Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Abu Dhabi Prepares For The Future of Food

This is a historic year for Agriculture Technology (AgTech) in the UAE. This March the Abu Dhabi government approved an AED 1 billion package to support the AgTech sector

This is a historic year for Agriculture Technology (AgTech) in the UAE. This March the Abu Dhabi government approved an AED 1 billion package to support the AgTech sector. The package is part of Ghadan 21 (Tomorrow 21), which is a three-year AED 50 billion program designed to accelerate the capital’s economic growth and reduce dependency on oil revenues. It is led by the Abu Dhabi Investment Office (ADIO), which was created in 2018 with the mandate to increase foreign direct investment. In this article, we are going to take a deep dive into the initiative.

What is it?

The stimulus consists of cash and non-cash benefits, which include rebates of up to 75% of R&D costs subject to eligibility and commercialization criteria.

Who is eligible?

Local and international companies are eligible. The program is focused on three specific sectors in the AgTech industry that have been identified for their strategic significance: precision farming and agriculture robotics, indoor farming, and bioenergy (algae).

But why?

The government has taken this major decision primarily for three reasons.

Firstly, the government seeks to establish Abu Dhabi as a global center for innovation in agriculture, especially in desert environments. This is achievable because the AgTech industry is in its early stages globally. As such, there is an opportunity to become global leaders if we become knowledge exporters. R&D is underfunded globally, which is why the initiative targets R&D and seeks to attract the best talent from around the world.

Secondly, agriculture is a high-risk industry due to the sheer number of variables that cannot be controlled, which is why governments around the world provide various levels of assurances and support. AgTech promises to decrease these risks in the medium term. However, developing and localizing these solutions to the UAE’s environment adds a degree of complexity. This is why the government’s initiatives are crucial for the success of this industry as a whole.

Finally, the government recognizes the urgency of addressing food security and diversifying the economy. Currently the UAE imports over 90% of its food, and the country’s population is forecast to increase from today’s 9.4 million to 11.5 million by 2025. Demand for food, especially high-quality produce, is set to rise sharply. A booming AgTech industry should meaningfully reduce dependence on imports.

What is expected?

Like any investor, the government seeks the highest return for its investment. The government measures success by analyzing which initiative will have the largest GDP multiplier (i.e. where 1 AED will generate the biggest knock on effect). In addition to reducing dependency on food imports and oil revenues, the package is expected to generate a contribution of AED 1.65 billion to the GDP and create more than 2,900 jobs in Abu Dhabi by 2021.

Are there any other benefits?

In addition to funding R&D, the initiative allows it to be easy to setup in AD with world-class infrastructure etc. and attract global level talent here to make UAE a global center of excellence for this industry.

Additionally, …

Government funding alone does not ensure success. Regulations need to keep pace with technological and commercial innovation. The ADIO acts as a bridge for industry to discuss the regulatory environment. These discussions have played in a key role in recent regulatory changes for the agricultural industry.

The Abu Dhabi government consolidated regulation of the agriculture sector through the establishment of the Abu Dhabi Agriculture and Food Safety Authority (ADAFSA). This new organization has taken on the roles of the Abu Dhabi Food Control Authority, the Abu Dhabi Farmers’ Services Centre, and the Food Security Centre – Abu Dhabi. It is responsible for overseeing agriculture, food safety, food security, and biosecurity. The founding of ADAFSA is another step in accelerating the emirate’s efforts to drive scientific research and agricultural development while helping to build partnerships between the public and private sectors, according to Sheikh Mansour bin Zayed Al Nahyan, the deputy prime minister and minister of presidential affairs. He told local media:

“Food security continues to be a national and strategic priority that entails concerted actions between the government and private sectors in order to ensure a well-integrated food security strategy that is conducive to unlocking the value in the agriculture and food supply chains, and ensuring all segments of society have access to all food supplies”.

Like any new industry, businesses in the AgTech industry will inevitably discover that some aspects of the existing regulatory framework do not meet their commercial needs. This is natural as regulators cannot predict future industry requirements with 100% accuracy. However, it is encouraging to see that the government is proactive about increasing their understanding and are taking decisive actions. We are more optimistic than before about the AgTech industry’s prospects in the UAE.

For more information, please visit www.investinabudhabi.ae or follow them on Instagram, Twitter, LinkedIn and Facebook.

Digant Raj Kapoor

People Manager

Sources

Gulf News – 11 March 2019

The National – 11 March 2019

Arabian Business – 11 March 2019

ADIO Website – seen on 26 August 2019

Zawya – 15 May 2019

AgFunder News – 25 March 2019

World Future Energy Summit – 27 March 2019

This Startup Is Building A Massive Indoor Farm In A Rust Belt Steel Town

The farm, from a startup called Fifth Season, will begin selling spinach, lettuce, and other leafy greens early next year, using a robot-based system that the founders say is cost-competitive with growing and transporting the same crops from a traditional farm

Fifth Season will begin selling spinach, lettuce, and other leafy greens—all grown inside with the help of robots—early next year.

[Photo: courtesy Fifth Season]

10.22.19

In a vacant lot next to one of the last remaining steel mills in Braddock, Pennsylvania, a town just south of Pittsburgh, a massive new indoor farm is taking shape. The farm, from a startup called Fifth Season, will begin selling spinach, lettuce, and other leafy greens early next year, using a robot-based system that the founders say is cost-competitive with growing and transporting the same crops from a traditional farm.

It’s more affordable, they argue than some others in the vertical farming industry. “We looked at vertical farming and realized that the industrywide struggle to make the economics work was a huge factor, and something that would really prevent the industry from truly taking off,” says Austin Webb, co-founder, and CEO of Fifth Season, which incubated its first farm at Carnegie Mellon University. “The per-unit economics don’t work. Companies are losing money for every pound that they sell. And that obviously needs to change.”

[Photo: courtesy Fifth Season]

Like others in the space, the startup touts the advantages of growing indoors. It’s possible to use only a tiny fraction of the water that’s used to grow greens in fields; most lettuce is currently grown in drought-prone California and Arizona. (In Arizona, farmers will also soon start losing access to water from the Colorado River.) Growing indoors eliminates the need for pesticides. It eliminates food safety hazards like E. coli contamination. And if crops are grown close to end markets—in this case, restaurants and stores in Pittsburgh—it also eliminates the emissions from trucks traveling thousands of miles and the problem of less-than-fresh produce that may be more likely to be thrown out because it’s already starting to wilt. “When we look at the food distribution system, we looked at it and saw an overly complicated broken system, where no one’s connected to their food, and there’s a lot of food waste,” Webb says.

[Photo: courtesy Fifth Season]

Some past efforts at indoor farming have failed because of high costs, such as FarmedHere, near Chicago, which shut down in 2017 in part because of the cost of labor. “When you look at vertical farms and labor is 40% to 60% of their cost—labor for them is actually more than the all-in delivered cost of Western-grown field produce—it’s just not going to work,” he says. The company’s system, which it has running now at another location and which it’s recreating at the new location, uses around 40 robots. “Together, they’re completely integrated so that our facility is, in a sense, one robotic system.”

Robots plant seeds in trays and deliver trays to grow rooms, where automated systems control everything from the amount of nutrients the plants receive to the schedule of lighting and the amount of carbon dioxide in the air. When a crop is ready, it goes into an automated harvesting system, and then to an automated packaging system, and the trays are sent back to be automatically cleaned and sanitized and then replanted. “We essentially looked at it and said that we should create an automated fulfillment center,” says Webb. “The difference being that instead of pallets of boxes, it should be trays of plants.” Solar panels on the roof and a battery backup system means that the facility can continue operating even if extreme weather takes out the electric grid.

[Photo: courtesy Fifth Season]

Other companies in the industry are also developing automated systems, including Plenty, a Softbank-funded Silicon Valley startup that now has a suite of state-of-the-art custom robotics. Plenty hasn’t shared the details of the cost of its system. But Fifth Season estimates, as an example, that its own robot used for storing and retrieving plants may cost two to three times less. It also uses space more efficiently than some other companies; because everything is automated and humans don’t need to access rows of produce on scissor-lift equipment, the aisles between plants can shrink, growing more produce in the same amount of space. (The new farm is 60,000 square feet, a little smaller than the 69,000-square-foot farm run by another company called Aerofarms.) During its first full year of operation, it expects to grow half a million pounds of greens and herbs, with prices in line with organically grown produce. At that price point, the payback period of the full system will be less than two years.

