Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Container Farms Bring Fresh Vegetables To Remote Canadian Community

Over 1,000 kilometres northeast of Yellowknife sit two steel shipping containers that are changing how we understand and respond to food production challenges in Canada’s North, and in other harsh and isolated locations

Over 1,000 kilometers northeast of Yellowknife sit two steel shipping containers that are changing how we understand and respond to food production challenges in Canada’s North, and in other harsh and isolated locations.

These containers have been retrofitted into a research station in Gjoa Haven, Nunavut, where the local community is working with government researchers and a non-profit organization to understand what is needed to create local food sources, clean energy generation, resilient building materials, scalability and adaptability to local needs, and even job opportunities and training.

The local community of Gjoa Haven has named the initiative Naurvik, which means “growing place.” It is a first-of-its-kind venture in Canada’s North, being built and adapted on-site.

Listening closely to Gjoa Haven Elders and community members, the Arctic Research Foundation, Agriculture and Agri-Food Canada, the National Research Council of Canada, and the Canadian Space Agency are actively collaborating on the design and testing of this green energy-powered controlled environment production unit for growing plants in Canada’s North. The community is deciding what plants they want to grow. It’s then up to the research partners to figure out how to adapt the research to their needs, and to train community partners to operate and maintain the system in the harsh and remote location.

“When I first heard of [the project] I thought it would never work up here. No. Not in this 40 below zero. Now I know anything is possible if you have the right idea... I had a taste of the vegetation. It was fresh”, said Peter Akkikungnaq, Gjoa Haven Elder.

By actively working with the local community, and tailoring solutions to their needs, Naurvik is creating a roadmap of how to deliver effective programs, infrastructure, and research in Canada’s North. By integrating resilience and adaptability into the design, the goal is that the model will be able to respond to needs in other harsh and isolated locations, not only in Canada’s North but also on space missions.

“The Canadian Space Agency is looking at innovative solutions to food production challenges that are common to astronauts on deep-space missions and people on Earth living in remote or extreme environments, such as the northern community of Gjoa Haven. While working towards to help with the development of advanced, robust designs for a terrestrial food production system, we are hoping to find strategies that could help astronauts grow food in space”, said Christian Lange, Head of Exploration Strategic Planning, Canadian Space Agency.

While the project is in its early stages, it’s hoped that by 2025 a community-led, renewable energy-powered plant food production system will be fully operational in Gjoa Haven. It will serve as a scalable blueprint for collaborative partnerships and co-designed projects in the Arctic and will be a focal point for innovative research and educational opportunities.

“This is an effective, novel approach to community-driven collaboration with science institutions in Canada’s North, and that’s the reason why it has been so successful. It will generate research for the benefit of all Canadians while also producing tangible benefits for Gjoa Haven and, eventually, other communities throughout the Arctic”, Adrian Schimnowski, CEO, Arctic Research Foundation, comments.

For more information:

Arctic Research Foundation

www.arcticfocus.org

Publication date: Mon 10 Feb 2020

Improving The Profitability and Sustainability of Indoor Leafy-greens Production

A multi-university team of horticulturists, engineers and agricultural economists led by Michigan State University (MSU) has received a four-year, $2.7 million grant from the U.S. Department of Agriculture (USDA) to study indoor production of leafy greens. Industry partners have matched funding, bringing the project total to $5.4 million

February 11, 2020

By urbanagnews

A multi-university team of horticulturists, engineers and agricultural economists led by Michigan State University (MSU) has received a four-year, $2.7 million grant from the U.S. Department of Agriculture (USDA) to study indoor production of leafy greens. Industry partners have matched funding, bringing the project total to $5.4 million. The investigators on the grant include Erik Runkle, Roberto Lopez and Simone Valle de Souza of Michigan State University, Chieri Kubota of Ohio State University, Cary Mitchell of Purdue University and Murat Kacira of University of Arizona.

Leafy greens include commonly consumed vegetables such as lettuce, kale, and microgreens. Production challenges outdoors have led to interest in growing these specialty crops hydroponically in controlled environments, such as indoor farms. However, there is little information on whether this is economically viable. Capital and operating costs can be significant for startups, especially as it relates to light-emitting diodes (LEDs) and cooling systems. Leafy greens are a good candidate for indoor farming because they can be grown rapidly and in relatively small spaces. Indoor environments are heavily controlled, so growers aren’t constrained to a small geographic area within the U.S. There are, however, other geographic concerns.

The team and its collaborators have three major goals:

Define optimal profitability based on yield and other high-value attributes of the plants, such as nutrition content

Optimize indoor environmental conditions, such as humidity, air movement, temperature, light and carbon dioxide concentration, to increase yield and high-value attributes

Encourage indoor farming stakeholders to collaborate with academic and industry groups that are working in controlled-environment agriculture.

The long-term project goals are to help integrate indoor farming into the specialty-crop segment of agriculture in the U.S.; to increase the sustainability and hence profitability of this rapidly emerging sector, and to locally produce leafy greens that have higher quality attributes. To this end, our economists will better understand operating and capital expenditures (capex), and define risk and production scenarios that are most profitable. Our horticulturists and engineers will improve production efficiency, product quality, and value-added attributes of leafy greens for reliable, consistent, year-round production. In addition, the team will design and test more effective localized air-distribution methods suitable for indoor production systems, as well as develop strategies to better manage humidity around plants to reduce tip burn. While the project focuses on leafy greens, the results will also inform a wide range of controlled-environment growers through the development of growth recipes, strategies for nutritional content and anthocyanin enhancement, environmental management recommendations, and insights for economic sustainability as well as market and consumer perception of locally produced crops.

For more information, visit the project website at scri-optimia.org.

