Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Investing In Vertical Farming: Five Take-Aways

Humans have 12,000 years of experience growing food, but only a generation or so worth of experience growing crops indoors

April 5, 2019

Erik Kobayashi-Solomon Contributor

“Eyewatering”

That’s the best description for recent capital inflows into the vertical farming industry. Take a look:

July 2017: Softbank invests $200 million in Plenty.

August 2017: IKEA and the Sheikh of Dubai invest $40 million in AeroFarms (with $115 million invested in the company over its life)

December 2018: GV (Google Ventures) invests $90 million in Bowery Farming.

As someone focused on climate change investing, it’s hard not to take note of the scale of capital flows into private vertical farming companies.

As I mentioned in Agriculture is Broken; AgTech Can Fix It, there is a lot to like about the idea of applying modern technological solutions to the problem of food production. The global population is expanding while the earth is heating up. Something must be done to keep us out of the dismal realm of Malthus.

However, I am enough of a contrarian to become circumspect when I see massive cash flowing into a trendy investment area. Getting good information is particularly hard during boom times, because everyone, it seems, is working some angle.

In my quest to find some good, unbiased information about the industry, I struck up a friendship with Dr. Paul Gauthier, a plant physiologist specializing in vertical farming research. Dr. Gauthier runs the Princeton Vertical Farming Project and will soon transfer his lab and research from Princeton University to Delaware Valley University where he has been selected for the K.H. Littlefield Endowed Professorship of Plant Science.

I spent a day with Paul in Princeton and came away with five important take-aways about vertical farming.

Dr. Paul Gauthier at work at the Princeton Vertical Farming Project labs

PRINCETON UNIVERSITY

“You can’t feed the planet with lettuce alone.”

Lettuce, herbs, and microgreens are easy crops to grow indoors, so a lot of indoor farms are focused solely on producing them. Farmers, though, cannot escape two economic facts: 1) markets conform to the dynamics of supply and demand and 2) farm inventories are perishable.

If your vertical farm and three competitors each have enormous warehouses stuffed full of lettuce growing under LEDs and destined for the same metropolitan area, the price of lettuce in that area is likely to fall and / or someone will be trashing a lot of wilting greens.

Other crops can be grown indoors too – Gauthier has grown berries, eggplants, peppers, and even grain in his lab – but it takes an expert understanding of what plants need to grow and thrive and many cycles of trial and error.

Rows of produce grow inside plastic trays at the Bowery Farming Inc. indoor farm in Kearny, New Jersey, U.S., on Tuesday, Aug. 7, 2018. The startup says automation, space-saving vertically stacked crops and a year-round growing season make its operations 100-plus times more productive per square foot than traditional farms. Photographer: David Williams/Bloomberg

© 2018 BLOOMBERG FINANCE LP

More basic science needs to be done

Humans have 12,000 years of experience growing food, but only a generation or so worth of experience growing crops indoors. We are still progressing up the technology learning curve, to the extent that there is a lack of good data about basic questions -- comparing crop yields for plants grown outdoors in soil, inside a greenhouse, and indoors using hydroponics, for instance.

What’s more, traditional farming techniques are based on conditions that are not applicable to vertical farming. Outdoors, food crops are exposed to variations in rainfall, light and wind, and must compete with other plants to scavenge for nutrients in variable-quality soil while exposed to the threat of animal or insect predation.

The fact that vertical farming removes the uncertainties inherent in nature is a positive, but by taking plants from their natural habitats, we are implicitly saying that we understand everything about what a plant needs to thrive. We don’t. Without that understanding, we are left with overproducing crops that are easy to grow indoors: lettuce, herbs, and leafy greens.

The recently passed Farm Bill provides support for research and investment into vertical farms and that’s a big positive for the industry, but we still have further to go. Without taking time to understand the science, though, vertical farming is not likely to be able to live up to its lofty implied promises (or investment valuations).

Photographer: David Williams/Bloomberg

© 2018 BLOOMBERG FINANCE LP

Vertical Farming is not a pie-in-the-sky, but it’s not a lay-up either.

The cost of powering LED grow lights is one of the biggest hurdles a vertical farm must overcome for its produce to be competitive with fruits and vegetables from a traditional farm.

Costs are so high, in fact, that professor emeritus at Cornell, Dr. Louis Albright, has characterized vertical farms as “pie-in-the-sky” ventures. Albright famously calculates, for instance, that the cost of a loaf of bread would be $24 if farmed indoors – price prohibitive to anyone but Ricky Gervais.

Gauthier acknowledges that energy prices are high but points out that that many are experimenting with using less light to grow crops. Scientific work has shown that only about 6% of available sunlight is used in crop photosynthesis, so there may be ways of growing the same plants with less light.

LED technology is continually improving and at some point, governments around the world will decide to stop externalizing the cost of emitting greenhouse gases. Until that time, however, large scale vertical farm profitability is likely to remain low.

Photographer: David Williams/Bloomberg | © 2018 BLOOMBERG FINANCE LP

Vertical farming offers some great sustainability benefits

While energy costs are not a lay-up, vertical farming does create enormous efficiencies in other areas. Water usage may be drastically reduced because the same water can be recycled time and again through the same hydroponic system.

Fertilizer use can be greatly reduced and herbicides and pesticides for weed and pest control are unnecessary. These agricultural chemicals – which are habitually over-applied, only to run off into rivers and lakes – are likely responsible for everything from ocean dead zones to algal blooms to die-offs among pollinating insect.

Factoring in the economic benefits we enjoy as a result of clean oceans and thriving pollinators, it’s clear that vertical farming offers real value to society. As long as the price of carbon emissions and environmental pollution is not priced explicitly, though, it will be difficult for many people to accurately perceive the benefits.

An employee checks lettuce grown in an indoor farm at a Spread Co. plant in Kameoka, Kyoto Prefecture, Japan, on Tuesday, Oct. 2, 2018. Spread is preparing to open the world’s largest automated leaf-vegetable factory. It’s the company’s second vertical farm and could mark a turning point for vertical farming -- bringing the cost low enough to compete with traditional farms on a large scale. Photographer: Tomohiro Ohsumi/Bloomberg

© 2018 BLOOMBERG FINANCE LP

The future is probably hybrid

In some environments – the Middle East, for instance – a move to vertical farming is a no-brainer. An indoor farm in Saudi Arabia, for instance, can use solar energy to power LEDs at low cost without shading out other farmland. At present, virtually all vegetables must be imported into the country, so having locally-grown crops there would be a big win.

In other geographies, though, the expense of establishing a facility places a high bar on growth and profitability that vertical farms have had trouble clearing. For instance, AeroFarms, a large vertical farming and equipment operation mentioned in the introduction, only started generating a (small) profit eight years into its nine-year life.

Facing high capital and operating expenses, I doubt if large, industrial vertical farms can profitably become the primary source of most US consumers’ fruits and vegetables anytime soon.

However, smaller, tuck-in vertical farming installations on presently operating farms could produce countercyclical crops and supply a local alternative to food that is normally imported.

For instance, a farmer in the upper Midwest could build out hydroponics facilities in an old barn or an unused plot of land that would be used to grow strawberries for sale in Chicago and Minneapolis supermarkets in January. Berries fetch a high price mid-winter in this part of the country, and selling fresh local produce into this market could add a nice, countercyclical income stream to the farmer.

Gauthier’s vision is even more local. He adapts Bill Gates’s 1980 vision of a personal computer in every home and predicts that in the future, every home will have its own hydroponic vegetable plot.

Erik Kobayashi-Solomon Contributor

I am the founder of IOI Capital, the manager of a private investment partnership dedicated to investing in public and private companies focusing on ways to help civilization mitigate and adapt to the effects of climate change. My expertise in valuing private and publicly-traded companies has been sought out by top institutions, including the World Bank, and I have appeared on national TV programs such as The Nightly Business Report and in the international media. In 2014, I published The Intelligent Option Investor: Applying Value Investing to the World of Options (McGraw-Hill) and before becoming a Forbes contributor, I worked as a hedge fund risk manager, an investment banker in Tokyo and New York, a Market Strategist for Morningstar and as the Director of Research for a financial data start-up in Chicago.

