting Out Fruits will take place in Frankfort, Kentucky at Kentucky State University on September 20 – 22nd, 2019.

Head to the Putting Out Fruits homepage for ticket info. (http://bit.ly/2UuUzxz)

The aquaponics movement is expanding rapidly, and the Aquaponics Association’s annual conferences are growing along with it. Two years ago we were in Portland, Oregon for “Putting Down Roots”; and last year we were in Hartford, Connecticut for “Putting Up Shoots”. Finally, this year’s theme reflects the culmination of our journey as we take the next step learning and growing together. We will produce tangible “fruits” to advance the practice of aquaponics, both for individual growers and for the aquaponics movement as a whole.

A major component of the Conference will be the tour and interactive session at the KSU Aquaculture Research Center. This Center hosts one of the most advanced aquaculture research programs in the nation, including indoor aquaponics research systems, saltwater aquaponics research, a 30’ x 70’ aquaponics demonstration greenhouse, a 10,000sq foot recirculating aquaculture research building, and 33 research ponds.

We’ve heard from many of you through our online survey [thank you for your input!] and we are excited to focus this year’s content around the following hot topics:

– Integrated pest management

– Nutrient deficiencies and nutrient supplementation

– STEM curriculum and classroom aquaponics

– Growing cannabis in controlled environments

– Food safety

– Organic certification

– International case studies

– “Green” solution applications

– Successes with higher risk / higher reward and non-typical crops in aquaponics

– Post-secondary aquaponics research

Conference attendees will walk away with cutting edge information, new connections and a greater understanding of core knowledge and best practices. In addition to farm-to-table tours and hands on activities, learning tracks will focus on Aquaponics Research, STEM Education, hobby/home aquaponics, commercial farming, and community based endeavors. Interactive sessions will allow all participants to discuss and plan what we can do together to advance aquaponics.

As always, the Conference will feature top aquaponics experts and a vendor showroom of aquaponics technology and services.

We are also still looking for presenters to cover the following topics: aquaculture and fish diseases (recognition and treatment); filtration and biofiltration; automation of aquaponics systems (feeding, monitoring, etc.); and case studies of successful small / medium / large growing facilities. Please submit presentation proposals by July 15.

To purchase your ticket and/or to submit a presentation proposal, please visit https://aquaponicsassociation.org/2019-conference/.

We hope to see you in Kentucky!

Kate Wildrick

Senior Advisor & Conference Planner

Aquaponics Association

Futuristic Farming Takes Root In Georgia

Agriculture is Georgia’s number one industry, but there is one local farmer innovating the way growers do business in the Peach State

by: Martin Staunton

June 27, 2019

SAVANNAH, Ga. (WSAV)

Agriculture is Georgia’s number one industry, but there is one local farmer innovating the way growers do business in the Peach State.

Grant Anderson, owner of BetterFresh Farms, says traditional farming goes back countless generations for his family in Effingham County. But many family, friends, and neighbors near Guyton thought he was taking a huge risk when he walked away from his job in finance to start BetterFresh Farms two years ago.

“A lot of them thought I was a little crazy,” Anderson said with a chuckle, recounting their reaction to his decision to grow lettuce hydroponically.

The Agriculture Commissioner’s Office reports BetterFresh is the first commercial hydroponics farm to be established in Georgia. Anderson is investing in a new hydroponics container that’s state-of-the-art and it will double his lettuce production.

The new equipment was built in Canada by a company called Local Food Champions. Jason Carrier, President and owner, was on hand for delivery, his first to the Peach State.

“This is absolutely the future and this is bigger than all of us,” Carrier said. “So we are hoping we can get out there and feed some people. Farm to table in record time. This is farming for everybody.”

Hydroponics requires no soil, 90% less water than pivot irrigation, and eliminates the need for chemicals to control weeds and insects. Anderson only needed enough land to place two growing units — each is roughly the size of a shipping container — to bring this futuristic farming method to Effingham County.

“It doesn’t require the soil. It just requires the moisture to germinate,” he explained. “From there, we give it a nutrient recipe that supplies it enough nutrient to grow for a few weeks until it matures to a point where we can move it into our towers.”

The grow towers are the real game-changers for farming when it comes to harvest.

“It takes the seasonality out of harvesting, which is huge from a farm operation, as far as being able to cash week-in and week-out every year and not worry about the bumper crop or the drought that may impact your crop,” Anderson said. “We have consistent volume each week.”

BetterFresh Farms is moving operations to Candler County after joining a partnership with the City of Metter and Georgia Southern University, launching an Agri-Business Incubator. It’s got the backing of the Agriculture Commissioner’s Office under their “Georgia Grown” branding.

“Georgia Grown is going to be a tremendous partner, as far as the marketing of our product and helping people becomes aware of how we do what we do,” said Anderson.

City leaders in Metter say their new partnership with Anderson does more than just bring his farm to their town, it helps them lead the way in terms of one of the future paths for farming. Heidi Jeffers, the Tourism & Business Development Director for the City of Metter, says hydroponic farming can be a powerful weapon in the fight against hunger.

“It changes how we feed our people in Georgia and all over the United States. Hydroponics is a great technology that’s coming about with some great new changes and we are certainly excited to have this in Metter,” Jeffers said, adding that the city is proud to partner with a farming pioneer in Georgia.

“We’re excited to be on the cutting edge of hydroponics,” she said. “With this, it’s completely organic, uses less water, and really changes, a game-changer for this type of produce.”

Thinking of his ancestors, Anderson believes it might have taken some real convincing to bring them onboard when it comes to launching BetterFresh Farms, but he says he’s sure they are proud he’s carrying the family tradition in agriculture forward.

“It may not be the way my ancestors would have envisioned farming working out, but I feel like, with time, we’re all supposed to try and improve,” he said. “I feel like this was my opportunity to maybe pick the torch up and run with it.”

Georgia grown hydroponic crops a hit with Savannah chefs

The choice of lettuce as a crop was a no brainer for Anderson, given his proximity to Savannah and the hundreds of restaurants in business in the Hostess City.

“Virtually every restaurant needs lettuce,” Anderson said. His clients rave about his product being locally grown and organic.

Chef Andrew Wilson with the Emporium Kitchen and Wine Market is most pleased to have a produce vendor who can customize his crop to meet the needs of his recipes.

“The really cool thing is that, not only can say that we are supporting a local farm, but I can also say that they are growing what I ask them to grow specifically for this menu, which in turn means specifically for you the guest. It’s like you’re getting exclusivity,” Wilson explained.

One of Savannah’s newest pizza parlors, Squirrel’s Pizza on Bull Street, is nuts about BetterFresh lettuce.

“It flies outta here. The product that comes in, we can barely hold on to it,” said Jimmy Powell, Managing Partner with Squirrels. “We’re making phone calls the next day asking for special deliveries and requests.”

Anderson says his customer list is growing. He adds that he’s never missed a delivery in two years, and even though he’s up against giants in the industry — he likes his chances for future growth.

“Personally, I believe I have a competitive advantage, even if I am a small fish in a big pond, so to speak,” Anderson said with a grin on his face and a gleam in his eye.