US: CHARLESTON, SC - Lowcountry-Based Hydroponic Lettuce Farm Going Mobile

A growing trend in produce farming has some of the Lowcountry's leafy greens growing indoors

by Brooke Schwieters

February 7th, 2020 (WCIV)

CHARLESTON, S.C. (WCIV) — A growing trend in produce farming has some of the Lowcountry's leafy greens growing indoors. Now they're going mobile. Charleston-based Vertical Roots is the nation’s largest hydroponic container farming operation. With an eco-friendly focus on sustainable farming, Vertical Roots uses recycled shipping containers to grow lettuce.

“There’s no soil. The lettuce grows in coconut and there’s basically a stream of water that allows us to grow the lettuce, so instead of lettuce having to travel 2,000 miles, this is grown right here in our backyard," explained Andrew Hare, general manager of Vertical Roots.

Now the operation is hitting the road with its new mobile hydroponic farm, the Lettuce LOCALmotive, hoping to educate the community about the growing trend.“

This was something that we wanted to do to get out into the community and educate the community in different ways of growing, the alternatives from conventional farming,” said Hare. “Obviously bringing a farm to different locations isn’t the easiest thing, so we decided to convert a delivery truck into a farm on wheels.”

When guests step inside, they will experience a true hydroponic farm operation, receive a tutorial on how the technology works, and even get hands-on experience seeding plants.

As part of the start to it's Southeast tour, Lettuce LOCALmotive farm will make its first two stops at Publix stores in Charleston:

Saturday, Feb. 8 | 10 am – 4 pm | 3642 Savannah Hwy #132, Johns Island, SC 29455

Saturday, Feb. 15 | 10 am – 4 pm | 162 Seven Farms Drive #100, Daniel Island, SC 29492

As Close To A Crystal Ball On Brexit As You’re Going To Get

Next month the UK will formally begin withdrawing from the European Union. How will that affect your market and your supply chain? What are the implications and are you prepared?

Next month the UK will formally begin withdrawing from the European Union. How will that affect your market and your supply chain? What are the implications and are you prepared?

Agricultural Trade After Brexit

Caroline Heil

Associate M&A Corporate

Ernst & Young

Agriculture has a prominent role in the European Union (EU) and agricultural trade is one of the most important parts of the Community’s Common Market. The development of a customs union and free movement of agricultural products was - from its beginning in the 1950s - always framed by the idea of a Common Agricultural Policy (CAP) to be established among the Member States. With the United Kingdom (UK) as a strong player on the ag market leaving the EU, an influential voice in CAP will be gone. But the relationship between the UK and EU after the end of the transition period on 31 December 2020 that was agreed upon in the Withdrawal Agreement, is still unclear and subject to negotiations.

In the session Agricultural Trade after Brexit, we will focus on the influence Brexit will most likely have on agricultural trade and the ag market in Europe and what trade between EU and UK might be like as of 1st January 2021. We will build and face different scenarios likely to happen and outline potential threats, but also opportunities that may come with Brexit.

Visit our website for more details

Subscribe to receive updates about

Women in Agribusiness Summit Europe.

Thank you to our sponsors

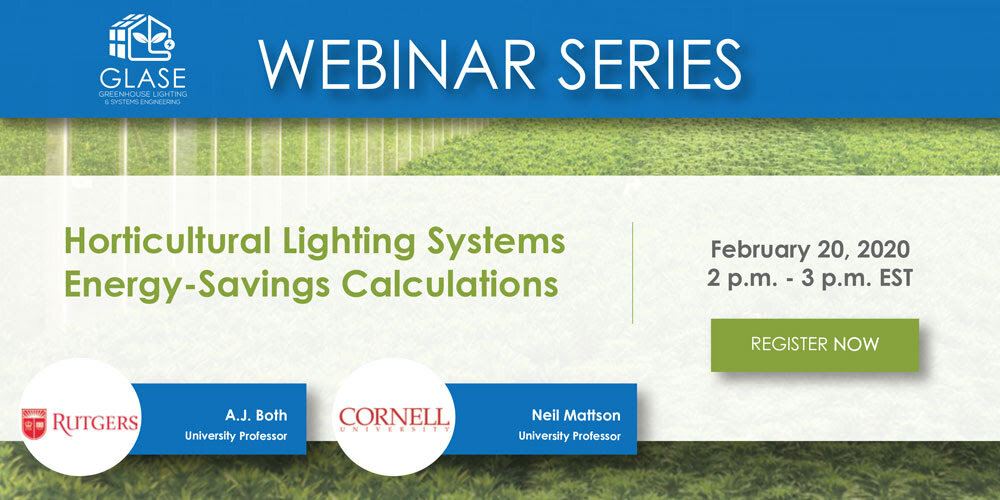

GLASE Webinar - February 20, 2020

During this webinar, Dr. Neil Mattson from Cornell University and Dr. A.J. Both from Rutgers University will provide updates on research findings and present calculation tools that can be used to assess the operational costs for and benefits from supplemental lighting system

Horticultural Lighting Systems

Energy-Savings Calculations

Date: February 20, 2020

Time: 2 p.m. - 3 p.m. EST

Presented by: A.J. Both and Neil Mattson

Register Here

Supplemental lighting is a major cost component for controlled environment agriculture facilities. While lamp efficiency (efficacy) is an important factor, other key factors include crop needs (intensity and duration), cropping strategy (time of year and harvesting schedule), availability of sunlight (location and structural design), heating and cooling requirements (location and energy costs), and electric rate schedules (time of day and demand charges).

During this webinar, Dr. Neil Mattson from Cornell University and Dr. A.J. Both from Rutgers University will provide updates on research findings and present calculation tools that can be used to assess the operational costs for and benefits from supplemental lighting systems.

Special thanks to our Industry partners

Join today

If you have any questions or would like to know more about GLASE, please contact its executive director Erico Mattos at em796@cornell.edu

US: New York - 4th Annual Fresh In February by NYC Ag Collective

Wed, February 26, 2020 - 6:30 PM – 9:00 PM EST - Project Farmhouse - 76 East 13th Street - New York, NY 10003

Fresh in February is An Annual Networking Event Showcasing Some of

NYC's Most Innovative Urban Farms and Agtech Startups.