This Urban Farm Grows Strawberries In Shipping Containers In Central Paris

Mónica R. Goya

In terms of humidity, air quality and light, Agricool has created the perfect environment by growing strawberries in customized, reclaimed shipping containers. Every year, seven tons of strawberries are produced in each container. According to Agricool, these containers can yield 120 times as much as a field. | Mónica R. Goya

Agricool is a Parisian urban agriculture tech start-up that recently raised $28 million to scale its business: growing strawberries in reclaimed shipping containers in central Paris using vertical farming methods. Since the plants are cultivated using aeroponics — that is, by spraying a mist of water and nutrients on the plants' exposed roots (as opposed to the plants growing in soil) — their process uses 90 percent less water than conventional agriculture. Pesticides aren't needed because they grow in a controlled environment, and their carbon footprint is almost nonexistent because the transportation radius is less than 20 kilometers. Additionally, they claim to be 120 times more productive than traditional, soil-based agriculture, and their LED lights are powered by renewable energy.

The final design of each shipping container looks modern, with its external shell covered by a wooden panel. One of the reasons why the company uses reclaimed containers is because they are weatherproof. | Mónica R. Goya

Founded in 2015 by Gonzague Gru and Guillaume Fourdinier — two friends who grew up on farms in the French countryside — Agricool's principles are based on sustainability without compromising profitability. Furthermore, their business model can be imitated anywhere. Proof of their scalability is that they operate a strawberry container in Dubai. With their latest round of investments, they are planning to add about 100 containers to their current fleet by 2021.

Vertical farming makes the most of available space. Also, the company designs and produces its own LED lights, which are tailored specifically to its needs.

Mónica R. Goya

When the right time comes, colonies of bumblebees are brought into the shipping containers for pollination. | Mónica R. Goya

Their strawberries can be purchased at Monoprix supermarkets, as well as La Grande Epicerie de Paris, one of the city's most exclusive food halls.

Lab tests are conducted to assess the sugar levels and nutrients of the fruit. According to Agricool's own lab tests and external tests, their strawberries contain 30 percent more vitamins and 20 percent more sugar than conventional ones. | Mónica R. Goya

Remy Faury is an engineer who works on the research and development team at Agricool. The company's R&D team makes up 70 percent of the company.

Mónica R. Goya

Maria Foncillas is a "cooltivatrice" or an urban farmer, at Agricool.

Mónica R. Goya

At Agricool, several varieties of strawberries are grown throughout the year. These ones, in particular, belong to the Magnum variety. The growing cycle of the fruit is two months from seed to harvest.

DelFresco Pure Goes Vertical With CubicFarm

April 10, 2019

Jo-Ann Ostermann, of CubicFarm and Carl Mastronardi of DelFresco Produce demonstrated the vertical farming system by CubicFarm at CPMA in Montreal.

MONTRÉAL—Vertical farms are all over the news as players want to cash in on consumer demand for local fresh produce, but it’s not as easy as dropping a container next to a supermarket.

That’s where a background in greenhouse growing comes in.

Kingsville, ON-based DelFresco Produce Ltd. is working with CubicFarm Systems, Milner, BC, to expand the company’s product line and footprint with container farms.

“We’re starting with 14 units, and we’re going to see how quickly we can get this going,” said DelFresco President Carl Mastronardi. “Once we see that it’s going well, we’re going to expand it.”

Mastronardi envisions nationwide expansion over the next five years and is drawing on decades of experience growing greenhouse produce in Canada.

Growing in containers is a hot trend right now, but not everyone’s up for the challenge.

“A lot of people are getting into it, and a lot are failing,” he said.

Part of that is the technology, and part is the high cost of labor – two things for which CubicFarm and DelFresco believe they have the solution. CubicFarms’ system is fully automated, instead of relying on racks that have to be manually rotated. That cuts down tremendously on labor, Mastronardi said.

The technology has evolved over the past decade and a half. Most growers wouldn’t consider lights for vegetables because the energy cost is too high.

Nowadays, the LED lights are highly specific, emitting only the light necessary for optimal plant growth, with new tech constantly coming online, said Jo-Ann Ostermann, vice president of CubicFarm.

“We’re getting better and better at it every day,” she said.

Mastronardi is no stranger to taking risks with a new technology. DelFresco launched greenhouse strawberries in Ontario several years ago, and Mastronardi was recognized by the Ontario Produce Marketing Association as its Produce Person of the Year for the endeavor in 2018.

With this new venture, DelFresco is aimed at flavor and safety.

“What we’re trying to do is give the consumer a real safe product, and a taste experience,” he said.

Products planned for launch include living garden lettuces, which consumers can buy with roots intact and continue growing at home, as well as living microgreens that stay fresher longer.

“The biggest advantage is a better flavor profile whether it’s 120 degrees outside or 20 degrees outside,” Mastronardi said.

Tagged cpma, greenhouse

Pamela Riemenschneider is Retail Editor for Blue Book Services

Asia: Grapes On Mars? Georgia Winemakers Aiming High

Georgia is immensely proud of its ancient wine-making tradition, claiming to have been the first nation to make wine. Now it wants to be the first to grow grapes on Mars

APRIL 10, 2019

TBILISI: Georgia is immensely proud of its ancient wine-making tradition, claiming to have been the first nation to make wine. Now it wants to be the first to grow grapes on Mars.

Nestling between the Great Caucasus Mountains and the Black Sea, Georgia has a mild climate that is perfect for vineyards and has developed a thriving wine tourism industry.

Now Nikoloz Doborjginidze has co-founded a project to develop grape varieties that can be grown on Mars.

“Georgians were first winemakers on Earth and now we hope to pioneer viticulture on the planet next door,” he told AFP.

After NASA called for the public to contribute ideas for a “sustained human presence” on the Red Planet, a group of Georgian researchers and entrepreneurs got together to propel the country’s winemaking onto an interplanetary level.

Marika Tarasashvili, an astrobiologist working on a project to develop grape varieties that can be grown on Mars, works at a laboratory in Tbilisi on Feb. 26, 2019, as Georgia claiming to be the first nation to make wine thousands of years ago, now wants to be the first to grow grapes on Mars. AFP / VANO SHLAMOV

Their project is called IX Millennium — a reference to Georgia’s long history of wine-making.

Since archaeologists found traces of wine residue in ancient clay vessels, the country has boasted that it has been making wine for 8,000 years — longer than any other nation.

IX Millennium is managed by a consortium set up by the Georgian Space Research Agency, Tbilisi’s Business and Technology University, the National Museum and a company called Space Farms.

While it might seem like the stuff of science fiction, the idea of humans quaffing wine on the fourth planet from the Sun is coming closer to reality.

NASA hopes to launch a manned mission to Mars within 25 years, while billionaire Elon Musk’s SpaceX company has set a goal of outstripping the US space agency by a decade.

‘Breakthrough’ results

One of the scientists working on the project, astrobiologist Marika Tarasashvili, is developing bacteria that could turn Martian soil into fertile earth.

Researchers had already achieved “breakthrough” results in experiments, she said, smiling, as she gazed into a glass vial with faux-Martian soil in a cramped Tbilisi laboratory.

The scientists collected bacteria from regions of Georgia with “extreme ecosystems” such as hot sulphurous springs, then bred strains capable of living in Martian conditions, she says.

The idea is for the bacteria to transform the lifeless surface of Mars into fertile soil “on which future colonists will be able to cultivate plants,” she said.

Tarasashvili and her colleagues are also testing the skins of Georgia’s 525 indigenous grape varieties to establish which are most resistant to the high levels of ultra-violet radiation hitting the Martian surface.

Preliminary results showed that pale-skinned Rkatsiteli grapes — a popular variety that produces white wines with crisp green-apple flavours — best endures ultra-violet rays.

“In the distant future, Martian colonists will be able to grow plants directly in Martian soil,” said Tusia Garibashvili, founder of Space Farms company, part of the IX Millennium project.

“But first we need to create a model of completely controlled sustainable Martian greenhouses.”

Her company is currently building a vertical farming laboratory, which she calls “the ideal technology for Martian agriculture of the future.”

The plants will grow in a special facility located inside a trendy Tbilisi hotel, laid out in vertically stacked layers with carefully controlled temperature, light and humidity.

The next step will be to test Georgian grape varieties in a simulated Martian environment in a laboratory now under construction at the Business and Technology University.

“Plants will be subjected to sub-zero [Celsius] temperatures, high levels of radiation and carbon monoxide [and] high-altitude air pressure,” said BTU Dean Nino Enukidze.

