Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Why An Entrepreneur Believes Urban Farming Is The Future In D.C.

Acky's company, Little Wild Things uses small, under utilized outdoor spaces in D.C., 80 percent of her farming is done indoors. When chefs call, Acky and her team deliver quickly

by WJLA

Friday, July 19th 2019

Mary Acky owns Little Wild Things, an indoor farming business in D.C. Friday, July 19, 2019. (ABC7 photo)

WASHINGTON (WJLA) — Down an unmarked trail at a monastery in Northeast Washington, you might not expect a farm delivering to some of the District's top restaurants.

Please Click Here to View the Video

And in an unmarked warehouse near Union Market, you probably wouldn’t expect an indoor farm.

But that’s exactly what’s happening. Meet Mary Acky—a young entrepreneur— she’s innovating the way America farms are created.

Acky and her team of six employees, don’t just grow regular fruits and vegetables. They grow micro greens. Smaller, nutrient packed greens ready to eat just days after planting.

In terms of health, micro greens in general have about 4-6 times the nutrient density of a fully grown version of a plant.

Acky's company, Little Wild Things uses small, under utilized outdoor spaces in D.C., 80 percent of her farming is done indoors. When chefs call, Acky and her team deliver quickly.

She believes farming innovation in cities, both indoor and outdoor, must be the future.

Anyone can order from Little Wild Things by going to their website or visiting them at the Dupont Farmers Market.

Don’t Let Monsanto Decide If Its GMOs Are “Safe” or Not

t's so important that we submit comments urging USDA not to let chemical companies approve their own genetically engineered plant experiments!

t's so important that we submit comments urging USDA not to let chemical companies approve their own genetically engineered plant experiments!

The Trump administration just released new rules to change how genetically engineered crops (GE crops or GMOs) are regulated. Unfortunately the rules being proposed would make almost every GMO exempt from regulation and instead allow the companies that make GMOs decide the safety of their own products before selling them. If we don’t stop these new rules, the vast majority of GMOs will not be reviewed by the government. Instead chemical and food companies would decide whether or not their own GMOs are harmful. Talk about a conflict of interest!

Stop the Trump Administration from letting chemical companies decide if the GMOs they sell are safe!

With these new rules, the United States Department of Agriculture (USDA) is proposing a radical voluntary review system for GE crops. These new regulations leave it up to chemical companies—like Monsanto/Bayer and Dow—to “self-determine” review; in other words, these chemical companies would make their own determinations as to whether or not their GE plant experiments should even be reported to USDA at all.

If a chemical company has “self-determined” that its GE plant experiment does not need USDA oversight, it would skip being evaluated under the standards of our federal health and environmental laws. It would go straight to farm fields to be planted or to market to be sold. We at Center for Food Safety (CFS) believe that it should not be up to a chemical company—interested in improving its bottom line—to decide what is safe for our health, endangered species, and the environment.

And even in the rare instances when a company will volunteer to have their GE plant experiment regulated by USDA, the agency is proposing such a narrow scope of its review that it will only have a meaningful review processfor a tiny percentage of GMOs. This allows for the illusion of regulation, while actually letting the companies go scot-free.

One of the big problems with GMOs is their ability to cross-contaminate with conventional and organic crops as well as with plants in wildlife refuges. USDA perversely touts that there will be fewer “unauthorized releases” of GMOs with this new system, but that’s only because the vast majority of GE plant experiments will be totally exempt from any regulation in the first place! It’s like saying the crime rate will go down because the government legalized most forms of robbery. In reality, deregulating nearly all GMOs with no oversight will dramatically increase the frequency of contamination—which has already cost U.S. farmers billions of dollars over the past decade. When you go from bad oversight to no oversight, many more incidents of contamination are sure to follow.

Don’t let USDA fool you; self-regulation is no regulation at all!

Under the new proposal, the vast majority of GE plant experiments would not even have to be reported to USDA, much less grown with measures to prevent escape. So rather than increasing its monitoring of open air GE plant experiments, USDA’s new proposal abdicates the agency’s responsibility entirely, and leaves it solely up to chemical companies to self-police their new experiments. This change would exacerbate harm to farmers and the environment from increased contamination, while leaving the public completely in the dark as to where these new experiments are taking place.

USDA’s proposed GE regulations work very hard to make sure as little as possible is regulated. These proposed regulations rely on chemical companies deciding whether or not their GE plant experiments should be reviewed by a government agency at all. They do not address the massive increase in overall pesticide use that GMOs have caused or the continuing epidemic of increasingly pesticide-resistant “superweeds.” They fail to protect endangered species or farm workers. They even leave dangerous new “biopharm” GMOs completely unregulated, making our food system vulnerable to contamination from experimental pharmaceuticals. These rules leave our public health and environment completely at the mercy of chemical companies. USDA could do so much better, but instead it’s just doing the bidding of Monsanto and other chemical companies.

Onwards,

George Kimbrell

Legal Director

Center for Food Safety

One Giant Leap: Space Programs Spin Off Vertical Farming, by Joel L. Cuello, Ph.D.

The author's NASA-sponsored project on design and demonstration of NASA’s first Hybrid Solar and Electric Lighting System for Bioregenerative Space Life Support for application in future long-duration manned missions to the Moon and Mars

The vertical farming industry will likely in

turn ultimately enable NASA

and other space programs

to realize their future food production

systems on the Moon, Mars and even beyond.

Original Content Written for The Association for Vertical Farming

NASA's Apollo 11 Lunar landing and moonwalk on 20 July 1962. (Photos courtesy of NASA)

As the 50th anniversary of Apollo 11's first Lunar landing and moonwalk on 20 July 1969 is observed this year, it is fitting to recall the myriad innovation spinoffs that NASA's space program had gifted mankind, ranging from the integrated circuit to computer microchips to satellite television to cordless tools to electric vehicles to freeze-dried food to memory foam, etc. -- and yes, still unbeknown to many, vertical farming.

The author's NASA-sponsored project on design and demonstration of NASA’s first Hybrid Solar and Electric Lighting System for Bioregenerative Space Life Support for application in future long-duration manned missions to the Moon and Mars.

While the Apollo program itself did not initiate or develop space farming, its unprecedented success directly led NASA to establish around 1978 the Controlled Ecological Life Support System (CELSS) division within its Advanced Life Support program with the aim in part of developing the technologies and strategies necessary to grow food and regenerate resources on the Lunar surface or on Mars for future long-duration manned missions and habitation.

Nearly two decades before NASA, however, the then Soviet Space program commenced activities beginning in 1961 toward developing its own bioregenerative space life support system. In 1968, the Soviets first realized growing crops in their completely sealed controlled-environment system Bios-2, located in the Siberian city of Krasnoyarsk, wherein they successfully cultivated wheat, carrots, cucumber, dill and other vegetable crops. (Bios-2 should not be confused with Biosphere 2 in Arizona which was constructed much later between 1987 and 1991.) An improved underground test facility, Bios-3, was subsequently built by the Soviets in 1972.

Fast forward to the 1980's and 1990's, NASA's CELSS program made significant advances in the cultivation of a whole range of crops in closed controlled-environment systems under optimized environmental conditions of lighting, temperature, relative humidity, air flow, nutrient compositions, etc.

The foregoing advances by both NASA and the Soviet Space program paved the way for the emergence of the first commercial vertical farms (or plant factories) in the United States and Japan. General Electric's Geniponics based in New York and Alaska as well as General Mills' Phytofarms of America in Illinois were established in the 1970's and operated through the 1980's, though eventually closing down owing to economic challenges.