About this Event

Fresh in February is back! Join the NYC Agriculture Collective - the largest consortium of agtech organizations on the East Coast - for this annual networking event at the beautiful Project Farmhouse near Union Square.

You'll get to meet some of New York's leading urban farms & agtech startups and sample fresh produce grown right here in the dead of winter!

Date And Time

Wed, February 26, 2020

6:30 PM – 9:00 PM EST

Location

Project Farmhouse

76 East 13th Street

New York, NY 10003

United States

Register Now to Save: $25 online / $35 at the door.

Local food bites and drink tickets are included

Confirmed exhibitors include:

Tags: United States Events New York Events Things To Do In New York, NY New York Networking New York Food & Drink Networking

Indoor Farming Companies Rank High On FoodTech 500 List

At No. 3 on the list, Bowery Farming, New York, N.Y., is an automated, indoor vertical farm as well. Ranking No. 125, Crop One Holdings includes the FreshBox Farms brand of leafy greens grown and distributed to retailers from its indoor Massachusetts farm

February 7, 2020

AeroFarms, Bowery Farming, and Crop One Holdings are ranked at Nos. 1, 3 and 125, respectively. The three companies have northeastern indoor farms and specialize in leafy greens.“

We’re proud to be recognized,” Marc Oshima, chief marketing officer of Newark, N.J.-based AeroFarms, said in a news release. “Forward Fooding says our proprietary aeroponic technology is transforming the future of food, now.”Inspired by the Fortune 500, the FoodTech 500 list of mission-driven companies was created by Forward Fooding, a global network of entrepreneurs enabling collaborations and partnerships among established food organizations and startups.

There were more than 1,200 applications from 54 countries in eight categories, according to the Forward Fooding website.

At No. 3 on the list, Bowery Farming, New York, N.Y., is an automated, indoor vertical farm as well.

Ranking No. 125, Crop One Holdings includes the FreshBox Farms brand of leafy greens grown and distributed to retailers from its indoor Massachusetts farm.

Find out what other companies made the list at https://forwardfooding.com/foodtech500.

Logo courtesy Forward Fooding

Related Topics: Sustainability Ag Sustainability Sustainability/Going Green Produce Tech Technology Northeast (U.S.) New York New York City New York Produce New Jersey New Jersey Produce Massachusetts

Autogrow Launches Wireless Smart Sensor Network Into US $40 Billion Global Greenhouse Market

“We’ve advocated for a long time in the industry that you can’t manage what you don’t measure and the decisions you make are only as good as the sensor technology gathering the data

5 February 2020

Leading AgTech expert Autogrow has released a wireless smart sensor giving greenhouse operators high-density microclimate data to improve yield, quality and decision making.

Each Folium sensor gathers environmental data including temperature, humidity, CO2, PAR, RAD and barometric pressure, which growers can view on a heatmap - immediately seeing differences across their grow areas. Folium enables greenhouse operators unlimited depth of environmental analysis, as the number of sensors is completely scalable.

“We’ve advocated for a long time in the industry that you can’t manage what you don’t measure and the decisions you make are only as good as the sensor technology gathering the data. Folium will go a long way to giving growers actionable data using state-of-the-art heat mapping technology. It reveals what the eye can’t see,” explains CEO Darryn Keiller.

“According to market analysts, the global greenhouse market is looking to exceed US$40billion in the next 5 years, so it’s a growth market we are excited to support. With over two years of research and development, and a huge amount of hard work from my team, it’s fantastic to have Folium in the market and offer greenhouse growers new technology that will substantially impact their bottom line.”

Folium’s target customer is large greenhouse growers who, simply by the size of their operations, require high-density climate data to ensure all areas of their facilities are providing the optimal environment for growth. The sensor network reliably scales to any size greenhouse.

Chief Technology Officer Jonathan Morgan notes that sensor technology can be incredibly complex but the experience for the grower should be easy and meaningful.

“We’ve been lucky to work with some fantastic growers throughout the development of Folium who have shared their time, knowledge and grow operations to ensure we are solving some of the pain points they experience when dealing with microclimates,” says Mr. Morgan.

“This is just the beginning of what Folium will be able to do. With the way our technology has been designed, we can easily introduce new features that continually support growers. They can also add more Folium units as their business grows and being connected to our cloud platform gives them access anywhere at any time.”

For more information www.autogrow.com/products/folium

PHOTOS: Folium unit in a greenhouse / Heatmap image showing PAR readings

Kylie Horomia

Head of Brand & Communications

(m) +6421 733 025

About Autogrow

Autogrow leverages the power of technology, data science, and plant biology to provide indoor growers affordable, accessible and easy-to-use innovation – 24/7, anywhere in the world.

Our solutions support growers and resellers in over 40 countries producing over 100 different crop types.

We are the experts in Controlled Environment Agriculture (CEA) and continue to stay ahead of a rapidly evolving landscape.

Autogrow, Level 1, Building 3, 61 Constellation Drive, Mairangi Bay, Auckland 0632, New Zealand

Can You Fit A 2-Acre Garden In A Shipping Container?

As the bustling streets of Brooklyn, New York rumble nearby, most passersby have no idea there’s a bountiful garden just steps away

WRITTEN BY SAM BURNS

As the bustling streets of Brooklyn, New York rumble nearby, most passersby have no idea there’s a bountiful garden just steps away. It may have something to do with the fact that this garden’s not in a field or in someone’s lawn but in a parking lot, with acres and acres of fresh food growing inside shipping containers!

When people can’t go to the farm, why not bring the farm to the people? That’s what Square Roots is doing by growing fresh, nutritious food in cities to feed the communities around them.