“Martian dreams aside, our experiments are providing information that is vital as humanity confronts a multitude of environmental challenges,” said Enukidze.

“We will be able to identify and breed food crops resistant to the problems caused by global climate change.”

AFP

From Fumes to Farming: Pittsburgh Sheds Industrial ‘Steel City’ Past to Open Nation’s Largest Urban Farm

Pittsburgh, the western Pennsylvania city once a hub for soot-spewing steel and coke mills, is about to become home to the nation’s largest urban farm. A 23-acre urban farm project named the Hilltop Urban Farm is set to open in 2019 just two miles from downtown Pittsburgh

iStock/linephoto

Pittsburgh, the western Pennsylvania city once a hub for soot-spewing steel and coke mills, is about to become home to the nation’s largest urban farm.

A 23-acre urban farm project named the Hilltop Urban Farm is set to open in 2019 just two miles from downtown Pittsburgh.

“The land was just kind of sitting there, fenced and looking very post-apocalyptic,” Aaron Sukenik, head of the Hilltop Alliance, which is building the farm, told the Thomson Reuters Foundation.

“On top of farmland where winter peas and other fresh produce will be grown by local residents and sold in the community, the farm will feature a fruit orchard, a youth farm and skills-building program. Hillside land will eventually have trails,” Reuters notes of the project.

“I can’t imagine the last time that a mayor had the opportunity to cut a ribbon on a farm in the city of Pittsburgh, and not just a farm, but the largest urban farm in America,” the city’s Mayor Bill Peduto boasted at the project’s ribbon cutting last month.

At the center of America’s Rust Belt, which runs from Detroit up to Buffalo, Pittsburgh has made inroads in recent years to reimagine itself and shake-off much of the rust image. While once known as the Steel City, with skies black from industrial pollution, it’s also been the home to mega food brand Kraft Heinz, which is now working toward improved sustainability initiatives and decreasing its carbon footprint, including how it manufactures within its hometown city and around the world by reducing greenhouse gas emissions, energy and water usage, and decreasing its waste by 15 percent globally by 2020, it notes on its website.

Pittsburgh’s relationship with industrialist Andrew Carnegie (1835-1919) injected the city with world-class museums, libraries, and universities. And its association with pop artist Andy Warhol (1928-1987) who was born in the city, also lends itself to a thriving eclectic art scene (even though Warhol distanced himself from Pittsburgh and spent most of his adult life in New York City) that has come to shape much of the city’s post-industrial image.

And one can’t talk about Pittsburgh without acknowledging its spiritual life-blood, which, despite the city being home to the world’s best-selling ketchup, is not red at all, but black and gold — the colors of the city’s three major sports franchises: the Pittsburgh Pirates, Penguins, and Steelers. With 16 championship wins between them, the Steel City is better known these days as The City of Champions, a wellspring of pride for locals. (With another Stanley Cup win earlier this summer, the Penguins became the first team to win back-to-back championships in nearly two decades.)

“Every fanbase thinks it has the best and most passionate on the planet. Regardless of the city, there is a legion of fans walking around with an inferiority complex, just waiting for someone to ever question their fandom,” Tyler Conway wrote in the Bleacher Report in 2014. “Pittsburgh has those people. They’re there, they’re annoying and no one ever wants to sit within 10 rows of them at a stadium. But taken as a whole, the fans stand out for their duality between passion and rationality.”

That mix of passion and rationality sustains the city through the long, grey winters, and hot, humid summers. And for a city that’s not quite sure how to shed its 100-year-old industrial image, team spirit offers unity, a common ground and a strong foundation in visioning about the city’s future.

“Pittsburgh is the forefront for the next generation of creative connoisseurs in the Northeast,” Michaela Trimble wrote in Vogue. “Google now calls the town’s old Nabisco factory home; Uber tested its first driverless cars here; and new, community-focused hotels like Ace Hotel Pittsburgh are collaboratively beckoning in a new meaning to black and yellow pride.”

The steel mills that once lined Pittsburgh’s three rivers have long been abandoned — some retooled into trendy shops, restaurants, hotels, and lofts. Parts of the city have become artistic hipster havens with New Yorkers escaping the high rents of Brooklyn just five hours east to open restaurants, bars, coffee shops, and art galleries in the more affordable neighborhoods of Pittsburgh.

the Farm plans

Urban farms and farming projects are of course nothing new — they can be found in major U.S. cities like Chicago and New York. Twenty percent of fresh food can now be attributed to urban operations. The number of farmers markets has also increased significantly in recent years. The USDA notes that in 1994, the number of markets across the U.S. totaled 1,755. Today there are more than 8,000 farmers markets nationwide, most of which are found in densely-populated urban areas. But food deserts –areas without easy access to fresh foods — are significantly more common than farmers markets or urban farm projects. According to the USDA, more than 23 million Americans live in food deserts.

It’s an issue Pittsburgh-based nonprofit The Fruit Tree Planting Foundation works to address both locally and globally through its fruit orchard-planting projects and educational programs. “As a Pittsburgh-based tree planting organization, we couldn’t be more proud of our city and this initiative to improve food security for our residents,” Cem Akin, FTPF’s executive director, told Organic Authority, adding that the group extends a “standing offer” to Hilltop to provide fruit trees “for any of their nonprofit efforts in the future.”

While not as dire as the burnout in Rust Belt cities like Detroit or Buffalo, Pittsburgh still struggles. For one, Pittsburgh’s layout isn’t a grid (not even close), which can leave its local communities isolated and insular. That can present difficulties when it comes to change — like adding more community gardens, farmers markets, or conventional supermarkets. There can be issues with both community interest and the logistical side of implementation. Pittsburgh also has the largest percentage of communities with “low-supermarket access” in the U.S. for its size (250k – 500k). The Hilltop Urban Farm project is aiming to not only help the city in reshaping its identity and embrace a food-centered upgrade, but it may also serve to solve a very real problem for thousands of residents in these challenged communities, where access to fresh, healthy food isn’t abundant — particularly in the city’s Southside neighborhood where the farm will be located.

“You just have blight, just so much blight in Rust Belt cities,” Heather Manzo, a farm and food business educator for Penn State Extension, an applied research arm of the Pennsylvania State University, and co-author of a 2014 report on the farm project, told Reuters.

“So you see the longstanding residents of neighborhoods who are used to trying to find their place in the world looking at this blight and just say ‘We can do something different, we can do something better’.”

First ICA Maxi Store in Sweden, One of 84 Grocery Locations, Launches Sale of Onsite-Grown Produce

Freight Farms customer ICA Maxi Högskolan now offers customers leafy greens grown onsite just steps from in-store shelves

NEWS PROVIDED BY Freight Farms

April 10, 2019

BOSTON, April 10, 2019 /PRNewswire/ -- Freight Farms is pleased to announce the launch of ICA Maxi Högskolan's own line of produce grown onsite for shoppers. Located in Halmstad Sweden, Freight Farms customer ICA Maxi Högskolan is one of ICA Gruppen's 1,300 grocery stores in the country. This month, the store began harvesting a range of hydroponically-grown greens for shoppers from Freight Farms' flagship container farm, the Leafy Green Machine.

Freight Farms' Scandinavian distributor, FutuFarm, installs a Leafy Green Machine at ICA Maxi Högskolan in Halmstad.

ICA Maxi Högskolan employees, Max Rydberg and Douglas Klang, now grow produce onsite for customers in Freight Farms' Leafy Green Machine.

"We're excited to be the first ICA Maxi store to implement an onsite farm," said Rikard Hillarp, owner ICA Maxi Högskolan. "By growing crops just steps from our shelves, we're able to offer our customers what are truly the freshest greens possible."

Freight Farms' containerized farming technology allows ICA Maxi Högskolan to create and maintain the optimal growing conditions to harvest produce year-round using less than 5 gallons of water per day. Beyond the store's initial offering of butterhead lettuce, spinach, and herbs, the farm's integrated IoT data platform, farmhand, will also allow the store to grow non-native crops otherwise unavailable in the region, regardless of seasonal limitations in Sweden's Nordic climate.

"Freight Farms' technology is especially helpful in Sweden, where our short growing seasons can limit crop availability throughout the year and increase our reliance on imported produce," added Hillarp. "We're now able to shorten the distance food travels to get to our customers from 2,000 kilometers to just 30 meters."