Learn more about his work at betterfreshfarms.com

These Tech Start-Ups Are Changing What It Means To Farm

Feeding a rapidly expanding population without depleting the Earth’s finite resources, is one of the major challenges of the 21st century

The future of farming? Image: REUTERS/Ilya Naymushin

01 Jul 2019

Briony Harris Senior Writer, Formative Content

This article is part of the Annual Meeting of the New Champions

Feeding a rapidly expanding population without depleting the Earth’s finite resources, is one of the major challenges of the 21st century.

These four entrepreneurs - who have all been selected as the World Economic Forum’s Technology Pioneers for 2019 - have a vision to transform the way we farm in order to help feed the world.

Mini-farms in underground parking lots

In an abandoned car park in downtown Beijing, trays and trays of planting beds are stacked on top of each other.

This is a mini-farm, right in the heart of the city, and it supplies nearby hotels with lettuce, celery, herbs, kale and other green vegetables.

“It’s no longer impossible to grow food where people work and live”, says Stuart Oda, who co-founded the agriculture start-up Alesca Life in 2013, referring to the amount of disused urban infrastructure available, including things such as old shipping containers.

LEDs provide the light, and mineral nutrients are added to water instead of soil. Internet-linked devices monitor humidity, acidity levels and the amount of dissolved oxygen in the water, allowing such variables to be adjusted to increase yields.

“Our system allows us to automate all of the major points of human error that could lead to a loss of crop,” Oda says.

Stuart Oda shows his container farms to the UAE’s minister for food security . | Image: Stuart Oda

The proximity of the mini-farms to the customers means that the produce is fresh, and reduces transport and packaging.

Alesca Life has signed an agreement to distribute 1,000 container farms across the Middle East, Africa, China, and North America.

Oda’s decision to launch his company was prompted by the change he could see happening all around him in China, including rapid urbanization, population growth and land degradation of traditional farms.

“There’s a real sense of urgency to dealing with these challenges and I want to dedicate all my productive years, including my passion and my youth, to addressing them,” he says.

2. Finding a market for ugly fruit and veg

Christine Moseley has witnessed massive food waste at first hand.

During the harvest of romaine lettuce, Moseley watched as 25% of each plant was put into uniform packaging, while the rest was discarded.

“I knew then we had a broken food system. It was my ‘aha’ moment and I vowed not to stop until I found a way for that produce to be utilized for consumption,” she told Forbes.

That was when she decided to start Full Harvest, a B2B platform to sell rather than waste unsightly or unwanted fruit and veg.

Roughly one-third of the food produced in the world for human consumption every year — approximately 1.3 billion tonnes — gets lost or wasted, according to the Food and Agricultural Organization of the UN.

In the US alone, 9 billion kilos of ‘ugly’ and surplus produce are wasted each year simply due to the cosmetic standards of grocery stores.

Supermarkets often only buy perfect produce

Image: Reuters/Ngwyen Huy Khan

Full Harvest connects food companies with trucking firms and farms so that they can make use of the imperfect and surplus produce.

This not only makes good use of the food, it also stops water being wasted and limits carbon dioxide emissions from agriculture.

3. Preventing waste with NASA’s hyperspectral imaging

Hyperspectral imaging sees information on parts of the electromagnetic spectrum that human eyes cannot. That means it can test the freshness of food - from beef steaks to avocados - without even touching it.

The technology - first developed by NASA for aerial imaging - detects the internal quality and chemical composition of food products.

ImpactVision then uses machine-learning techniques to assess the quality of the product, providing food companies with real-time information about their stock.

With an avocado, for example, the images can determine the fruit’s ripeness and reject any rotten ones. Previous systems have depended on sampling - and then wasting - fruits.

“Using advanced imaging and machine learning, we help food companies learn about the quality of their food products non-invasively, providing real-time continuous data,” says ImpactVision’s CFO Rachael Gan.

“That leads to optimized decision-making during processing that in turn reduces waste.”

Can you tell which avocado is ripe without touching . Image: REUTERS/Siphiwe Sibeko

ImpactVision is now working with several leading food producers and supermarkets in the US and believes the data it gathers has the power to transform food supply chains in the same way as GPS transformed navigation.

As food quality control is digitized, this new technique could also help spot contamination and prevent costly food recalls at a later date.

Have you read?

4. More productive seeds

“Seeds are the heroes of modern agriculture. If we improve seeds, then we determine how much land, how much water, how much fertilizer will be used,” says Ponsi Trivisvavet, CEO of Inari Agriculture. “We can solve these major environmental problems by going back to the root cause - the seed.”

Image: FAO

Inari operates a seed foundry where a plant’s genes are edited - some genes may be knocked out, others inserted and others fine-tuned. "Everything we do would probably happen naturally over the next 1,000 years or so,” says Trivisvavet. “We’re just speeding up that process.”

Three changes were simultaneously carried out on tomato plant seeds in order to grow the size of the branch, increase the number of flowers and expand the size of the fruit. This led to an increase of productivity of more than 90%, something which has never happened before in the history of crop development, according to Trivisvavet.

The same technology is being used for soybeans, where the genes of the seed are being edited to increase the number of pods per node, and the number of seeds per pod.

Inari’s seed foundry uses AI-powered computuational crop design to understand the genomes of the crop and how they interact with each other.

“The gene editing itself is easier than identifying where the changes need to be made,” Trivisvavet says. “AI tells us where the changes need to be.”

Among the areas being worked on is making crops more drought-resistant and less dependent on fertilizer.

“We’re working out how to feed the world without starving the planet,” Trivisvavet says.

“If we can grow food with less inputs, then we can return land to nature and lighten the ecological footprint of farming.”

Written by Briony Harris, Senior Writer, Formative Content

The views expressed in this article are those of the author alone and not the World Economic Forum.

Transforming Parking Garages to Serve On-Demand Economy

Miami-based parking network REEF Technology has announced plans to transform parking lots and garages across the country into tech-forward hubs geared towards the on-demand economy

June 28, 2019

Miami-based parking network REEF Technology has announced plans to transform parking lots and garages across the country into tech-forward hubs geared towards the on-demand economy.

The company owns more than 4,500 parking facilities across the United States, and has now expanded to offer space for businesses specializing in last-mile and delivery-only food services, bike- and scooter-rental stations and ride sharing. The company also plans to include micro fulfilment centers and spaces for pop-up businesses at its properties.

“At REEF, we believe a parking lot should be more than a place to store your car.” said Ari Ojalvo, CEO of REEF Technology. “Rather, it can be a hub for the community, connecting people to the businesses and services that keep us all moving forward. REEF will completely transform what people, cities and businesses can expect from parking garages, in the same way the introduction of smartphone apps completely changed the way we think about cellphones.”

A key component of the company’s plans involves last-block, delivery-only kitchen facilities for restaurant partners. Housed in proprietary containers, REEF Kitchens allows restaurant partners to open and quickly expand their businesses, while also providing faster delivery to customers. Each container is able to accommodate from one to five restaurant brands or concepts. Restaurants can run operations directly, or contract with REEF to staff and prepare delivery-only menu items. The concept is already active in Miami and London, with plans to open several hundred additional kitchens across North America and the U.K.