[Photo: courtesy Fifth Season]

In Braddock, where the population has shrunk more than 90% since its high point in the 1920s to around 2,000 people today, the new farm can provide some new jobs, despite the automation. Three shifts a day will employ 20 workers each. “These are manufacturing-like jobs where we’ve got folks that are helping us operate our machinery,” Webb says. “We’ve got folks that are monitoring the health of the equipment. All of that is something where someone can come from a previous job and you’re not necessarily saying you’re going to do something that’s totally completely different, such as sit at a computer and write code.” As the company expands, it will also hire more engineers and plant scientists.

The startup hopes to replicate the new facility, designed as a modular system, throughout the country. “We’re able to take what we’re building in Braddock and take those blueprints and really hit the repeat button quickly,” he says.

ABOUT THE AUTHOR

Adele Peters is a staff writer at Fast Company who focuses on solutions to some of the world's largest problems, from climate change to homelessness. Previously, she worked with GOOD, BioLite, and the Sustainable Products and Solutions program at UC Berkeley, and contributed to the second edition of the bestselling book "Worldchanging: A User's Guide for the 21st Century."

You Might Also Like:

Robots are already farming crops inside this Silicon Valley warehouse

Live in your own farm in the sky in this plant-covered apartment building

Video: The most crucial advice Patreon CEO Jack Conte has for any struggling creator

SPONSORED: OLD DOMINION

How Old Dominion is using technology to better serve its customers

Vertical Farming Reaches New Heights In Germany With Fraunhofer IME

The AVF was invited to visit its member Fraunhofer IME in Aachen, Germany, one of 72 institutes of the Fraunhofer-Gesellschaft, the leading organization for applied science in Europe with over 26,000 employees and various international branches around the world

OCTOBER 22, 2019 | KYLE BALDOCK | Indoor Vertical Farming - Association

Visit to the Fraunhofer IME in Aachen: On September 4th, the AVF was invited to visit its member IME and experience their groundbreaking, innovative vertical farming technologies live on the spot.

Aachen, 04. September 2019: The AVF was invited to visit its member Fraunhofer IME in Aachen, Germany, one of 72 institutes of the Fraunhofer-Gesellschaft, the leading organization for applied science in Europe with over 26,000 employees and various international branches around the world.

The Fraunhofer Institute for Molecular Biology and Applied Ecology IME has six different sites in Germany and conducts research in the field of applied life sciences from the molecular level to entire ecosystems. Its division “Molecular Biotechnology” is located in Aachen, Germany and conducts R&D in the field of biotechnology with a strong focus on plant-based applications.

Over the last 10 years, the IME has developed and established two different vertical farming systems at the Aachen site in cooperation with the Fraunhofer IPT and IIS (à VertiPharm) as well as the Fraunhofer IML (à OrbiPlant™):

VertiPharm, a fully automated vertical farm with a strong focus on different research applications (e.g. plant cultivation, plant phenotyping, biopharmaceutical production) and OrbiPlant™, a novel and cost-efficient approach to vertical farming of food crops. These two vertical farming systems are complemented by LEDitGrow, an innovative multi-chamber system for the rapid development of plant growth protocols and the optimization of specific plant target values.

The design of the two IME vertical farming systems, their degree of automation, data management, efficiency and productivity, as well as their application and research possibilities go beyond the current state of the art of indoor farming technology. The systems provide an unprecedented basis to promote vertical farming, not only in Germany but worldwide. The different technology platforms are available for cooperation projects. Potential cooperation partners are encouraged to get in contact with IME (see below).

During a facility tour AVF had the opportunity to visit the different systems that are outlined below.

Fig.1: LEDitGROW plant cultivation unit for the accelerated multi-parameter development of plant growth protocols (© Ann-Katrin Beuel, IME).

LEDitGROW – Multi-parameter single plant cultivation system

A LEDitGROW unit comprises 24 single plant cultivation chambers, each equipped with various different LED-based light spectra including UVA. The unit has been designed to fit into a phytotron to run experiments at defined temperature, humidity and CO2 concentration. Each plant chamber can hold a single plant or several tissue culture petri dishes and can be individually supplied with nutrient solution.

The parallelization of cultivation conditions together with a statistical multi-parameter design of experiment (DoE) approach allows the rapid establishment of species-specific growth recipes as well as the optimization of specific target values such as biomass, secondary plant metabolites or morphology.

VertiPharm – Automated multifunctional research platform for vertical farming

Fig. 2: Top view on VertiPharm’s vertical farming unit (above, © AVF) and N. benthamiana plants under LED lighting in one layer of the vertical farm unit (below, © Andreas Reimann, IME).

The highlight of the IME in Aachen is the fully automated, pilot-scale vertical farming research platform featuring core functionalities such as multi-tier-based vertical farming, single plant handling, sensor-based in-process control, 2D/3D plant scanning, vacuum plant infiltration, downstream processing and central data management.

The impressive construction of the vertical farm unit consists of eight cultivation levels and provides ~550m2 of net cultivation area for the continuous or batch-wise cultivation of plants under highest reproducibility.

Different parameters such as temperature, humidity, CO2-concentration, LED-based lighting and composition of the plant nutrient solution can be defined and monitored in the central control system. Each plant receives a unique ID during seeding and is tracked individually throughout the entire cultivation time until harvest. Movement, sensor and measurement data are continuously recorded and can be used for in-process control or retrospective analysis of cultivation parameters and specific plant characteristics.

The fully automated facility can be used to produce food and non-food plants of different varieties and sizes. In addition to the vertical farming of plants a separate vacuum-infiltration unit connected to a fermentation suite allows the rapid production of recombinant biopharmaceuticals (e.g. vaccines, antibodies or enzymes) in plants by Agrobacterium-mediated gene transfer. Thanks to this multifunctionality the plant production research platform at Fraunhofer IME enables a broad spectrum of applications in different plant-based fields but also in the field of engineering, for instance:

Cultivation of food plants

Cultivation of medicinal/ specialty plants

Cultivation of ornamental plants

Production of recombinant biopharmaceuticals

Plant breeding and plant phenotyping

Software-based applications (e.g. digitization of production, artificial intelligence, augmented reality-assisted maintenance)

OrbiPlant™ – groundbreaking vertical farming system for the cost-efficient production of food crops

Fig. 3: OrbiPlantTM pilot-scale system with various leafy greens and herbs on a conveyor belt. The plant size gradually increases along the four conveyor belt loops (© Andreas Reimann, IME).

OrbiPlant™ represents an innovative approach to vertical farming of food crops that can truly make a difference to the spread and market penetration of vertical farming.

The major difference to classical tier-based approaches is a continuous conveyor belt system that is flexibly arranged in vertical loops allowing the easy placement of seeds or seedlings on one end of the conveyor system and the easy harvest on the other end. In between plants grow self-sufficiently under specific LED lighting conditions that can be adapted to the respective growth stage.

The conveyor belt movement can be specifically adjusted to a plant’s growth cycle and takes advantage of a growth-stimulating orbitropal effect on the plant, which is stemming from the changing gravitational orientation of the plant on the conveyor belt. The water-nutrient supply is ensured by aeroponic nozzles inside the belt loops. The innovative OrbiPlant system has several key improvements over current vertical farming systems:

High plant biomass yields and short growth cycles

Low production costs (e.g. <0.40 € per lettuce head)

Optimal cost-efficiency due to minimal hardware and personnel costs

Modular conveyor belt concept easily adaptable to different plants and growth cycles as well as to different building geometries

Improved vertical heat convection

Low LED lighting requirement

Flexible degree of automation depending on customer need

OrbiPlant is not only providing a cost-effective, optimized production platform for food crops with minimal space and resource requirements, but its unique design and flexibility has the potential to take vertical farming to a new level. It overcomes the shortcomings of today’s most commonly used horizontal rack systems, saves energy, utilizes intelligent automation, and enables easy handling and operation.