It was in Japan in the 1980's, however, when the then fledgling vertical farming industry truly took root and flourished in part through their proactive adoption and incorporation of emerging technology innovations. For instance, TS Farm (Q.P. Corporation) was first in employing aeroponic systems, while Cosmo Plant Co. Ltd. in 2000 became the world's first commercial LED-based vertical farm and began producing up to 7,000 heads of lettuce per day, significantly exceeding the industry norm of 3,000 to 5,000 heads of lettuce per day in the 1990's.

Vertical farming today, of course, has gone global and, in parallel with advances in lighting technologies, climate control, data analytics, automation and other innovations, has correspondingly been setting new achievements in both yield and resource sustainability.

And just as the space program spun off the Vertical Farming industry, there is poetic symmetry in the very real prospects that it will be the vertical farming industry that will ultimately enable NASA, as well as other space programs, to develop and fully realize its bioregenerative space life support systems for future Lunar and Martian human habitats.

Just as Elon Musk's Space X, Jeff Bezos' Blue Origin and Richard Branson's Virgin Galactic have partnered with NASA to innovate on and advance space transportation, it is highly likely that partnerships with NASA for the design and operation of its future Lunar and Martian space farms will be brokered with the likes of AeroFarms, Plenty, Bowery Farming, CropOne Holdings, Gotham Greens, Infarm, AEssense and/or other vertical farming companies, some of which have yet to be formed.

In the future the vertical farming industry may indeed extend its prospects from the mere terrestrial to the extraterrestrial.

_________________________

Prof. Joel Cuello is Vice Chair of the Association for Vertical Farming (AVF) and Professor of Biosystems Engineering at The University of Arizona. He conducted his U.S. National Research Council postdoctoral research fellowship at NASA John F. Kennedy Space Center in Cape Canaveral, Florida in 1994.

Email cuelloj@email.arizona.edu

NatureFresh™ Farms Introduces New Procurement Manager in Mexico

With over 21 years of experience in the agriculture industry, Paul Hulsbos will be taking on the role of Procurement Manager at NatureFresh™ Farms in Mexico. Among his new responsibilities, Paul will be aligning growers to support NatureFresh™ Farms winter programs as well as set up yearly commitments

Leamington, ON (July 18, 2019) - NatureFresh™ Farms announces and welcomes the newest addition, Paul Hulsbos, to their sales team as Procurement Manager based in Mexico.

With over 21 years of experience in the agriculture industry, Paul Hulsbos will be taking on the role of Procurement Manager at NatureFresh™ Farms in Mexico. Among his new responsibilities, Paul will be aligning growers to support NatureFresh™ Farms winter programs as well as set up yearly commitments.

Originally from the Netherlands Paul began his career in agriculture working at a family owned importer/exporter company and was responsible for sales and marketing of produce based in Holland. Since then, Paul has relocated to Mexico where he has been working to keep up with industry growth and be closer to the market.

Excited to begin a new journey with NatureFresh™ Farms, Paul considers it to be a defining moment in his career. “I’m looking forward to contributing my experience to the procurement team at NatureFresh™ Farms while strengthening their presence in Mexico,” said Paul. “My new adventure with them is a life changing decision but one I am very much excited about.”

General Manager; John Ketler, also shared his excitement for Paul’s arrival. “We are thrilled to have Paul join the team,” said John. “He brings a great amount of experience to this new position and will greatly assist in building relations and our efforts in year-round production in Mexico.”

As NatureFresh™ Farms focuses on company growth and developing relations, Paul’s presence in Mexico will strengthen intercommunication between locations in Canada, the United States, and Mexico. NatureFresh™ Farms is excited for their future with the continuous expansion of their team, their advancements in technology and product innovation allowing them to provide fresh produce all year round.

Case Study From Freight Farms

A conversation with Steve Huntley of Enlightened Crops on how he discovered Freight Farms and leveraged previous business experience into his new venture of Container Farming

A conversation with Steve Huntley of Enlightened Crops on how he discovered Freight Farms and leveraged previous business experience into his new venture of Container Farming

07/18/19

Launching a Successful Second Career With Container Farming

Case Study From | Freight Farms

Steve wasn’t always a farmer. After some years in the corporate world, he started a small service business with his wife Cathy. The business focused on plumbing, heating, and cooling, and the couple ran it successfully for 18 years. In 2017, Steve and Cathy decided that they were interested in moving on to something that would be more flexible as they looked towards retirement.

They set out looking for a new venture that would benefit the community–especially in the downtown area. One thing they found was a lack of fresh produce availability in Downtown; They decided to explore that route and ran into the concept of hydroponic farming.

A friendly face

Steve wasn’t the only person in Grand Rapids interested in hydroponics. Brian Harris had previously purchased a Leafy Green Machine (LGM) and was a long-time friend of Steve’s from a job 30 years ago! Steve had been thinking of pursuing hydroponics with a free-standing warehouse system, but after seeing Brian on local TV, he reached out and saw the LGM for himself. After working at the farm with Brian a few times, Steve was convinced this is was what he was looking for.

Fellow Freight Farms Brian Harris of Green Collar Farms

“We were very impressed with the Freight Farm, how efficient everything was–it was already pre-set up and there was great support. We did some calculations and, with good yields, we could supply a lot of product to the urban area.”

— Steve Huntley

No experience, no problem

Steve felt comfortable pursuing a new farming career in spite of having almost no agricultural background. While he had grown up in a farming community, the closest Steve had gotten to commercial food production was a small personal garden at home. However, he was sure that with the farm’s smart set up, and the support of Brian, fellow farmers, and the Freight Farms team, he could be successful.

THE BUSINESS

Previous business experience helped Steve think strategically about his market.

“First thing you want to find out is if the market’s available: It could be a great idea, but if the market’s not ready or saturated, it won’t work.”

With this in mind, Steve created a market research form with questions for chefs and sous chefs, their initial target customers. The goal was to get a sense of the market, and they came away with a resounding yes, especially for access to good quality produce year-round in Michigan’s seasonal climate.

Knowing that the demand was there, Steve and Cathy looked at their potential yields, calculated potential expenses and profits, and decided they were ready to start farming.

Taking a leap of faith

Before the arrival of his farm, Steve had marketed the produce to chefs that were excited about the idea of local, chemical-free produce. However, without samples, he wasn’t able to finalize any agreements. At that point, he had to trust that his due diligence had been enough.

“The leap of faith is necessary for anyone starting any business. You can get all the data, but nothing is guaranteed. You have to just make an educated guess...If you’re passionate about it...it will work out for you.”

— Steve Huntley

Friends > competitors

In spite of the fact that Steve and Brian are both Freight Farmers in the same city, Steve doesn’t believe they’re anywhere near saturating the market and becoming direct competitors. Steve explains: “The Freight Farm is such a unique concept that there’s enough to go around in our area. We do experience competition from other types of–mainly larger–hydroponic farms, but we’re carving out our niche.”

Finding customers

Since launching his farm, Steve’s customers include several high end restaurants, an urban fresh food grocery store, and–most recently–a fresh food distribution company that delivers Steve’s greens to stores around the city.

Steve initially focused on restaurants because they had smaller demands that would be more achievable while him and Cathy were getting comfortable in the farm. He approached several high end restaurants (the ones that would want to pay a premium for greens) with samples from his newly-arrived farm and some informative brochures.

These he either mailed or, more successfully, dropped off in person during off-peak restaurant hours. Once Steve’s farm was producing higher yields, he approached retail stores in his area with the same tactic.

“I was surprised that a lot of these chefs were willing to talk with me and try out our samples. You don’t get everyone of them, but if you go back every couple of months, at some point they’ll need your product.”