“There’s explosive growth and opportunity in the food delivery business,” said Aziz Ihsanoglu, head of strategy at REEF Technology. “Based on the success of our REEF KITCHENS in the U.K. and Miami, we’re confident restaurants and consumers will enjoy the possibilities our business creates.”

BREAKING NEWS: CDC Warns Against Papayas From Mexico Amidst New Outbreak

More than 60 people are confirmed sick with Salmonella infections in a multistate outbreak linked to fresh papayas from Mexico, according to a public alert issued on Friday.

More than 60 people are confirmed sick with Salmonella infections in a multistate outbreak linked to fresh papayas from Mexico, according to a public alert issued on Friday.

Federal officials are advising that consumers in certain states not eat any fresh papayas from Mexico until further notice. Those states are Connecticut, Massachusetts, New Jersey, New York, Pennsylvania, and Rhode Island, according to the public alert from the Centers for Disease Control and Prevention.

Consumers in those six states are urged to check their homes for papayas imported from Mexico and dispose of them. “Throw the papayas away, even if some of them were eaten and no one has gotten sick. Do not eat fruit salads or other mixes that include papayas from Mexico,” the CDC’s alert says. “If you aren’t sure the papaya you bought is from Mexico, you can ask the place of purchase. When in doubt, don’t eat the papaya. Throw it out.”

HLB Specialties not impacted

HLB Specialties, an importer of tropical fruits with offices in the United States and Europe, has issued a letter to its customers, letting them know that HLB papayas have not been implicated by the outbreak.

"We source papayas from Brazil, Guatemala, and Mexico and our fruit has not in any way been implicated in the outbreak," says Melissa Hartmann de Barros with HLB Specialties. "Our Mexican papayas are grown organically and exclusively by our partner-grower in the state of Michoacán. They adhere to strict organic protocols and we have never had any type of recall due to bacteria or disease-causing agents," she added.

"Our papayas are grown and packed in certified fields and packing houses and we are therefore confident that all our papayas, including our Mexican-grown fruits, are safe for consumption. We caution retailers and wholesalers to make a distinction between the different countries of origin. For now the alert refers to Mexican papayas, and we await the development of the investigation and will keep our customers informed about any developments as they narrow it down to a specific grower and label." HLB Specialties has a dedicated person on staff to answer any questions. Please email FoodSafety@hlbspec.com with any concerns.

Salmonella is a bacteria found in raw foods that have been handled with poor hygiene. It is not a problem linked to a specific kind of food, but with incorrect handling, most likely in post-production with the use of unsanitary water or an unclean packing house.

For more information:

Melissa Hartmann de Barros

HLB Specialties

Ph: +1 (954) 475-8808

melissa@hlbspec.com

www.hlbinfo.com

Publication date: 7/1/2019

CO2 GRO Inc. Provides a Corporate Update

GROW’s first lease revenue from a commercial U.S. installation began in March. A second mostly U.S. hemp installation is now contributing for a combined revenue run rate of C$240K/y from about 100,000 square feet of combined grow area

TORONTO, ON June 27, 2019 (Access Wire) Toronto based CO2 GRO Inc. ("GROW") (TSX-V: GROW, OTCQB: BLONF, Frankfurt: 4021) is pleased to provide a review of operations and business prospects ahead of its Annual Shareholder meeting June 27 at 11 AM 40 King Street West 58th floor.

Entering 2020 Revenue Projection Unchanged

GROW’s first lease revenue from a commercial U.S. installation began in March. A second mostly U.S. hemp installation is now contributing for a combined revenue run rate of C$240K/y from about 100,000 square feet of combined grow area. The contracts are perpetual while CO2 Delivery Solutions are onsite.

GROW still forecasts a contracted year-end lease revenue run rate of $10M/y entering 2020 expecting half of its sixteen active grow trial and commercial pilot proposals to proceed to commercial agreements. Nine are in the U.S., six are in Canada with Licensed Producers (LPs) and one is for a large UAE lettuce greenhouse. Several are with our AG Industrial Partners.

Further Indoor and Outdoor Research Trials and Patents

GROW has retained the University of Guelph to perform an outdoor grow trial in the Holland Marsh Ontario area on lettuce, celery, carrots and onions.

Indoors, GROW is working with the University in Guelph and a medical tobacco company in a grow trial to assess faster speed to plant maturity, larger plant biomass and greater targeted bacteria efficacy and concentration for cancer and other human drugs.

Internationally outdoors, GROW expects to move forward with Praxair Inc. on a flower grow trial in Columbia at their request. Equipment procurement is expected shortly that would activate a signed technology assessment agreement.

GROW has further strengthened its patent portfolio by filing patents relating to pathogen resistance and suppression and for selectively increasing plant metabolism.

Management Title Changes

The following title changes are to more closely reflect current responsibilities:

John Archibald from CEO to President, CEO

Aaron Archibald from VP Operations to Chief Operating Officer

Sam Kanes from VP Business Development to VP Communications

Branding Name Change to CO2 Delivery Solutions

GROW is operating with aquaponic, hydroponic, aeroponic and regular plant growers indoors and outdoors. Generation two equipment has both dissolved CO2 and dissolved oxygen capability. GROW is changing its brand name from CO2 Foliar Spray to CO2 Delivery Solutions to more accurately reflect the variety of Solutions GROW envisions for enhancing plant growth.

About CO2 GRO Inc.

GROW's mission is to accelerate all indoor and outdoor value plant growth naturally, safely, and economically using its patent pending CO2 Delivery Technology. GROW’s global target retail plant markets are food at $8 trillion per year (Plunkett Mar 2017), non-food at an estimated $1.2 trillion per year with retail tobacco at $760 billion (BA Tobacco 2017), floriculture at $100 billion by 2022 (MarketResearch.Biz estimate). Legal cannabis at $52.5 billion per year by 2023 (Statista) and legal US hemp CBD at $22B per year by 2022 (the Brightfield Group).

GROW's CO2 Delivery Solutions are commercially proven, scalable and easily adopted into existing irrigation systems.

They work by dissolving CO2 gas into water for use on plant leaves across the entire plant leaf surface which is a semi permeable membrane. The dissolved concentrated CO2 then penetrates a leaf's surface area naturally, similar to how humans dissolve oxygen in their lungs into liquid bloodstreams.

Foliar spraying of dissolved nutrients and chemicals on plant leaves has been used for over 60 years by millions of indoor and outdoor growers. To date, outdoor growers have not had any way to enhance plant CO2 gas uptake for faster growth.

Indoor CO2 gassing has enhanced plant yields for over 60 years but 60% of the CO2 gas used is typically lost from ventilation. Current greenhouse CO2 gassing levels of up to 1500 PPM are not ideal for worker health and safety. GROW's safer CO2 Delivery Solutions can be used both indoors and outdoors with minimal dissolved CO2 gas lost and much greater CO2 plant availability resulting in higher plant yields than both CO2 gassing and no CO2 gassing plants.