The AVF in cooperation with the Fraunhofer IME welcomes company and stakeholder inquiries on the presented systems.

Contacts:

Christine Zimmermann-Lössl, AVF Chairwoman

Email: czl@vertical-farming.net

Marvin Spence, AVF Project Manager

Email: ms@vertical-farming.net

Andreas Reimann, Senior Acquisition and Project Manager at Fraunhofer IME, Business Field Indoor Farming/Vertical farming

Email: andreas.reimann@ime.fraunhofer.de

Visit Fraunhofer IME’s website to learn more about them.

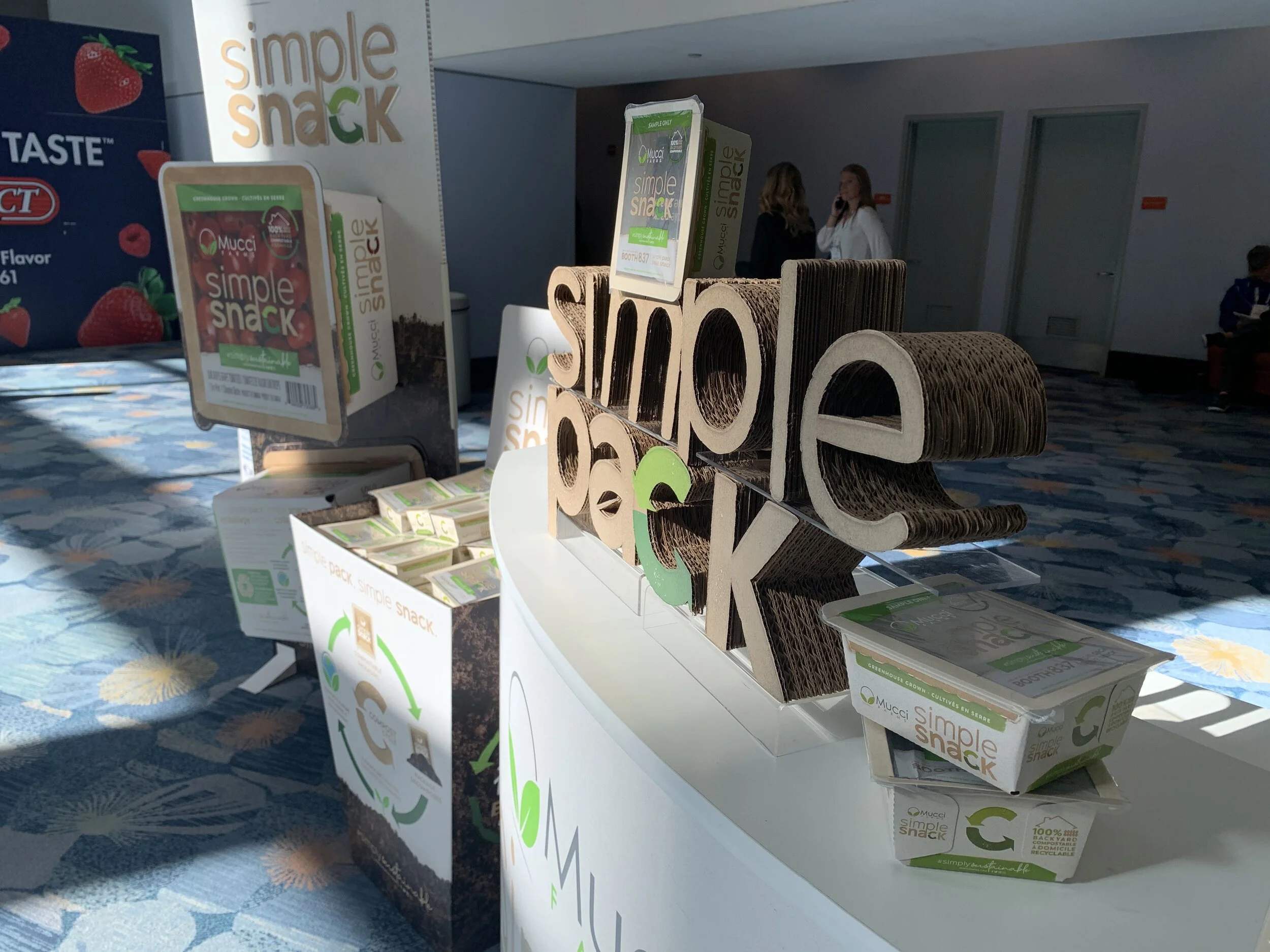

Mucci Farms Wins Best Sustainable Packaging Award At Fresh Summit 2019

“To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing

October 21st, 2019 (Anaheim, California) – Mucci Farms announces that they have been awarded the top prize for Best Sustainable Packaging at the PMA’s Fresh Summit Conference and Expo for Simple Snack, a plastic-free, backyard compostable series of packaging. “To win this category, in particular, is exciting because sustainability is by far the top of mind subject in the food industry today,” says Emily Murracas, Director of Marketing.

“We’ve been recognized in the industry for flavour and innovation over the years, so we are ecstatic to be able to package those award-winning products in a package that helps to address a global concern. It’s also very special to win in a competitive category that included submissions from packaging suppliers and fellow marketers.”

A vertically integrated greenhouse grower extensively committed to sustainability at all ends of the business, Simple Snack adds to those commitments. The package is composed of a tray made from agricultural waste and the lidding film is made of sugar-cane and wood fibers using a process that emphasizes social and environmental responsibility.

“Consumer feedback over the last several months has been almost exclusively focused on the reduction of plastic, so we feel like we’ve addressed that concern by coming up with a truly plastic-free package,” said Fernanda Albuquerque, Packaging Development Manager. “We also saw the value of being able to add key messaging to the tray which gave our designers a larger canvas for branding, information, and education.”

A dedicated partner of the Produce Marketing Association, Mucci Farms also sponsored the annual Center for Growing Talent 5k race, which seamlessly fits with their company objectives to be a health and wellness conscious brand. Race participants were served refreshing smoothies made with the Award Winning SmucciesTM Sweet Strawberries. Additionally, the company had a sampling station at the show entrance where attendees could take home a sample of their very own Simple Snack package.

On the show floor, the Mucci Farms team welcomed buyers and attendees to their world of colours that included their entire lineup of offerings including their newest item, Zingers shishito peppers and the highly sought after CuteCumber Poppers. With chefs on hand putting together a variety of flavourful samples, the Mucci Farms booth has become a featured destination every year.

The Fresh Summit Conference & Expo took place from October 18-20 in Anaheim, California.

For Info:

Ajit Saxena

Public Relations & Digital Marketing Manager

519-326-8881 Ext 2253

asaxena@muccifarms.com

New Zealand: Vertical Farming Takes Off In Former Wellington Nightclub

The lights are still there, but the moody blues have been replaced by state-of-the-art multi-colored LED grow lights. Shoots Microgreens is a start-up company growing tiny crops mainly for restaurants, but with some of the produce sold through stores such as Moore Wilson

To View The Video, Please Click Here | ROSA WOODS/STUFF

Shoots Microgreens is one of NZ's first vertical farms, housed in a former nightclub.

Once nightclub goers used to bounce off the walls of a Wellington basement, but now it's been transformed into an urban market garden supplying over 80 restaurants.

The lights are still there, but the moody blues have been replaced by state-of-the-art multi coloured LED grow lights.

Shoots Microgreens is a start-up company growing tiny crops mainly for restaurants, but with some of the produce sold through stores such as Moore Wilson.

Microgreens are the intense flavoured first shoots and leaves, and are popular among chefs and bartenders for garnishing meals and cocktails. Many familiar leaves can be used as microgreens, including mustard, basil, rocket and coriander.

Co-owner Matt Keltie started the business last year and it now employs three fulltime workers, although it is yet to make a profit.

While ostensibly a hydroponic-style system, Shoots Microgreens is marketing itself as different to such common garden businesses that have been around for decades.

ROSA WOODS/STUFF

Shoots Microgreens co-owner Matt Keltie has started a business in a former Wellington nightclub.