— Steve Huntley

Steve also runs a small farm stand for friends and neighbors. Since he frequently schedules more production than he needs to make sure regular customers always get their demands met, this means that there are usually crops left over. Steve sells surplus produce through a simple online portal (using Eat from Farms) that customers can use to order whatever Steve has in stock. He also uses surpluses as an opportunity to donate to local food banks.

Crops and yields

So what is Steve actually selling to this wonderfully diverse customer base?

After lots of feedback and testing, Steve has narrowed his production down to a few superstar crops: Arugula and basil form 80 percent of the farm’s production, while artisanal lettuces make up the remainder of the farm’s weekly output. Steve differentiates his produce for his different customers: the grocery store sells a selection of everything he grows, while the restaurants mainly purchase arugula and lettuce.

When it comes to yields, Steve is always looking to optimize. Currently he grows 8-10 ounces of basil and 16 ounces of arugula per tower.

Determining Price

Steve begins his price negotiations by calculating all of his expenses–seeds, electricity, etc–to get a sense of the overall and unit costs of the farm. This helps him go into meetings with a good idea of what price he needs to make a profit. After a few rounds of negotiating, Steve and his buyer are able to land on a price that works for everyone.

Thanks to the quality of his produce, Steve is able to negotiate a premium price for his crops. Steve also gets higher prices by promising his customers that he will keep the price consistent.

“[Customers] like the fact that they can budget, they don’t have to worry about prices going up and down; We can give them a price that is consistent all year long.”

Marketing

Steve relies on the popularity of local food as a way to differentiate himself at the store, saying “Local is huge” for consumers, who increasingly want locally-sourced food that is fresher, cleaner, and more transparently-grown.

Demos are one of Steve’s greatest marketing strategies: every time they’re able to give people a taste they see their sales go up. When people ask if the produce is organic, Steve doesn’t skip a beat. He tells them: “We’re not certified organic, but we don’t have any contaminants in our soil because we don’t use soil, there are no toxins from the air or the rain…We’re better than organic.”

SITE & OPERATIONS

Convenient Location

The Enlightened Crops farm is located on the west side of Downtown Grand Rapids, Michigan in a parking lot near the expressway. The site is very convenient–it’s kiddy-cornered with the grocery store Steve sells to, and is just a few minutes driving distance away from the restaurant customers.

Steve shares the site with Brian–in fact, Brian already had the site set up by the time Steve was ready to buy. All Steve had to do when his farm arrived was set up an electrical connection. Since there’s no running water, Steve uses a water reservoir tank and is able to pump water directly into the farm.

Ramping Up

The Leafy Green Machine was delivered mostly pre-assembled, so the first few days were spent on the finishing touches: hanging towers, calibrating sensors, and connecting pumps. Steve was able to rely on his new neighbor, Brian, and the Freight Farms team for support througout.

Even with the support, the first few months had their challenges. Steve and Cathy had trouble finding the right watering and harvesting schedules, which led them to over-water the plants and leave them in their towers for too long. However, by tracking their operations carefully they were able to learn from their mistake. Steve advises new farmers to do the same: “Use analytics as much as you can to track how long you have certain towers in, what plants in what towers, and what area of the farm...It all helped us to go back and look at that data as we were learning those first six months.”

Day-to-day Operations

Most days, it’s just Steve and Cathy working in the farm, with occasional help from their son. Together they’re able to share the farm work, which on top of seeding, transplants, harvesting, and cleaning also includes keeping careful track of their plants, all the way from the seeds’ log numbers, to the final destination. This not only helps the Huntleys track their yields, but is important in staying transparent with their customers.

Steve and Cathy spend a combined 20 hours working on their business. This involves a general 70-30 split of time spent in the farm compared to meetings or marketing activities; These proportions can change when Steve is actively working on winning new business.

Packaging

Steve’s customers have varied packaging requirements. Restaurants simply ask for the crops to be delivered in 1-2 lb bags. Retail outlets require much more specific packaging, including food-safe clamshells, UPC codes, barcodes, and printed labels with product specifications. This sounds complicated, but Steve encourages new farmers not to be intimidated: “There’s a lot more work getting started with a retail chain, but once it’s up and going, it’s really not that bad at all.”

As with other parts of the business, Steve is constantly looking ahead at ways to make his product better. With packaging, this means moving away from plastic as much as possible. To that end, Steve is working with the University of Michigan to develop plant-based clamshells, as well as with the store itself to find ways to display and sell the produce in a way that doesn’t require any plastic.

Delivery

Delivery is simple for Steve since all his customers are located nearby. He delivers to the grocery store three times a week, usually by walking the produce across the street, and then makes one-time weekly deliveries to his restaurant customers. Individuals purchasing online will come to the farm or to Steve’s house to grab their orders.

COMMUNITY

Many of the people in Steve’s life where justifiably surprised when he announced he was starting a farming business. However, once they learned more about the technology, the surprise turned into excitement.

The community reaction

“The more educated people get, the more interested they become in our kind of farming: local, no chemicals, and fresh.”

The customers’ reactions

“[My customers] are drawn to the taste and the smell–they take a bite and they love how fresh it is, the appearance of it is beautiful and green.”

LIFESTYLE

Not only does Enlightened Crops create a benefit for the community, but it has also had a positive impact in Steve’s life. Steve exalts, “For most of my life, I was working the 8-5, if I was lucky! The farm gives us a lot of flexibility which, as we slide into retirement age, was very important to us. I love working down at the farm–it’s quite and relaxing, not physically demanding, plus we can plan our day!”

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

07/18/19, 08:50 AM | Indoor & Vertical Farming | case study

Manufacturer Recalls Salads, Sandwiches Sold At Target, Fresh Market Due To Health Risk

The manufacturer of some salads and sandwiches sold at Target and The Fresh Market has issued a recall due to potential listeria contamination, according to the U.S. Food and Drug Administration

The manufacturer of some salads and sandwiches sold at Target and The Fresh Market has issued a recall due to potential listeria contamination, according to the U.S. Food and Drug Administration.

Elevation Foods is voluntarily recalling some containers of Archer Farms-brand egg salad; Freskëtbrand egg salad, tuna salad, and Thai lobster salad; and Archer Farms-brand deviled egg sandwiches produced on June 18, 2019.

On its website, The Fresh Market says its Thai lobster salad that's sold both prepackaged and by the pound at its self-serve seafood is included in the recall.

According to Elevation Foods, fewer than 1,087 cases of product were shipped to retailer warehouses throughout the United States.

Archer Farms Egg Salad is one of several salads included in a voluntary recall by Elevation Foods. (Photo: Provided)

To see if you have a product that's included in the recall, check the “use by” date printed on the side of the container and the lot number. The FDA website lists the following items as impacted by the recall:

Archer Farms-brand Egg Salad packaged in a 12-ounce clear, square plastic container, Lot Number W1906042A, Use By 12AUG2019 (printed on the side of each container) UPC 085239018682, distributed nationwide;

Freskët-brand Egg Salad packaged in a 32-ounce clear, square plastic container, Lot Number W1906042, Use By 12AUG2019A (printed on the side of each container;

Freskët-brand Tuna Salad packaged in a 5-pound white, round plastic container, Lot Number W1906054, Use By 02AUG2019A (printed on the side of each container;

Freskët-brand Thai Lobster Salad packaged in a 5-pound white, round plastic container, Lot Number W1906041, Use By 02AUG2019A (printed on the side of each container);

Archer Farms Deviled Egg Sandwich Half Sandwich with Bacon, UPC 220505000002, distributed nationwide;

Archer Farms Deviled Egg Sandwich on Multigrain, UPC 498780203566, distributed nationwide.