By removing the miles between the food source and consumers, produce maintains nutrient density and stays fresh for far longer, significantly reducing food waste for both retailers and consumers.

On March 29, ICA Maxi Högskolan kicked off its launch with a Harvest Festival for customers, selling produce and offering free samples of the newly-harvested greens and a Q&A with store employees Max Rydberg and Douglas Klang, now the newest onsite farmers.

"Our team innovated the technology to empower individuals and businesses all over the world to decentralize the food system in meaningful ways specific to their local community or environment," said Freight Farms CEO Brad McNamara. "We're thrilled to work with industry leaders like Rikard Hillarp and retailers like ICA Maxi, who together have the forward-thinking vision and reach to disrupt the grocery industry internationally."

About Freight Farms

In 2012, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container—the Leafy Green Machine—with the mission of democratizing and decentralizing the local production of fresh, healthy food. Now with the Greenery and integral IoT data platform, farmhand®, Freight Farms has the largest network of connected farms in the world, with global customers ranging from small business farmers to corporate, hospitality, retail, education, and nonprofit sectors.

To learn more, please visit freightfarms.com, or visit us on Instagram, Twitter, or Facebook. For inquiries local to Scandinavia, please contact Freight Farms' official distributor, FutuFarm, for more information.

About ICA Gruppen, ICA Maxi

With a focus on food and health, ICA Gruppen is one of the Nordic region's main players in grocery retail, with 2,079 wholly-owned or retailer-owned stores and pharmacies. Its ethos is defined by three entrepreneurial values: drive, innovation and the desire to take on responsibility. ICA Gruppen believes it has a great responsibility—and great opportunity—to have a genuine impact on the value chain by conducting its operations in a climate-conscious manner. To ICA Gruppen, a commitment to community engagement and improvement in sustainability mean long-term success. ICA Maxi stores, individually owned by grocery industry entrepreneurs, are the largest food stores within ICA Gruppen, with 84 locations across Sweden.

SOURCE Freight Farms

Related Links

How Monsanto & Bayer Are Trying To Take Over The Cannabis Industry

Unfortunately, Bayer and Monsanto could create a monopoly on marijuana seeds in the same way we have seen them do with corn and soy. They have an incredible amount of corporate power and through enforcing international patent law, could end up with total control over the cannabis industry, including medicinal cannabis use and research.

Responsible for genetically modified organisms (GMOs) and the pesticides that are sprayed on them, Monsanto is on the tips of everyone’s tongues lately. Health conscious individuals are doing everything they can to boycott this company and support others instead, even if that means opting for much pricier organic produce.

There are a number of reasons for their concern, including the fact that no long-term studies have been done to show the potential health effects of consuming genetically modified foods or the high levels of pesticides that came with them. The mere fact that this company is responsible for some of the worst chemicals ever created, including Agent Orange, DDT, asbestos, and aspartame, also contributes to this widespread mistrust.

Last September, Bayer, the largest pharmaceutical company in the world, made a deal to buy out Monsanto for $66 billion, even though Monsanto was voted “the most evil company in the world” back in 2013. Unfortunately, this buyout only strengthened Monsanto’s lobbying power.

This corporate giant has now set its sights on another product, one that has garnered increasing attention lately as laws relax and medicinal uses become better understood: cannabis. Despite claiming otherwise, evidence suggests Monsanto may already have ties to cannabis production, a worrisome connection for anyone who uses cannabis medically or even enjoys an occasional puff.

How Is This Connection Made?

Monsanto and Miracle-Gro already have a business partnership. Hawthorne is a front for Miracle-Gro and has already purchased three of the largest cannabis producers in the business, Botanicare, Gavita, and General Hydroponics. A number of other companies have already received buy-out offers, but have refused.

According to a Hydroponics Lighting Representative, “They want to bypass hydroponics retail stores. . . . When we said we won’t get in bed with them they said, ‘Well, we could just buy your whole company like we did with Gavita and do whatever we want.’ ”

Miracle-Gro CEO Jim Hagedorn has gone so far as to announce his plans for reefer referendums. “Invest, like, half a billion in [taking over] the pot business,” he recommends. “It is the biggest thing I’ve ever seen in lawn and garden.”

One only has to connect the dots to see where this is heading, and it’s not surprising. The cannabis industry is on the brink of a major boom, and it makes sense that a huge corporation like Monsanto would like to get in on the action.

Now What?

Nothing has been decided at this moment, but we can see clearly that it is a possibility, and even if Monsanto/Bayer does take over the cannabis industry, it is not certain that they will create genetically modified strains. Even if they don’t, however, it is up to you to decide if this is a company you would like to support or not. If you actively choose non-GMO products, then you’ll certainly need to do your research to ensure the strains you are getting are not coming from a Monsanto-owned grow business.

Unfortunately, Bayer and Monsanto could create a monopoly on marijuana seeds in the same way we have seen them do with corn and soy. They have an incredible amount of corporate power and through enforcing international patent law, could end up with total control over the cannabis industry, including medicinal cannabis use and research.

Don’t Forget, As the Consumer, You Hold the Power

There will undoubtedly be some backlash against Monsanto — as if they haven’t gotten enough already — but it is absolutely necessary to call out this company for their ruthless business practices. DO NOT SUPPORT Monsanto or Bayer by buying any cannabis products coming from companies that they own. More information about Monsanto’s involvement in the cannabis industry, whether direct or indirect, will surely surface soon, and it is up to you to stay informed and make the appropriate decisions. A safe bet would be to grow your own and keep the seeds, if you are living in an area where this is legal. Spread this information far and wide; we cannot let Monsanto take over the cannabis industry.

Much Love

Lettuce Lads Aim To Transform Hydroponic Farming

The Lettuce Lads show off their demonstration version of a high-volume, high-density hydroponics growing system at the Canmore Greenhouse on Saturday (April 6).

Photo credit: Aryn Toombs / Rocky Mountain Outlook

BY ARYN TOOMBS | APR 11, 2019

CANMORE – Soon your Bow Valley burger will be topped with fresh locally grown butterhead lettuce courtesy of the Lettuce Lads.

Crisp and nutritious greens aside, customers will be tasting the results of a giant leap in hydroponic agriculture technology.

For the past year, the Lettuce Lads have been developing patented technology that promises growth rates in excess of 200 percent of traditional hydroponics and greenhouse techniques, while requiring significantly less electricity, water and labour.

“What we’re trying to prove here is that we can grow more for less,” said Lettuce Lads co-founder Caleb Allen.

Currently in the demonstration stage, leafy greens are grown in a multi-tiered belted system where optimal amounts of light and water are provided to the plants.

Allen and head engineer Kyle West brainstormed ideas centered around making hydroponic operations more profitable for growers.

“Most hydroponic operations aren’t profitable because they have very high utility costs, high labour costs and that results from a low density setup,” said Allen.

The density of plant growth is what sets the Lettuce Lads system apart from other shipping container and greenhouse systems.

Our system can grow 246 per cent more grams per square foot than our competition,” he said.

The Lettuce Lads also said they are able to get 518 per cent more grams per kilowatt hour of power used than other systems.

The end goal they say is that they can drive down the cost of production for growers, resulting in savings for consumers as well.

“You can already buy hydroponically grown lettuce right now at Save-on-Foods – it’s like $4.50, $5 a head – so we’re going to have that quality or higher, and we’re going to reduce the cost and make it more accessible across the country,” said Matt Howlett, head of marketing and communications for the Lettuce Lads.

Provincially the greenhouse industry has seen flat growth since 2015, with a peak of 188 business province wide in that year, decreasing to 174 in 2017 and rising to 186 at the end of 2018 according to Statistics Canada.

During the same period, the consumer price index commodity price of energy rose sharply to a peak in January 2018 of 164.3 before declining to

159.6 in December.

Energy costs have a direct impact on the profitability of greenhouses because of the size of the growing spaces and way that those environments are heated.

The Lettuce Lads system does away with what they call “competition with the environment,” reducing energy costs by creating a small dense environmentally controlled space.

“If they use our technology in their existing systems they’ll be able to grow more efficiently and be able to grow year round because we’re driving up the output while driving down the utility costs,” said Allen.

Reducing labour costs is also a result of the belted system that moves plants through the multi-tiered growing space to where the farmer is located, instead of the farmer having to go to the plant.