First, the location: vertical farms have sprung up in a number of major urban centres where the crops are grown close to where people consume them – in high rises, derelict buildings and abandoned warehouses – reducing carbon emissions and maximising unused spaces in cities.

"It's all about using an efficient production area, recycling water, and having a lower carbon footprint."

Secondly, the crops are grown without the need to cart in soil and spray the chemicals that conventional growers use to control animal pests, fungal diseases and weeds.

Thirdly, everything is recycled including the water and growing trays, and deliveries are made using e-bikes.

Keltie started the business in a garage before moving into a smaller space than where he is now. Once he had successfully realised the proof of concept and started to supply restaurants, he had enough confidence to launch the business.

The Energy Efficiency and Conservation Authority (Eeca) helped with a $12,300 investment in the special LED grow lights under its "Gen Less" campaign.

Ray McGregor delivers microgreens for company Shoots Microgreens on an e-bike. | SUPPLIED

Compared with traditional incandescent hydroponic lamps, the LEDs are cool to the touch, and can be frequency controlled to improve productivity – they grow the shoots around twice as fast as their halogen counterparts.

The LEDs conserve 45 percent more lighting electricity, saving Keltie's business about $25,000 a year on its power bill.

With customisable spectrums of light, the colour of LEDs can be adjusted to optimise the growth of each specific variety of microgreens. As they do not produce heat, they can be stacked at every vertical layer, with no risk of heat damaging plants, as with incandescent hydroponic lamps.

Every day chefs order their microgreens and are delivered or collected.

The non-soil medium the plants are grown in is a trade secret, although Keltie is planning on moving to a hemp-based medium once it becomes available.

Keltie says the taste of the microgreens is governed by the light applied to the plants – the lights are one component but managing and changing alone or all components of the growing system influences the plants.

"When I take two trays of the same plants grown under different numbers of bulbs, some chefs can tell me how they've been grown because there's a subtle difference in flavour. It's all about the mix of water and lights.

"Not only do the LEDs provide the right growing spectrums, they are hellishly efficient in terms of power."

A supplier provides the fertiliser in the right sorts of ratios but Keltie is starting to test which plants take up which nutrients, so he can apply a specific rather than a broad spectrum mix. For example, peas do not require much nitrogen.

ROSA WOODS/STUFF | . Microgreens are used as garnishes or in cocktails.

He admits there has been a lot of trial and error in the start-up period.

"When people say how far down the track are you with your learning, I say about 5 per cent, I've still got a solid 95 percent left to learn. But we hope to start soon in Auckland, once we've ironed out the issues here."

Prices start at $7.25 for a tray of peas, which grow in a little over a week, whereas slower growing red sorrel is priced accordingly higher.

Quotes from famous historical figures are mashed up in a call to arms for climate change campaign Gen Less, encouraging New Zealanders to get more out of life by using less.

Capitol Restaurant owner-chef Tom Hutchison says he buys the microgreens every day.

"It's good that they're doing well, the product is fantastic."

Hutchison is not so much a fan of the very young greens, preferring the more mature, larger leaves.

Eeca technology innovation manager Dinesh Chand worked with Keltie to help get the project off the ground.

"This project not only shows potential for LEDs to reduce electricity use and increase productivity, but is a great example of reducing transport-related emissions. In this case, supplying locally eliminates the equivalent annual carbon emissions of taking 20 cars off the road."

GETTY-IMAGES

In London. microgreens are grown in old air raid shelters beneath some of the capital's busiest streets.

Vertical farming can save up to six times the ground space that conventional farming uses. Keltie said it was not a replacement for traditional New Zealand farming yet, but was part of its future.

Eeca chief executive Andrew Caseley said the authority's intention in running the Gen Less campaign was to mobilise New Zealanders to be world leaders in clean and clever energy use.

Companies that have already joined Gen Less, include Westpac, Countdown, New Zealand Post, Stuff, Wishbone Design, Ecostore, Lewis Road, and Ethique.

"Less" refers to reducing greenhouse gas emissions from energy use. People could join the campaign by walking their children to school, switching to a more efficient car such as an EV, buying sustainable goods and services, and using LED bulbs, he said.

Indoor-Farming Company Square Roots Expands Into Michigan

Square Roots, an indoor seed-to-sales urban farm headquartered in Brooklyn, New York, will open its newest indoor farm at the Gordon Food Service headquarters in Wyoming, Michigan

September 30, 2019

An artist's rendering of the new Square Roots' indoor farm at Gordon Food Service, Wyoming, Mich. ( Courtesy Square Roots )

Today, Square Roots, an indoor seed-to-sales urban farm headquartered in Brooklyn, New York, will open its newest indoor farm at the Gordon Food Service headquarters in Wyoming, Michigan. This is the beginning of a strategic partnership that will see Square Roots’ high-tech farms built on or near Gordon Food Service locations across the continent, helping to bring hyper-local produce to customers year-round.

Link To Facebook Video - Opening of Square Roots New Michigan Farm Campus

The fact that so much has happened in just six months is credited to Square Roots’ modular, scalable farm-tech platform. The company can bring this model to any city in the world, and it can be done fast.

“As the network of farms gets larger, it gets smarter,” the company said. “Cloud-connected farms and data-empowered farmers learn from each other, enabling Square Roots to replicate success from one location to another, seamlessly. Opening the Michigan farm brings us closer to the vision of a distributed network of indoor farms, built across the world, to bring real food to people in cities while empowering thousands of next-gen leaders in urban farming.”

The opening of the new facility in Michigan has also opened up a new pool of applications for Square Roots’ Next-Gen Farmer Training Program — half of the newest applicants are from the Michigan area.

Staff for the Michigan site is already in place: Brian Mitchell, the new Farm Manager, is coming from an 87,000 square-foot indoor aquaponics facility, and the Assistant Farm Managers are Lauren Niergarth, a horticulture major from Michigan State University, and Eli Zimmer, a former Next-Gen Farmer from Brooklyn.

Lighting Research Consortium Brings CEA Community Industry-Ready Technologies

The goal of the consortium, an initiative between NYSERDA, Cornell University and Rensselaer Polytechnic Institute, with Rutgers University participating as a collaborator, is to reduce carbon emissions, Erico explains

Without light, plants can't grow. The continued advance of controlled environment agriculture means that sunlight is often supplemented and in some cases completely replaced by artificial lighting. It works well, but there's one caveat: artificial lighting can take a lot of energy. Reason enough for the New York State Energy Research and Development Authority (NYSERDA) to kickstart the Greenhouse Lighting and Systems Engineering (GLASE) consortium with $5 million in funding. That was in June 2017. What's happened since then? Erico Mattos, the consortium's Executive Director, tells us more.

The goal of the consortium, an initiative between NYSERDA, Cornell University and Rensselaer Polytechnic Institute, with Rutgers University participating as a collaborator, is to reduce carbon emissions, Erico explains. "NYSERDA saw the growth of the CEA industry, indoor farms and greenhouses, and with technologies evolving really fast, especially on greenhouse systems like lighting controls and LEDs, they realized that there's a lot of room for technology development that can help reduce the energy consumption of lighting and integrated systems in greenhouses. So NYSERDA sponsored this program with the objective to reduce the carbon emissions coming from greenhouses' electricity use by 70% from the levels of 2017."

Cornell University Greenhouse

To achieve this ambitious goal, a combination of engineering and plant physiology is used. “At Rensselaer Polytechnic Institute we work with the center for Lighting Enabled Systems & Applications (LESA). Led by Dr. Elsebeth Kolmos, LESA engineers are developing new LED research modules, new driver technologies, and spectroanalysis to optimize plant growth under LED lights. At Cornell University, a team of researchers led by Dr. Neil Mattson is developing integrated lighting control systems based on plant physiology responses to optimize crop production yield and reduce operational costs in commercial greenhouses".

Focus on food, but everyone benefits

The consortium focuses their research on food crops - they work with the following crop models:

Lettuce

Strawberry

Tomatoes

"Those are the crops we use to do research. But the outcomes of this research," Erico points out, "can be applied to any of the industries. And our outreach activities, which are not sponsored by the NYSERDA funds but paid for by membership fees, are open to the entire CEA industry. They're pretty much crop agnostic." That means cannabis or ornamental growers, for instance, can also benefit from the consortium's efforts.