Tucked away inside your everyday shipping container is the equivalent of a two-acre farm. Leaves from a variety of herbs and greens line the walls in columns, as purple lights shine on them and young farmers are hard at work tending to their needs. Let’s take a look at how this all works and what it means for our future with food!

Courtesy of Square Roots

As we face growing populations and changing climates, our ability to grow enough food to support everyone’s health remains in question. But this fascinating look into the future of food with Square Roots gives us the inspiration to keep pushing the barriers on our definitions of what “farming” is, where it happens, and who does it.

On a mission to bring nutritious food to people living in the city and counteract the nutrient loss that happens in our typical food system (when produce is shipped many, many miles), Square Roots is perfecting a sustainable model of farming that can change what we can eat in our growing cities.

To give us an introduction to their work, here’s BEME News:

Dive deeper into Square Roots!

Square Roots has sure been up to a lot in the two years since that video was released! Not only are they continuing their awesome Next-Gen Farmer Training Program to help young people get started in the industry, but they’ve also taken major steps to increase the transparency of information about our food and access to it with some amazing new launches!

Since Square Roots has data collection and technology in their DNA, they’ve decided to let the public in on it. In late 2018, they started putting QR codes on the back of all of their produce packaging so consumers can read the life story of their food; where it was grown, when, how, and by whom! Think about that: when was the last time you knew who picked that bag of spinach you just plucked off the shelf? Or what sort of environment it’s coming from? Square Roots Transparency Timeline lifts the curtain on the stories of our food system and hands the consumer more power. (Read more about their Transparency Timetable here!)

Last year, Square Roots opened its first farm campus outside of New York City!

Gordon Food Service, one of the United States’ leading foodservice providers, has signed on to have Square Roots campuses of indoor farms built on or around their distribution and retail centers around the country. Square Roots wrote in their blog that:

“It’s been exciting for us to witness a company as large as Gordon Food Service move so fast to address the increasing consumer demand for locally-grown food. It’s also very clear that Gordon Food Service takes its role as a responsible member of the food supply chain seriously. They recognize that, at their scale, adoption of innovative solutions like Square Roots can drive significant positive change throughout the entire foodservice industry.”

We couldn’t agree more! When the goliaths in any industry shift their practices, they can begin a huge ripple effect. And this first farm is surely a big one. Read more about the farm–which they opened in September 2019 (congrats, y’all!)–in this blog post!

You can learn more about Square Roots by visiting their website or touring one of their farms in person! And subscribe to their blog to receive updates from them directly in your inbox. (They post great stuff! I highly suggest taking a look.)

View of the Square Roots Brooklyn Farm Campus | Courtesy of Square Roots

Can you imagine what it’d be like if your family had access to fresh food all year round?

How would that impact your lives? As our societies and populations have grown steadily over the years, it seems like we’ve been scrambling to establish a food industry that can accommodate our needs. But something else has been happening as humanity grows: our innovations have adapted. We’ve developed new technologies and uncovered more secrets from the natural world, meaning, we have an immensely better grasp on how plants grow and the tools needed to help them. Every year inches us closer and closer to a solution.

Square Roots is a really great piece of the puzzle, but of course, they aren’t the only ones using their knowledge to make a dent in this problem.

What can you do?

Well first, if you live in New York City you can use this locator to see if Square Roots is selling their produce at a market near you. (And make sure you scan those neat QR codes on the back of their produce—they’ll give you all of the information about who grew the food and where it comes from!)

But for the rest of us without a shipping container garden in a parking lot nearby, what can we do? I’ll just give you one piece of advice (and trust me, I’m giving it to myself as well): grow a plant inside! Any plant! Basil, thyme, spinach, tomatoes, strawberries, I don’t care. If you can avoid buying one product at the market, that’s a great start. Plus, you’ll know exactly where that wonderful basil on your hunk of mozzarella came from. This article can give you some ideas.

If that doesn’t seem like something that’s possible, there are also great directories to find farmer’s markets and CSA’s near you! A simple Google search should suffice in pulling up your local options. But for those living in the United States, the Department of Agriculture’s farmer’s market and CSA directories are a really great resource. Just click those respective links and enter your zip code to see what’s happening near you!

Do you have any other tips? Share with us on Twitter or Facebook!

Stay open to new possibilities!

Sam

“No problem can be solved from the same level of consciousness that created it.” —Albert Einstein

Freight Farms Raises $15M in Series B funding Led By Ospraie Ag Science

Freight Farms, the containerized vertical farming company, announced that it has raised $15 million in Series B funding led by Ospraie Ag Science, an investment firm committed to supporting sustainable solutions that improve the quality of life for both farmers and society

Freight Farms, the containerized vertical farming company, announced that it has raised $15 million in Series B funding led by Ospraie Ag Science, an investment firm committed to supporting sustainable solutions that improve the quality of life for both farmers and society. The investment round, which received participation from existing investor Spark Capital, brings the company's total funding to more than $28 million.

Proceeds from the Series B fundraise will be used to advance the technical potential of Freight Farms’ platform through continued innovation, with new services designed to benefit its growing global network of farmers and corporate partners. The investment follows the announcement of Freight Farms’ strategic national partnership with Sodexo to grow food onsite at educational and corporate campuses nationwide and will support ongoing contributions to collaborative research projects and partnerships.

“Freight Farms has redefined vertical farming and made decentralizing the food system something that’s possible and meaningful right now, not in the ‘future of food,’” said Jason Mraz, President of Ospraie Ag Science. “Full traceability, high nutrition without herbicides and pesticides, year-round availability – these are elements that should be inherent to food sourcing. Freight Farms’ Greenery makes it possible to meet this burgeoning global demand from campuses, hospitals, municipal institutions, and corporate businesses, while also enabling small business farmers to meet these needs for their customers.”

“It’s a big step forward for the industry when financial markets recognize and champion the value of creating a distributed food system,” added Brad McNamara, Freight Farms CEO. “Aligned on mission-driven growth as a team, there is a massive opportunity before us to scale across global markets, propelling meaningful technology that’s already doing good.”