Forward-Looking Statements This news release may contain forward-looking statements that are based on CO2 GRO's expectations, estimates and projections regarding its business and the economic environment in which it operates. These statements are not guarantees of future performance and involve risks and uncertainties that are difficult to control or predict. Therefore, actual outcomes and results may differ materially from those expressed in these forward-looking statements and readers should not place undue reliance on such statements. Statements speak only as of the date on which they are made, and the Company undertakes no obligation to update them publicly to reflect new information or the occurrence of future events or circumstances, unless otherwise required to do so by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For more information, please visit www.co2gro.ca or contact Sam Kanes, VP Communications at 416-315-7477.

Automated Containers Make Organic Urban Farming Feasible

Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location

The future of agriculture can be found in commercial containers, in which plants can be grown hydroponically.

Hydroponic farming has many benefits, including saving the resources involved in soil cultivation and avoiding the uncertainty of weather conditions, according to Seedo, an innovator in the field of commercial growth containers.

Approximately 40 percent of the costs of produce in large city supermarkets are used to cover logistics and shipping. Commercial containers such as those from Seedo would expand the potential for urban farming to anywhere, anytime. Plants can be cultivated 24/7, regardless of location.

For example, the automated urban farm is ideally suited to the growing market for medical cannabis and medical cannabis products. Seedo is the technology behind the world's first automated medical cannabis farm, which will yield significantly more plants than traditional controlled greenhouses.

Another opportunity for the Seedo technology is to improve the agriculture of at-risk countries, where global warming and other concerns threaten consistent farming and food production.

In some areas, farmers can use Seedo equipment and technology for growing not only medicinal herbs, but also greens such as lettuce, kale, and wheatgrass; herbs such as parsley, dill, and basil; and vegetables such as cherry tomatoes and bell peppers, and even strawberries. In the home, individuals can set up a small unit that grows plants easily and effectively without intervention.

Seedo, a pioneer in agriculture and technology with 20 years of experience, is now delivering indoor growth systems to homes and businesses across the country. Currently, Seedo has sold more than 3,000 home units through pre-orders.

The Seedo products use artificial intelligence software to control and monitor plant development from the moment the seed is planted. The software tracks each plant's development, and responds by taking action to optimize growth. The hermetically sealed systems are designed to yield consistent results regardless of the local climate.

Growers need only to plant seeds or seedlings and monitor the growth process via the Seedo app.

Other features of the Seedo system include a unique lighting system that self-adjusts based on an individual plant's stage of growth, and a smell-proof cover with built-in CO2 cartridges to prevent smell leaks.

Equally important to note is that all produce cultivated with Seedo's technology (both home and commercial) is pesticide-free, of high quality, and has a significantly extended shelf life.

Visit seedo.com for more information about investing in the growth industry of indoor gardening, and to learn more about the Seedo technology and products.

Seedo is a publicly traded company with the ticker symbol OTCQB:SEDO.

Start-Up-Nursery From Munich Convinces Food Service Industry With Microgreens From Vertical Farming

Urban & vertical farming-projects are becoming more and more present in the current, modern agriculture

"We Want To Offer A Sustainable And Regional Alternative To Cresses”

Urban & vertical farming-projects are becoming more and more present in the current, modern agriculture. For example, the South-German city of Munich has recently got their own regional cultivation project: under the name of Munich Micros, an ambitious team of innovative growers brings around 25 types of local cultivations to market. After the success in regional wholesale and food service industry, the cultivation company intends to steadily increase the production capacity as well as the product range.

The success story started 4 years ago when the growers were deepening their knowledge of the advanced vertical-farming-technology in Canada and the United States. This brought forth the idea of getting a similar cultivation project off the ground in the German region of Munich. “The theme of vertical farming, also known as indoor farming, first came to mind in my kitchen. Little by little, we worked out the idea and ended up with a test project which led to our first production. After receiving positive feedback from many different star chefs we ended up in the current production hall in Munich-Planegg last year. In May of 2018 – after three years of experimenting – we could finally set up our company and had a product at our disposal that could compete with the best in the world”, co-founder and company director Kevin Jühlcke says.

In no time at all, the high-tech cultivation company has been able to realize a successful distribution channel. A part of the harvest is being traded right away, according to Jühlcke. "Our USP is the fact that we can offer breeds that are not available anywhere else. On top of that, we also offer the guarantee of the product being locally produced. At its core our product is comparable to Koppert Cress, at the same time however, we are polar opposites. After all, Koppert is a giant industrial group and our ideas about offering sustainable and regional alternatives are in stark contrast to theirs.”

Exclusivity in wholesale

Most of the microgreens are being sold by two exclusive wholesale companies – Hermann Fischer KG and Früchte Feldbrach GmbH – and mainly ends up in local bars and restaurants, and institutions. Due to the regional production and modern cultivation methods, there is still a lot of interest in a new product range, says Andre Bukethal on behalf of Früchte Feldbrach, located near the wholesale market in Munich. “Thanks to our exclusive cooperation with regional cress-growers we now also have an interesting USP on the wholesale market. Besides that, to a trader like us, it’s also important to actively support regional growers when they take an initiative if we can.“

The new product range is not only making a name for itself in Munich and its surrounding area: after all Früchte Feldbrach has also been able to find a few new customers in the area of Regensburg, says Bukethal. “Around this time, restaurant owners are creating their new menus and because of that are looking for new, regional specialties they can offer. For this reason, we are promoting our product once more, and quite clearly, via word-of-mouth advertising as well as via our new and improved company website.”

Sales outside of the region?

Parallel to the steady development of the Munich Micros GmbH brand it will eventually become inevitable that we will also start selling our product outside of the region's borders. In this case, as well, people are trying to find an innovative solution with which the regional character of the cresses won't be compromised. Jühlcke: “The next step, of course, is to also supply our products outside of Munich. Ideally, we can eventually start outsourcing our production by opening up multiple indoor farms in the locations we need them to be. This way we can also sell regional cresses there. The dilemma, however, is that we are currently operating in such a High Quality-segment that growing too big would not be ideal either. In certain situations, the risk of growing too big will lead to a loss of product quality.”

At the moment, the terrain we operate on still offers plenty of opportunities to expand on our current capacity. The team of growers is working on a fitting and modern solution to realize this increase in scale. “One of our owners is an expert in the field of automation and together we work on a concept with which we will be able to use sealed containers and solar energy to cultivate despite outside temperatures. We could also move the containers to a different location if needed and have the production coordinated on location by 1 or 2 employees. This is where we as a company are trying to head towards.”

25 Cresses-breeds, available 365 days a year

On the current location – despite the weather conditions – we are already continuously producing the same amount of products. “We can produce the same quality product 12 months a year. With 18 mono varieties and an additional amount of mixed breeds, our core product range exists of 25 varieties that are available year round. In certain cases, we also provide exclusive cresses breeds to individual restaurant owners. Compared to the Koppert Cress-catalog, we have also developed some entirely new breeds like leaf mustard, basil mix with 5 varieties and a special protein mix intended for vegetarian cuisine. The next step is to realize the production of sweet cresses: we are currently developing a new type of wheatgrass with a sweet and pleasant taste.”