And while the consortium was started in New York, that doesn't mean it's geographically limited. "We started in New York because all the founding members are here, but at this time we have members all across the US, we have 22 industry members today, including an international body of farms, in the Middle East. For now, we're establishing a base in the US, the next step is going international."

Diagram of GLASE work frame

Sharing knowledge and technology

The consortium focuses on the following types of industry members:

CEA growers

Lighting, sensing and control manufacturers

Basic manufacturers (companies that make the LEDs, drivers, etc. that go into lighting, sensing and control)

Retailers

Service providers

So what do those members actually get out of it? "Growers get all this knowledge that we are generating. With the GLASE consortium, we have more than 300 technical milestones, from the development of new LEDs to implemented systems in greenhouses."

For growers, GLASE offers knowledge and technology transfer. "The knowledge transfer happens through our outreach activities, like webinars, industry talks, industry advisory board meetings where growers come together with manufacturers and we discuss all the research that we're doing." In addition, grower members have access to the GLASE researchers at Cornell, RPI and Rutgers University.

When it comes to the technology transfer, members of the consortium have first-hand access to technology that's developed by those researchers. "If there's any IP, for example, it's disclosed to members first - they have the right of first refusal.”

GLASE Commercial pilot: SAF Produce, Berlin, NY

Practical results

According to Erico, these are exciting times for the consortium. After the start-up phase, now the time has come to start harvesting. For instance, the consortium has developed their own LED module for lighting research. They use these to research how growers can best use lighting in their cultivation. But there's also something in it for the manufacturers: "Everything we do in these research fixtures, they can take that information and use this to guide product development.”

This research is conducted in the context of the milestones set by NYSERDA, but the GLASE researchers do get feedback from industry members during quarterly meetings (two of them by phone, two of them in-person meetings) on how this knowledge can be applied practically. "For example," Erico says, "they can make recommendations on what to research next, or on how to better implement the technology we're developing into commercial facilities." Using this feedback, the researchers tweak or adjust their research to end up with a practically implementable solution. “We are working to de-risk the technology development process by validating new technics in the lab and in commercial pilot greenhouses to provide the CEA community industry ready technologies.”

GLASE Commercial pilot: Wheatfield Gardens, Buffalo, NY

For the practical implementation, GLASE is working with two commercial lettuce greenhouses in New York State: SAF Produce in Berlin, and Wheatfield Gardens in Buffalo. Both greenhouses were retrofitted with LEDs. "It is our goal to implement all the technologies that were developed by GLASE in each of those greenhouses, establishing a baseline on the energy consumption and then compare the results before and after." This is an ongoing process, and GLASE will publish the results at a later stage.

For more information:

Greenhouse Lighting and Systems Engineering

glase.org

Publication date: 9/18/2019

Author: Jan Jacob Mekes

© HortiDaily.com

Major UK Supermarket Marks & Spencer Will Launch Infarm Vertical Farms In Six More London Stores

For the last few weeks, M&S shoppers have been able to purchase fresh herbs like Italian, Greek, or Bordeaux Basil, Mint, Curly Parsley and Mountain Coriander. The herbs are sold with their roots attached to maintain freshness

October 18, 2019

Infarm display of herbs at Marks & Spencer's Clapham Junction store in London | STEVE AGER

Elizabeth Rushe Contributor

I write about sustainability and food innovation in the EU.

“We believe that by offering produce grown and harvested in the heart of city, that's how we want to practise this form of agriculture - resilient and sustainable and beneficial for the planet, while meeting the needs and desires of city dwellers like Londoners,” Co-founder of vertical farming start-up Infarm, Osnat Michaeli, told me yesterday on the phone from London, speaking about Infarm’s new partnership with UK supermarket Marks & Spencer.

Marks & Spencer is a much-loved retailer in the UK, which was established 134 years ago and is known for high-quality clothing, homewares, and food products. Infarm’s hydroponic vertical farms will be launched in six more Marks & Spencer stores in central London by the end of the year, following the initial launch at the 105-year-old Clapham Junction location in early September, which has been reopened as a food hall.

For the last few weeks, M&S shoppers have been able to purchase fresh herbs like Italian, Greek, or Bordeaux Basil, Mint, Curly Parsley and Mountain Coriander. The herbs are sold with their roots attached to maintain freshness. Infarm chose London for this rollout because it represents many of the sustainability challenges that people will experience in cities over the next decade, Michaeli told Forbes.

Each of the individual hydroponic farms are cloud-connected and remotely controlled by the Infarm central farming platform, "Our farmer in the cloud," Michaeli explained. Twice a week, “infarmers” visit the farms in-store to harvest and pack the mature plants, and place new seedlings in the system.

Infarm is a Berlin-based vertical farming start-up founded in 2013, which raised $100 million in Series B funding earlier this year. With over five hundred of their hydroponic vertical farms in supermarkets (like Metro in Germany) and distribution centres around the world, which grow 200,000 plants each month, the huge number of plants and cloud-controlled system gives Infarm a vast amount of data to work with. “We improve our growing recipes on a week to week basis,” Michaeli said.

According to Infarm’s website, their vertical farms use 95% less water than soil-based farming, take up only 0.5% of the space, use zero chemical pesticides, need 90% less transportation and 75% less fertiliser.

This partnership with M&S is a model of Infarm’s goal to disrupt the supply chain, by getting rid of it. “We're redefining the entire food supply chain from start to finish,” Michaeli told me, “Instead of building huge scale farms outside of the city and then distributing produce, our approach is to distribute the farms themselves throughout the city, bringing the nutritional produce to consumers right at the point of sale.”

Other retailers in the UK are also committing resources to vertical farming. Ocado, the online supermarket, announced earlier this year that they are investing £17M in vertical farming, and the high-end department store John Lewis also shared plans to grow salads in their supermarkets with the help of LettUs Grow.

Infarm also hopes to work closely with farmers across the UK as they grow their presence there. “I believe that local producers and farmers are now and will continue to be vital to food supply needs in communities everywhere,” Michaeli says, “I hope that we can all work together to tackle some of these problems.”

I’m a freelance writer from Ireland, based in Berlin. I’m interested in the future of food and how we’re going to feed the world in the decades ahead. To learn about what exactly is going on in the soil, I spent a year training in organic horticulture in 2014, growing the likes of pumpkins, tomatoes -- and of course potatoes -- in the wilds of the northwest of Ireland. This year of training made a huge impact on me and within a few months, I changed my diet to plant-based. My background includes working for startups in Berlin and my writing on food innovation and sustainability has been published by Vice, Pacific Stand and Paste Magazine.

HYVE To Exhibit At MISSION TOMORROW - On Display Will Be Indoor Farming For The Future

Indoor farming is in its infancy but holds great promise for the future. HYVE is positioned to be a leader in the industry and its systems promise to not only alter the way the world grows fresh crops and feeds people using smaller geographic footprints but also serves as systems that create jobs

HYVE Indoor Vertical Farming Systems is pleased to be an exhibitor at MISSION TOMORROW on October 23rd and 24th at the Richmond Raceway in Richmond, Virginia. MISSION TOMORROW brings together nearly 150 businesses and organizations from across Central Virginia and the Greater Richmond, Virginia Area to introduce an estimated 12,000 7th grade students to the opportunities for education and employment in the future.

Sponsored by many fine companies including Dominion Energy, Altria, Kings Dominion, Facebook, CarMax, and gsk Pharmaceuticals, among others. According to its site MISSION TOMORROW says, “This fun event is designed to introduce the next generation of the local workforce to a variety of career opportunities available in the region through interactive engagement with the exhibitors.”

Indoor farming is in its infancy but holds great promise for the future. HYVE is positioned to be a leader in the industry and its systems promise to not only alter the way the world grows fresh crops and feeds people using smaller geographic footprints but also serves as systems that create jobs.

According to Alia Clements, Program Manager for HYVE: “Vertical farming is a positive influencer and disrupter when it comes to providing fresh, healthy food and other crops for a growing population. Our systems are an example and precursor for an industry trend that will supplement traditional farming in meeting the world’s food needs. We are very interested in participating and educating people at MISSION TOMORROW because many students or even the general public have no idea just how dynamic and positive vertical farming can be for future generations.”

