Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Is Vertical Farming The Post-COVID Future of Food Production?

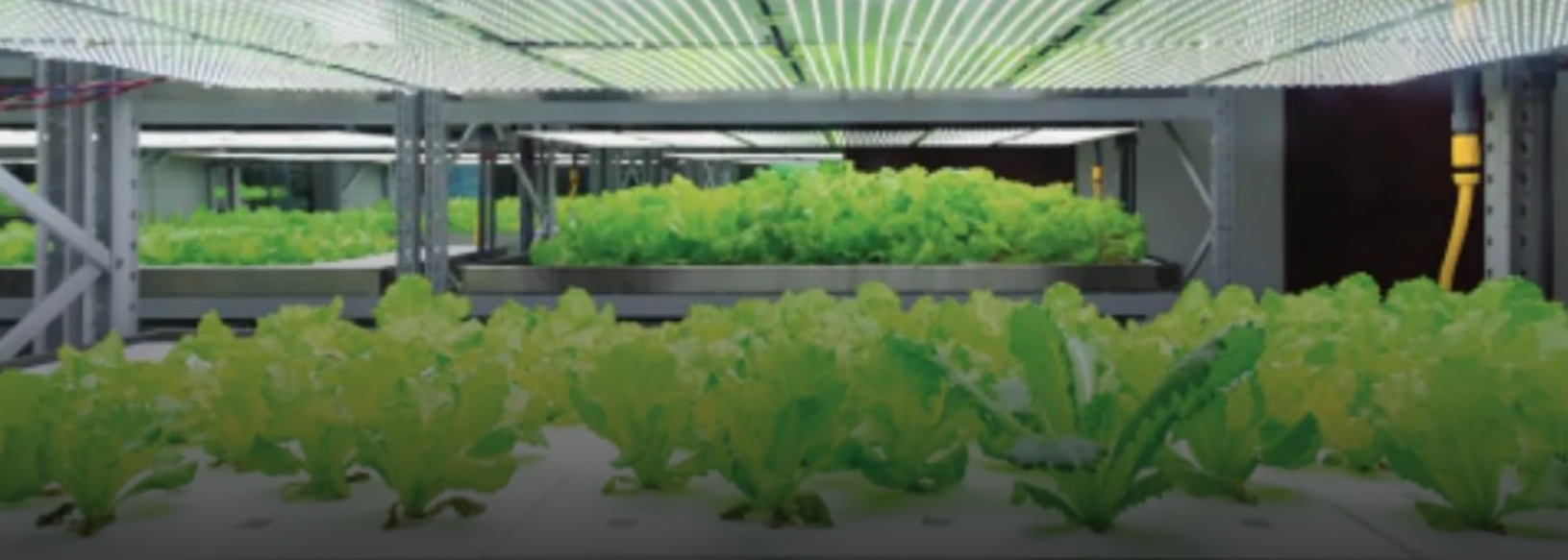

New Canadian agtech company Local Leaf Farms opens first vertical farming facility, producing fresh, safe andsustainable hyper-local produce. Barrie location is the first of 20 planned to open by the end of 2025

NEWS PROVIDED BY: Local Leaf Farms

Jun 22, 2020

New Canadian agtech company Local Leaf Farms opens first vertical farming facility, producing fresh, safe, and sustainable hyper-local produce. Barrie location is the first of 20 planned to open by the end of 2025.

BARRIE, ON, June 22, 2020,/CNW/ - New Canadian agtech company Local Leaf Farms officially opened its first vertical farming facility today, establishing itself as a company ready to transform Canada's food industry. Using vertical farming technology, Local Leaf produces hyper-local produce that's fresher, more sustainable, and fully traceable - directly addressing many of the challenges of food production highlighted by the COVID-19 pandemic.

Alongside the launch, Local Leaf also released the findings of a study conducted by IPSOS that confirmed the ways in which COVID-19 has impacted the way Canadians are making decisions about food: according to the survey, 68% of Canadians say the pandemic has made food safety more important to them and 47% say locally produced food is today their top purchase driver.

"Canadian consumers are demanding greater transparency about the food they eat. And that demand has never been more urgent," said Steve Jones, President, and CEO of Local Leaf Farms. "As we begin to consider a post-COVID reality, we need to have real discussions about the stability - and overall future - of food production in this country. Local Leaf is bringing leading-edge technology to the food sector to produce the fresh, safe, and sustainable produce that Canadians are asking for."

Today, the average package of leafy greens in Canadian grocery stores travels 3,000 km before it lands in a shopper's cart. This journey can take up to two weeks and can cause produce to lose up to 70% of its nutritional value - not to mention the impact on its taste, texture, and flavour. Local Leaf Farms' technology allows the company to reimagine the journey food takes from the farm to the store. All Local Leaf Farms produce can be at local grocery stores just hours after it was harvested, not only because of proximity but because, unlike any other produce sold in Canada, it can be 'drop shipped': delivered directly, without the need to pass through distribution centres, maximizing freshness and shelf life.

Local Leaf also offers a fully traceable food source, with instant access to information about the food from seed to shelf. The company's proprietary technology and mobile app allow retailers and consumers to know exactly where their produce comes from, including detailed information on how it was grown, when and by whom. The farm, which includes an 20,000 square foot community garden, is even open to the public once a month, allowing people to see and connect with their food.

Of particular importance in our current reality, vertical farms like Local Leaf eliminate the need to rely on migrant labour - a workforce that has faced a severe threat in the face of COVID-19.

A growing number of Canadian investors and stakeholders are recognizing the need for Canada to rebuild its capacity to produce goods through stronger innovation - and are looking to the vertical farming industry as a viable solution. Federal Minister of Innovation, Science and Industry, Navdeep Bains, is a vocal supporter of Local Leaf Farms' mission.

"It is vitally important that all Canadians have access to healthy, sustainable food," said Minister Bains. "Local Leaf Farms is taking an innovative approach to this challenge by using the latest in agricultural and digital supply chain technologies, and data-driven decision making, to produce a reliable domestic supply of nutritious food, with a smaller environmental footprint."

The IPSOS research also identified the following key insights about changing consumer perceptions:

Nearly all Canadians (96%) prefer to buy produce grown in Canada, whether in their local community (21%), their province (41%), or elsewhere in the country (34%).

There is a widespread belief (68%) that eliminating plastic from food packaging is important, and a stated preference (51%) for non-plastic, compostable, plant-based material. By contrast, just 21% would prefer produce to come packaged in recycled plastic, sometimes referred to as recycled PET.

Food safety matters: 88% of Canadians consider food safety important to their purchase decision when buying leafy greens and produce.

The top food safety concerts are hygiene-based: almost 1 in 2 Canadians are concerned about product handling safety standards and 1 in 4 called out the cleanliness of the growing environment.

Local Leaf's Barrie location services grocery stores, food service providers, and home meal kit providers within 50km of the farm. All of the produce, which is sold under the My Local Leaf brand, is pesticide- and herbicide-free, non-GMO and packaged in 100% plastic-free compostable packaging. The company is on track to open its next location in Kingston in the coming months - and has a scale goal to launch 20 locations across the country by the end of 2025.

For more information about Local Leaf Farms, visit localleaffarms.com.

SOURCE Local Leaf Farms

For further information: Julie Pieterse, Craft Public Relations, 647-282-6118 | julie@craftpublicrelations.com

The Origins of Hydroponics

If one of you went to your grandfather and told him that people are growing plants and crops solely using water and have eliminated the soil use, he would've probably sighed and thought "Is this why we spend money on this nalayak's education?

Adhyayan Panwar | 22 Jun 2020

If one of you went to your grandfather and told him that people are growing plants and crops solely using water and have eliminated the soil use, he would've probably sighed and thought "Is this why we spend money on this nalayak's education?".

However, this is actually a practice. Plants can be and have been grown (for a while now) using almost no soil and “hydroponics” is the name given to this practice. Plants' roots are submerged in a water-based liquid, with extra nutrients and minerals added which are essential for the growth of the plants. In some cases, a medium is used so that the roots can hold the plants' weight and keep them upright. This medium is porous so that it can hold moisture and oxygen that the plants will require. The most popular media are clay, coir, brick shards, etc.