No illnesses have been reported, but listeria monocytogenes can cause serious and sometimes fatal infections in young children, frail or elderly people, and others with weakened immune systems, according to the FDA.

Fresket Thai Lobster Salad is one of several salads included in a voluntary recall by Elevation Foods. (Photo: Provided)

In otherwise healthy people, listeria monocytogenes can cause short-term symptoms such as high fever, severe headache, stiffness, nausea, abdominal pain, and diarrhea, according to the FDA. Listeria infection can cause miscarriages and stillbirths among pregnant women.

Elevation Foods identified the problem with the products after receiving positive test results for three containers of affected egg salad which were sampled and tested by the Florida Department of Agriculture and Consumer Services, according to the FDA website. Elevation Foods is continuing to investigate potential sources of the problem.

Consumers who have purchased any of the recalled products are urged to return them to the place of purchase for a full refund. Consumers with questions can call 866-761-9566 at any time.

Wilmington’s First Vertical Farm Clears A Final Hurdle

An amendment to the City Code was needed for Second Chances Farm, which aims to employ people returning from the prison system with urban agriculture jobs, to start operating in its Northeast location.

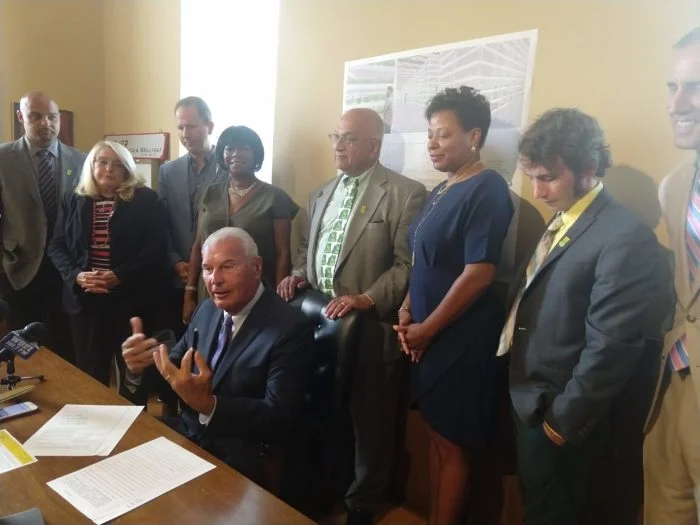

City Council member Zanthia Oliver and Mayor Mike Purzycki show off recently harvested hydroponic lettuce from Second Chance Farms. (Photo by Holly Quinn)

An amendment to the City Code was needed for Second Chances Farm, which aims to employ people returning from the prison system with urban agriculture jobs, to start operating in its Northeast location.

A lot of things have had to come together in order to make Second Chances Farm, founded by entrepreneur and TEDxWilmington organizer Ajit George, a reality.

As an Opportunity Zone project, there were applications and approvals; a reentry program was established with a Delaware Department of Corrections contractor; a location on Bowers Street in Northeast Wilmington was secured.

There was one more detail: The City of Wilmington, which has been supportive of the program that aims to employ people returning from the prison system with $15-an-hour “green collar” urban agriculture jobs, had to officially put it in writing that indoor farms are permitted in the city.

On Wednesday, July 30, at the offices of Second Chance Farms on West 13th Street, the legislation sponsored by City Council member Zanthia Oliver, which amended Chapter 48 of the City Code to permit indoor commercial horticultural operations, was signed by Mayor Mike Purzycki.

A small version of the hydroponic unit is up and running in the office, growing four tiers of lettuce and basil under the cool LED lights; the units that will be in the Northeast location — 400 of them — will be eight tiers high.

“There’s no soil used, just water,” said Evan Bartle, chief growing officer for Second Chances Farm, lifting a panel of basil plants to show the roots. What looks like soil at the base of the plants is actually rockwool — “rock that has been spun out like cotton candy,” Bartle said. The reusable medium, a standard in commercial hydroponics, is used to support the plants above the water.

After signing the amendment, they mayor ceremonially cut the first leaves of lettuce with (slightly) oversized golden scissors and had a taste.

“This is the baby lettuce that restaurants love,” said George. (And, yes, it tastes very good — members of the press were also given samples of the lettuce to try.)

When the farm official opens on Bowers Street, in a building conveniently named The Opportunity Center, it will provide jobs for returning citizens with the goal of reducing recidivism in Wilmington, while providing locally grown, chemical-free produce to businesses in the region.

In addition to the vertical farm, the facility will offer services including CrossFit or a gym to employees and community members.

Check out more pics from the event:

(Photos by Holly Quinn)

"Global CEA Census Ending - Last Day To Participate - Monday July 22"

3 June 2019 (NEW YORK): Global automation specialist Autogrow and New York based Agritecture Consulting are appealing to growers to take part in the inaugural Global CEA Census.

The Census seeks to understand the scale and nature of Controlled Environment Agriculture (CEA) to better determine the roadblocks to accelerating the industry. This includes greenhouses, vertical farms, indoor rooms and hoop or tunnel houses.

Both Agritecture and Autogrow believe a great deal of CEA activity worldwide is not well documented, with data being fragmented and often unreliable, making it difficult to provide support or solutions on a larger scale.

“We do a lot of work with city leaders around the world and the conversations are about how the infrastructure needs to be in place in order to use new technology, drive costs down and operate sustainably. Through the Census we hope to highlight who is growing, what they’re growing, where they are growing and what they need to take it to the next level,” notes Agritecture Founder Henry Gordon-Smith.

“Based on that information both Autogrow and Agritecture can then work closer with governments, growers and city planners on where they can focus their efforts and utilize valuable resources.”

One of the biggest known roadblocks to adoption of new technology today is internet connection on the farm. Without connectivity growers are unable to join the growing trend of cloud-based software and remote access.

Autogrow CEO, Darryn Keiller says “We need to understand whether growers are ready for innovation, and if they aren’t, how we can get them there.”

“New crop production technologies are heavily reliant on growers having multi-modal internet to the farm and commercial grade onsite network infrastructure. If this isn’t addressed, and supported at a government level, then we will see an ever widening ‘digital divide’ at the farm level.”

“All the best technology in the world is of no use if it can’t be connected to the farm.”

Additionally, the Census hopes to record best practice solutions to share across the industry.

“There are some amazing growers around the world who are using creative solutions for things like water usage, labor shortages, energy consumption or improved marketing activities using social media. We want to capture that and share to the wider community. Only by banding together can we hope to push our industry forward in a positive way,” explains Henry.

The Census will run until 22 July with a report on the findings published in September. All submissions will remain confidential and only anonymized data will be reported.

WIN A TRIP TO NYC: Submissions will also go in a draw to win a trip to New York to attend this year’s NYC AgTech Week running from 21-26 September.

Take the survey, enter the draw and have your say -

https://www.surveymonkey.com/r/global-cea-census

Survey Terms and Conditions - https://www.agritecture.com/cea-census-terms-conditions

About Autogrow

Autogrow leverages the power of technology, data science and plant biology to provide indoor growers affordable, accessible and easy-to-use innovation – 24/7, anywhere in the world.

Our hardware, software and data solutions support growers and resellers in over 40 countries producing over 100 different crop types.

With over 25 years in business, we have a depth of experience and passionate, fun people creating original ideas and making them a reality for our growers.

About Agritecture Consulting

Agritecture Consulting provides a comprehensive approach to CEA project development.