“Traditional hydroponics in shipping containers requires more labour,” said Howlett.

“A farmer with traditional hydroponics would have to go into the container, sometimes have to use a stepladder in order to reach something higher up. He’s going to have to take a tray off, sometimes a 10 to 20 foot tray of produce out and put it on a worktable in order to harvest it.”

The Lettuce Lads say their system does not require the use of worktables.

“The farmer can more or less do all of their work without having to move,” said Allen. “This is plug and play. You drop the plant in and you pull the plant out.”

The end result of lower production costs is equal access to good quality food without wastage.

The next stage of development for the system is a custom-designed sensor package and the use of artificial intelligence in tracking plant growth.

The lads have connected with a horticulturalist in the United States and engineers from NEDlabs in Edmonton to build a sensor system to track microclimates throughout the growth space.

“If you imagine a shipping container, the bottom left versus the top right on the other side is going to have different humidity, different temperatures and different issues, so we want to be able to avoid that and know its coming before it happens and make sure the farmers and producers are aware of these issues and are able to fix those issues,” said Howlett.

Knowing what is being grown also means that farmers can grow the right amount of product to meet market demand, without having to worry as much about product loss.

“We want in the long run to plug [the farmer]into our overall system of saying ‘hey, this grocery store needs this amount at this time, we know you’re going to hit this amount,’ ” he said.

“We know that we can help him or her sell that.”

Current container technology has space for approximately 1,800 growing spots, whereas the demonstration Lettuce Lads system has space for

.3,500 with the eventual goal of 5,000 within a 40 foot by 9 standard space.

The current setup at their temporary lease at the Canmore Greenhouse is just over 30 feet.

For now the focus is on the production of leafy greens, with the possibility of looking at multi harvest plants like peppers and tomatoes in the future.

“We started with a rex butterhead lettuce, which is a burger lettuce, because we knew that a lot of the restaurants and the grocers around here have high demand for it,” said Howlett.

“We’ve already got letters of intent from several of those folks,” he said.

The Lettuce Lads are inviting the public to their launch at the Canmore Greenhouse located at 60 Lincoln Park on April 23 from 5 pm to 9 pm.

A short presentation and discussion about the future of hydroponic growing in the Bow Valley will take place at 7:30.

Go to www.lettucelads.co for more information.

Salmonella Outbreak Linked To Caito Foods Fresh-Cut Melons

Federal health agencies are investigating a Salmonella Carrau outbreak involving 93 people, linked to fresh-cut cantaloupe, honeydew and watermelon from Caito Foods, Indianapoli

April 14, 2019

( Courtesy FDA. )

Federal health agencies are investigating a Salmonella Carrau outbreak involving 93 people, linked to fresh-cut cantaloupe, honeydew and watermelon from Caito Foods, Indianapolis.

The company recalled all fresh-cut melon products from the Indianapolis processing facility April 12 and temporarily suspended production while the company and Food and Drug Administration investigate, according to a recall notice from Caito.

Retailers that received the products include Kroger Co., Target, Walmart and Whole Foods. Caito Foods and SpartanNash, which are also listed, distribute to independent retailers, according to the recall notice.

The products have best by/use by dates of April 18, and the recall extends to consumers who might have fresh-cut melon products from Caito. The products include fresh-cut cantaloupe, honeydew and watermelon, and melon medleys and mixed fruit products. For a full list of products, brands, lot codes and Universal Product Codes, see the recall notice on the FDA’s recall website.

The products were packaged in clear, plastic clamshell containers and distributed in Illinois, Indiana, Iowa, Kansas, Kentucky, Michigan, Minnesota, Missouri, Nebraska, New York, North Carolina, Ohio, Pennsylvania, Tennessee, West Virginia, and Wisconsin, according to the recall notice.

The Centers for Disease Control and Prevention and the FDA notified Caito Foods of the outbreak, according to the notice.

The FDA traced the melon products to Caito through patient interviews, according to the FDA.

Salmonella Carrau is a rare type of salmonella, but has been historically seen in imported melons, according to the FDA, and Caito reported imported melons were used in the products. The FDA is examining shipping records to determine a source, according to an FDA news release that accompanied the recall notice.

The investigation includes collecting samples at the Indianapolis facility where the products were processed and packed.

2018 Caito recall

Caito Foods was named in a Salmonella Adelaide outbreak linked to fresh-cut cantaloupe, honeydew and watermelon in 2018. The company recalled hundred of similar products in that outbreak, which involved 70 people.

“Epidemiologic and preliminary traceback evidence indicated that pre-cut melon distributed by Caito Foods LLC was a likely source of this outbreak,” according to a CDC news release on the 2018 investigation.

For more information:

CDC

Tel: 404-639-3286

Email: media@cdc.gov

Related articles:

UPDATED: Caito recalls fresh-cut melons in salmonella outbreak

Melon recall expands, hundreds of retailers pull products

Salmonella outbreak linked to fresh-cut melons over

Related Topics: Salmonella Outbreak Honeydew Watermelons Cantaloupe FDA

Syngenta Adds New Director To The Board

April 15, 2019

BASEL, Switzerland--(BUSINESS WIRE)-- Following the Annual General Meeting of Shareholders on Friday, April 12, it was announced that Louise O. Fresco will join the Board of Directors as an Independent Non-Executive Director, effective April 12, 2019.

Fresco is currently President of Wageningen University & Research in The Netherlands. She combines a long academic career as a professor at both Wageningen and Amsterdam universities with extensive involvement in policy and development in Africa, Asia and Latin America.

“We are delighted to have Louise join the Syngenta Board,” said Frank Ning, Syngenta Chairman. “Her experience and expertise in sustainable healthy food production together with her ability to engage people in the benefits of science and agriculture will be greatly valued.”

This appointment comes just days after Syngenta announced it will accelerate its innovation to address the increasing challenges faced by farmers around the world including climate change, soil erosion and biodiversity loss, as well as changing consumer expectations and views on agricultural technology. Syngenta has made this commitment in response to listening sessions held at the end of 2018, during which there was a clear call for innovation and more action to address these challenges.

“Joining the Board will give me a chance to work towards more sustainable food production and reducing the environmental impact based on the latest scientific insights,” said Fresco. “I am particularly interested in how the best science can help smallholders increase yields sustainably.”

Fresco spent 10 years of her career as Assistant Director-General of the Food and Agriculture Organization of the UN. She is a member of eight scientific academies, and has served on the boards of Rabobank and Unilever. Her book “Hamburgers in Paradise, the stories behind the food we eat,” has been translated into 13 languages. She has published multiple books and writes a bi-weekly column in NRC, the leading evening newspaper of The Netherlands. She has also presented a 6-part documentary on food and development for Dutch public television, and in 2009 she was a speaker at the TED Conference in Palm Springs, California.

About Syngenta

Syngenta is one of the world’s leading agriculture companies. Our ambition is to help safely feed the world while taking care of the planet. We aim to improve the sustainability, quality and safety of agriculture with world class science and innovative crop solutions. Our technologies enable millions of farmers around the world to make better use of limited agricultural resources. With 28,000 people in more than 90 countries we are working to transform how crops are grown. Through partnerships, collaboration and The Good Growth Plan we are committed to improving farm productivity, rescuing land from degradation, enhancing biodiversity and revitalizing rural communities.

To learn more visit www.syngenta.com and www.goodgrowthplan.com.

Follow us on Twitter at www.twitter.com/Syngenta and www.twitter.com/SyngentaUS.

Cautionary Statement Regarding Forward-Looking Statements

This document contains forward-looking statements, which can be identified by terminology such as ‘expect’, ‘would’, ‘will’, ‘potential’, ‘plans’, ‘prospects’, ‘estimated’, ‘aiming’, ‘on track’ and similar expressions. Such statements may be subject to risks and uncertainties that could cause the actual results to differ materially from these statements. For Syngenta, such risks and uncertainties include risks relating to legal proceedings, regulatory approvals, new product development, increasing competition, customer credit risk, general economic and market conditions, compliance and remediation, intellectual property rights, implementation of organizational changes, impairment of intangible assets, consumer perceptions of genetically modified crops and organisms or crop protection chemicals, climatic variations, fluctuations in exchange rates and/or commodity prices, single source supply arrangements, political uncertainty, natural disasters, and breaches of data security or other disruptions of information technology. Syngenta assumes no obligation to update forward-looking statements to reflect actual results, changed assumptions or other factors.