The solution contains all important nutrients present in appropriate proportions which ensure optimal growth. The main constituents are Nitrogen (N), Potassium (K), Calcium (Ca), Magnesium (Mg), etc. These are just some of the sixteen elements that are required by plants. Growing systems that don't use a medium are called liquid hydroponic systems which includes NFT (nutrient film technique, in which plants are put in slits in a tube through which nutrient solution is pumped), floating hydroponics, etc. When a medium is used, it's called aggregate hydroponics system which is further divided into open and closed systems. Rockwool is the most widely used medium in open system hydroponics.

Hydroponics is not, by any means, a new technology. Let's trace this practice right back to its origins.

THE ORIGINS:

The origins of hydroponics can be traced back to the ancient city of Babylon, where present-day Iraq is located. The Hanging Gardens of Babylon, one of the Seven Wonders of the Ancient World, is the first known example of soil-less growth of plants. This was around 600 BC. Later on, around 1100 BC, the Aztec Indians got creative with their growing techniques and created gardens that seemed to be floating. These “floating gardens” were called 'chinampas', which had a strong combination of roots and lashes, laden with sediment from lake-bottoms, providing nutrients to the crops and plantations.

Similar floating plantations were discovered by Marco Polo on his visit to China, which left him bewildered as he hadn't seen anything like this ever before. The first scientific perspective towards this soil-less technique is attributed to the Italian genius, Leonardo da Vinci, who observed that plants and crops needed to absorb minerals to survive. His findings were published after his death, that implied his famous branching rule: "all the branches of a tree at every stage of its height when put together are equal in thickness to the trunk".

THE JOURNEY:

In 1627, Sylva Sylvarum was published. Written by Francis Bacon, Sylva Sylvarum contained the earliest work on growing terrestrial plants with soil-less techniques. Major discoveries were made in the 17th century. Jean Baptista van Helmont, a Belgian chemist, discovered and proved that plants obtain the necessary minerals and nutrients (he called them "substances") from water. He performed the willow tree experiment, where the tree gained 164 pounds or 74.4 kg but the soil amount remained the same throughout the experiment. John Woodward performed the spear-mint experiment, which showed that plants grow better in impure water than to distilled water. The first standardized nutrient solution was created in the 18th century by Julius von Schaps and Wilhelm Knop which laid the foundations of hydroponics as we know it today. This solution made it possible to grow roots without any medium. Knop went on to create yet another solution, which is still in use today.

The word “hydroponic” was first used in 1937, coined by Dr. William Frederick Gericke, aptly known as the “father of hydroponics” (he made news when he was able to grow tomato vines more than 7-meters long just using mineral-nutrients solutions, right in his backyard!). The word is a combination of the Greek words “hydro” (meaning water) and “ponos” ( meaning labour). This means water-work, literally. After leaving his University position, Gericke wrote and published ‘Complete Guide to Soil-less Gardening’ in 1940. Then came into the picture Dennis R. Hoagland, who created a nutrient formula that provided the plants with all the nutrients essential for growth and catered to a large diversity of plant species. The Hoagland solution still serves as the basis for most of the nutrient solutions that are being utilised even today. Alongside Daniel I. Aaron, Hoagland published ‘The Water Culture Method for Growing Plants without Soil’, which is considered the most important text in hydroponics culture. There are accounts of the US Army using hydroponics to grow fresh food for the troops stationed in the infertile Pacific Islands, during World War II.

As the hydroponics technology picked up the attention across the world and the usage grew, it’s inevitable commercialisation took place. Lawrence Brooks founded ‘General Hydroponics’ in 1976. Now, even after 40 years, GH remains one of the leaders of continuously expanding the market of hydroponic mineral-nutrient solutions. In 1982, a new area called ‘The Land Pavilion’ was opened in Disneyworld’s EPCOT Center, where a ride goes through “gardens of tomorrow”, which are grown using hydroponic technology.

When you think about hydroponics, aside from the typical applications of the practice, you may also think about its applications in space and space travel. NASA is actually quite heavily invested in the practice of hydroponics. A research department completely dedicated to hydroponics and bio-farming was developed by NASA where they researched the growing of plants in extreme environments and hydroponic technology was a big player in the research.

THE PRESENT:

There’s no other way to put it, hydroponics is thriving. As per a recent Hydroponics Market Research Report, it is projected that the hydroponics market will be worth $27.29 billion by the year 2022. Currently, almost 90 percent of lettuce and tomatoes that are being grown in the US and Canada are being grown using hydroponics. As the population of the world keeps growing, hydroponics becomes a more viable substitute for traditional farming. Hydroponically grown crops take only 25 percent of the area used by traditional soil growing, for the same amount of crops. We all know the harrowing threat of water scarcity in the coming years. With hydroponics, water usage can be cut down by 90 percent. This is just another reason why hydroponics is booming. Zero pesticides and herbicide involvement, growth rate twice as fast as traditional agriculture, nutrient solutions with perfect pH eliminating soil worries, and the list is never-ending, which is why hydroponics is need for the present.

Countries have already started dedicating acres of lands for commercial hydroponics, including 10,000 acres in Holland, Israel reserving 30,000 acres, Australia and New Zealand having 8,00 acres between them and Canada with hundreds of acres of land for large-scale commercial greenhouses, mainly growing tomatoes, peppers, and cucumber. In India, hydroponics is still a pretty new technology but initiatives are being taken. Many startups have taken it upon them to make hydroponics more popular, affordable and accessible. These startups use new technologies like IoT (Internet of Things), data analysis, etc to perfect the procedure and make it as efficient as possible.

THE UNKNOWN:

While we don’t know what the future holds exactly, we can make a couple of calculated predictions as a society. Statistics and reports already indicate that hydroponics will have a special place in the coming years. As the concept of space travel and exploration becomes closer to reality with each passing day, hydroponics will find a place in long flights across space, where agriculture is restricted due to area and soil-weight limits. Similarly, when Mars colonisation does become a reality (Elon, we are looking at you) we won’t have to suffer the infertile and barren lands of unexplored planets since hydroponics will allow basic levels of agriculture, which is said to be the foundational step of every human civilization. Several companies across the globe have also begun providing ways to grow vegetables at home as well. As technological advances are being made, it won’t be surprising to see people growing their own assortments of vegetables in their own houses. There are already plenty of homes today that have home hydroponic installations.

With the drastic need for more and more land for the ever increasing urban sprawl, which reduces the land available for agriculture, hydroponics will eventually creep into our daily lives and get infused with our culture. Startups, commercial giants and space agencies have already begun traversing into this field. So, don't be surprised, when in the coming years every edible thing you see has hydroponic origins and your neighbor in a high-rise skyscraper is a successful farmer.

Adhyayan Pan

Indoor Agtech Virtual Innovation Summit July 23, 2020

By sharing best practice from around the globe, and facilitating new connections and collaborations, the summit offers an invaluable platform to develop new business and accelerate projects across the Indoor AgTech ecosystem

We Are Proud To Be A Marketing Partner

Save 10% With Discount Code iGROW10

Major names join speaker line-up for virtual summit

We are thrilled to announce the first speakers confirmed for the 2020 virtual Indoor AgTech Innovation Summit on July 23.

They'll share critical intelligence on how the indoor farming industry is shaping the agri-food landscape, and redesigning food systems to meet consumer demand for fresh produce.

VIEW SPEAKER LINE-UP

Hear from and connect with international thought leaders including:

WHAT ARE OUR EXPERTS SAYING?

"Instead of shutting down, we implemented South Korean-style measures for our warehouse, farm, and office. Then, we launched a new nationally distributed product that allows folks to grow mushrooms at home rather than travel to the grocery store."

Andrew Carter, CEO, SMALLHOLD

"COVID-19 has raised awareness about the prospects for automation such as machines working in packing houses and indoor environments. I think it’s fair to say that humans can be relieved of those tasks."

Elyse Lipman, Director of Strategy, LIPMAN FAMILY FARMS

"Given current pressures on the U.S. food system, one thing is clear: the importance of strengthening our country’s food supply chain through decentralized, regional supply chains."

Viraj Puri, CEO and Co-Founder, GOTHAM GREENS

READ MORE INSIGHTS FROM OUR SPEAKERS>>

Secure your place at Indoor AgTech and save 10% with discount code iGROW10

and connect with the world’s leading farm operators, food retailers, and investors for a jam-packed day full of 1-1 video meetings, live panel sessions, and interactive roundtable discussion groups.

BOOK NOW WITH CODE iGROW10

We look forward to welcoming you online.