In operation since 2014, Agritecture has helped more than eighty organizations determine the feasibility of their ideas, validate their business strategies, recruit talent for their projects, and manage operational challenges.

Our job is to jumpstart your knowledge of CEA, help you navigate barriers to entry, make industry connections, and mitigate risk. Our consulting services are backed by several years of operations data and a team of experienced growers, engineers, and sustainability managers.

Coworking Produce Subscriptions - Wework And Freight Farms Are Offering Members Fresh Greens

Unconventional partnerships often bring about the best ideas, and this rings true with a collaboration formed between WeWork and Freight Farms, in which members of the coworking space are able to receive fresh and locally grown produce

By: Ellen Smith - Jul 19, 2019

References: freightfarms

Unconventional partnerships often bring about the best ideas, and this rings true with a collaboration formed between WeWork and Freight Farms, in which members of the coworking space are able to receive fresh and locally grown produce.

This partnership follows the announcement that WeWork is making moves in the agricultural space, as the brand announced the WeWork Food Labs at the beginning of 2019.

In this particular partnership with Freight Farms, WeWork is aligning its brand with conscious consumerism and sustainability, allowing its members to subscribe to a weekly delivery of fresh greens delivered to WeWork locations.

The subscription program is available for $12.50 weekly, or $50 monthly, effectively bridging accessible food, with convenience and affordability

WEWORK X FREIGHT FARMS

A UNIQUE FARM-TO-OFFICE PROGRAM DIRECTLY AT YOUR WEWORK LOCATION

PROGRAM BASICS

Weekly delivery of fresh greens

Pick up at your WeWork location

Greens delivered less than 24-hours after harvest

$50/month (only $12.50 per box!)

Start date week of July 8th, 2019

24 deliveries between July and December

REGISTER TODAY

FREQUENTLY ASKED QUESTIONS

+ How long is the program?

Each session is 6 months (24 weeks) long. The program starts the week of July 8th through the week of December 16th. You’ll be setup to auto-renew and we’ll be sure to remind you with plenty of time if you’d prefer to cancel instead.

+ How does pick-up work?

For WeWork offices we’ll be delivering shares on Tuesday afternoons after harvesting that same morning. Shares will be delivered between 2 - 4 pm close to your community manager’s desk.

+ What if I’m out during pick-up?

Since we deliver only once a week, we will not be able to defer pick up on an individual basis (we will find alternate days and notify you if pick-up conflicts with a holiday). If there’s no way around picking up your share, we recommend gifting it to someone in your office.

+ How does payment work?

The cost for the full subscription is due upon sign-up. At $50/month, the full subscription cost is $300.

+ How frequently will I be charged?

Your subscription will automatically renew at 24 weeks unless you decide to cancel. If you don’t cancel in time, we will have already planted your shares of the greens and we won’t be able to retroactively cancel your subscription or issue a refund.

+ How does cancellation work?

All of the program dates are scheduled around the farm’s growing schedule. As an early adopter, you will have the option to cancel within the first month (July 8 - August 2) for a $250 refund and you would still receive shares through those four weeks. After August 2nd, there is no cancellation allowed. However, you would be able to transfer the remainder of your subscription to someone else at a WeWork office.

+ How do I provide input?

After your first month, we’ll begin soliciting periodic feedback to influence what we grow in the WeWork farm. You will see the direct impact roughly 2 months after providing feedback since that is the typical time it takes to grow new crops.

+ How can I get in contact with Freight Farms about my share?

For any and all questions, simply email weworkgrown@freightfarms.com and the WeWork designated member of our Grown Ops team will provide you with an answer.

+ How often will you be emailing me directly?

We will be reaching out… Once a week, to remind you about pick up and share recipes. Once a month, with reminders to collect feedback. As needed, if there’s any change to the pick up schedule. Towards the end of your subscription, with information about auto-renewal and the cancellation window. And ASAP, in response to any of your emails!

Archer Farms Products Recalled Due To Possible Listeria Contamination

Some Archer Farms products are being recalled due to a possible Listeria contamination. Elevation Foods announced Friday that they are recalling containers of Archer Farms egg salad and deviled egg sandwiches

July 20, 2019

Several Freskët-Brand Products Also Affected By Recall

NEW YORK (CBSNewYork) — Some Archer Farms products are being recalled due to a possible Listeria contamination.

Elevation Foods announced Friday that they are recalling containers of Archer Farms egg salad and deviled egg sandwiches.

Elevation Foods recalled containers of Archer Farms egg salad and deviled egg sandwiches. in July 2019. (Credit: FDA)

The following products are affected by the recall:

Archer Farms-brand Egg Salad packaged in a 12-ounce clear, square plastic container, Lot Number W1906042A, Use By 12AUG2019 (printed on the side of each container) UPC 085239018682

Archer Farms Deviled Egg Sandwich Half Sandwich with Bacon, UPC 220505000002

Archer Farms Deviled Egg Sandwich on Multigrain, UPC 498780203566

All of the affected Archer Farms products were distributed nationwide.

The following Freskët-brand products are also being recalled:

Freskët-brand Egg Salad packaged in a 32-ounce clear, square plastic container, Lot Number W1906042, Use By 12AUG2019A (printed on the side of each container

Freskët-brand Tuna Salad packaged in a 5-pound white, round plastic container, Lot Number W1906054, Use By 02AUG2019A (printed on the side of each container

Freskët-brand Thai Lobster Salad packaged in a 5-pound white, round plastic container, Lot Number W1906041, Use By 02AUG2019A (printed on the side of each container)

The recall does not say where the Freskët-brand products were distributed.

No illnesses have been reported at this time.

According to the Food and Drug Administration, fewer than 1,087 cases of the products have been shipped to retailer warehouses throughout the United States.

Elevation Foods recalled containers of Archer Farms egg salad and deviled egg sandwiches. in July 2019. (Credit: FDA)

Listeria monocytogenes can cause serious and sometimes fatal infections in young children, elderly people and those with weakened immune systems. Symptoms include high fever, severe headaches, stiffness, nausea, abdominal pain and diarrhea.

Anyone who bought a recalled product should return it for a full refund.

Anyone with questions can call 866-761-9566.

Visit fda.gov for more information on this recall.

Filed Under:Archer Farms, listeria, Recall

Vertical Farming Outfit Raises $100M In Funding

Vertical farming operation AeroFarms has raised $100 million in a Series E funding round, bringing its total funding to $238 million

Credit: George Hodan

Author: Lauren Manning

Vertical farming operation AeroFarms has raised $100 million in a Series E funding round, bringing its total funding to $238 million. The funding will help the company expand its warehouse facilities that hold its vertical farms and look into growing different types of produce. The company has been on a slow and steady growth trajectory.

Ingka Group, parent company of furniture maker Ikea, led the funding round, bringing AeroFarm's total funding to $238 million. In 2019, the vertical farming company closed a deal with Singapore Airlines to provide fresh produce for in-flight food.

Based in New Jersey, AeroFarms is one of the oldest players in the indoor farming sector, founded in 2004. It is part of the Precision Indoor Plants Consortium, which focuses on growing crops specifically for indoor farming and optimizing their flavors.

Investors keep pouring dollars into indoor farming operations, which promise to provide retailers and consumers with efficiently produced, fresh and tasty produce. Indoor farming is projected to be a $3 billion market by 2024 as consumers continue to show an interest in finding more local produce.

But a numerous hurdles still challenge indoor farmers’ hopes of scaling beyond a niche industry. For starters, many indoor farms are limited in what they can produce, sticking to leafy greens and herbs. High electricity costs and water input needed to power indoor farms also have some asking whether they really are more resource-efficient than traditional farming.