Founded in 2010 by CEO Brad McNamara and COO Jon Friedman, Freight Farms debuted the first vertical hydroponic farm built inside an intermodal shipping container—the Leafy Green Machine—with the mission of democratizing and decentralizing the local production of fresh, healthy food. This innovation, with integral IoT data platform farmhand, launched a new category of indoor farming and propelled Freight Farms into the largest network of IoT-connected farms in the world. Freight Farm’s 2019 launch of the Greenery raised the industry bar, advancing the limits of containerized vertical farming to put the most progressive, accessible, and scalable vertical farming technology into the hands of people of diverse industry, age, and mission.

“With the Greenery and farmhand, we’ve created an infrastructure that lowers the barrier of entry into food production, an industry that’s historically been difficult to get into,” said Jon Friedman, Freight Farms COO. “With this platform, we’re also able to harness and build upon a wider set of technologies including cloud IoT, automation, and machine learning, while enabling new developments in plant science for future generations.”

For more information:

Talia Pinzari

Tel: +1 (781) 635-6392

Email: talia@pinzaripr.com

www.freightfarms.com

Publication date: Wed 12 Feb 2020

Nature Fresh Farms Becomes First Greenhouse To Offer Employees Health Services Through the weCHC’s Mobile Clinic

“The weCHC Mobile Clinic treats illness or injury but can also serve as a family doctor for our local and foreign employees seeking proactive health care,” Jeff Gagnon, Nature Fresh Farms corp

Leamington, ON (February 12, 2019) – On January 23rd the new weCHC on Wheels mobile health clinic arrived at Nature Fresh Farms greenhouse facilities delivering health services to its employees.

Nature Fresh Farms became the first greenhouse to offer the weCHC mobile clinic health and personal support services to its employees. The 38-foot bus was parked outside of their Plant 1 greenhouse offering services including diagnosis and treatment of conditions, counseling and brief intervention services, system navigation, and referrals to all employees in need.

The mobile clinic alternates between the company’s Plant 1 and Plant 2 facilities every week providing on-site health care services. Employees can make an appointment between 10:30 AM to 2 PM with 8 slots every Thursday. Available for consultation will be a Nurse Practitioner who will provide immediate care and ongoing support as needed. A confidential service, all information will be kept on file and available for employee’s personal health services to access.

“The weCHC Mobile Clinic treats illness or injury but can also serve as a family doctor for our local and foreign employees seeking proactive health care,” explained Jeff Gagnon, Corporate Compliance Director at Nature Fresh Farms. “Wellness is an important value at Nature Fresh Farms, and we are very appreciative to have this program offered to our employees currently at two of our locations.”

Nature Fresh Farms also provides employees and their families with workplace wellness resources through the Employee Assistance Program. EAP is a voluntary program providing specialized services, at no cost to employees, through qualified professionals and experts such as counselors, financial consultants, health professionals, and lawyers. It has become a very successful service used by many of our employees and their families. Nature Fresh Farms hopes that programs such as EAP and weCHC on Wheels will give its employees greater accessibility to healthcare services.

“The programs we offer at Nature Fresh Farms are meant not only to attract and maintain employees but to provide them with the best possible care,” shared General Manager of Nature Fresh Farms, John Ketler. “We understand that many of our employees are busy balancing work and home life or coming from abroad that are in need of convenient forms of access to healthcare. This mobile unit brings a convenient, simple and quick way to provide diagnosis and care of what they may be experiencing.”

Nature Fresh Farms is committed to addressing and understanding the needs of their employees by investing in their wellbeing through these programs. Offering both physical and mental health assistance, they hope to continue making the workplace a happier, healthier, and more productive place to work.

About Nature Fresh Farms

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

A.G. Kawamura Joins Board of Indoor Growing Tech Company

“A.G.’s extensive expertise in innovative farming and sustainable agriculture will be invaluable to the Agt3 Holdings Board,” CEO Ed Horton said in the release

February 7, 2020

Agt3 Holdings, a Laguna Niguel, Calif., indoor vertical growing technology company, has appointed former California Secretary of Agriculture A.G. Kawamura to its board.

Kawamura, who led the California Department of Food and Agriculture from 2003-10, is a founding member of Orange County Produce. The Agt3 Holdings board is made of agriculture industry leaders with “unparalleled experience and expertise in sustainable, economically strong urban farming,” according to a news release.

“A.G.’s extensive expertise in innovative farming and sustainable agriculture will be invaluable to the Agt3 Holdings Board,” CEO Ed Horton said in the release.

Kawamura is involved in numerous agriculture groups and is a co-chairman of Solutions From the Land, a member of AGree Initiatives’ Ag Advisory Committee, a member of the Board on Agriculture and Natural Resources, a Western Growers board member, a member of the advisory committee for the Agricultural Sustainability Institute at the University of California-Davis, and a trustee for the Council on Agriculture, Science, and Technology.“

With the rapid expansion of urban agriculture, innovative vertical farms like Agt3 Holdings offer a solution to the changing landscape,” Kawamura said in the release. “I look forward to collaborating with Ag t3 Holdings and its board of like-minded visionaries.”

Lead Photo and logo courtesy Agt3 Holdings; graphic by Amelia Freidline )

Related Topics: Greenhouse Produce Tech

Soup-To-Nuts Podcast: Crop One Farms Rises To Meet Demand For Nutrient-Dense Produce With Vertical Farms

The quickly emerging vertical or indoor farming sector often is touted for its environmental sustainability, but according to ongoing research conducted by one of a player in the space, produce grown indoors also offers notable health benefits to people beyond those which are farmed outdoors

31-Jan-2020 By Elizabeth Crawford

The quickly emerging vertical or indoor farming sector often is touted for its environmental sustainability, but according to ongoing research conducted by one of a player in the space, produce grown indoors also offers notable health benefits to people beyond those which are farmed outdoors.