She adds: “We have targeted education as a market for our smaller indoor farming hydroponic systems known as LF-ONE or “Little Farm” because it teaches many of the

STEM elements needed in classrooms with a very positive hands-on approach. We’ll be showing and actual LF-ONE unit at MISSION TOMORROW along with a video on our large- scale complete hydroponic systems for commercial growers.”

Ken Bryant, Director of Marketing for HYVE says “Vertical farming holds tremendous promise for commercial farming both today and especially in the future. Twenty years from now it is likely to be very common to see crops grown indoors year-round in spaces that take much less real estate, deliver excellent return-on-investment for the growers,

and provide consumers with a healthy choice for fresh food. Add-in that our systems eliminate the need for harmful pesticides and herbicides and create an environment where crops can be grown year-round with great predictability and you can see why this is a very exciting industry. We believe HYVE is positioned to be a leader in this field because we differentiate ourselves from others with our complete system that provides all the elements needed for indoor vertical farming. Students now in the 7th grade can be leaders in this industry and at the forefront of doing something very special, that will influence generations to come as we build a better world together. MISSION TOMORROW is one platform to help educate those students on how they can be change agents.

HYVE systems are 100% hydroponic, use LED grow lighting, and thus use fewer natural resources and reduce carbon footprint. By growing indoors many of the elements of nature that plague traditional crop harvest can be mitigated. With vertical indoor farming, factors such as floods, droughts, and things of that nature are not factored in the food supply chain.

HYVE head grower Paul Edmondson is very excited about the future of indoor farming and all that the method offers. He says “For many years I have grown crops and have been subject to many uncontrollable forces of nature. Predictability, quality of crops, cost evaluation - all these have been things that are out of control many times for traditional farmers and their conventional methods. Indoor contained environment agriculture will not supplant traditional methods but will give farmers a great advantage moving forward to help them achieve a real measure of controlled, predictable growth. I have personally grown more than 60 varieties of plants in our labs using our systems and am confident that HYVE indoor farming systems will be something exciting for the industry and world of growing.”

MISSION TOMORROW counts among its collaborators the Richmond Chamber of Commerce and more information on the event can be found at https://www.chamberrva.com/programs/mission-tomorrow/.

Information on HYVE systems can be found at www.growhyve.com.

Paris Is Turning Abundant Car Parks Into Underground Farms

Falling ownership in car sales in Paris has increased the space of abandoned car parks in the city. This venture has taken a green turn as the city is transforming old car parks to grow mushrooms or even salad

Falling ownership in car sales in Paris has increased the space of abandoned car parks in the city. This venture has taken a green turn as the city is transforming old car parks to grow mushrooms or even salad.

Paris had built too many underground car parks in the 1960s and 70s, when the city tried to keep with the mushrooming housing blocks, building underground parking for residents hence became inevitable.

Sources allege, beneath Paris there are millions of square meters of car park. Figures however allege, a steady decline in car ownership in Paris, a trend which city authorities are keen to encourage. The drop in the number of car owners is also attributed to the new, convenient cab and bike services to move around the city.

As a result, some of the car parks find themselves surplus to the requirements. The city is hence calling for new ideas which can transform Paris’s underground to reveal its full potential. A number of competitions have taken place with this focus.

Urban farmers - Cycloponics were selected as one of the winners for rejuvenating three car parks in Paris. One of their projects was the redundant La Chapelle, a no-go area used by drug dealers and prostitutes. The space now is however blooming. The group made the space conducive for cultivating main crop: oyster, shiitake and white button mushrooms. They also grow chicory, a northern French delicacy that grows in the dark.

The produced harvest is sold through nearby organic grocery stores, which also means urban food is grown and consumed within a short distance. This method also reduces the pollution that comes along with the transportation.

In France there are a lot of regulations around operating a business underground not least for security reasons. Other businesses have been rejected for applications. Permits for such kind of farming have however been possible.

The city’s car parks are as a result experiencing a green makeover.

Posted in Environment, NewsTagged Paris, underground farms

CubicFarm® Systems Corp. Announces The Appointment of Vice President, Investor Relations and Corporate Communications

Ms. Lim has more than 10 years’ experience in investor relations and corporate communications for public and private mineral resource and technology companies, providing support in areas such as corporate financing, media relations, public relations, branding, regulatory compliance and event management

Vancouver, BC – (AccessWire – October 18, 2019) – CubicFarm® Systems Corp. (TSXV: CUB) (“CubicFarms” or the “Company”) announces that it has appointed Kimberly Lim as Vice President, Investor Relations and Corporate Communications. Her responsibilities will include the execution of comprehensive investor relations and corporate communications strategies and assisting the Company with its objective of growing and diversifying its shareholder base.

Dave Dinesen, CEO of CubicFarms commented: "We are delighted to have Kimberly join our team. She brings an exceptional background and perspective to this dual role, and we look forward to her contributions in helping to inform our stakeholders about all the great work underway at CubicFarms.”

Ms. Lim has more than 10 years’ experience in investor relations and corporate communications for public and private mineral resource and technology companies, providing support in areas such as corporate financing, media relations, public relations, branding, regulatory compliance and event management. Ms. Lim holds a Bachelor of Arts in Psychology and Economics from the University of British Columbia.

Ms. Lim is eligible to purchase the Company’s stock options pursuant to its stock option plan. The appointment remains subject to regulatory approval.

Neither the TSX Venture Exchange nor it’s Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Singapore Airlines Introduces A New “Farm-To-Plane” Food Range In Business Class

At the beginning of this month, Singapore Airlines began partnering with AeroFarms to have a fresh produce supply for its business class meals out of Newark Liberty International. Don’t let the name fool you – the company name has nothing to do with aviation

by Chris Loh

October 13, 2019

At the beginning of this month, Singapore Airlines began partnering with AeroFarms to have a fresh produce supply for its business class meals out of Newark Liberty International. Don’t let the name fool you – the company name has nothing to do with aviation. Rather, it’s because the ‘farm’ uses aeroponic technology. At its facilities, food is grown in vertically stacked layers just miles from Newark’s airport. This will allow Singapore Airlines to deliver a high-quality dining experience with incredibly fresh ingredients.

The produce will be served only to business class passengers flying to Singapore from Newark. Photo: Singapore Airlines

The farm to plane concept

“We wanted to be more sustainable and reduce our carbon footprint by using hyper-local produce, and we wanted the in-flight food to taste as vibrant as possible,” he says. “We’re always trying to innovate when it comes to on-board dining so AeroFarms was a great fit.” -Antony McNeil, Food and beverage director for Singapore Airlines.

This farm-to-plane concept has been in development internally at Singapore Airlines for nearly two years. This adoption has two aims: enhanced passenger experience and a lower carbon footprint.

Exclusive to passengers with a business class ticket from Newark to Singapore, guests will enjoy extremely fresh produce that is grown just a few miles from the airport.

“The produce will make its way into the dishes within hours and up to no more than a few days of being harvested and delivered to our kitchens,” says James Boyd, spokesperson for Singapore Airlines.

According to CNN, Singapore Airlines says that the airline aims to introduce AeroFarms’ produce to premium economy class riders eventually.

The flight between Newark and Singapore takes place on an Airbus A350ULR. Photo: Finnair

The produce available

CNN also reports that the farm-fresh collaboration between Singapore and AeroFarms will have a focus on dark leafy varietals. This includes leafy greens such as baby arugula, kale, mustard greens and bok choy; vegetables that are rich in vitamins and nutrients and known for their crisp, clean taste. Come December, the salad will include AeroFarms Baby Pak Choi, zucchini ribbons and Japanese pumpkin or sweet potatoes.

The airline, for the most part, sources the majority of its produce for the daily Newark-Singapore route from more distant sources such as California and Mexico.

The route and flight

The Newark to Singapore route is widely known as the world’s longest flight for which Singapore Airlines uses an Airbus A350-900ULR. The quirky aspect of this service is that it only flies business and premium economy class passengers. This flight covers a distance of approximately 15,350 km in about 18 and 1/2 hours.