According to Jühlcke there is not only a notable trend regarding healthy foods but also an increasing trend concerning the transportation and origin of the product. “What hides behind a product? Where does it come from? These are the most important themes within the fresh produce industry together with the uncompromising freshness of the product. Everything that is delivered per day has been harvested in the early morning of that same day. This means that our products need to go through the entire supply chain in just a couple of hours.” Jühlcke knows that is also customary to provide this same service with their new products: “Our product range will be developing in the direction of edible flowers, different types of lettuce, herbs, and baby-vegetables in the years to come.”

This article previously appeared in the 4th edition, the 33e volume of the AGF Primeur trade journal. See www.agfprimeur.nl.

For more information:

Munich Micros

www.munich-micros.de

Kevin Juehlcke

munich.micros@gmail.com

Andre Bukethal

a.bukethal@fruechte-feldbrach.de

Publication date: 6/28/2019

© HortiDaily.com

Micro Lab Farms in Needles, CA Helps Individuals Get Started With Modular Farming With Shipping Container Greenhouses

America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade

America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade. Micro Lab Farms is a California based company that empowers anyone to efficiently launch or expand a high-quality marijuana operation.

Needles, CA - America’s medical cannabis industry is growing at a steady pace, with marijuana sales expected to amount to $50 billion in the upcoming decade. This explosive growth has been driven largely in part due to all the legislative changes around the herb that have taken place recently. Entrepreneurs looking to capitalize on the numerous business opportunities can jump into the “green rush” and get started almost immediately with today’s technology. Micro Lab Farms is a California based company that empowers anyone to efficiently launch or expand a high-quality marijuana operation.

Micro Lab Farms is known for their cutting-edge, eco-friendly growing systems which are optimized for productivity and profitability. Entrepreneurs from all backgrounds are looking into container farms from Micro Lab Farms to streamline the start-up process. Micro Lab Farms in California has gained recognition for their turnkey solutions that provide a full-featured environment to grow in any climate and any season.

These plug and grow systems are designed for automation and easy operation, allowing users to begin generating revenue almost immediately. Micro Lab Farms retrofits shipping containers and specifically modifies them to provide a controlled environment that allows for year-round production. A spokesperson for their company said, “Our grow lab is an affordable, scalable, efficient, and automated system. As a full turnkey solution, a grower can be up and running in a short amount of time. The return on investment can be achieved in as little as 6 months.”

Micro Lab Farms has developed ecological grow labs that utilize 90% less water and 80% less fertilizer. Since these are food-grade containers, no pesticides or pollutants are required to harvest high-grade medicinal cannabis. The California company offers soil, soilless, and hydroponic high yield and low impact solutions. Their 20’ and 40' shipping container greenhouses come equipped with an LED expert series lighting system, a rolling table system, a reverse osmosis water purification system, an HVAC system, a steel man door, and both, a dehumidifier and humidifier. Micro Lab Farms can develop a personalized solution to fit each individual’s growing needs, as they can include additional features such as clean rooms, shelving systems, prep stations, additional sensors and controls, as well as flower, clone and drying labs. Their grow labs are modular, stackable, and can be self-contained with solar and natural gas energy solutions.

Each grow lab is a completely secure and monitored environment. They are equipped with a mobile device compatible cloud-based control system, allowing users to seamlessly oversee their product from seed to harvest, through Micro Lab Farms’ remote monitoring and controlling app. The app provides real-time data of all the key components of the farm including the air, water, humidity, nutrients, and plant growth. Giving users clear visibility and maximum control over every aspect of their grow operation and eliminating all surprises.

Micro Lab Farms is located at 3353 Needles Hwy, Needles, CA 92363. For inquiries, contact their team via phone at (951) 266-6096 or via email at info@microlabfarms.com. Visit their website for additional information regarding their services.

Best Practices For Vertical Farming: An Analysis of Pros And Cons

Vertical farming can be done from anywhere and has a number of different advantages along with disadvantages. We evaluate how you can start vertical farming

written by Green Coast

May 20, 2019

Vertical farming can be done from anywhere and has a number of different advantages along with disadvantages. We evaluate how you can start vertical farming.

Best Practices For Vertical Farming (Including Pros and Cons)

At Green Coast, we are focused on providing you with the best insights on how to live a better life through green living and renewable energy.

We believe that renewable energy and green living is packed with punchy terminology and hard to understand science.

We are here to help make complex ideas more straightforward. One that is growing tremendously is indoor vertical farming through greenhouses or DIY applications at your home. Our guide will provide everything you need to know about vertical farming, including products, applications, best practices and more.

What is vertical farming?

Vertical farming refers to a method of growing plants or crops in vertically stacked layers. The concept behind this type of farming is quite different from conventional or horizontal farming. The growing methods may include the use of soil, aeroponic or hydroponic practices.

However, the basics of vertical farming remain the same while utilizing each of these methods.

What is Domestic Vertical Farming

In the past few years, innovators and inventors come up with numerous ideas for vertical farming at home. Now you have plenty of options when it comes to practicing vertical farming at the comfort of our home.

However, prior to setting up your own vertical farm, it is essential to know the construction and running cost of such a farm. You need suitable materials to build the structure and electricity to run the system.

How To Start Vertical Farming At Home

To start vertical farming within or around your house, it is advisable to go for a prototype with a view to check the feasibility. In fact, you can set up a DIY vertical farm using the materials available in your home. This will save you some initial cost of establishing such a facility.

To begin with, make use of regular plastic bottles as efficient pots or containers. You can also automate the supply of water without using electricity. This method makes it possible to provide water through evaporation.

The procedure for building a DIY vertical farm within your home includes the following steps.

Grab some water bottles of equal size

Remove the bottom of each bottle by cutting it

Use the lid of two of the bottles for using them as the tower and funnel

Fill the pots you have made from the bottles with a mixture of dirt and manure

Place these pots vertically on the rack you have dedicated for your vertical farm

Use a bottle as the water tank. Make small holes in it to provide a slow but continuous supply of water

Place this bottle on the tower and connect it with the funnel connecting all the pots

Now it’s time to plant the seeds or young plants

If you have been successful in running this type of vertical farm at home, it’s time to take it to the next level. This transformation may not be cheap, as you need to purchase most of the essential components.

In order to build a fully automated vertical farm, you need a regular supply of electricity. The technology used for this purpose is innovative and expensive. Moreover, you must also know how to operate the vertical farm systems.

Products like AeroGarden make is easy for you to start your own indoor farm at your house.

Best Practices For Vertical Farming

Apart from being revolutionary, vertical farming is a more sustainable method of growing crops. It utilizes almost 70% less water and helps to save a reasonable amount of resources. In addition, it is an eco-friendly method, which proves to be efficient in almost every environmental condition.

Here are some of the best practices that you can employ while building your own vertical farm.

Hydroponics

Hydroponics serves as the most viable system of growing plants without soil. It is gaining the attention of both domestic as well as commercial farmers, who are looking forward to setting up a vertical farm.

The basic concept behind this method is to grow plants in a nutrient rich solution. This practice works by suspending plant roots in a solution, which offers a suitable amount of nutrients for the plants to grow.