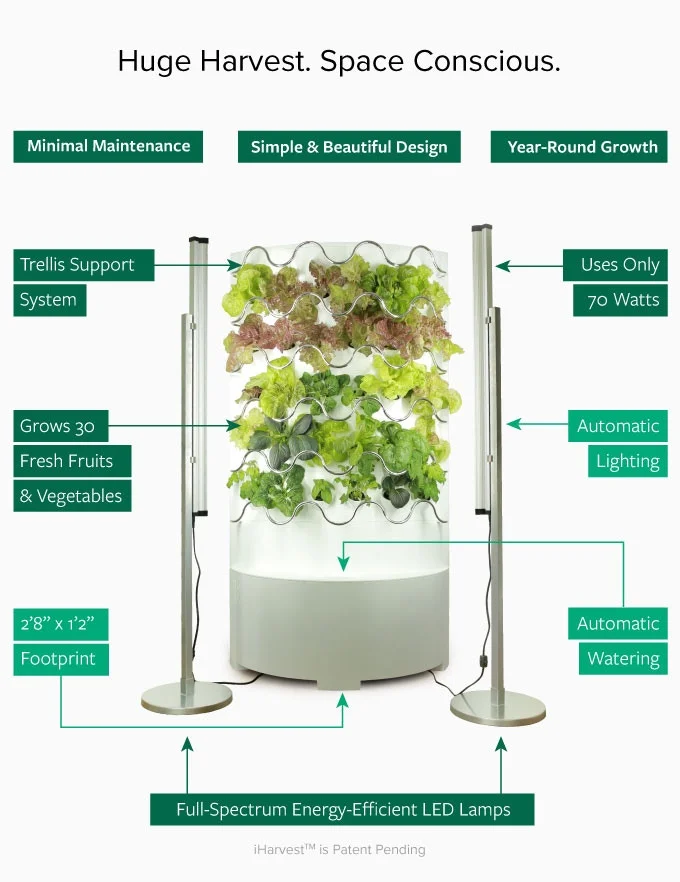

Indoor Garden Works’ (IGWorks™) iHarvest Kickstarter Introduces A Beautiful, Soilless Indoor Garden For Growing Big Fruits And Vegetables At Home

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening

April 14, 2019 | San Clemente, California

IGWorks™ announces the April 16th launch of their Kickstarter campaign for the patent pending iHarvest™: a beautiful hydroponic system that will reinvent vegetable gardening.

“All the existing systems were either too small to grow real food or too ugly to enjoy with your family and friends,” shared founder and CEO Dave Stevens. The solution was a hydroponic, automated and fully self-contained system that simultaneously grows up to 30 fruits and vegetables, all within 2.5 sq. feet of floor space.

The iHarvest™ makes it easy for the indoor home gardener to grow a wide variety of fruits and vegetables, including cucumbers, strawberries, beans and more, while saving up to $1,000 a year on groceries.

The Perfect Garden for Small Spaces

Smaller indoor and outdoor spaces, limited time, harsh seasons and unpredictable climates can make it increasingly challenging to grow healthy produce at home. “We knew that the answer lied in hydroponics; however, the existing systems were either unattractive, cumbersome, costly or challenging to use,“ said Stevens. “I wanted an attractive, indoor garden that could easily fit into the smallest apartment, while also providing enough produce to help feed a family year-round.”

Realizing that there was nothing on the market that met his needs, Stevens enlisted a team of individuals, including engineers and business advisors, to bring iHarvest™ and IGWorks™ to life. The result was an eye-catching self-contained growing wall that enhances spaces with a burst of greenery and light.

Experience how iHarvest™ will reinvent indoor gardening:

Faster Growing Time – Harvest your produce 30-50% faster than traditional vegetable gardens

Fresh, Healthy Produce –Grow your food precisely the way that you want it including zero pesticides, zero herbicides, and without GMO’s.

Automated LED Lights – High-efficiency, visually pleasing, full spectrum LED lights allow the user to predetermine when the sun rises and sets while using the same amount of energy (72W) of a standard lightbulb.

95% Less Water – Requires 20 X less water than traditional growing methods

Vertical Design – Fits in the smallest of spaces, while the included trellis easily accommodates hanging vegetation.

Easily Assembled - Simply add seeds to the medium, place into the pod, add water and grow.

Early Kickstarter supporters will receive the iHarvest™ for a substantially reduced price, $449 versus the projected retail price of $850, a 47% savings. “This innovative system will reinvent the way that consumers look at indoor gardening, making it easy to grow fresh produce in every home,” said Stevens. “By supporting iHarvest™ on Kickstarter, supporters can help bring the future of gardening to market.”

Visit the iHarvest™ pre-release Kickstarter page, learn more about what inspired the product, and see how iHarvest™ will transform the way that we look at indoor produce gardening.

CO2 GRO Provides A Summary of its Participation in The GFIA Global Forum Conference

TORONTO, ON – April 10, 2019 – Toronto based CO2 GRO Inc. (“GROW”) (TSX-V: GROW, OTCQB: BLONF, Frankfurt: 4021) attendance at the GFIA Global Ag Tech Conference April 1-2 in Abu Dhabi was successful and productive. GFIA stated there were over 7000 delegates from 122 countries this year. This Middle East based Conference is the largest global showcase of Sustainable Agriculture Innovation.

GROW’s objectives in attending the conference were two fold.

To meet with potential Middle East and EU Agri Industrial Partners/Distributors which resulted in the following;

Aaron Archibald, COO, CO2 GRO Inc. attended the GFIA conference on behalf of GROW. Aaron’s presentation on CO2 Foliar Spray was very well received. GROW had a well-attended trade booth at the conference.

GROW will take the next step with a major EU greenhouse manufacturer concerning how to work together.

To meet potential Middle East, EU and other international customers the result of which is below;

Aaron identified numerous quality revenue opportunities at the Conference. In addition, Aaron visited major indoor greenhouses that had expressed interest in the CO2 Foliar Spray technology, reviewing initial installation requirements and terms. Currently, none of these facilities can use CO2 gas due to excessive heat that has to be vented. This leaves CO2 Foliar Spray as the only logical value added CO2 gas service that can be integrated into existing spray racks.

Aaron Archibald, COO, commented “we were fully booked with one on one meetings with potential Ag customers and clients. A very clear message from the conference is the great importance the Emirates government is placing on food security and sustainability, areas where we believe GROW can make a significant contribution. The GFIA Global Ag Tech Conference was tailor made to showcase our CO2 Foliar Spray technology”.

About CO2 GRO Inc.

GROW's mission is to accelerate all indoor and outdoor value plant growth naturally, safely, and economically using its patent pending CO2 Foliar Spray technology. GROW’s global target retail plant markets are food at $8 trillion per year (Plunkett Mar 2017), non-food at an estimated $1.2 trillion per year with retail tobacco at $760 billion (BA Tobacco 2017), floriculture at $100 billion by 2022 (MarketResearch.Biz estimate). Legal cannabis at $52.5 billion per year by 2023 (Statista) and legal US hemp CBD at $22B per year by 2022 (the Brightfield Group).

GROW's CO2 technologies are commercially proven, scalable and easily adopted into existing irrigation systems.

The CO2 technologies work by transferring CO2 gas into water and foliar spraying water across the entire plant leaf surface which is a semi permeable membrane. The dissolved concentrated CO2 then penetrates a leaf's surface area naturally like nicotine dissolves through human skin from a soluble nicotine patch.

Foliar spraying of water, dissolved nutrients and chemicals on plant leaves has been used for over 60 years by millions of indoor and outdoor growers. To date, outdoor growers have not had any way to enhance plant CO2 gas uptake for faster growth.

Indoor CO2 gassing has enhanced plant yields for over 60 years but 60% of the CO2 gas used is typically lost from ventilation. Current greenhouse CO2 gassing levels of up to 1500 PPM are not ideal for worker health and safety. GROW’s safer infused CO2 Foliar Spray can be used by both indoor and outdoor plant growers with minimal dissolved CO2 gas lost and much greater CO2 plant bioavailability resulting in higher plant yields than both CO2 gassing and no gassing plant yields.