Best wishes,

Oscar Brennecke

Conference Producer

Indoor AgTech Innovation Summit

+44 (0)1273 789 989

oscar.brennecke@rethinkevents.com

THANKS TO OUR PARTNERS

Platinum Partner:

Marketing and Media Partners:

Shipping Container Farms Come to London as Growers Ditch Soil

In the era of climate change and Brexit, British farming is facing unprecedented challenges. How to supply environmentally friendly, locally sourced, and competitively priced food?

Vegetables Are Grown Vertically Supplied With Nutrient-Rich Water

20 June 2020

Racks of vegetables grown in a shipping container in London CREDIT: Fiona Hanson

In the era of climate change and Brexit, British farming is facing unprecedented challenges. How to supply environmentally friendly, locally sourced, and competitively priced food?

One part of the answer could lie in a shipping container in an east London car park, just moment’s away from the capital’s business district. Inside are racks of leafy green vegetables, grown vertically using hydroponic technology. Instead of being planted in soil, the vegetables are plugged into a system of nutrient-rich water and kept at the optimal temperature, under specially designed lighting.

The result is flavorsome lettuces, kale, basil, and other leaves, free of pesticides and using up to 95 percent less water than traditional agriculture over a fraction of the space. The shipping containers, which are custom made, mean the produce can be located virtually on the doorstep of its market, effectively eliminating food miles.“

Traditional organic farming is not sustainable if we're going to feed a population,” says Sebastian Sainsbury, the founder of Crate to Plate, which has just had its first harvest.

Not only does Crate to Plate use otherwise wasted space - these three shipping containers can grow the equivalent of an acre’s soil - but the proximity to customers keeps the produce fresh.“ When you harvest the lettuce from the soil, within 48 hours, you've lost 40 percent of the nutritional value. And it goes down every day,”

Indoor farming has boomed in recent years, particularly in the US, where Mr. Sainsbury lived until recently and where he developed his business.

But the UK is yet to fully capitalize on its opportunities, says Dr. Robert Hancock of the James Hutton Institute, which is supporting pioneering vertical farming techniques from its facility in Dundee.“

Even with current technologies and current efficiencies, there's probably a lot more that can be done. And I think that indoor farming can interface a lot more with the broader agricultural picture,” he said.

Lead Farmer of Crate to Plate, a hydroponic vertical farm producing leafy greens and herbs.

CREDIT: Fiona Hanson

Environment Secretary George Eustice this week said vertical farming would have a vital role to play in helping British farming meet the challenges of climate change and post-Brexit food security.

“There are a lot of pressures on land use,” he told the parliamentary environment committee, highlighting “the tricky issue” of repairing biodiversity and soil health in our intensely farmed landscapes.

Mr. Hancock highlighted the UK’s strawberry industry, which relies on imports of propagated plants from the Netherlands, as one example of where indoor farming could boost British production. Britain produces just 7 percent of its fruit and 53 percent of its vegetables. But ultimately, he says, vertical farming can only ever be part of the answer and will likely be limited to salads, berries, and niche crops.

“The replacement for calorie crops I don't think is ever going to happen,” he said.

Crate to Plate is the latest of several hydroponic farming ventures started by those outside of traditional agriculture (Mr. Sainsbury is an ex-banker), many of which haven’t translated to long-term success. The key to seeing vertical farming at scale will be getting more existing farmers on board, says Mr. Hancock.“

They understand the economics of growing.

And they also understand the routes to market,” he said.

The government is hoping that the end of the EU's Common Agricultural Policy could be a chance for new blood to enter the agricultural industry, and will offer older farmers a “golden handshake” if they retire early.

Mr. Sainsbury employs three recent agricultural graduates and says the younger generation are eager to explore new technologies. He has also had interest from farmers keen to locate his shipping containers on their land.

So far, Crate to Plate’s economies of scale and niche produce puts them out of reach of the average supermarket shopper (think £10+ salads marketed to City workers). But they have hopes of moving into residential areas, amid a growing trend for urban farming. The dream, says Mr. Sainsbury, would be a vegetable farm in every urban neighborhood, manned by a dedicated farmer and producing fresh produce for everyone to buy.“

The aim is to make it as local as possible,” he said.

JPFA Webinar June 30 - The Challenges And Impact of COVID-19

The Japan Plant Factory Association (JPFA) is organizing its 138th online workshop. The workshop is free of charge

Japan Plant Factory Association / JPFA

Japan Plant Factory Association (JPFA) is a non-profit organization founded in 2010 and is devoted to academic and business advancements in the global industry of plant factory/controlled environment agriculture. Our mission is to develop and disseminate sustainable systems that can address global challenges: food, environment, energy, resource and people's health. With international industry-academia collaborations, we manage around 20 R&D projects, workshops, training courses, etc. based in a Chiba University campus in Kashiwanoha, a smart city in Japan.

Monthly workshops are one of our important education/knowledge sharing activities with JPFA members and others. We have been organizing workshops since 2010 on a wide variety of topics, including plant physiology, new technologies towards next generation, cultivation methodology on multiple crops, business case studies of commercial plant factory operations, to name just a few.

The Japan Plant Factory Association (JPFA) is organizing its 138th online workshop. The workshop is free of charge.

Some sessions include the presentation of 80 Acres Farms on tomato production in indoor farms, a survey report on the impact of COVID-19 by JPFA and a lively panel discussion with leading plant factory companies from Japan and China. Such as, 808 Factory, Greenland, Saladbowl, and Future Agro-Tech, all together with researchers on plant factory and indoor breeding from JPFA and Chiba University.

Date

Scheduled to be released on June 30, 2020.

Free viewing will be available from 13:00 (JST) on June 30 to 13:00 (JST) July 15, 2020.

Theme

As the coronavirus disease (COVID-19) creates challenges worldwide, we feel concerted effort is crucial to our sector more than ever before.

The global challenges/impacts of COVID-19 in the sector, the future role, possibilities and direction of plant factory will be discussed to rethink about what we can do together for our future.

Outline

I. Keynote: “beyond leafy greens: tomato crop production in indoor farms” by Mike Zelkind, 80 Acres Farms + Q & A Session

II. “Report on COVID-19 survey by JPFA” Eri Hayashi (JPFA)

III. Panel discussion: “the challenges and impact of COVID-19, future role and direction of Plant Factory”

*Please kindly note that some contents might be only in Japanese.

Panelists:

Bai Baosuo (Future Agro-Tech (Beijing)

Katashi Kai (Shinnippou, 808 Factory)

Susumu Tanaka (Saladbowl)

Toyoki Kozai (JPFA)

Toru Maruo (Chiba University)

Yuhei Shimada (greenLand)

Moderator: Eri Hayashi (JPFA)

Fee Free of charge

How to watch

Advanced registration is required.

Registration deadline: 13:00 (JST) on July 14, 2020

Please register at https://select-type.com/e/?id=n2duYvX-Gas

After the registration, you will receive the link with access to the workshop videos a day before the release. Please apply one by one. If you cannot access the registration website, please send us the email with your "name", "organization", "country" and "questions to the webinar speaker/panelists (optional)" to info.english@npoplantfactory.org

For more information on the workshop:

JPFA Workshop website

https://select-type.com/s/JPFA-Training

https://npoplantfactory.org/information/1499/

If you have not joined the survey yet, please take the survey, Urgent Survey on the Impact of COVID-19 (Vol.1) before the workshop/online viewing starts.

For more information:

Japan Plant Factory Association (JPFA) International Relations & Consulting

Nozomi Hiramatsu, Eri Hayashi

info.english@npoplantfactory.org

Farm Fresh Produce - Fresh Is Better

In 2010, we planted the seed of a new idea. When Steven Ceccarelli started this company, his goal was to take a fresh approach to growing and packing produce. Today, Farm Fresh has grown into one of the most innovative and reliable produce distribution operations around.

Fresher is better - Fresh produce, of course. But also fresh ideas. New ways of thinking about the age-old business of getting great tasting sweet potatoes and blueberries and napa cabbage and more - from field to table. Not throwing out the past for the safe of shiny new objects, but taking a clear-eyed look at what works, what we can improve, and where there are opportunities for smart, strategic growth.

The Difference

What makes Farm Fresh Outstanding in the field?

We get it. Because we grow it.