However, it requires great attention and knowledge to grow plants using just a solution. The liquid needs to be circulated frequently and you need to maintain an ideal composition of such a solution.

Aeroponics

Aeroponics is a technique that allows growing plants without soil and with a minimum amount of water. In fact, the plants literally grow in air, with roots exposed. The mist environment provides the necessary amount of moisture to the root, so that plant can grow.

No doubt, aeroponics is the most advanced and efficient way of growing crops through vertical farming. The amount of water consumed is 90% less than conventional farming. It is even more efficient than hydroponics system when it comes to vertical farming.

Moreover, while growing in an aeroponics system, the plants absorb more nutrients and mineral. Hence, the vegetables produced through this method are more fresh, tasty, nutrient-rich, and healthy.

Aquaponics

This system is identical to the hydroponics system but it has some additional benefits. The idea behind this system is to create an ecosystem where plants and fish benefit each other. This suggests that when you grow fish in indoor ponds, the water becomes nutrient rich. This water serves as a food source for the plants growing in your vertical farm.

On the other hand, plants will clean and purify the water and make it available for the fish. This saves you a lot, as there is no need to recycle the pond’s water frequently. A small-scale aquaponics system appears to be an ideal option while running a vertical farm at home.

Most of the commercial vertical farms also use this innovative system to enhance their yield. In addition, this allows them to make more profits by yielding two products at the same time. This allows solving any of the financial issues faced by the owners of commercial vertical farms.

Vertical Farming Requirements

Unlike other farming options, vertical farming systems require the latest structural and engineering equipment. The whole process of farming takes place through automation. This ensures to treat crops with utmost attention and care. As a result, it is possible to get the maximum amount of yield while utilizing minimum space.

Depending on the size, the height of a vertical farm may reach up to 30 feet. At such height, it is not viable to control the irrigation, lighting, and fertigation. Hence, automation is the only method to manage your vertical farm in a proper manner.

Given below are the various equipment and systems, necessary to run a vertical farm at home as well as commercially.

Climate Control System

Vertical farming allows us to grow plants under a controlled environment, it is essential to manage its different aspects. This includes controlling humidity, lighting, temperature, and CO2. The climate control system relies on various devices, engineered specifically for this purpose.

Controlling the environment is crucial for the healthy growth of plants in a vertical farm. If you are starting this type of venture on a big scale, it would be appropriate to purchase an efficient climate control system.

Hydroponics System

This system provides a required amount of water, oxygen, and nutrients to the crop. The hydroponic system helps to grow plants without any soil; hence, you need to provide all the nutrients through a solution.

You need to add a calculated amount of nutrient for nurturing the plants. For this purpose, you need to be precise enough to feed the crop. Over or under-dose can damage the plants or affect their growth and yield.

Irrigation & Fertigation Controllers

This system allows you to save energy by managing irrigation and fertigation requirements of a vertical farm. These controllers are highly efficient and help to monitor different aspects of your vertical farm.

List of Top Indoor Farming Products to Purchase Online

You are probably wondering how do I buy the right equipment to start indoor and vertical farming. Here are some amazing products that are easy to use and are affordable to start your indoor gardening.

Watex WX139 Urban Farming Vertical Garden, Cool Grey

Watex urban farming kit is an ideal option if you are building a vertical farm at Home. It has all the essential ingredients to start a vertical farm of your own. The pots are durable and lightweight. Moreover, UV-resistant color protects the pots from damage.

The design and layout of the whole structure make it perfect for placing at small places like a balcony or patio. This DIY kit offers easy installment. Even a person with minimum technical knowledge can assemble it.

It comes with an integrated irrigation system, which works on a micro-drip irrigation mechanism. The 12 pots setup offered by this vertical garden is highly suitable for the beginners.

SHOP NOW AT AMAZON

AeroGarden 800296-0100 Seed Starting System for Farm Models, Black

The latest design of the AeroGarden Seed Starting System ensures healthier development of roots. This system allows you to remove and transplant the seedling without any hassle. Due to strong roots, the plant grows faster.

The AeroGarden helps to nurture the seeds by providing a sufficient amount of water and plant food. It promotes healthy growth of seeds through reliable germination. The seed starting system serves well if you plan to run a vertical farm at home.

It comes with durable—re-usable seed starter tray, plant food, and Grow Sponges (Biodegradable).

SHOP NOW AT AMAZON

AeroGarden Liquid Nutrients (1 Liter) (Pack of 2)

This specially formulated and patented pack of liquid nutrients offers sustainable germination and better growth. The liquid is capable of providing essential nutrients to the plants whether growing in hydroponics or aeroponics system.

These nutrients offer faster growth with maximum output. AeroGarden Liquid Nutrient is also beneficial for other houseplants. The liquid in both packs is sufficient for more than 100 feedings. The pH buffering system works well with all types of hydroponic applications.

SHOP NOW AT AMAZON

Combo: Year-Round Vertical Freestanding Garden Planter (4 Tier, White) Plus Expansion Packs For Indoor Outdoor Use: Altifarm Urban Grow System + Grow Lights + Greenhouse Cover + Mobility Wheels

This vertical farm system is ideal for both indoor and outdoor use. It comes with greenhouse cover, mobility wheels, grow lights, and 4 tier planter. It helps to grow all types of herbs or vegetables irrespective of the season.

Setting up this vertical farm is quite easy, as it just takes a few minutes to assemble all the parts. Its built-in watering system helps to maintain a regular supply of moisture for plants.

SHOP NOW AT AMAZON

Advantages And Disadvantages Of Vertical Farming

Just like any other technological developments and innovations, vertical farming also has its pros and cons. To give you a better understanding, both the advantages and disadvantages of vertical farming are discussed below.

Vertical Farming Advantages

Here are some of the benefits and advantages of vertical farming.

Improves Production— One of the most important vertical farming objectives is to get maximum production by using minimum land. It manages to grow plants in almost every condition. Hence, there is no need to wait for a specific season to grow your crops.

Less Land Required— You can grow a sufficient amount of crops by utilizing less land. On the contrary, conventional farming uses more land and resources, which also increases the cost of production.

Environment-Friendly— Vertical farming utilizes less amount of resources as compared to traditional farming. You need a minimum amount of water, space and fertilizers to grow your crop. Hence, it helps to overcome various environment-related issues by conserving natural resources.

Immediate Availability of Agricultural Products— Unlike conventional farming, vertical farming allows growing your crops within an urban area. This makes it easy to provide a fresh supply of produce without any delay. The farm-to-market process reduces from days to just hours.

Vertical Farming Disadvantages

Here are some of the limitations, challenges, and disadvantages of vertical farming.

Economic Viability— One of the major disadvantages associated with vertical farming is its cost. It is not even possible to calculate the economic feasibility of setting up a vertical farm. The major portion of investment relates to the purchasing of high-tech instruments. The cost of running such a farm also fluctuates depending on the requirements of the crop.

A Threat to the Rural Community— There is no doubt, rural community relies heavily on agriculture for its sustenance. This is what drives their economy. By shifting farms from rural area to the urban part of the cities, we may cause trouble to the rural areas by disrupting their economy.