The Growing Technology of The Future on Master Chef Sweden

Now the smart farming technology of the future is making a real entry into the Swedish households via TV

January 22, 2020

Now the smart farming technology of the future is making a real entry into the Swedish households via TV.

The chefs participating in the popular TV4 program Master Chef Sweden spice up their dishes by harvesting vegetables directly from the hydroponic herb-wall, installed in the studio. The system is supplied by foodtech company Swegreen.

Master Chef Sweden is one of Sweden's most popular television programs with viewership figures of around 1.3 million per episode. The program runs on TV4, and celebrates its 10th anniversary this year. To spice up the decade anniversary season, the production company Meter Television together with TV4 decided to let the competing chefs harvest vegetables on-site while broadcasting.

Hydroponic growing technology builds upon crops growing in vertical planting systems without the use of soil, where nutrients are added and solute into the irrigation water. The technology allows for cutting down up to 99% of the water consumption figures compared to traditional farming. Swegreen has installed two hydroponic green walls in the studio of Master Chef Sweden, one with leafy greens and diverse salads and one with different herbs and spices.

Swegreen runs one of Europe's largest fully circular and smart urban farming facilities, at Kungsholmen in central Stockholm on floor -3 of the iconic Newspaper Tower, DN.

- The new hydroponic and vertical farming technology enables the cultivation of greens and herbs in the urban environment and creates great settings for sustainable and local food production. At our facility, we can recycle both water and nutrients as well as energy by the help of our advanced technology; and of course, we distribute our products locally to avoid unnecessary transportation, says Swegreen's CEO, Andreas Dahlin.

- To begin with, we are proud of the collaboration with Master Chef Sweden and for allowing the TV audience to see and get to know about the herb-wall in one of the country's most popular TV programs. In addition, we hope to raise consumer awareness over the sustainability issues in our mainstream food chains and that food could be produced close to where it is consumed, says Andreas Dahlin.

SweGreen is an innovation and technology company providing futuristic, smart and circular solutions for controlled-environment urban farming which enables vertical farming entrepreneurs to use it under a licensed model, by the help of remote monitoring and data-sciences.

For more information:

Andreas Dahlin, CEO, andreas.dahlin@swegreen.se +46(0)709-240032

Sepehr Mousavi, Chief Sustainability Officer, sepehr.mousavi@swegreen.se +46(0)733-140033

US: Florida - Making Microgreens A Household Word

In The Box, which is a completely retrofitted shipping container, Rodriguez sustainably grows an assorted variety of herbs and microgreens, using a minimal amount of water, energy, and soil

January 30, 2020

These broccoli microgreens are 40 to 50 times higher in nutritional value than the conventional form of broccoli. LOIS KINDLE PHOTOS

Farmer Seeks To Make Microgreens

A Household Word

By LOIS KINDLE

Eco-farmer Dario Rodriguez shows the container he uses to sell a variety of microgreens he sustainably grows at The Box Eco-Farm in Ruskin.

Dario Rodriguez wants the whole world to know about the nutritive value of microgreens, but for now, he’ll settle for South Shore and surrounding areas. LOIS KINDLE PHOTOS

The owner of Sustainable Eco-System LLC began his quest to make organic microgreens more mainstream by establishing The Box Eco-Urban Farm and setting it up at the Circle Pond Tiny Home Community in Ruskin last December.

In The Box, which is a completely retrofitted shipping container, Rodriguez sustainably grows an assorted variety of herbs and microgreens, using a minimal amount of water, energy, and soil.

“(The Box) allows for the maximum production of highly nutritional food in the smallest amount of space,” he said. “That’s what makes us eco-farmers.”

As part of his sustainability mission, Rodriguez sells only locally to individuals, restaurants, nutritionists, and chefs. His service area is South Shore, Brandon and some parts of south Tampa.

“To avoid the use of fossil fuels, I would rather place another box in Wesley Chapel, for example, rather than make deliveries there,” said Rodriguez, 49. “We do not ship what we grow.”

Microgreens are green, tiny vegetables with high concentrations of flavor and nutritional value. For example, broccoli microgreens are 40 to 50 times higher in nutritional value than the conventional form of broccoli, Rodriguez said.

Rodriguez’s wife, Iliana, helps him sell microgreens at the Firehouse Cultural Center in Ruskin.

Currently, he is growing broccoli, basil, red cabbage, peas, cilantro, arugula, parsley, kale, radish, sunflower, wheatgrass, and fennel Greek and mustard kohlrabi – all as microgreens. About 48 veggies can be grown as microgreens, Rodriguez said.

“When you buy microgreens from us, I like to tell you about their nutrients and health benefits, which have been acknowledged by the FDA,” he said.

The farmer also likes to tell you about their uses.

“Microgreens can be used in salads, sandwiches and as a topping for soups, pasta, eggs, and rice,” he said. “You don’t cook them; they’re tender without heat.”

Although Rodriguez and The Box are new to the area, he already has many satisfied customers.

“I bought four boxes last week: salad mix, broccoli, arugula, and radish,” said Dee Hood of Ruskin. “I use them on salads, and they’re so good, I just cut and eat them on their own.

“My teenage granddaughter and her boyfriend had some for lunch and loved them,” Hood continued. “I knew they were good for you, but I had no idea they would taste so good.”

Wheat grass, foreground is one of many microgreens Rodriguez currently grows in The Box.

Rodriguez uses high-density seeds in an organic growing medium like jute. In The Box, he’s able to control all of the production parameters: temperature, airflow and the humidity content of the air. The urban farm has a capacity of 720 10-inch by 20-inch trays of microgreens.

Rodriguez and his family moved to Ruskin from Argentina in 2016, when one of his three daughters began studying international business at the University of Tampa.