In addition to working with a reliable team of experienced growers, we own and operate our own sweet potato farm. Not only does this mean we know first-hand the challenges our partners face — it also means we have greater control over supply.

We give you fresh thinking. Every step of the way.

We’re a grower. We’re a packer. We’re a distributor. We’ve been across the country and around the world. We understand every link in the chain — and we make sure each and every one is strong enough to keep you supplied with everything you need, week in and week out, whatever the weather, wherever you are.

You buy it, you name it.

You’ve spent time and money building your brand, so it only makes sense to show it off every chance you get. We’ll work with you to create completely customized packaging for your shipments, so it’s your private label that customers see when the produce arrives.

We’re sustainable for the long haul.

The entire Farm Fresh operation is designed to work toward an optimized carbon footprint, which in practice means:

• Using natural pesticides and conserving water in the fields

• Installing a rain water collection system at our warehouse

• Exploring ways to incorporate recycled materials and generate solar power in our buildings

• Developing smart packaging solutions that maximize truck-packing efficiency

• Deploying advanced logistics and near-siting to minimize road-based emissions

We mind the GAP.

We proudly follow the standards of GLOBALG.A.P., a key reference in the worldwide push towards best practices in the produce industry, now covering more than 100 countries.

We’ve got nothing to hide.

Around here, one day of really hard work is just like any other; we don’t need time to clean up or hide things under the rug when company comes. So if you want to see what we’re all about, drop by anytime.

Fresh produce, fresh ideas, fresh opportunities — let’s find out what we can do to help each other grow.

Toll-Free: 1-800-606-9267 (YAMS)

Fax: 1-800-807-9267 (YAMS)

Local N.C. Phone: 910-920-9871

Local Quebec, Canada: (514) 461-0836

Local Mississippi Phone: (662) 796-1977

Cell Phone: (910) 508-8933

Pricey Greens From Indoor Farms Are Thriving In The Covid Era

By Saturday, March 14, even before Mayor Bill de Blasio announced the shutdown of all in-restaurant dining in New York City the next night, Viraj Puri, chief executive officer of the Brooklyn, N.Y.-based indoor urban farming company Gotham Greens

Deena Shanker Bookmark

Published: June 19, 2020, 4:30 PM

Updated: June 20, 2020, 6:35 PM

(Bloomberg Businessweek)

By Saturday, March 14, even before Mayor Bill de Blasio announced the shutdown of all in-restaurant dining in New York City the next night, Viraj Puri, chief executive officer of the Brooklyn, N.Y.-based indoor urban farming company Gotham Greens

Read more at https://www.bloombergquint.com/businessweek/novel-farming-sees-massive-jump-in-demand-amid-coronavirus

Copyright © BloombergQuint

Horticultural Team Sheds Light on Growing Sea Beans in Shipping Containers

Trident Technical College horticulture students Lindsey Clarke and Clara Wooters work at an unusual farm located inside 40-foot-long shipping containers

By Tony Bertauski

June 20, 2020

Sea beans grown in a hydroponic system which feeds the plants a layer of nutrient solution on a timed schedule. Lindsey Clarke/Provided

Trident Technical College horticulture students Lindsey Clarke and Clara Wooters work at an unusual farm located inside 40-foot-long shipping containers.

For more about Heron Farms, visit www.heronfarms.com.

Sam Norton is the founder of Heron Farms. He did his graduate research on halophytes, which includes sea beans, also known as sea pickle. He’s not your typical farmer. He wears a white lab coat and nitrile gloves. He’s more of a farming scientist and, like many good scientists, affectionately refers to the crop by its genus rather than common name, Salicornia.

Sea beans are succulent halophytes that don’t produce beans or pickles. The foliage is edible and salty. Succulents are plants that store water in their leaves. Halophytes tolerate saline conditions. And as halophytes go, sea beans are among the saltiest.

Sea beans grow in hypersaline soils that are uninhabitable for most plants. They are the first plant into a barren salty flat. As it pulls salt from the soil, it transforms the ground into a habitable region for other plants and, over time, sea beans are crowded out. As a crop, this makes it difficult to farm outdoors.

The halophytes pull salt from the soil, which transforms the ground into a habitable region for other plants. Lindsey Clarke/Provided

A shipping container can grow 4,800 plants. While sea beans are their main crop, they are growing four new halophytes and plan to grow as many as 35. They use a hydroponic system called nutrient film technique that only uses 20 gallons of water a week. Plugs of sea beans grow in plastic channels, or gutters, three inches apart. A thin layer of nutrient solution cycles through the channels on a timed schedule.

The foliage tips are harvested three times from seed to the final cut in 60 days. These are the fleshy parts that can be cooked or eaten raw. The stems are woody and don’t have much of a culinary use, but breweries have used them in gose-style beer for a salty flavor.

With a proficient research background, Sam is maximizing production within the confines of a shipping container. He and his team follow every plant, from seed to harvest, and study the effects of light, nutrients, spacing, and other environmental factors.

Sunway Goes Into Agritech

Sunway Group is venturing into agricultural technology (agritech) to help reduce Malaysia’s food import bill and encourage and reduce the carbon footprint on the food consumed in the country

By Jennifer Jacobs | The Edge Markets | June 5, 2020

Sunway Chief Innovation Officer and Sunway iLabs Director, Matt van Leeuwen

Sunway Group is venturing into agricultural technology (agritech) to help reduce Malaysia’s food import bill and encourage and reduce the carbon footprint on the food consumed in the country.

It is building a 50,000 sq ft urban farming innovation hub, Sunway FutureX, to help urban farming professionals, tech companies, researchers and young talents collaborate and create solutions for food and agritech. The hub should be completed by the third quarter of this year.

Sunway FutureX, an initiative led by Sunway Innovation Labs (Sunway iLabs), will be located in the heart of Sunway City Kuala Lumpur and it will feature FutureX Farm, an indoor and outdoor smart farming area, FutureX Talent, a research and development centre, and FutureX Campus, a training and collaborative space.

“Bringing together a wide pool of expertise and resources from ecosystem players, Sunway FutureX will aim to create decentralised urban farms to serve local communities, and to address supply chain challenges and the distance between the farm and the fork.

“We hope to build new innovations, which will contribute to improved long-term food security and sustainability in our nation,” says Matt Van Leeuwen, the Sunway Group chief innovation officer and Sunway iLabs director, in a press release.

It is looking to create an agritech ecosystem and one of its first partners will be Sunway Property. “We aim to nourish our communities with the fresh produce grown at our farms and educate them on sustainable living and urban farming.”

Ultimately, it hopes to empower homeowners to grow their own food. “This will be a model for Sunway Property to replicate throughout their cities in Malaysia and allow us to scale up quickly.”

The press release quoted reports that claimed Malaysia imports most of its food from countries such as China, India, Thailand, Indonesia and New Zealand because only about 8% of its agricultural land is used for agro-food production.

“Malaysia’s food import bill has grown significantly over the last two decades and exceeded RM52 billion in 2018. Research shows that imported food loses an alarming amount of nutrients during processing, packaging and transportation before it reaches consumers.

“In addition, traditional farming methods and existing logistics involved in the supply chain contribute in a big way to the carbon footprint. With the world experiencing unprecedented challenges amid the global Covid-19 pandemic, the threat to food security has increased,” the press release adds.

It goes on to say that in urban cities like the Klang Valley where land is limited and expensive, Sunway sees the potential of harvesting the power of talent and technology to build urban farms in underutilised spaces such as rooftops, car parks and even within buildings.

Sunway adds that recent developments in technology have enabled efficient urban farming techniques that require less water and no pesticide to produce consistent yields while revitalising underutilised spaces. “In recent years, urban farming has rapidly gained attention in cities all over the world as a feasible instrument in realising food sustainability and sustainable development.”

FutureX Farm will partner with Thought For Food (TFF), a global non-profit organisation dedicated to entrepreneurial innovation for food and agriculture.

“We see many exciting opportunities to collaborate with Sunway iLabs to provide a sandbox for start-ups from our global TFF innovation platform to carry out pilot projects to test out their solutions to fit local market needs,” Thought For Food chief executive officer (CEO) Christine Gould says.

Thought for Food will be partnering with Sunway iLabs to launch various programmes, including the TFF Digital Asean Lab, to engage, empower and accelerate the next generation of purpose-driven food and agritech innovators.