Requires Constant Energy— Vertical farming depends mostly on electricity for running all its mechanism. You need electricity to provide a sufficient amount of light to the plants and run various high-tech equipment. Hence, this type of farming leaves behind some sort of carbon footprints.

Complex Processes— Since vertical farming requires a lot of automation and electrical equipment, it is not an easy task for an ordinary person to handle this type of farming.

Conclusion on Vertical Farming

Vertical farming is an innovative and sustainable method of growing crops. Unlike contemporary agricultural practices, vertical farming helps to yield more produce by utilizing minimum resources. The most amazing and encouraging aspect of this type of farming is that you can even set up a vertical farm at your home. Despite some of its disadvantages, vertical farming appears to be the future of our agriculture.

What are your favorite components of vertical farming? Please let us know in the comments below. We’d love to hear from you.

Related Resources

Follow our green living blog for the latest industry insights and topics

A complete overview of flora and fauna

Best greywater systems for your home

Top 25 Vertical Farming Companies

The phrase “vertical farming” probably doesn’t need to be explained even though it’s quite new

May 3, 2019 By MAI TAO

The phrase “vertical farming” probably doesn’t need to be explained even though it’s quite new. But anyway, vertical farming refers to the practice of producing fruits and vegetables vertically, in stacked layers, perhaps on many floors inside a building, using artificial lights instead of the sun, and a whole range of relatively new technologies.

The two main reasons why it’s a much-discussed topic now is because:

there are a number of startup companies emerging in the sector and attracting tens of millions of dollars in investment; and

more people live in cities than do in rural areas, a global trend which seems irreversible, and this means that the demand for fresh produce will increase in urban areas, and bringing the production closer to the consumer would make sense.

The third thing we could have added is that there is the range of new technologies available now that make vertical farming in urban areas cost-effective and possibly profitable. But we already mentioned that.

Some of these technologies have been available for some time, decades even, but they were probably too expensive in the past to make vertical farming a viable business proposition.

The key technologies in vertical farming include:

perception technologies – cameras and other sensors which can monitor for colour and other factors, such as disease;

artificial intelligence – which can process the data from the sensors and formulate solutions;

automated and even autonomous mechatronics – robots and other automated machines which pick the produce when it is ready for market, or apply cures to ailments during their growing.

The above list is a very simple breakdown of the fundamental technologies that will be required to, basically, reduce to a minimum or even eliminate the need for human involvement.

If vertical farms are run like traditional greenhouses, there would be too much human input required and it probably would not be profitable.

It’s the new automation technologies that will make it work.

Carnegie Mellon University is among a number of organizations which have developed integrated systems for vertical farming. CMU’s version is called ACESys, short for Automation, Culture, Environment, and Systems Model for Vertical Farming.

An academic paper probably worth checking out is called Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture.

In their introduction to the paper, the authors note: “Greenhouse cultivation has evolved from simple covered rows of open-fields crops to highly sophisticated controlled environment agriculture facilities that projected the image of plant factories for urban farming.

“The advances and improvements in CEA have promoted the scientific solutions for the efficient production of plants in populated cities and multi-story buildings.”

So the interest in the field is strong and most people seem to think it’s a viable business proposition.

And to underline the positivity about the sector, Research and Markets forecasts the vertical farming market will grow to a value of $3 billion by 2024, from virtually nothing now.

However, not everyone is convinced, and some people have dismissed the whole idea as a scam. They say it won’t work, will be too expensive and not be able to yield enough to provide adequate returns on investment.

But in some sectors, such as marijuana production, indoor farming is providing a strong foundation for healthy profits, although we are not encouraging that sort of thing – this article is more about produce such as lettuce and other healthy vegetables and fruit, usually found in greengrocers.

Anyway, whatever we or anyone else thinks of the prospects, there are a large number of companies which have entered the field and we thought it would a good idea to make a list of them.

It’s a very new business sector, so this list is not ordered on any scientific basis – just 20 companies that are notable and active.

We’re not going to include Samsung for now even though it’s been on this website recently for demonstrating a home vertical farming product. The reason is that vertical farms are currently not central to Samsung’s business by any stretch of the imagination, although the company may have a contribution to make to the sector going forward.

1. AeroFarms

This company has won many plaudits for its operation and uses its own patented “aeroponic technology… to take indoor vertical farming to a new level of precision and productivity with minimal environmental impact and virtually zero risk”.

The company has raised at least $138 million in funding since launch in 2004, according to CrunchBase. Some of its backers are quite impressive, as this article in Ag Funder News reports.

The term “aeroponic” farming refers to the process of growing plants in an air or mist environment without the use of soil or any earth-like material, which is known as “geoponics”.

Aeroponic systems enable the production of plants using 95 percent less water, which is what AeroFarms says it does.

2. Plenty

Although Plenty doesn’t make seem to mention aeroponics on its website, it’s difficult to see how it can reduce the water consumption of its vertical farms by 95 percent, as it claims to do, without the air-and-mist system as described above.

Like the other big vertical farming companies on this list, Plenty is another one that retails its produce, which include kale and other greens, as well as some exotic herbs.

Plenty is probably the biggest company in terms of the amount of money it has raised in funding – approximately $226 million, according to CrunchBase.

Green Spirit Farms started raising money as early as 2013, but has not disclosed the amounts. Area Development reported that the company was investing $27 million in a vertical farm system in Pennsylvania, which would suggest it’s well financed.

However, given that it doesn’t seem to have a website of its own, it’s difficult to say what its current and future activities are with full confidence. Owler estimates its annual revenues to be $1.2 million.

You’d think any farming startup of any kind would steer clear of everything that’s genetically modified, but the fact that Bowery makes a point of saying it uses “zero pesticides and non-GMO” seeds might suggest that some vertical farming companies don’t have the same ideas.

Having raised more than $140 million in investment since inception in 2015, Bowery has carefully developed a distribution network in the US. Its leafy greens are available to buy in Whole Foods Market and Foragers. It also supplies a number of restaurants and sells online.

It doesn’t look like Bowery supplies its platform to other companies, even though some might be interested in its claims, such as: 95 percent less water usage than traditional agriculture; 100 times more productive on the same amount of land; and from harvest to shelf “within a few days”.

5. BrightFarms

Another of the big-money startups, BrightFarms has so far raised more than $112 million since its establishment in 2010, according to CrunchBase.

But unlike some of the other big companies, it isn’t into aeroponics as much. It seems more interested in hydroponics, which refers to growing plants with water, or, to be more accurate, mineral nutrient solutions in a water solvent.

Neither aquaponics nor hydroponics use soil. How each one compares in terms of quality, efficiency and profitability will probably only become clear a few years from now when we see how well these companies have done. Chances are they’ll all probably use a mix of systems.

BrightFarms has a long list of impressive-sounding partners, including Giant, Walmart and Metro Market, among others.

This company is one of many which have started up in the New York area. Strange to say it about such a new sector, but the market for vertical farming produce may be saturated – in that city at least.