“We came as a two-year adventure,” said Rodriguez, who earned a master’s degree in global sustainability in 2018 from the University of South Florida. “But we’ve been here almost four years now, so we’ve decided to stay.”

He has invested $124,000 thus far between the Ruskin location and another at Fat Beet Farm in Oldsmar, where he grows mushrooms.

This is the completely retrofitted shipping container Rodriguez located at the Circle Pond Tiny Home Community in Ruskin to grow his microgreens. The Box allows him to produce the maximum amount of highly nutritional food in the smallest amount of space.

Rodriguez sells his microgreens for $3 per box, which is well below what you’d pay at a commercial establishment, and because they’re grown in an organic medium you can harvest as needed and they last longer.

Every Friday, you can find him set up at the Firehouse Cultural Center from 11 a.m. to 2 p.m. Microgreens can be preordered, paid for and picked up there.

To do so, call 813-416-5444, email sustainableecosystems@gmail.com or visit www.sustainablemicrogreens.net.

Facebook Twitter Share

Minette Batters To Deliver The Keynote Address

Minette Batters is the first female president in the 112-year history of the National Farmers' Union. She has been called the most powerful farmer in the UK. Join us as she shares her insights into one of today's most pressing agricultural issues

Minette Batters is the first female president in the 112-year history of the National Farmers' Union. She has been called the most powerful farmer in the UK. Join us as she shares her insights into one of today's most pressing agricultural issues.

"How Farming Can Help Mitigate Climate Change"

Minette Batters

President

National Farmers' Union

Farming and food are much maligned as a problem of the modern age, but it’s rarely recognized for its adaptability and phenomenal successes. For too long, farming has been on the wrong end of the climate debate, rarely recognized for its role in the carbon cycle and even more rarely recognized for the enormous potential of agriculture to deliver a range of solutions for mitigating anthropogenic carbon emissions.

The NFU has a vision for UK agriculture to have a Net Zero contribution to climate change by 2040. The NFU is optimistic about the future role of farming in producing climate-friendly food, protecting the environment and fulfilling our moral imperative to produce safe, sustainable and affordable food at home and for our customers overseas. Ms. Batters will present the NFU vision, industry action and the critical need for the government to get agricultural policy and trade policy aligned.

US: Local Bartender Opens Hydroponic Farming Company In Patchogue New York

Mahony told GreaterPatchogue that hydroponics is a forgiving style of farming because you can fine-tune the plants by adjusting nutrient levels, the light intake, and how acidic or basic crops are. “You can ‘hack the plants,'” he said. “You can change the flavor profiles by changing these factors.”

February 5, 2020

Many locals in Patchogue know Cory Mahony for his skills behind the bar at James Joyce Pub.

What most don’t know is after his late-night shifts, he heads a few blocks west in the village to a 1,000-square-foot building.

There, he takes his bartending gear off and begins his passion work as a hydroponic farmer.

For the uninitiated, hydroponics, known as vertical farming, is a growing style using technology to produce food in a “controlled, soilless setting,” according to the U.S. Department of Agriculture.

“With hydroponics, you use 90 percent less water than traditional farming and everything grows 50 percent faster,” said Mahony.

The 24-year-old first learned of the style while flipping through a Forbes Magazine article.

“I read about it a couple of years ago,” said Mahony. “I thought it was so cool, so fascinating.”

So he began doing his due diligence. He bought books and spent countless hours researching online.

He remembers the first thing he ever grew in his parents’ house in Holbrook.

“It was basil,” he said. “It actually came out really good.”

Then he made arugula. Then butterhead lettuce.

He shared his yield with his friends and family, and they all loved it.

“I felt I can do it after that,” he said.

Mahony told GreaterPatchogue that hydroponics is a forgiving style of farming because you can fine-tune the plants by adjusting nutrient levels, the light intake, and how acidic or basic crops are.

“You can ‘hack the plants,'” he said. “You can change the flavor profiles by changing these factors.”

After graduating from Stony Brook University with a degree in business and entrepreneurship, he began his work as a bartender. His goal was to stash away as much cash as possible so he could move his growing operations to a larger location.

After two years, Mahony found the perfect spot for his company, Urban Fields Agriculture, at 37 Bransford Street in Patchogue.

“It was 2 a.m. at [James Joyce] and a real estate agent was at the bar,” Mahony said. “She pulled out the MLSLI app, we saw the spot, and I checked it out first thing in the morning.”

He officially moved into the space three months ago.

He’s growing what made him famous amongst friends: basil, arugula, and lettuce. Mahony also grows nutrient-packed microgreens. And everything is organic and GMO-free, he says.

“You can grow anything, too,” added Mahony. “I’d like to stick to the leafy greens because they grow faster.”

Urban Fields Agriculture’s first harvest was last month.

He plans to sell his products to local restaurants and, eventually, nearby supermarkets.

Dave Chiarella, co-owner of PeraBell Food Bar in town, is a big fan of Mahony’s work.

“The basil is delicious and beautiful,” said Chiarella.

The Main Street restaurant uses the local farmer’s crops in its cocktails.

“We make a nice bourbon drink with them and named it the Urban Bourbon,” added Chiarella.

As he continues to grow his business, Mahony looks forward to filling the nearby eateries with his freshly-grown products.

“There can be a blizzard outside and I am still coming with your locally, grown order,” said Mahony.

To learn more about Urban Fields Agriculture, click here.

Scroll down for photos.

The soilless crops at Urban Fields Agriculture

Cory Mahony at his 1,000-square-foot farming facility in Patchogue

Cory Mahony plucking some basil

Argula growing at Urban Fields Agriculture

Cory Mahony harvests his first basil in Patchogue

Nicholas Esposito Content Manager

Nick Esposito is Greater Long Island's content manager and an award-winning journalist who studied at St. Joseph's in Patchogue. If you have story ideas, please email him at nicholas@greaterlongisland.com.