Sunway Group embarked on its journey towards food sustainability last year by repurposing 40 hectares of undeveloped land in Sunway City Ipoh for food and agriculture. Located at The Banjaran Hotsprings Retreat, Sunway Organic Gardens produces pesticide-free fruits and vegetables with fresh water from mountains for its guests, locals who work there and their communities.

Sunway Pyramid, Sunway Real Estate Investment Trust (REIT) and Sunway Hotels & Resorts have also joined forces to introduce the "Food CPR — Compost. Plant. Reduce." campaign aimed at tackling the food waste problem in Malaysia. Food waste will be channelled into Sunway Pyramid and Sunway Hotels & Resorts on-site compost machines to be processed into fertilisers. The compost will be free for the public to collect at Sunway Pyramid’s compost collection area at B1 Blue Zone Carpark Lobby.

NEW YORK: Vertical Farming Takes Root in Hudson Valley

Vertical Field launched in Israel in 2006 as an agricultural supply solution for the nation’s urban markets. Miner stated the firm began as a “green wall company” that took the horizontal aspect of rooftop gardens and switched it on its side

By Phil Hall

June 20, 2020

Among the more disturbing aspects of the COVID-19 pandemic involved food costs and supplies. The U.S. Department of Agriculture reported a 2.6% increase in food prices nationwide from March to April, marking the largest monthly increase in 46 years. These increases have been fueled by disruptions in the supply chain due to worker illnesses in processing plants.

For restaurants and food retailers, not being able to access materials or being charged higher-than-normal exacerbates an already acute problem of trying to maintain revenue streams during the pandemic.

However, a pair of regional businesses have begun using agricultural technology from the Israeli company Vertical Field that takes the farm-to-table concept and turns it into a container-to-table approach.

“The way it works is that we take a container, just the standard shipping container,” explained Sam Miner, Vertical Field’s U.S. launch manager.

“And the main thing that we do is we put these modules on the wall that have irrigation lines behind it. We simply fill those modules with soil and we put in the right lighting equipment. And once you put plants in there, they just grow fairly simple.”

John Lekic, chef and owner of Poughkeepsie’s Farmers & Chefs restaurant, poses in front of his Vertical Field container used for growing greens and herbs. Photo courtesy Vertical Field.

Vertical Field launched in Israel in 2006 as an agricultural supply solution for the nation’s urban markets. Miner stated the firm began as a “green wall company” that took the horizontal aspect of rooftop gardens and switched it on its side.

The company now has 400 projects around the world, including a massive installation in Vietnam that Miner described as being “tremendous, like a football field.”

This spring, Vertical Field made its way into the U.S. market through a pair of Hudson Valley installations. John Lekic, chef and owner of Poughkeepsie’s Farmers & Chefs restaurant, learned about the technology at a Culinary Institute of America symposium in late 2019 and was intrigued about operating his own food source.

“We were planning to bring in the container in March and we actually brought in a container days after the emergency thing was declared in New York,” he said. “It was a perfect timing. Ten days later, we planted our first crop, mostly salad greens, and in the middle of May we already had to harvest. We are going to have a third one this week.”

Lekic praised the technology for allowing several harvests per week, noting the ability to “harvest them the day of serving.” He also praised the user-friendly aspect of the 20-foot containers.

“It’s super easy to maintain,” he said. “Once the container is set up and the mechanism is in place, you have an app that does the irrigation and controls the temperature and the humidity. It’s not really complicated — after you do it once or twice, the planting and everything else becomes really easy to maintain. It does not require a lot of time.”

Lekic is now growing herbs and leafy vegetables in the containers, adding “it’s still a playground for us.”

Another Hudson Valley business that has Vertical Field’s technology in place is the Evergreen Kosher supermarket in Monsey, which installed its containers at the end of May. Menachem Lubinsky, president of Brooklyn-based Lubicom Business Consulting and marketing director for Evergreen, praised the product for creating a speedy supply of produce.

“If something takes normally three months to grow, the technology can accelerate that to three weeks,” he said. “A restaurant or a supermarket can be in control of their supply.”

Lubinsky said he reached out to Vertical Field following news reports during the pandemic of truckers not being able to deliver goods and farms destroying crops because they suddenly had no outlets for selling. Besides selling the harvested crops, Evergreen is planning to make the containers a visitors’ attraction.

“The customer will be able to see the process of how it grows because one of the walls of the container is glass,” he said. “It’s kind of like an educational experience just for a family to go over to see how this whole process grows. And there’s a very large kosher constituency there who are concerned about consuming insects. This eliminates that concern because of the way it grows — it is insect-free.”

Lubinsky said that Vertical Field is planning to build on its technology to accommodate the growing of a wider variety of items, including strawberries and vegetables.

Expert Insights: Advancing Indoor and Vertical Farming Opportunities during COVID-19

The indoor and vertical farming industry has fast-tracked many opportunities to help feed consumers during a global pandemic. The virtual Indoor AgTech Innovation Summit will identify how the world’s leading farm operators found a gap in the market to meet consumer demand and deliver fresh and healthy produce with discussions led by Lipman Farms, Gotham Greens and Smallhold.

The indoor and vertical farming industry has fast-tracked many opportunities to help feed consumers during a global pandemic. The virtual Indoor AgTech Innovation Summit will identify how the world’s leading farm operators found a gap in the market to meet consumer demand and deliver fresh and healthy produce with discussions led by Lipman Farms, Gotham Greens and Smallhold.

Here’s what our experts have to say about the current crisis:

Elyse Lipman, Director of Strategy, Lipman Farms, USA

Will the legacy of COVID 19 be further automation in the food production sector? Will we ever reach a contactless food system? COVID-19 has raised awareness about prospects of automation, but it’s also reinforced the importance of people in this business. At Lipman, each and every stage of the value chain requires coordination and care by our team members. The human element of what we do is important for providing food for people to eat – and we know that the quality of our products and sustainability of our company depends on the people behind the scenes. That said, where there are opportunities for automation that make sense such as machines in packing houses and indoor environments. I think it’s fair to say that humans can be relieved of those tasks and refocused on others. To help us stay ahead of the curve on food safety, for example, we use a web-based training platform that helps customize training, track completions, and easily identify opportunities for improvement. COVID-19 has only reinforced how technology can serve as valuable tools, while also creating new roles for people that are still safe and distanced across the food system.

At Lipman, we’ve diversified our farming techniques over the decades with indoor, outdoor, and hybrid growing environments. We know that growing produce in any capacity requires ingenuity, a learning mindset, and constant adaptation. Two years ago we acquired Huron Produce and while our Suntastic hot house brand continues to deliver high-quality products on the retail shelf, some of the most exciting learnings for us have come from the collaborations between teams. We see indoor ag as both distinct and complementary to our conventional farming practices. I think COVID-19 also revealed to our customers the vulnerabilities of relying on any one supply source, and the value in being able to source from multiple channels.

Viraj Puri, CEO and Co-Founder, Gotham Greens, USA

Demand for local and resilient supply chains is growing, how can indoor agriculture capitalize on this opportunity? Given current pressures on the U.S. food system, one thing is clear: the importance of strengthening our country’s food supply chain through decentralized, regional supply chains. Our business model has enabled us to remain nimble during these unprecedented times and continue to deliver fresh, locally grown produce to customers and our communities. Growing produce indoors certainly has an increasing role to play in the future of sustainable food production. While indoor farming may not represent the future of all fresh produce production, for certain types of crops like leafy greens, herbs, tomatoes and cucumbers, it will become more prevalent.

Gotham Greens has been rapidly expanding our footprint across the US, including opening four new greenhouses in the past 6 months. Today Gotham Greens operates 500,000 square feet of greenhouse across five U.S. states with more than 350 employees. Just last month we opened our newest greenhouse in the Denver Metro area. Although we never envisioned our Denver greenhouse opening during a global pandemic, we’re proud to be providing people in the Mountain Region and across the country with healthy, safe and fresh food options they can get excited about.

Andrew Carter, CEO, SMALLHOLD, USA

Although somewhat harder to find, consumers are still out there. How have Smallhold gone about finding them?

Strangely, consumers have found us. People who try our mushrooms love them and tell their friends. While we scrambled a bit in the beginning, we kept moving full steam. Instead of shutting down, we implemented South Korean-style measures for our warehouse, farm, and office. Then, we launched a new nationally distributed product that allows folks to grow mushrooms at home rather than travel to the grocery store. Now Smallhold is in homes in every state as we gear up for a national expansion of our retail presence in 2020. The product was featured in Bon Appetit, Vice’s Garage, and HypeBeast and is still going strong, although it is not a core business line for us, we continue to see it grow.