Gotham Greens has so fair raised at least $45 million since its launch in 2011. It has four production-scale facilities, in New York City and in Chicago, and plans for more in several other states.

And, like BrightFarms, it’s more of a proponent for the hydroponic method, although it may well eventually mix it all up and try different approaches in different facilities.

7. Iron Ox

This company appears to use robotics perhaps more than the others, in the picking process at least, and claims to operate fully autonomous indoor farmings. It too is a proponent of hydroponics, and is a retail-oriented company.

Its products are similar to the others’ – leafy greens such as lettuce and kale or things like that. It’s one of the newer startups on the list so a lot might change.

Iron Ox has only recently started supplying its products to local markets in California. The company has so far raised over $6 million in funding, according to CrunchBase.

8. InFarm

Most of the above companies are US-based, but there are also numerous vertical farming startups in Europe and Asia. InFarm is based in Berlin, Germany, and has so far raised approximately $35 million in investment.

The company appears to be going into the exotic herbs market, including Thai basil, Peruvian mint and such like. But it’s also growing fairly common herbs such as dill, basil, sage and so on.

It doesn’t say on its website whether it uses hydroponic or aeroponic systems, but it does claim to use 95 percent less water, which would suggest it uses at least one of those. However, it says it uses 75 percent less fertilizer, which might suggest it mixes earth-based processes into its technology. Most likely, it uses a hydropic system.

9. AgriCool

French vertical farm startup uses an aeroponic system to grow fruit and vegetables. It appears to like strawberries more than other produce. Not a bad idea since strawberries are hugely popular in France, which has a massive traditional agriculture industry.

AgriCool says its aim is to be within 20 km of its customers and offers a program called “Cooltivator”, through which customers can learn how to use its technology and possibly become producers and distributors themselves.

So far, AgriCool has more than $41 million in funding since its launch in 2015, according to VentureBeat. The company also uses shipping containers as “Cooltainers” in which its aeroponic farms can be set up.

10. CropOne

While we couldn’t immediately find how much funding CropOne has raised, we did find that it has signed a $40 million joint venture agreement with Emirates Airlines to build what is described as “the world’s largest vertical farming facility” in Dubai, UAE.

It follows, perhaps, that it will eventually supply a lot of its produce to Emirates Airlines for its flight passengers.

CropOne, founded in 2011, claims to use just 1 percent of the amount of the water required by traditional agriculture, using a hydroponic system. It’s also big on big data, with “millions of data points collected each day” about its plants, which are mainly edible leafy greens.

11. Illumitex

Halfway through this list, and we feel the need to chill out, and what better way to relax than write about Illumitex, which supplies LED lights – light emitting diodes – which are popular among cannabis growers.

Of course, all sort of other companies uses LED lights, but Illumitex’s biggest customers are probably in the dope sector.

LED lights are claimed to use 90 percent less energy than incandescent lighting and 60 percent less than fluorescent lighting. This energy efficiency – and, therefore, lower cost – is a critical factor in the likelihood of making profits in vertical farming being quite high.

Lights supplied by Illumitex, founded in 2005, are installed in some of the world’s largest vertical farms.

12. PodPonics

Not much information is immediately available about this company, but according to the Angel investment website, it raised almost $5 million in 2014, which is a long ago in startup terms.

The company constructed a vertical farming facility in and is said to be doing something similar in the Middle East. However, without being able to find the company’s website, we can’t really say much more.

13. Surna

Getting even closer to the “demon weed”, this company specializes in providing water-efficient solutions for indoor cannabis cultivation, and counts more than 800 grow facilities as clients and partners.

The company appears to use hydroponic systems in the main, but given its long client list, it probably installs a variety of technologies, depending on the customers’ requirements.

Surna is based in Boulder, Colorado, one of the first states to decriminalize cannabis, now at the centre of a flourishing industry. However, the company says it can grow anything anywhere, including “potatoes on Mars”.

14. Freight Farms

Rather like AgriCool, Freight Farms manufactures a product called the “Greenery”. As its name suggests anyway, Freight Farms provides shipping containers modified as hydroponic indoor farms – the Greenery.

In fact, Freight Farms claims to be the world’s leading manufacturer of container farming technology, and provides ready-made or “turnkey” container farms. Or plug-and-play maybe.

As you might expect, these farms can be managed through smartphones. The company has a whole range of tech solutions built around its central product.

Freight Farms has so far raised almost $15 million in funding since its founding in 2010, according to Owler.

15. Voeks Inc

Voeks Inc, a US company, appears to have no connection with a similarly named company, called Voeks, in the Netherlands, Europe – that one seems to be for former employees of Shell.

Voeks Inc provides a range of services including for vertical farms, mostly in the areas of heating and irrigation systems, as well as nutrient delivery.

Its client list includes some big names, such as Monsanto, Syngenta, and Bayer, which is in the process of taking over Monsanto.

16. SananBio

SananBio provides vertical farming solutions which mainly involve the hardware, such as the lights and the platforms.

Backed by a significant scientific research and development unit, the company is one of the leading suppliers of vertical farm systems in Asia and is expanding in the US.

It emphasizes hydroponic equipment on its website, but it’s likely that it customizes its solutions depending on its clients’ requirements.

Interestingly, Sanan claims to be the largest LED chip manufacturer in the world, and we’ve already mentioned how crucial LED lights are to indoor farming.

17. HelioSpectra

Talking about LED lights, which basically replace sunlight, HelioSpectra is one of the leading suppliers in the indoor farming market, with a big client base from the cannabis growing sector.

But HelioSpectra aren’t all into growing cannabis, however. The company’s lights are also used to grow a variety of lettuce types, tomatoes, and peppers, among other fresh produce.

18. Agrilution

Back to a complete vertical farming systems supplier, but with a couple of slight differences. Not only because Agrilution is European – German, to be more precise – but also because it supplies what it describes as a “personal vertical farming ecosystem”.

In other words, its “PlantCube” product can be installed into the average home, taking up a similar amount of space as a dining table or large fish tank.

Perhaps similar to the product being tested by Samsung, Agrilution’s PlantCube uses a hydroponic process.

19. Altius Farms

Specializing in aeroponic systems, Altius provides what it calls “tower gardens” among its products. Just imagine a multi-level plant pot and you’ll get the idea.

The company integrates its farms into a variety of urban spaces, fromschools to urban youth centres and veterans’ homes, sometimes on rooftops, sometimes at ground level.

Altius looks more like a social venture than a private enterprise, and we couldn’t immediately find whether it has raised any equity finance.

20. Badia Farms

Vertical farms are the culmination of emerging technology in a relatively new market, so there’s bound to be many companies claiming to be the “first” or “biggest”, and of course “revolutionary”.

Badia Farms claims to be building the Middle East’s Gulf states’ first indoor vertical farm, in readiness to supply “micro-greens and herbs” to top restaurants in places such as Dubai.

The company’s multi-story greenhouse will use the hydroponic method for growing, and already boasts a prestigious client base.

21. Intelligent Growth Solutions

Another vertical farming specialist, also with an eye on the Middle East, Intelligent Growth Solutions is actually a Scottish company.