In order to expand their footprint and get their products on more diners’ dinner tables, indoor farming startups are eyeing partnerships with key retailers and doubling down on efforts to be able to provide fresh leafy greens to hundreds of grocery stores, according to Reuters.

The East and West coasts have hotbeds for indoor ag innovation, but the Midwest is getting its own urban farming campuses soon thanks to Elon Musk’s Square Roots. The Brooklyn-based company inked a deal with Gordon Food Service’s campuses in Wyoming and Michigan that involves setting up 10 specially designed shipping containers to provide fresh produce to the food supply company’s supply chain. The herbs and greens grown on campus will be sold commercially to chefs and to consumers who shop at Gordon Food Service’s retail store.

Google Ventures backed Bowery Farming, which recently raised $90 million, is expanding to its third farm and has supply deals with key NYC establishments like Whole Foods, Foragers and Sweetgreen. Competitor Bright Farms is opening three new greenhouses in Massachusetts, New York, and North Carolina and sells to numerous retailers including Tops Friendly Markets, Food Lion, and Jungle Jim’s.

Vertical farming operation Plenty also raised $200 million in June and is hoping to branch into other types of crop cultivation like strawberries and tomatoes. It’s banking on e-commerce by selling its packaged salads through online grocery delivery platform Good Eggs.

The indoor ag industry is sprouting across the pond, too, with online grocery company Ocado recently taking a 58% stake in Jones Foods Co., the largest vertical farm in Europe, and joining forces with mission-driven indoor farming startup Infinite Acres.

Recommended Reading:

Filed Under: Fresh food Natural/organic Corporate

Namibia: Farm Shalom Thrives In The Desert

The stretch of land east of Swakopmund is vast, extremely arid and it appears lifeless but in the Namib Desert where one would not have expected an agronomic venture is where Farm Shalom thrives, growing a variety of veggies such as peppers, spinach and different types of flowers

2019-07-01

WINDHOEK - The stretch of land east of Swakopmund is vast, extremely arid and it appears lifeless but in the Namib Desert where one would not have expected an agronomic venture is where Farm Shalom thrives, growing a variety of veggies such as peppers, spinach and different types of flowers.

Most of the desert wildlife consists of arthropods and other small animals that live on very little water although this desert that stretches all the way to northern Namibia is inhabited by larger animals in the northern part of Namibia where its vast expanse stretches all the way to Angola.

Namibia is the driest sub-Saharan country and is the most severely affected by climate change, with rising temperatures, rainfall variability and increased droughts and severe flooding but AvaGro grows flowers and vegetables on a commercial basis in the Namib Desert.

The head of agronomist at AvaGro Ranjit Patil told New Era upon enquiry that the eight-hectare Shalom farm located 10 kilometres outside Swakopmund on the banks of the Swakop River has 27 greenhouses “where we grow cucumbers, peppers and tomatoes.”

On this piece of land turned into farmland in the oldest desert in the world, Patil and his team the majority of whom are Namibians employed as salaried workers, also grow roses and gerberas, beetroot, eggplant, herbs and spinach ‘’using open field cultivation.”

“We use high tech agriculture as climate change threatens traditional farming methods. These high-tech agriculture methods are tried and tested in India and we are replicating success here in Namibia. This involves setting up greenhouses to create a controlled environment and use of hydroponic methods like the growing media, cocopeat. Cocopeat has high water holding capacity, is heat stabilising and has high levels of porosity, which makes it ideal for farming in challenging environmental conditions,” narrated the head agronomist who holds a Master’s degree in agriculture.

“We also use soil optimisation methods for the crops we cultivate in the open, by adding manure and grass to the soil,” Patil further elaborated when queried how they have managed to utilise the desert into productive land.

“Namibia is the driest sub-Saharan country and is most severely affected by climate change, with rising temperatures, rainfall variability and increased droughts and floods. The desert soil causes limited fertility and irrigation, requires highly capital-intensive methods of production and reduces crop production,” he said in response to a question from this newspaper.

“Climate-adapted cultivation methods are needed to secure sufficient food availability in the country. High-tech agriculture with media cultivation (cocopeat) is an effective solution to overcome challenges of soil through greenhouse efficiencies. Since in India we have similar climatic conditions so it’s a win -win situation to share our expert skills with fellow Namibians,” says an upbeat Patil.

The Indian company bought the plot in 2015 and set up its first greenhouses in 2016 and 97 percent of its staff compliment of 30 employees are Namibian creating much-needed jobs for locals.

On the challenges faced he says, “climate is a key challenge that we address with precision agriculture. We address the challenge of skill through customised training programmes,” and the company uses a hydroponic system, cocopeat, to optimise growth to offset water scarcity.

Productive-wise “We harvest six tonnes of tomatoes, three tonnes of peppers and 10,000 pieces of cucumber per greenhouse (350 square metre) per season (comprising six months). We have two seasons per year and harvest on a regular basis,” says the head of agronomist at Shalom Farm.

“We work with smallholder farmers, agri-preneurs and established medium and large-scale cultivators to develop bespoke production plans to advance food sovereignty. In terms of market access, we have off-take agreements with local wholesalers and retailers,” he said on market access.

“At Shalom, we’re contributing to the shift from traditional farming to precision agriculture. This involves applying efficient water-use systems, augmenting the soil and using hydroponic mediums to grow crops. At Shalom, we are showing what is possible with the right mix of determination, technology and skills. If we can foster sustainable agriculture in the desert, where constraints – water, soil and climate – are amplified; we can do it anywhere,” he said.

FOR SALE - 2015.5 Freight Farm - Computer Controlled Hydroponic Grow System - Minnesota

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

2015.5 Freight Farm - Computer Controlled

Hydroponic Grow System

FOR SALE

Location: Minnesota

Price: $40,000

2015.5 Freight Farm Leafy Green Machine (LGM)

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples

Butterhead lettuce, Oakleaf lettuce, Swiss Chard, Mustard Greens, Cabbage Leaves, Arugula, Cilantro, Mint, Dill, Oregano, Kale, Endive, Basil, Chives and Thyme

Yields

800+ heads of lettuce weekly

12 heads per tower (256 vertical towers)

1 LGM= 1.8 acres

LGM Included Accessories:

Zebra Printer and Bar Code System + Case of Ribbons & Paper

Numerous additional extras included.

Numerous warranties still in effect

Training, website and ongoing support available through Freight Farms.

Visit www.freightfarms.com for more information.

Vertical Greenhouse Production Becoming Popular In Turkey

Turkey is looking to improve its position in the global agriculture market and has directed its focus to vertical greenhouses

Turkey is looking to improve its position in the global agriculture market and has directed its focus to vertical greenhouses.

Vertical greenhouses are expected to triple within the next 30 years and they will bring significant savings in transportation, environmental and energy costs. Vertical greenhouses are expected to be built specifically in major cities in order to save space and to prevent price increase in agricultural products. Additionally, it will create more jobs for the people living in the area.

Vertical greenhouse production is also identified by the government as one of the most important investment areas and the government is offering grants and no-interest credits through state bank programs.

Growers can receive as many as 8 times more products from vertical greenhouses compared to other production methods and it also has significant environmental benefits due to less waste coming from the production process. Irrigation requirements for vertical greenhouses are also less than other production methods and with the right equipment, growers can grow 240 root plants in one square meter.

Source: Yeni Asir

Publication date: 7/4/2019

NASA Project Proves The New Mexico Chile Is Out of This World

A team of scientists at NASA is working to launch the Española chile pepper into space. This would be the first fruiting plant the United States has grown and harvested at the International Space Station

July 14, 2019

BY KAREN GRAHAM

A team of scientists at NASA is working to launch the Española chile pepper into space. This would be the first fruiting plant the United States has grown and harvested at the International Space Station.