How can a grower best manage the expectations of their investors in times as uncertain as these?

Fortunately, as we mentioned above, things are weirdly going well for us. There was a brief period during which we were uncertain, but once our DTC campaign results came in, we became our investors’ case study for what to do in situations like these. As with many things in life, communication is key. At Smallhold, we’ve always had an open dialogue with our investors, and the pandemic hasn’t changed that. Even as the global outlook changes week by week, we’ve worked to provide our investors with a regular cadence of communication and data alongside a clear narrative and plan of action that makes them feel comfortable with the quick decisions we have to make every day. When the world shifts, success can take many forms, and our stakeholders are happy with how we’ve managed it.

CubicFarms Leverages Its Expertise In Controlled-Environment Agriculture And Announces Launch of new Control Room System And Sale To Career Field Farmer And Entrepreneur

CubicFarms’ Control Room is assembled inside its proprietary stainless steel, fully insulated growing chamber with the option to customize features such as lighting, automated irrigation and nutrient delivery, and full climate control for temperature, humidity and carbon dioxide levels

VANCOUVER, BC, JUNE 18, 2020 – CubicFarm® Systems Corp. (TSXV:CUB) (“CubicFarms” or the “Company”) is pleased to announce the launch of its new Control Room system for sale to growers looking to grow crops more efficiently by controlling every aspect of the growing environment.

CubicFarms’ Control Room is assembled inside its proprietary stainless steel, fully insulated growing chamber with the option to customize features such as lighting, automated irrigation, and nutrient delivery, and full climate control for temperature, humidity, and carbon dioxide levels. The system has a variety of sensors available, all of which can be remotely monitored and controlled.

Photo: Inside a CubicFarms Control Room, complete with LED light fixtures, an automated heating, cooling and ventilation system, and wired environmental controls.

The Control Room enables growers to have complete control over the growing environment that is so crucial for high yields and quality – a capability especially well suited for research and development purposes. The temperature, humidity, lighting, and airflow can be properly calibrated to suit crop requirements.

“We are pleased to launch a new product that allows growers to conduct their own growing trials inside a controlled-environment chamber. We’ve had numerous inquiries for this kind of solution and are pleased to be able to support our customers with this technology. We see good market potential for this solution that helps growers fine-tune the optimal environmental parameters for growing crops indoors,” commented CubicFarms CEO Dave Dinesen.

“We are confident that once growers experience the consistency and quality of yields achieved in the Control Room, they will seek to automate growing inside our Fresh Produce system, which is essentially the Control Room plus motorized rows of trays containing crops that follow a patented path inside the chamber to ensure all sides of the crop are evenly bathed in light to maximize growth.”

CubicFarms control rooms can be placed inside an existing warehouse or greenhouse to serve as controlled-environment growing chambers to test and develop crop varieties. They can also be placed outside in many environments. It is well-suited for many types of growers, including:

Photo: CubicFarms control rooms being installed at the customer’s site.

Greenhouse growers and vertical farmers who have a need to hold larger plants in an environment separate from their existing facility. As an example, a hemp grower who would like to hold the mother plant used for cloning in an ideal environment;

Growers in the floral or nursery industry who need to hold plants or bulbs at a specific temperature or humidity; and

Growers undertaking research activities that require different environmental controls than their typical growing space.

CubicFarms announces first sale and installation of control rooms to BC-based field farmer and food entrepreneur

The Company is pleased to announce that it has sold three control rooms to a customer in British Columbia. The control rooms were recently installed at the customer’s site. The customer, an experienced field farmer, and consumer packaged foods expert, plans to engage in controlled-environment growing trials of various crops that have traditionally been grown in the field. Mr. Dinesen added: “I’m very excited that CubicFarms can support our customers by leveraging technology we already have, but in this unique way. Our customers never cease to amaze me in how creative and inspiring they are when looking to grow their businesses.”

Neither the TSX Venture Exchange nor it’s Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

About CubicFarm® Systems Corp.

CubicFarm Systems Corp. (“CubicFarms”) is a technology company that is developing and deploying technology to feed a changing world. Its proprietary technologies enable growers around the world to produce high-quality, predictable crop yields. CubicFarms has two distinct technologies that address two distinct markets. The first technology is its patented CubicFarm™ System, which contains patented technology for growing leafy greens and other crops. Using its unique, undulating-path growing system, the Company addresses the main challenges within the indoor farming industry by significantly reducing the need for physical labor and energy, and maximizing yield per cubic foot. CubicFarms leverages its patented technology by operating its own R&D facility in Pitt Meadows, British Columbia, selling the System to growers, licensing its technology and providing vertical farming expertise to its customers.

The second technology is CubicFarms’ HydroGreen System for growing nutritious livestock feed. This system utilizes a unique process to sprout grains, such as barley and wheat, in a controlled environment with minimal use of land, labor, and water. The HydroGreen System is fully automated and performs all growing functions including seeding, watering, lighting, harvesting, and re-seeding – all with the push of a button – to deliver nutritious livestock feed without the typical investment in fertilizer, chemicals, fuel, field equipment, and transportation. The HydroGreen System not only provides superior nutritious feed to benefit the animal but also enables significant environmental benefits to the farm.

Cautionary statement on forward-looking information

Certain statements in this release constitute "forward-looking statements" or "forward-looking information" within the meaning of applicable securities laws, including, without limitation, statements with respect to the market potential of the Control Room system and system capabilities. Such statements involve known and unknown risks, uncertainties, and other factors including evolving market conditions, which may cause the actual results, performance, or achievements of CubicFarm Systems Corp., or industry results, to be materially different from any future results, performance, or achievements expressed or implied by such forward-looking statements or information including the Company obtaining the approval of the Offering from the TSX Venture Exchange. Such statements can be identified by the use of words such as "may", "would", "could", "will", "intend", "expect", "believe", "plan", "anticipate", "estimate", "scheduled", "forecast", "predict", and other similar terminology, or state that certain actions, events, or results "may", "could", "would", "might", or "will" be taken, occur, or be achieved.

These statements reflect the Company's current expectations regarding future events, performance, and results and speak only as of the date of this news release. Consequently, there can be no assurances that such statements will prove to be accurate and actual results and future events could differ materially from those anticipated in such statements. Except as required by securities disclosure laws and regulations applicable to the Company, the Company undertakes no obligation to update these forward-looking statements if the Company's expectations regarding future events, performance, or results change.

Kimberly Lim

VP, Corporate Communications & Investor Relations

Mobile: 236.858.6491

Office: 1.888.280.9076

Email: kimberly@cubicfarms.com

VIDEO: June Indoor Science Cafe Recording Is Now Available!

Selecting An LED Fixture For Indoor Plant Production

Selecting An LED Fixture For Indoor Plant Production

This presentation 'Selecting an LED Fixture for Indoor Plant Production' was given by Dr. Erik Runkle (Michigan State University) during our 20th cafe forum on June 16th, 2020. Indoor Ag Science Cafe is organized by the OptimIA project team funded by the USDA SCRI grant program.

From Macau's Casinos To a Kallang Farm: The Gaming Industry Professional Who Now Grows Baby Spinach

His indoor hydroponics farm, Artisan Green, specializes in growing baby spinach. The 3,200 sq ft farm is located in Kallang in central Singapore, with its entire set-up costing Mr. Poh slightly under a million-dollar

Mr Ray Poh founded Artisan Green in 2018. (Photo: Artisan Green)

23 May 2020

SINGAPORE: For five years, Mr. Ray Poh mingled with high rollers in Macau, which has been dubbed the gambling capital of the world.

It was a lucrative career filled with opportunities to travel frequently. But in 2015, Mr. Poh gave all of that up.

“I did think about making it a career,” said Mr. Poh, who had studied in Australia since the age of 12. “But I think at the end of the five years, I realized that I’d been away for most of my life from my mum, who was back in Singapore. That was one of the main factors (that led me to leave).”

It took him a year to completely leave the industry, but by 2016, Mr. Poh had decided on a very different career path: Urban farming.