Partnership Brings Container Farms To Students Across The U.S.

Freight Farms and Sodexo have partnered to bring hydroponic vertical farming technology to schools and universities across the U.S. The collaboration will usher in the implementation of Freight Farms’ Greenery container farms to campuses across the U.S., enabling the onsite growth of fresh, traceable produce year-round

Freight Farms and Sodexo have partnered to bring hydroponic vertical farming technology to schools and universities across the U.S. The collaboration will usher in the implementation of Freight Farms’ Greenery container farms to campuses across the U.S., enabling the onsite growth of fresh, traceable produce year-round.

“Students, institutions, and corporate businesses want healthy, safe, and delicious food, and they want it sourced as sustainably as possible. Sodexo is proud to use and support the latest agricultural technology to create meaningful food system change," said Kenny Lipsman, Director of Produce Category for Sodexo. “Our partnership with Freight Farms allows us to grow nutritious, superior-quality food on-site for our clients, just steps from the kitchens and serveries.

As part of Sodexo’s Better Tomorrow Commitments, developed in accordance with the United Nations’ Sustainable Development Goals, this technology allows for traceability, reductions in food waste, and year-round crop consistency.”

Co-founder and CEO of Freight Farms Brad McNamara, continued, “Sodexo’s commitment to offer onsite food production to its customers helps accelerate food system decentralization — leading the charge for better sourcing practices at an institutional level. Sodexo’s adoption of Freight Farms on-site programming will demonstrate to their customers and client communities the positive impact hyper-local food production can have on priorities from nutrition and food safety to emissions reduction.”

For more information:

Freight Farms

www.freightfarms.com

Sodexo

www.sodexo.com

Publication date: Wed 29 Jan 2020

Join The FarmTech Society And Help The CEA Industry Grow

FTS strengthens the CEA sector as it develops and implements resilient, circular methods and technologies for indoor growing

The FarmTech Society has enjoyed a flying start to its activities in 2019. FTS is designed and built as an industry association for the benefit of the Controlled Environment Agriculture industry, with a mission to unite and support the Controlled Environment Agriculture (CEA) industry. FTS strengthens the CEA sector as it develops and implements resilient, circular methods and technologies for indoor growing.

Highlights of FarmTech Society’s first year include

FarmTech Society was officially registered

ASBL (non-profit in Belgium) with a transparent governance structure

Formally established the board of directors and created an advisory board

Developed our policy Advocacy efforts in the EU

Registered FTS as an EU advocacy organization, the only one with a focus on CEA

Included as Horizon 2020 EU project

Initiated Urban Heat Island Mitigation working group

Started Educational activities

Founded the international FTS education committee

Included as a partner in the Erasmus+ EU project partner PonicsVET

Partnering with the Vertical Farming field lab in the Westland

Made big steps forward in the certification of indoor farmed produce

Initiated the B2C certificate with Global G.A.P., an international standard for indoor farmed produce

Developed the FTS Network

Co-organized 5 international events, workshops and conferences

Attracted membership from 16 countries covering most continents

Selected by RAI/GreenTech as a preferred partner

Partnered w1ith Indoor Ag-Con, PublicGoodAg, and Ponic Jobs

The FarmTech Society has four focus areas. Firstly, we support the education of farmers of the future by engaging in initiatives that develop courses and create credentials that meet industry needs. Secondly, we engage with policymakers to help develop and promote policies that foster innovation and support CEA businesses. Thirdly, we support the establishment of standards and best practices that help the industry grow and innovate. Finally, we provide an international network for our members.

Join the FTS! Find us at farmtechsociety.org

Vertical Farming Provides A Different Approach To Raising The Foods We Eat

Inspired by a growing population, shrinking farmland and more people living in urban areas – the future of farming may have already arrived

Feb 04, 2020

By: Kai Beech

Inspired by a growing population, shrinking farmland and more people living in urban areas – the future of farming may have already arrived.

Tucked away in an industrial area of Lakewood, Colorado, is an agricultural oasis called Infinite Harvest.

“What we got is our butterhead lettuce what we sell as a living product with roots attached to it,” said James Romano, who operates Infinite Harvest – a vertical hydroponic garden where they produce big yields in a relatively small space.

“We’ve got a 5,000-square-foot footprint in that we’ve got a little over 30,000 square feet of growing space, which allows us to manage about 52,000 heads of lettuce and about 8,000 square feet of microgreens,” he said.

Instead of growing goods in soil and under the sun, Romano produces plants underneath the glow of LED lights with water putting nutrients into their roots.

He says this controlled environment isn’t impacted by weather and changing seasons – which allows his team to harvest nearly year-round while using a lot less water.

“Your conventional farming is using hundreds of gallons of water to irrigate versus we recycle our water,” Romano said. “We treat it. We recirculate our water on a daily basis.”

More vertical gardens are sprouting up across the country and going to places like Leevers Locavore grocery store where they sell greens that are grown inside vertical farms.

It’s all clearly marked so you know when you’re buying some nontraditional fruits and vegetables.

Though indoor-grown produce is pricier than even organic options, store manager Chris Franklin says they’re well worth the extra cost.

“Absolutely I think it’s worth. You look at just the nutrition density,” he said. “I love the fact that they’re local, even hyper-local.”

At the University of Colorado Boulder, they have a vertical greenhouse attached to their on-campus dining hall.

“We’re using all student labor and we’re growing about 60 to 100 pounds and we’re harvesting that amount weekly,” said Alex Macmillan, CU Boulder’s farm manager.

Macmillan calls this an academic advancement of agriculture and a way this college can decrease its carbon footprint while increasing its production.

“Students look in their every day and they can see the progress,” he said. “Everyone likes eating stuff that’s good for them and that tastes good and is fresh and that’s what we’re able to provide.”

Vertical farming is taking produce to new heights by providing ultra-nutrient dense food while also conserving precious natural resources.