New Mexico chili peppers were grown in 3-gallon pots in the Ghosh Grove, Rockledge, Florida, USA from seeds bought from the Chili Pepper Institute, New Mexico State University, Las Cruces, New Mexico,

Asit K. Ghosh Thaumaturgist (CC BY-SA 3.0)

One of the issues over long-term space missions is how to supply the needed food for the trip. Free-dried food can take up a lot of space and weight on an extended voyage and won't be that tasty. Back in the early 2000s,

NASA began exploring ways to supplement astronauts’ diets with plants that can be grown in space or on other worlds.NASA began by experimenting with growing seeds in simulated space environments here on Earth. With improved technologies, NASA is now learning to grow vegetables and fruits on the International Space Station (ISS). But it's not easy growing plants with less gravity than is found on Earth.

Seeds tend to move around in zero-gravity and water clumps up. Remember, you can't pour a glass of water in space. There is also the need to be frugal when it comes to space - we mean the size of the garden

ASA Image: ISS021-E-006274 A close-up view of the Cell Biology Experiment Facility (CBEF) SPACE SEED experiment is featured in this image photographed by an Expedition 21 crew member in the Kibo laboratory on the International Space Station. ISS021-E-006274 A close-up view of the Cell Biology Experiment Facility (CBEF) SPACE SEED experiment is featured in this image photographed by an Expedition 21 crew member in the Kibo laboratory on the International Space Station. NASA

Differences in lighting, temperature and even the medium used to grow the seeds had to be tested. And because of the weight of soil, NASA has been looking at methods like hydroponics and aeroponics. Hydroponics involves delivering water and nutrients to plant roots using liquid solutions, and with aeroponics, plants are grown in a misty air environment.

The first edible veggie is grown in space

The first portable growing box for space, equipped with LED lights, called Veggie, was tested at the orbiting outpost in 2014. After a few problems were worked out, astronauts got their first taste of NASA-approved space-grown lettuce in 2015. Now, there are two Veggie boxes and a third called the Advanced Plant Habitat.

A picture of Tokyo Bekana Chinese cabbage growing in a NASA Veggie unit. Image dated February 17, 2017.ISS Expedition 50 member

Since NASA's first attempts using the Veggie, a number of green leafy vegetables, as well as zinnias and a sunflower, have been grown successfully on the ISS. In 2018 the Veggie-3 experiment was tested with plant pillows and root mats. One of the goals is to grow food for crew consumption. Crops tested at this time include cabbage, lettuce, and mizuna.

Today, fruits and vegetables that can be safely stored at room temperature are eaten on space flights. Astronauts also have a greater variety of main courses to choose from, and many request personalized menus from lists of available foods including items like fruit salad and spaghetti.

But even with all the variety of foods available for bringing on board the ISS, there is still the need for growing vegetables and fruits on space flights. And now that we are getting good at growing green, leafy vegetables, it was time to experiment with growing a fruiting plant.

Assorted bags of snack food and dehydrated food, as served on the ISS.NASA

The New Mexico Chile

Jacob Torres is part of a team of 20 people at NASA in Florida, working on a way to grow vegetables on board the ISS. Torres is originally from the Espanola Valley in New Mexico. When Torres arrived at NASA in 2018 for an internship, scientists were exploring the possibility of growing Hatch peppers, a New Mexico chile.

Torres suggested that NASA look at the state's Española pepper instead. There was a good reason for the suggestion. Hatch peppers are grown in the deserts of New Mexico, while the Española pepper grows at higher elevations and has a shorter growth period. Tosses thought they would be better for growing in space.

After experimenting with growing the Española peppers here on Earth under simulated space conditions, the little peppers are ready to be sent off to the ISS sometime between November and January 2020. If successful, the Española pepper would be the first fruiting plant - a flowering plant that grows a seed pod to procreate -- to be grown at the International Space Station

New Mexico chiles dried on the plant in Mesilla, New Mexico, 2016.Dicklyon

.“What an honor, what a privilege, and what a great way to represent the Espanola Valley,” said Victor Romero from the Espanola Valley Chamber of Commerce. Locals are thrilled with the publicity. “I think it’s going to open a lot of doors, you know? Hopefully, it grows there in space, and I think everyone will jump into the growing of the chile,” said chile farmer Fidel Martinez.

The española is an old chile pepper, has a slightly stronger pungent and bitter flavor and matures early to red, first grown by the Spanish settlers in the San Juan Valley, near modern-day Española, New Mexico. The Española Improved is a hybrid of the Sandia and Española, and provides Española's taste and early maturation, with a better yield, and larger peppers.

More about nasa, espaola pepper, fruiting plants, new mexico chile, international space station

New Zealand: $2.75m of Funding to Make Northland Hydroponic Horticultural Capital

The partnership will enable Maungatapere Berries, owned by the Malley Family, to develop the first phase of a high-tech education, training and employment operation, as part of a 20ha hydroponic orchard expansion, doubling its workforce to 360 over the next five to eight years

Regional Economic Development Minister Shane Jones announces $2.75million of Provincial Growth Fund money for Maungatapere Berries, which grows fruit hydroponically, west of Whangārei.

Northern Advocate

13 Jul, 2019

Northland could become the hydroponic horticultural capital of the country with a $2.37-million Provincial Growth Fund loan going to a Whangarei company to expand its already huge hydroponic operation and create 45 new full time jobs.

The $2.37m PGF partnership was announced by the Minister of Regional Economic Development, Shane Jones, at Whangarei business Maungatapere Berries that will create the first centre for growing excellence in the New Zealand hydroponics horticulture industry.

The partnership will enable Maungatapere Berries, owned by the Malley Family, to develop the first phase of a high-tech education, training and employment operation, as part of a 20ha hydroponic orchard expansion, doubling its workforce to 360 over the next five to eight years.

As new generation growers Patrick and Rebecca Malley said they are excited at the potential of hydroponics as one of the greatest untapped opportunities for the future of sustainable horticulture in Northland.

Maungatapere Berries director Patrick Malley and berryfruit manager Aroha Heta.

"Our plan, as part of the PGF partnership, is to further build on the extensive work the family's business has already undertaken in hydroponics providing permanent employment opportunities for locals in horticulture,'' Patrick Malley said.

"We aim to use it as a template designed to create better paying jobs and lifelong careers for young Northlanders as well as improving the social and economic benefits for local communities.''

The hydroponic orchard will focus on berryfruit and other fruit varieties that flourish when grown hydroponically in Northland's warm semi-tropical climate. He said the hydroponic centre of excellence will become a sustainable farming reference site for Northland growers with the aim of introducing and increasing the production of hydroponic fruit crops in the region and improving the economic opportunities for the Northland region.

The Malley family first started developing part of their 37ha kiwifruit orchard into a hydroponic berry operation four years ago, focusing on growing high-quality, good-tasting fruit to supply the New Zealand domestic market all year round.

They have continued investing and expanding their operation, which employs 45 fulltime staff and an additional 180 staff during the peak season, and includes an advanced packhouse servicing the domestic market, with future plans to export.

He said ongoing research into new fruit crops combined with greenhouse innovation and a strategy to build deep capability has the potential to develop a large environmentally sustainable horticultural industry that supports real growth in living wage employment and social equality for Northland.