His indoor hydroponics farm, Artisan Green, specializes in growing baby spinach. The 3,200 sq ft farm is located in Kallang in central Singapore, with its entire set-up costing Mr. Poh slightly under a million dollars.

Although Artisan Green was founded in 2018, a year before Singapore announced its ’30 by 30’ goal to produce 30 percent of Singapore’s nutritional needs locally by 2030, it is part of an increasing wave of indoor farms looking to use sustainable methods to grow to produce locally.

In April, the Ministry of Environment and Water Resources announced a S$30 million 30x30 Express grant for the agri-food industry to speed up the production of commonly consumed food items like eggs, vegetables, and fish.

READ: COVID-19 pandemic highlights importance of strengthening Singapore's food security, say experts

READ: Interest in urban farming sprouts amid COVID-19 outbreak

A FAMILY BUSINESS

While casino gaming was never something he had been interested in, a chat with his mother post-graduation was enough to convince Mr. Poh to enter the family business.

“I was thinking of entering the banking industry, but the thought of being behind a desk didn’t appeal to me much. So we were having a discussion and she said, why don’t you give this a try. Your father needs some help in the company, perhaps you can go out and see what you can do,” he said.

Initially, he did business development with his father’s manufacturing company, developing products such as slot machines. As he became more involved in product design, so his interest in the industry grew, he said.

The exterior of Artisan Green. (Photo: Artisan Green)

After a year, his boss convinced him that he ought to head to Macau to advance his understanding of the industry, which turned out to be a fruitful experience.

“I think at the very start when I first went there, I didn’t know anything or anyone in Macau, so the main thing I did was to network around. I met a lot of good people, and at the same time, obviously, you meet people that are not so good.

“What I did was learn what to do and what not to do. It was a very good experience,” he said.

Being new to the industry also meant that people did not take him seriously. Mr. Poh had to work hard to brush up his knowledge on the casino gaming industry by doing research, reading industry magazines, and making friends who could teach him – skills which would later put him in good stead to enter a completely different industry.

CONTRIBUTING TO SUSTAINABILITY

When he told his family that he wanted to move out of casino gaming, they were supportive of his decision, said Mr. Poh.

“I think from the business aspect of things, it was more of a diversification. I’ve always thought that agriculture is something that’s evergreen. People will always need to eat. Whereas casino gaming is something like the entertainment sector,” he said, adding that he wanted to “do something more to contribute to the sustainability segment”.

“At first I thought about doing landscaping, but I didn’t really want to go back to study more. So I thought farming might be an easy way in.

“But I was very wrong about how easy it was. After doing the research, I quite naively thought that I would do this for about a year and network around, meet more people, and then move into landscaping. But it just took me down towards farming all the way,” he said.

Artisan Green has 120 growing racks, with six layers in each rack. (Photo: Artisan Green)

Just like when he started out in Macau, Mr. Poh had “zero knowledge” of the agriculture sector, and people also did not take him seriously when he started.

“I knew I had to build up my knowledge from ground-up again,” he said.

He attended courses and conferences, forged relationships with people in the industry, watched Youtube videos, and built prototypes.

Building the prototypes gave him the confidence to decide that he wanted to build his entire farm from scratch. After leasing space from Mapletree and procuring all his supplies and tools, Mr. Poh set himself to work as the main contractor of his own farm.

Save for the electrical wiring and the plumbing, Mr. Poh put the entire 3,200 sq ft farm together with his own hands over the course of three months.

“When I was building the farm, I was there from 9 am to 10 pm. I’d only eat one meal a day during the building because I didn’t want to waste time. So I would only eat one really huge brunch and then just work the entire day in the farm,” he said.

It was challenging work, as he did all the sawing, drilling, and lifting and even suffered a back injury from hunching over and moving around too much. While he admitted that he should have gotten a partner to build the farm with him in hindsight, Mr. Poh said that the process was necessary.

“Now that I’ve gone through this, I can safely say that I know pretty much everything in the farm. I’ve sourced for every single piece of equipment by myself which makes it even easier for me to understand other people’s systems.

“I can look at other people’s systems, I can derive how it’s built, how it’s done, and that experience isn’t something you can get from reading books or watching tutorials online,” he said.

WHAT KEEPS HIM GOING

Even with his extensive research, his lack of science and engineering knowledge posed challenges for him.

“I didn’t really do chemistry, so that was kind of hard to pick up, and I knew that I needed to get the foundational knowledge of farming in terms of the science aspect to be able to do well in it,” he said, as science was an integral part of farming.

He also had to engage professional engineers to help him ensure the farm was built well.

This was in addition to the time he had to sacrifice in those early months, when he was just starting out, with many weekends spent at the farm just to make sure that everything was running well.

And even with the farm up and running, the team also ran into other problems, such as nutrient deficiency issues for their spinach.

Artisan Green's team packing spinaches. (Photo: Artisan Green)

But what kept Mr. Poh going was his desire to “see the final product”.

“And we’re quite proud of what we’ve done with this current farm. We’ve had people from the industry – from the US, Europe – coming to visit us and they were quite impressed with the farm we’ve built. They told that it was comparable to some of the more advanced overseas farms as well.

“Hearing that gives us the motivation and a stronger belief in what we do.”

FUTURE PLANS

In the short-term, Artisan Green hopes to scale up its production from its current 30kg to 250kg of vegetables per week.

Although Malaysia’s Movement Control Order has temporarily disrupted the farm’s supply of equipment which they require to scale up, Mr. Poh is hoping to at least double the farm’s output by the end of the “circuit breaker” period and to hit 100kg per week by the end of the quarter.

In the longer-term, Mr. Poh is also looking to build his second farm – this time bigger, and with a wider variety of crops. But rather than growing specialty crops, Mr. Poh said he now wants to start growing crops such as Chinese cabbage, which he says there is a bigger demand for in Singapore.

“The next farm will have to be more automated, from end-to-end. That’s what our future goal is: to build the second farm and also to grow different crops, not just baby spinach, and work towards something where we can fulfill the whole ’30 by 30’ vision by the Government,” he said.

Source: CNA/cc

Tagged Topics

10 Crops You Can Grow At Home: Hydroponic Growing

Hydroponic growing is a method of growing plants in nutrient enriched water – just water and nutrients. There’s no soil involved; instead, nutrition is added directly to the water, to make up for what the plants would normally receive from the soil

Growing your own fruit and vegetables at home may be something you’ve considered before, but if you’ve hesitated because of the space the plants will take up or the mess it will make in your home, the good news is that neither of these things needs to stop you. Whether you have no floor space to spare, can’t grow outdoors, or simply don’t consider yourself green-fingered, it’s never been easier to grow your own crops at home.

What is Hydroponic Growing?

Hydroponic growing is a method of growing plants in nutrient-enriched water – just water and nutrients. There’s no soil involved; instead, nutrition is added directly to the water, to make up for what the plants would normally receive from the soil. Many plants will root and grow in something as simple as a glass jar, but you can make your hydroponic system as big or as little as you want.

What can I grow?

You can grow a massive variety of vegetables hydroponically so it really depends on what your favorites are.

Here’s a list of ten common fruit and veggies to get you started:

Lettuce

Probably the most common vegetable to be hydroponically grown, it’s not unusual to find people placing the head of a used lettuce into a glass or jar filled with water and leaving it to regrow. It really is that simple! You can harvest the lettuce as it grows, meaning you can have crispy lettuce leaves to add to your salads or sandwiches without affecting later harvests.

Spinach

As with many leafy vegetables, spinach also grows well in hydroponic systems. It is a cool plant, meaning it does not require much light and likes cool to warm temperatures so storing it near a window is the best option to ensure your spinach flourishes. You can harvest spinach all at once, or tear off some leaves as and when you need it.

Tomatoes

Whether you think of the tomato as a fruit or a vegetable, you can definitely grow it without soil. Many types of tomatoes take well to hydroponic systems, including traditional and cherry tomatoes. Whichever variety you grow, tomatoes require a lot of light. The good news is that, as they are a vine and can be trained to grow upwards, they only require a small amount of ground space.

Cucumber

Given enough space and support, cucumbers will grow abundantly in a hydroponic system – which is no surprise given that it is a water-loving fruit. Cucumber vines grow vertically, so it’s important to ensure they have some sort of structure or support to hold them up.

Peppers

Similar to tomatoes, peppers require lots of light and warm conditions. There are a few varieties or pepper that take well to hydroponic growing, but some of the best are Jalapeno, Habanero, Nairobi, and Fellini.