The flight from Singapore to Newark travels roughly through the North Pole. Image: GCMap

Conclusion

Singapore Airlines’ will be eager to partner with more farms in its other major US markets according to their spokesperson. This could be either vertical or traditional farms. CNN speculates that destinations like San Francisco, Los Angeles, and Seattle could be next.

The Green Revolution Spreading Across Our Rooftops

As concerns about climate change and dwindling natural resources grow, green roofs have become increasingly popular. The Toronto-based organization Green Roofs for Healthy Cities estimates an increase of about 15 percent in the number of green roofs in North America since 2013

The space on top of the 525W52 building in New York features plants, lounge chairs and a view of the Hudson. Credit 525 West 52nd Street

By Kelly DiNardo

October 9, 2019

When David Michaels moved to Chicago this year, he chose the Emme apartment building in part because of the third-floor green roof, which has a lawn, an area for grilling, fire pits and a 3,000-square-foot vegetable garden.

“The green space was a huge factor in choosing this apartment,” Mr. Michaels said. “My wife and I are out there every other night, grilling or relaxing. And we like that they host classes out there.”

The Emme actually has two rooftop gardens — the one visible to residents on a deck on the third floor and a 5,000-square-foot garden on the roof of the 14-story building. Both are run by the Roof Crop, an urban farm that grows food for restaurants on a handful of roofs in Chicago. Residents at the Emme can also subscribe to regular bundles of rooftop-grown fruits and vegetables.

As concerns about climate change and dwindling natural resources grow, green roofs have become increasingly popular. The Toronto-based organization Green Roofs for Healthy Cities estimates an increase of about 15 percent in the number of green roofs in North America since 2013.

Replacing black asphalt and shingles with plants can lower the surrounding air temperature, filter dirty stormwater and reduce a building’s energy use.

While it is difficult to calculate the savings, as utility costs vary from city to city, the National Research Council of Canada estimates a green roof can reduce air-conditioning use in a building by as much as 75 percent.

Beyond the energy savings, by lowering air-conditioning demand, green roofs also help to reduce air pollution and greenhouse gas emissions, according to the United States Environmental Protection Agency.

As understanding of the benefits grows, more cities around the world are passing green roof legislation. In 2010 Copenhagen began requiring green roofs on all new commercial buildings with a roof slope of less than 30 degrees. In 2016, the city of Córdoba in Argentina issued a bylaw that directed all rooftops — new or existing — of more than 1,300 square feet to be turned into green roofs. The same year, San Francisco began requiring that 15 to 30 percent of roof space on new buildings incorporate solar panels, green roofs or both. More recently, the New York City Council passed a suite of measures to reduce greenhouse gases, including a requirement for green roofs, solar panels or a combination of both on newly constructed buildings. Other cities support green roofs through non-legislative measures; Washington, D.C.’s stormwater regulations and Philadelphia’s tax credit both encourage green roofs.

Toronto was the first city in North America to pass a green roof law, in 2009, requiring new buildings or additions that are greater than 21,000 square feet to cover between 20 and 60 percent of their buildings with vegetation. Developers can opt-out for a fee, but fewer than 10 percent choose to do so, according to Jane Welsh, the project manager for environmental planning at Toronto’s City Hall. Many that do seek exemptions are simply looking to install smaller green roofs than are required by the Green Roof Bylaw.

The green terrace at the Summit New York building in Midtown East has living trees, barbecues, and an herb garden. Credit Quallsbenson

Since the law was enacted, roughly 640 green roofs, covering more than five million square feet collectively, have been constructed, effectively changing Toronto’s architectural DNA and making the city a leader in the green roof movement.

Simply put, a green roof is one that allows for the growth of vegetation, but the process is more involved than plopping down a few potted plants. Typically, a green or living roof is constructed of several layers including a waterproof membrane, a root barrier, a drainage layer, a growing medium — soil is too heavy — and plants.

As green roofs have become amenities for residents and employees, they often also include picnic tables, benches, fire pits, and other extras.

Before Toronto’s green roof bylaw took effect, the Hugh Garner Housing Co-operative in the city decided to build one when its roof membrane needed replacement. Residents were presented with three designs — one that evoked a circus, one modeled after an English garden and one that brought to mind a city park. Residents voted for the park in the early 2000s, and today, the 22,000-square-foot roof features flower beds, trees, an herb garden, gazebos and specially-made picnic tables that are wheelchair-accessible.

“In the summer, every picnic table will have folks eating dinner out there,” said Beata Domanska, a resident and former board member who advocated the green roof. “People are up there playing cards, reading, sun tanning. We have member events there. We’ve even had weddings up there. It’s become part of the culture here.”

Of course, green roofs are not entirely new.

“We’ve been using soil and plants as a roofing material for thousands of years,” said Steven Peck, the founder and president of Green Roofs for Healthy Cities. “The Vikings would flip their boats over and cover them in sod because it’s a great insulator. What’s new is the research the Germans have done. They essentially invented the lightweight extensive system.”

In the 1970s, German horticulturists, construction companies and others began developing waterproofing technologies and researching blends of growing mediums that would be lighter than soil. In the 1980s, Germany passed a mix of local and federal laws encouraging green roof development and today the country features approximately 925,000,000 square feet of living roof. The movement began to take root in the United States and Canada in the early 2000s, with developers, architects, and designers looking to imitate Germany’s achievement.

Today, the University of Toronto’s Green Roof Innovation Testing Laboratory has grown into a leader in green roof research. The state-of-the-art facility uses 33 testbeds, a weather station and more than 250 sensors gathering data on soil moisture, flow rates, temperature, rainfall, humidity and amounts of sun and wind to help researchers assess and improve green roof performance.

Research like this helped overcome some early hurdles when ambitious designs, plant choice, lack of irrigation or a combination of factors left plants dying and green roofs turning brown.

“The focus has shifted from pretty to performance,” explained Vanessa Keitges, the chief executive of Columbia Green Technologies, the firm behind more than 1,500 green roofs in North America, including Amazon’s headquarters in Seattle and the Zella Apartments there, which feature a deck with an herb garden, outdoor kitchen, dog run and plenty of seating. “We’re getting better at fine-tuning the plant palette so you don’t end up with a brown roof. We’ve moved to drip irrigation instead of spray. We’re designing systems that are much easier to maintain. We want them to be goof proof.”

A bird’s-eye view of the roof of the Zella Apartments in Seattle, where green areas available for residents’ use include a dog terrace, with waste bags provided, and an outdoor kitchen. CreditGreen Technologies/Weisman Design Group

City planners are looking to green roofs to mitigate the urban “heat island” effect, which describes a metropolitan area that’s significantly warmer than surrounding rural areas because of human activity. Air temperatures in cities, particularly after sunset, can be as much as 22 degrees Fahrenheit (around 12 degrees Celsius) warmer than less developed regions. The elevated temperatures raise energy consumption, increase air pollutants and compromise human health, with extreme heat now causing more deaths in the United States than all other weather events combined, according to the Centers for Disease Control and Prevention.

The vegetation on a living roof cools the surrounding air through evapotranspiration, the process in which moisture in plant leaves evaporates into the air, essentially working like an outdoor air-conditioning system. In addition, the increased insulation and decreased need for air-conditioning means less overheated air is put back into the surrounding environment.

The plants on green roofs also work like a giant sponge, soaking up water and therefore reducing the amount of rainwater that reaches street level, lowering the risk of flooding, minimizing sewer system overflow and filtering dirty runoff.

“Cities are built to be impervious,” Mr. Peck said. “The water runs off buildings and streets, and when it hits streams and estuaries, it can cause erosion. It’s also incredibly contaminated. If you want to have drinkable, fishable, swimmable water in and around our cities, we need to capture stormwater and use it as a resource, instead of just getting it away from the buildings as soon as possible.”

Beyond the long list of financial, health and environmental benefits, green roofs have become valued amenities in residential buildings.

“We were really keen on finding a place with outdoor space,” said Carolyn Kushner, who chose the apartment building 525W52 in New York in part because of the roof, which features lounge chairs overlooking the Hudson River, a large lawn, grilling stations, bocce ball and Ping-Pong and shuffleboard tables, all surrounded by shrubs and greenery. Dr. Kushner and her partner — who proposed on the roof — go up there several times a week. “We have a glass of wine and watch the sunset. The city can be really overwhelming if you don’t get that kind of greenery. It’s nice to have someplace to escape to.”