Forward-Looking Statements This news release may contain forward-looking statements that are based on CO2 GRO's expectations, estimates and projections regarding its business and the economic environment in which it operates. These statements are not guarantees of future performance and involve risks and uncertainties that are difficult to control or predict. Therefore, actual outcomes and results may differ materially from those expressed in these forward-looking statements and readers should not place undue reliance on such statements. Statements speak only as of the date on which they are made, and the Company undertakes no obligation to update them publicly to reflect new information or the occurrence of future events or circumstances, unless otherwise required to do so by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Machine Learning Is Making Pesto Even More Delicious

MELANIE GONICK

Intelligent Machines

Researchers at MIT have used AI to improve the flavor of basil. It’s part of a trend that is seeing artificial intelligence revolutionize farming.

by Will Knight

April 3, 2019

What makes basil so good? In some cases, it’s AI.

Machine learning has been used to create basil plants that are extra-delicious. While we sadly cannot report firsthand on the herb’s taste, the effort reflects a broader trend that involves using data science and machine learning to improve agriculture.

The researchers behind the AI-optimized basil used machine learning to determine the growing conditions that would maximize the concentration of the volatile compounds responsible for basil’s flavor. The study appears in the journal PLOS One today.

The basil was grown in hydroponic units within modified shipping containers in Middleton, Massachusetts. Temperature, light, humidity, and other environmental factors inside the containers could be controlled automatically. The researchers tested the taste of the plants by looking for certain compounds using gas chromatography and mass spectrometry. And they fed the resulting data into machine-learning algorithms developed at MIT and a company called Cognizant.

The research showed, counterintuitively, that exposing plants to light 24 hours a day generated the best taste. The research group plans to study how the technology might improve the disease-fighting capabilities of plants as well as how different flora may respond to the effects of climate change.

“We’re really interested in building networked tools that can take a plant's experience, its phenotype, the set of stresses it encounters, and its genetics, and digitize that to allow us to understand the plant-environment interaction,” said Caleb Harper, head of the MIT Media Lab’s OpenAg group, in a press release. His lab worked with colleagues from the University of Texas at Austin on the paper.

The idea of using machine learning to optimize plant yield and properties is rapidly taking off in agriculture. Last year, Wageningen University in the Netherlands organized an “Autonomous Greenhouse” contest, in which different teams competed to develop algorithms that increased the yield of cucumber plants while minimizing the resources required. They worked with greenhouses where a variety of factors are controlled by computer systems.

Similar technology is already being applied in some commercial farms, says Naveen Singla, who leads a data science team focused on crops at Bayer, a German multinational that acquired Monsanto last year. “Flavor is one of the areas where we are heavily using machine learning—to understand the flavor of different vegetables,” he says.

Singla adds that machine learning is a powerful tool for greenhouse growing, but less useful for open fields. “These controlled environments are where you can do a lot of optimizing by understanding the complex variables,” he says. “In the open environments it’s still a question how we can close the gap.”

Harper added that in the future his group will consider the genetic make-up of plants (something that Bayer feeds into its algorithms), and that they will look to release the technology to anyone. “Our goal is to design open-source technology at the intersection of data acquisition, sensing, and machine learning, and apply it to agricultural research in a way that hasn't been done before,” he said.

Learn from the humans leading the way in machine learning at EmTech Next.

Register Today!

June 11-12, 2019

Cambridge, MA

Register now

Will Knight Senior Editor, AI

Will Knight is MIT Technology Review’s Senior Editor for Artificial Intelligence. He covers the latest advances in AI and related fields, including machine learning, automated driving, and robotics. Will joined MIT Technology Review in 2008 from the UK science weekly New Scientist magazine.

Grow Light Global Market Estimated To Reach USD 5.80 Billion By 2022

The Grow Light Market is growing at the rapid pace; mainly due to the increasing government initiatives to adopt technologies. According to a recent study report published by the Market Research Future, Globally, the market for Grow Light is expected to gain prominence over the forecast period.

Business, Economy, Finances, Banking & Insurance

Press release from: Market Research Future

Global Grow Light Market, By Technology (LED, High Intensity Discharge, Fluorescent Lighting), By Installation (New Installation, Retrofit), By Application (Indoor Framing, Commercial Greenhouse, Vertical Framing) - Forecast 2022

Grow Light Global Market – Overview

The Grow Light Market is growing at the rapid pace; mainly due to the increasing government initiatives to adopt technologies. According to a recent study report published by the Market Research Future, Globally, the market for Grow Light is expected to gain prominence over the forecast period. The market is forecasted to witness a thriving growth by 2022, surpassing its previous growth records in terms of value with a striking CAGR during the anticipated period. Globally the Grow Light Market is expected to reach 5.80 Billion by 2022 at CAGR of more than ~13% from 2016 to 2022.

The key drivers contributing to the growth of the grow light market are growth in the indoor farming, government initiatives to adopt technologies such as LED, growing demand for energy efficiency, long lasting ‘Grow technology’ and environmentally safe products. Also, the demand for these products is increasing in countries such as Netherlands where supplemental lighting is required throughout the year.

However, low awareness among consumers, high cost of capital are the factors hindering the growth of the overall growth of the market. Whereas, high reliability, low power consumption, high commercial greenhouse practices are also propelling the growth of the grow light market.

Grow light is an electric light rather an artificial source of light which is designed to stimulate plant growth by emitting an electromagnetic spectrum for photosynthesis. Grow light is widely used in applications where natural light is not available or where supplemental light required. It is basically a type of electronic lamp designed to accelerate plant growth by electronic magnetic spectrum.

Plant factories support farming practices that are not dependent on the climate. Food factories produce organic vegetables. With the land available for farming depleting quickly, new types of farming are evolving.

Double Ended HPS lights are typically used in large commercial greenhouse or large indoor commercial gardening applications where high ceilings require more powerful lights to reach the plants. DE HPS lights are ideal for flowering and fruit production.

UV Light Bulbs are beneficial for plants. UV light activates a plant’s defence mechanisms. UV causes plants to produce oils, antioxidant vitamins and flavonoids to protect themselves from the damaging effects of UV. These compounds produce the vibrant colours, smells and tastes of your plants. If the light source does not produce UV, the colour, smell and taste of the produce gets changed effectively.

LED specialized grow lights. LED specialized grow lights offer homogenous light distribution. Light distribution at precisely the right wavelengths is made possible. LED light sources offer light distribution for good photosynthetic response. Vendors are able to stimulate plant growth. Flora series LEDs provide accelerated photosynthesis and energy savings.

Grow lamps are used in a wide variety of applications, including Home hobbyist, Agricultural universities, Educational programs, Plant physiological research, Biotechnology, Pharmacology, Greenhouses and Plant factories.

Grow Light Market - Competitive Analysis

Characterized by the presence of several major well-established players, the global Market of Grow Light appears to be highly competitive. Well established players incorporate acquisition, collaboration, partnership, expansion, and technology launch in order to gain competitive advantage in this market and to maintain their market position. Strategic partnerships between Key players support the growth and expansion plans of the key players during the forecast period. The Key players operating in the market compete based on product & technology launch, reputation and services. Well established players invest heavily in the R&D to develop products with the adept technologies that are completely on a different level compared to their competition, unrivalled design and features.

Key Players

• Osram LichtAG (Germany)

• General Electric Company (U.S.)

• Iwasaki Electric Co., Ltd. (Japan)

• LumiGrow, Inc. (U.S.)

• Gavita Holland B.V. (Netherlands)

• Hortilux Schreder B.V. (Netherlands)

• Sunlight Supply, Inc. (U.S.)

• Heliospectra AB (Sweden)

• Royal Philips (Netherlands)

• Platinum LED Lights LLC (U.S.)

The Global Grow Light Market is segmented in to 4 key dynamics for the convenience of the report and enhanced understanding;

Segmentation By Technology : Comprises LED, High Intensity Discharge, Fluorescent Lighting and other.

Segmentation By Installation : Comprises New Installation, Retrofit.

Segmentation By Application : Comprises Indoor Framing, Commercial Greenhouse, Vertical Framing, Landscaping and other.

Segmentation By Regions : Comprises Geographical regions - North America, Europe, APAC and

Rest of the World.