Celery

Celery is a great way to snack healthy, as well as being a great addition to soups, stir-fries, and stews. The fastest way to grow celery at home is to use the base of the last bunch you had from the grocery store. Simply place the celery on a plate of room temperature water until you see new growth from the roots, and then you can transplant it into your hydro system – even if that just means placing it into a tall glass which can support the celery as it grows.

Radishes

Radishes are one of the easiest vegetables to grow, thriving in cool conditions, and not requiring much light. They are usually harvested within a month, meaning you can have multiple harvests in a year. That being said, if radishes are kept constantly and persistently soaked, rot can become an issue, so make sure it’s the roots that are kept in water, rather than the radish itself.

Spring Onions

When it comes to spring onions, you can use the ends of a shop-bought onion and place it in a glass to allow for regrowth, or you can start them from bulbs. The bulbs and roots will sit down in the water, whilst the leafy green stems will rise upward: this makes it possible to grow a lot in a small amount of space.

Kale

Kale is another leaf that is easy to grow in a hydroponic system; in fact, it has been farmed hydroponically for years. The crop grows relatively quickly, and will happily regrow if you only harvest a couple of leaves at a time.

Strawberries

As strawberries enjoy wet conditions, they actually thrive in a hydroponic system; they provide bigger fruits than when grown in soil and can provide harvest all year round. Using a hydroponic system also means that strawberry plant containers can be stacked vertically, saving you floor space.

Hydroponic growing is becoming more popular due to the fact that in can be done from anywhere and doesn’t need to take up a lot of space. It’s a great way to get the satisfaction of growing your own crops, without needing a large gardening space.

We at the Nick Greens Grow Team understand that not everyone has the space to grow their own crops, but the joy of hydroponics is the simplicity of the process. Want to learn more about growing plants in water systems? Stay up-to-date with our weekly blog articles, and subscribe to our YouTube channel to learn more.

#hydroponics #hydroponicsystem #hydroponicsfarm #hydroponicsvegetables #hydroponicsstarwberry #hydroponicscelery #hydroponicsradish #hydroponicskale #hydroponicsgrowing #hydroponicsfarming #growfoodwithhydroponics #growingfoodathome #hydroponicgrowing #hydroponicfarming #hydroponicfarm #hydroponicsfarm #growathome #growfoodathome

Aquaponic Urban Farming In Berlin

Thanks to modern concepts, the Berlin start-up ECF Farmsystems is now breeding "perch" and "basil" in the middle of Berlin

REWE.de Nutrition

Perch and Basil From The Capital

Yes, you read it right! Thanks to modern concepts, the Berlin start-up ECF Farmsystems is now breeding "perch" and "basil" in the middle of Berlin. You can buy both in around 140 REWE stores in Berlin, Brandenburg and Mecklenburg-Western Pomerania. Together with the start-up, REWE is committed to holistic, sustainable and regional food production.

Perch and basil in the middle of Berlin

Regional and sustainable foods are absolutely on-trend right now. More and more people are concerned about the environment, want to avoid unnecessary transport routes and unnecessary packaging material. They like to buy products from their region, but groceries straight from the big city have so far been rare. Thanks to the aquaponics method, it is now possible to grow fruit, vegetables, and even fish in the city. Industrial wasteland and other unused areas in cities can be wonderfully upgraded as “urban farming” areas. Large flat roofs will also be the best areas for urban food cultivation in the future. The Berlin start-up ECF Farm is breeding on the site of an old malt factory fresh cichlid and basil in the middle of the capital. With success! The two entrepreneurs Nicolas Leschke and Christian Echternacht spent five years working on the ideal method of combining fish and plant breeding. Meanwhile, the two true experts in the field of aquaponics and advise interested parties across Europe.

Aquaponics?

AQUAkultur = Fish and other marine animals are raised in large basins on land.

HydroPONIK = Plants are not grown in soil, but in an inorganic substrate (gravel or expanded clay) in greenhouses and fed with an aqueous solution.

How does aquaponics work?

Aquaponics is a mixture of aquaculture and hydroponics, i.e. fish farming and vegetable cultivation are combined in an ingenious way. The principle is very simple: The fish are bred in large fish tanks in aquaculture and fed with organic food. In contrast to conventional aquacultures, the fish are not given antibiotics. Fish excrete ammonium, which is converted to nitrate in a special aquaculture filter. Nitrate is again the main component of the hydroponic plant fertilizer. Here comes the highlight of the method: The water in the fish tanks has to be replaced by three to five percent every day. It is guided from the aquaculture into the hydroponics facility using a special technique. There the basil is irrigated with the water from the fish tanks. The basil is fertilized automatically by the nitrate contained in the water. One can say that the fish feeds the basil. Incidentally, the urban farmers do not use pesticides or genetic engineering for growing herbs. All processes are optimized to protect the environment and resources. The water that the plants do not absorb is cleaned by a natural filter and remains partly in the hydroponic cycle and partly returned to the fish tanks. This creates a constant and resource-saving cycle. is cleaned by a natural filter and remains partly in the hydroponic cycle and is partly returned to the fish tank. This creates a constant and resource-saving cycle. is cleaned by a natural filter and remains partly in the hydroponic cycle and is partly returned to the fish tank. This creates a constant and resource-saving cycle.

Sustainability through "urban farming"?

Thanks to on-site production, manufacturers save six tons of plastic waste a year. For short transport, for example, you can completely do without plastic trays for irrigation. But not only the environment benefits from the short transport routes, the customer can also look forward to locally produced and extremely fresh products.

Is aquaponics a concept with a future? Certainly! With this technology, unused areas in the city can be used sensibly. In addition, water consumption is significantly lower than in conventional agriculture. The quality of the herbs and vegetables is also very high, as it is much easier to control in a closed cycle. However, it has not yet been possible to breed native fish using this technique. In the summer it gets very warm in the fish tanks and at these temperatures only tropical fish feel comfortable. For example the African cichlid, African catfish or the pakus from South America. The options for fruit and vegetable cultivation, on the other hand, are diverse: whether salad, herbs, tomatoes, Strawberries or zucchini - many types of fruit and vegetables can be easily grown in aquaponic farms. The big advantage: fruits and vegetables are only harvested when they are ripe. As a result, they taste much better than green harvested goods that only artificially ripen during transport.

In the vision of the two urban farmers, supermarkets will grow their own vegetables on roofs or other urban open spaces in the future. A first step in this direction is the sale of “perch from the capital” and “basil from the capital” in Berlin's REWE stores. Demand is high and customers are very satisfied with the regionally grown products.

The Race Is on To Grow Crops In The Sea And Feed Millions of People

With the quality of arable land declining and seawater encroaching on fertile cropland, researchers are trying to find a way to make crops grow in seawater

With the quality of arable land declining and seawater encroaching on fertile cropland, researchers are trying to find a way to make crops grow in seawater

17 June 2020

Chen Hanquan / WIRED

In December 2015, as representatives from United Nations member states were finalizing what would become the Paris Agreement on climate change, Duncan Cameron stood before a crowd of delegates and warned them about an environmental catastrophe happening right beneath their feet.

A soil biologist and co-director of the University of Sheffield’s Institute for Sustainable Food, Cameron had long known that the amount of farmland capable of growing nutrient-rich crops was shrinking, but he didn’t know how fast. For the previous year, Cameron’s team had analyzed the scattershot data available on arable land loss, and what they found was disturbing: in the past four decades, the world lost up to one-third of its arable land to soil degradation and resulting erosion. Without alternatives, already fragile agricultural systems are on the verge of collapse, raising the prospect of a world filled with farms that can’t grow enough food.“

It’s quite a terrifying amount,” Cameron says. “We hear that we can solve a lot of these problems in terms of food insecurity by wasting less and getting more efficient, but that isn't going to give us everything we need.” Now, an emerging group of startups and researchers are convinced that answers to the impending food crisis may not lie on land at all – instead they’re looking to the ocean and to feed future populations with crops grown on floating farms and fed by seawater.

These ambitious initiatives target a thorny mess of environmental and humanitarian issues — freshwater and land scarcity, global hunger, crop security, and agriculture’s enormous carbon footprint amongst others — but the scientific and logistical challenges they face are enormous. In a field where there are few easy answers, one problem looms above all others: what do we do about all the salt?