One early cause of hesitation in adopting living roofs was the upfront cost. Green roofs cost two to three times as much as a traditional roof.

“With so many environmental initiatives, it often boils down to money,” Ms. Domanska said. “One of the ways we’re able to sell this is that a green roof significantly extends the life span of a roof. Over time it saves money. That was very attractive to the people who live here. Now people see all the benefits, but initially, it was about the savings.”

Studies bear this out. A 2006 study from the University of Michigan compared the expected costs of conventional roofs with the cost of a 21,000-square-foot green roof and found that over its lifetime, the green roof would save about $200,000. Almost two-thirds of that would be in reduced energy needs for the building below.

“We’ve established best practices for creating green roofs,” Mr. Peck said. “We have political leaders looking for ways to improve the health and well-being of the people in their cities and also address climate change. We have research that shows the benefits of green roofs. It seems clear that the cities that invest in green infrastructure will be the cities that thrive.”

A version of this article appears in print on Oct. 12, 2019, in The New York Times International Edition.

Shenandoah Growers Opens Next Generation USDA Certified Indoor Biofarms In Virginia

The new BioFarms will solve persistent problems in the fresh product supply chain – delivering peak freshness, longer shelf life, enhanced food safety, reduced food miles, and year-round organic supply.

ROCKINGHAM, Va. — Shenandoah Growers, Inc., the US leader in indoor USDA certified organic agriculture, has begun harvests at its next generation BioFarm facilities in Rockingham and Elkwood, Virginia. The company will now grow, pack and ship locally grown, premium quality organic produce from its sustainable indoor farms to its customers in the Mid-Atlantic region 365 days a year.

Shenandoah Growers BioFarm Basil Plants

The new BioFarms will solve persistent problems in the fresh product supply chain – delivering peak freshness, longer shelf life, enhanced food safety, reduced food miles, and year-round organic supply. Shenandoah’s sustainable growing technology uses bioactive soil and fresh water, just like in nature, producing healthy organic plants and delivering on the company’s mission to reduce its carbon footprint and lead in environmental stewardship.

The Rockingham BioFarm will supply 100% of Shenandoah’s basil in the Mid-Atlantic region, marking the transition away from traditional field production. Basil is not only the best-selling herb, but it is also the most difficult to grow and ship nationally due to its vulnerability to weather volatility, disease and temperature damage. The Elkwood BioFarm will supply the company’s new line of local organic lettuces to Mid-Atlantic customers.

“Being able to grow the totality of our basil demand inside our pack house and not fly or truck hundreds or thousands of miles from the field was inconceivable when I entered the business over 20 years ago,” says Tim Heydon, CEO.

While Shenandoah Growers are pioneers in indoor organic agriculture, they are quick to emphasize that the company has been farming and operating in the industry for over 30 years. Chief Customer Officer Steven Wright intoned, “It’s one thing to be able to grow indoors, it’s quite another to harvest, pack and deliver with consistent quality 7 days a week, 52 weeks a year while meeting demand during peak seasons.”

The company points out that its indoor production units, many of which have been in operation for over 4 years, are proven efficient. According to company President, Phillip Karp, “Fundamentally we are about the democratization of sustainably grown organic produce, and for the promise of indoor agriculture to truly unlock its great potential, it must achieve cost parity with traditional farming. Anything we launch from our indoor farms will be scalable and profitable for us and our customers and affordable for the shopper.”

The company is in the process of accelerating its indoor farming capacity with a clearly defined plan to deploy additional next generation USDA certified organic Biofarms across its entire national platform of operating locations.

About Shenandoah Growers, Inc.

Founded in 1989, Shenandoah Growers is the leading grower and marketer of fresh organic culinary herbs in the United States, providing sustainable, USDA certified organic, regionally grown produce to retailers coast-to-coast. The Rockingham, Virginia-based company has developed the nation’s largest commercial indoor organic growing systems and continues to redefine how to bring fresh, organic, and sustainably farmed produce to market—operating across a nationally integrated platform of farms, production, and logistics facilities. For more information, please visit www.shenandoahgrowers.com.

Under the THAT’S TASTY® BRAND, Shenandoah Growers provides USDA organic, non-GMO, regionally grown, and sustainably farmed fresh culinary herbs and greens. Launched in 2017, the THAT’S TASTY BRAND offers consumers ways to add Pure Organic Flavor™ to their everyday cooking by offering a full line of products including living organic herb plants, fresh cut herbs, herb purees, lettuces and microgreens. www.thatstasty.com

95% of Tested Baby Foods In The US Contain Toxic Metals, Report Says

One in five baby foods tested had over 10 times the 1-ppb limit of lead endorsed by public health advocates, although experts agree that no level of lead is safe

By Sandee LaMotte, CNN

October 17, 2019

CNN)Toxic heavy metals damaging to your baby's brain development are likely in the baby food you are feeding your infant, according to a new investigation published Thursday.

Tests of 168 baby foods from major manufacturers in the US found 95% contained lead, 73% contained arsenic, 75% contained cadmium and 32% contained mercury. One-fourth of the foods contained all four heavy metals.

One in five baby foods tested had over 10 times the 1-ppb limit of lead endorsed by public health advocates, although experts agree that no level of lead is safe.

The results mimicked a previous study by the Food and Drug Administration that found one or more of the same metals in 33 of 39

Read Full Article Here

FOR SALE - 2016.5 Premium Freight Farm (LGM) - Computer Controlled Hydroponic Grow System - Florida

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Make & Model - 2016.5 Premium Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Florida

Price - $57,500

Description

Well maintained late 2016.5 LGM purchased from Freight Farms.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

Numerous additional extras included. (Original cost approx., $5,000.)

All standard Premium components

Custom stacked microgreens production module (in place of sink), programmed into control system

Additional back dehumidifier

Upgraded FF LEDs for propagation

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

1. ALL-WEATHER CONSTRUCTION

Steel frame with stainless interior, 40' x 8' x 9.6' overall footprint.

2. AUTOMATIC DOSING

Programmable nutrient & pH dosing for perfect growing conditions.

3. CUSTOM WORKBENCH

TIG-welded stainless workbench with integrated seedling growth stage.

4. COMMERCIAL VOLUME

Thousands of growing sites across 256 irrigated vertical towers.

5. HIGH-EFFICIENCY LED ARRAY

5:1 red / blue LED lighting optimized for green leafy growth.

6. INSULATED ENTRY

Padlock-proof safety door with controlled-environment insulation.

Product Booklet

All information is from sources deemed reliable but is subject to errors, omissions, changes in price, prior sale or withdrawal without notice.

No representation is made as to the accuracy of any description.

All measurements, yields and square footages are approximate and all information should be confirmed by the customer.

Disclaimer of Warranty - The 2016.5 Freight Farms LGM hydroponic farming container is being sold “as is” and the Seller disclaims all warranties of quality, whether express or implied, including the warranties of merchantability and fitness for a particular purpose.

US: Colorado - Students At Mountain Vista High School Were Ready To Start The Year By Getting Their Hands Dirty Via The Agricultural Business Course

For the past two years classes and interns have operated the Mountain Vista Farm, which utilizes a hydroponic growing system called the Leafy Green Machine

By James Conlan / Ag Journal

October 16, 2019

Students at Mountain Vista High School were ready to start the year by getting their hands dirty via the Agricultural Business course taught by David Larsen.

“As part of the program, students are responsible for all aspects of the Mountain View Farms business,” Larsen said.

After being introduced to the different business principles, students are tasked with integrating them into running a successful business. Some of these tasks include marketing, social media/website, communications, graphic design, printed literature, handling of money/accounting, customer service, food safety, and business plan development.

“Agriculturally, they have to figure out all of the elements including environment, nutrient, tech, engineering, and automation to keep the plants alive and healthy for sale,” he said.

For the past two years classes and interns have operated the Mountain Vista Farm, which utilizes a hydroponic growing system called the Leafy Green Machine.