Out of these applications, vertical farming accounted for the largest market share because it allows the growing of more number of plants within a single enclosed structure, with the usage of artificial lightings and these can be produce fruits and vegetables throughout the year, within urban areas. Grow light is an electric light rather an artificial source of light which is designed to stimulate plant growth by emitting an electromagnetic spectrum for photosynthesis. Grow light is widely used in applications where natural light is not available or where supplemental light required. It is basically a type of electronic lamp designed to accelerate plant growth by electronic magnetic spectrum.

The key drivers contributing to the growth of the grow light market are growth in the indoor farming, government initiatives to adopt technologies such as LED, growing demand for energy efficiency, long lasting grow technology and environmentally safe products. Also, the demand for these products is increasing in countries such as Netherlands where supplemental lighting is required throughout the year.

Grow Light Global Market – Regional Analysis

Geographically, Europe accounted for the largest market share in the global grow light market, whereas Asia-Pacific is expected to grow significantly over the forecast period. Europe accounted for the largest market share, because Netherlands is a leading exporter of horticultural produce which increases the usage of commercial greenhouse. Also, the concept of vertical farming is gaining popularity in this region.

Asia-Pacific region is expected to grow significantly over the forecast period, majorly due to increasing awareness about the benefits of this technology.

Ontario's U-Bud "Solves Every Problem We've Seen Since Canada Legalized Cannabis"

Ontario Start-Up Solves Every Problem Dedia Has Reported On Since Oct 17th's (2018) Federal Cannabis Legalisation

Company poised to go national providing solutions to cannabis consumers, landlords and condo boards, patients, environmentalists, the budget conscious and others. Local big name media has covered this unique solution that will soon be available Canada wide.

WireService.ca Media Release (12/29/2018)

Hamilton, ON - Providing a unique solution for the many cannabis related problems the media has reported on since legalisation, one small Ontario company is predicting unlimited green - of both varieties - coming their way in the new year. Industry watchers are excited, too.

U-Bud Cannabis Services, a startup that begun in the basement in the small town of Canfield, Ontario - about forty minutes from Hamilton - is about to explode onto the national scene.

They only began operations ten weeks ago - on October 17th, the day the federal government legalised cannabis for adult use. The service is already available in several major cities across the country and is expected to go national by the end of 2019.

The company is the focus of recent stories by CTV News Kitchener, 570 News Radio Kitchener, and the local Metroland weekly newspaper to name just a few.

President & CEO David Kurth has a strong background in sales management working with some of Canada's biggest retailers and his wife, Andria, a nurse, is working as the company's Director of Client Services. Now working with Calgary based partner, COO Andy Buchanan, who brings with him three decades of experience in strategy, risk and operations management, U-Bud is able to present a unique solution to every cannabis problem. It is simple, and yet brilliant.

"We help people legally and safely grow their cannabis," explains Kurth. "We take care of it all. We do an extremely professional set up with all the right grow equipment that they can lease instead of a large initial equipment investment, walk our customers through every single step of growing, do regular follow ups and checkups with them, clients can even request that we come help them through key steps along the way - we literally take them from seed to curing - and then we take it all down, and take it away unless they want to grow again. We take all the learning and guesswork out of it, and we actually guarantee the grow. Our customer is left with typically eight to fourteen ounces of fine, clean, cannabis that they grew themselves."

With their self contained tent virtually eliminating smells that might bother neighbours and U-Bud's professional services removing any risks of fire, mould, and other oft expressed concerns, U-Bud Cannabis Services provide an attractive solution for landlords and condo boards navigating the new legal landscape, too.

Essentially, U-Bud Cannabis Services solves every problem you've heard of since legalisation.

Some of those problems, from different perspectives, that the media has reported on are as below.... U-Bud solves problems that have arisen for:

THE CANNABIS CONSUMER: With stories of long delivery delays, recalls that include mould and bugs in cannabis flower, a no return policy and other customer complaints, it's no secret that many Cannabis consumers in Ontario are dissatisfied with what, to date, is their only legal purchase option - the government run OCS (Ontario Cannabis Store) website.

THE ENVIRONMENTALIST: There are environmental issues, too - in fact, many who live by the mantra "reduce, reuse, recycle" say they can't in good conscience purchase what they call the heavily over-packaged product on offer.

THE BUDGET CONSCIOUS: Additionally, the high cost of cannabis offered for sale on the OCS site is a definite barrier to access for many. When asked to explain, one local said "When I go to a dispensary - or even a few years ago when I'd buy from my friend - they give me a better deal if I buy more."

THE PATIENT: A patient with a two gram a day prescription for serious neurological issues said, "My licensed producer site that I am supposed to use as a medical patient is priced like the OCS site - its the same gram by gram, no matter how much you buy. There's no way I can afford my prescription like that." (U-Bud's David Kurth can attest to that - at first he'd expected U-Bud would primarily be of interest to recreational cannabis consumers, but that he's been contacted by many people with prescriptions for cannabis, "because the price point is much lower.") His wife and business partner, Andria, who comes from a nursing background and works directly with most of the customers says her heart is with the medical patients who truly need an alternative. "It's really important for sick people especially to know how their cannabis was grown. When we help them grow it at home, they maintain control of their own medicine. They often tell me they find that therapeutic."

LANDLORDS AND CONDO BOARDS (AND THOSE WHO HAVE TO DEAL WITH THEM): U-Bud President David Kurth, in a recent interview with Metroland Media pointed out that people often associate cannabis grows with mould, water, and electrical issues that can damage buildings, "What we do is not causing any electrical or water harm or damage. It's all self-contained."

THE BUSY PROFESSIONAL: might be able to afford all the equipment but they can't afford the time to learn the many intricacies to grow their four plants well. With the limited plant count and their limited time, it's nice to have cannabis professionals come in, set it up, and keep an eye on the plants, with a guaranteed grow being the outcome.

Visit U-bud online at:

On Social Media:

https://www.instagram.com/u_budcannabis/

https://www.facebook.com/ubud2018/

Ontario based David and Andria Kurth and Calgary based Andy Buchanon of U-Bud Cannabis Services are all available to the media for interviews.

Media Contact:

Tracy Lamourie

Lamourie Public Relations

lamouriePR@gmail.com

289-788-5881

World’s Top Furniture Retailer Set To Begin Serving Home-Grown Salad

The world’s biggest furniture retailer is preparing to serve lettuce grown in high-tech containers outside its stores as part of efforts to improve its environmental profile

Ikea, which demonstrated one of the LED-powered containers at an event at a store in Kaarst, western Germany, expects to start serving home-grown salad to customers at its restaurants from pilot projects at two stores in Sweden next month.

Circular farming involves waste food being turned into nutrients that are used to grow new crops.(iStock/Representative Image )

April 04, 2019

Reuters | Kaarst

The world’s biggest furniture retailer is preparing to serve lettuce grown in high-tech containers outside its stores as part of efforts to improve its environmental profile.

Ikea, which demonstrated one of the LED-powered containers at an event at a store in Kaarst, western Germany, expects to start serving home-grown salad to customers at its restaurants from pilot projects at two stores in Sweden next month.

“The conditions are perfect for maximum taste and growth and you also have the sustainability advantage because you don’t have the transport,” said Catarina Englund, innovation manager for the Ingka Group, which owns most Ikea stores.

The containers, managed by circular farming firm Bonbio, have four shelves, carrying up to 3,600 plants in total, fed by nutrients extracted from organic waste, including leftovers from Ikea’s restaurants.

Circular farming involves waste food being turned into nutrients that are used to grow new crops.

The system, known as hydroponic farming, means the plants need no soil or pesticides, and use 90 percent less water and less than half of the area of conventional farming, with the LED lights to be powered by renewable energy, Ikea said.

One of the world’s biggest sellers of LED lights, the retail major also sells home hydroponic kits for hobby indoor gardeners. Englund said about 15-20 kg of salad can be harvested a day from each container and the fact that the lettuce will be grown on site means production can be precisely tailored to the demand of a store, reducing food waste.

Sales of Ikea food like hot dogs or Swedish meatballs account for about 5 percent of the group’s 35 billion euros ($39.34 billion) of turnover.

The World's Largest Rooftop Urban Farm Is Set To Open In Paris Next Year

A joint project between Viparis and its partners Agripolis,

Cultures en Ville and Le Perchoir

In 2015, Viparis launched an extensive renovation project at the Paris Expo Porte de Versailles exhibition complex. This decade-long initiative will raise the complex to the highest international standards and make it a model of sustainable development.