Britain’s Ocado Is Raking 17 Million Pounds In Vertical Farming To Diversify

Britain’s Ocado is raking 17 million pounds ($22 million) into the emerging “vertical farming” trade, additional diversifying the online grocer and technology group’s enterprise. Vertical farming includes producing food indoors, with crops grown on a collection of stacked ranges in a controlled atmosphere

July 8, 2019

Britain’s Ocado is raking 17 million pounds ($22 million) into the emerging “vertical farming” trade, additional diversifying the online grocer and technology group’s enterprise.

Vertical farming includes producing food indoors, with crops grown on a collection of stacked ranges in a controlled atmosphere.

“We foresee a day the place clients’ vegetables are harvested hours earlier than they’re packed, meters from the place they’re shipped,” Ocado stated in a press release on Monday.

Ocado mentioned it had shaped a joint venture known as Infinite Acres with vertical farming contributors 80 Acres Farms and Priva Holding, with every holding a 3rd of the equity.

Priva is a Netherlands-primarily based industrial methods supplier to the horticultural trade, with a variety of merchandise and options for climate control and course of automation.

U.S.-primarily based 80 Acres offers plant science knowledge and operations administration, whereas Ocado will contribute its software and hardware methods, together with robotics, automation and AI.

Ocado stated it has additionally acquired a 58% stake in Jones Food Company (JFC), Europe’s largest working vertical farm, which is predicated in Scunthorpe, northern England.

JFC’s plant produces Vegetables and herbs for British prospects with its capability anticipated to develop to 420 tonnes a year.

Ocado, which mentioned its fairness investments within the joint venture and JFC would total 17 million pounds added that the density of vertical – farms permits them to be positioned a lot nearer to prospects, probably co-located after its companions’ distribution centers, supermarkets and close to population facilities.

Ocado has a 1 % share of Britain’s grocery market solely. Nevertheless, its 7.9-billion-pound stock market valuation has been driven by its technology.

This offers worldwide retailers with the infrastructure and software to develop their very own online grocery companies to compete with the likes of Amazon.

Ocado shares had been up 3% at 0809 GMT.

Solar Panels Could Make Saltwater Safe For Farming

A new device created by researchers at the King Abdullah University of Science and Technology in Saudi Arabia can purify water through solar power

An ambitious project in Saudi Arabia wants to capture wasted solar heat for good uses.

July 11, 2019

A new device created by researchers at the King Abdullah University of Science and Technology in Saudi Arabia can purify water through solar power. While there have been previous attempts to merge solar power and clean water, the scientists say they have developed a new three-stage system that radically increases efficiency.

The need to combine water purification through clean means is a growing one, giving the rise in man-made climate change. Water scarcity is increasing throughout a variety of places on the planet, from South Africa to India. "The water-energy nexus is one of the main issues threatening sustainable global development," says Wenbin Wang, a Ph.D. student at the University's Water Desalination and Reuse Center, in a press statement.

To combat the problem, the KAUST team looked at solar panels holistically. Silicon solar panels take in around 20 percent of the light they absorb, converting them into electricity. While that number is increasing, scientists predict that no photovoltaic (PV) panel will be able to absorb more than around 27 percent of the light. That leaves a significant amount of light being reflected, which generates heat.

The team, led by Professor Peng Wang of the Reuse Center, looked to put that heat to work.

"The PV panel generates a lot of heat, and the heat is considered a headache in PV,” Wang tells Cosmos. "The uniqueness of the device lies in its smart and effective use of the waste heat of the PV as a resource, which leads to its high efficiency in both electricity and fresh water production."

To capture the heat, the team built out a stack of water channels, separated by porous hydrophobic membranes and heat conduction layers. These layers were attached to the bottom of a commercial PV panel. Heat from the panel would vaporize seawater in the top channel, cross through the porous membrane, and then finally condense as fresh water in the third channel.

The team also put the vapor of the seawater to use. A thermal conduction layer to the next seawater channel would collect its heat, allowing the machine to recycle that energy and create even more fresh water.

RELATED STORIES

A Bright Future: How Solar Panels Work

Did Scientists Crack the Desalination Problem?

In tests, the team was able to generate up to 1.64 liters of water per square meter of solar panel surface every hour.

“In a sense, it utilizes solar energy to a much fuller capacity,” Wang tells Cosmos.

The next step for the team is to try and expand its project to the extent that it would be viable for agriculture. Many innovations in agriculture, like vertical farming, attempt to save water. Being able to use saltwater for farms could radically change how water is consumed around the world. In the U.S. alone, farming represents approximately 80 percent of the country's consumptive water use.

"Raising sheep in the field of PV farms is feasible because grass grows well using the fresh water from solar-panel washing," Wenbin says in the press statement. "A PV farm with sheep grazing while seawater is desalinated using our device could be ideal in arid regions near the coast."

American Society for Horticultural Science - 2019 Annual Conference - July 21 - 25 • Las Vegas, Nevada

The Annual Meeting of ASHS is where the latest science and technology is being showcased related to horticulture. Our mission is to bring together horticulture researchers, scientists, industry, academia, government, and students to cultivate ideas and share new techniques

2019 Annual Conference

Conference Program (pdf)

July 21 - 25 • Las Vegas, Nevada

The Tropicana Las Vegas

July 21 - Student Education & Career Day

The Annual Meeting of ASHS is where the latest science and technology is being showcased related to horticulture. Our mission is to bring together horticulture researchers, scientists, industry, academia, government, and students to cultivate ideas and share new techniques.

Since the conference is being held in Nevada, ASHS is partnering with Oasis Biotech, one of the more innovative and effective green industry entities in the United States, for an up-close journey into Vertical Farming at the Oasis Biotech facility.

Participants will be afforded access to the largest and most technologically advanced Indoor Vertical Farming facility ever designed and implemented in this country. Oasis Biotech uses state-of-the-art LED lighting technology and precise, cutting-edge hydroponic growing methods to generate a wide array of fresh, pesticide-free, non-GMO produce and non-traditional crops 365 days a year.

Attendees will have the opportunity to examine the agricultural system that recycles 100% of unused water and nutrient consumption while significantly reducing environmental impacts. On an inspiring expedition through the 215,000-square-foot indoor vertical farm, interested participants will witness the way that Oasis Biotech is attempting to make positive changes in farming.

Oasis Biotech boasts the ability to grow crops at a faster rate than traditional agriculture. Their LED and hydroponic systems reportedly ensure that crops receive optimal light spectrums and nutrient mixes, and they reduce loss from pests, diseases, and weather, which encourages higher yields. Oasis Biotech also calculates that they save 90% more water than other systems and are environmentally friendly.

The hour and a half tour will explain how this massive resource was created and how it is achieving its goal of producing more than one million pounds of microgreens, lettuce, and herbs.

The meeting focuses on the distribution of science through technical sessions, poster and abstract presentations, keynote speakers, and workshops. Enjoy networking and group activities where you can catch up with peers. There is also a spotlight on students–from career path mentoring to competitions and group activities to create relationships that can last throughout your career.

Program Information

• Keep checking the conference pages as new information is updated frequently

• Be part of the conference by submitting an oral or poster abstract - submission site is now open - Acceptance Email Expected April 15th.

• Submit a workshop (for ASHS Professional Interest Groups only) - submission site is now open

General Conference Information

• Check out the registration rates (below) and complete your registration starting in a few months

• Find out about discount rates for hotel and travel to the conference

• There are travel grant opportunities for students - don’t miss out!

Group Activities for 2019

• Luncheon Series with Featured Speakers

• Opening Reception & Pool Party

• Sightseeing and Professional Tours

• Student Education & Career Day

• Student Competitions and Scavenger Hunt

How India's Hydroponic Farmers Are Building Businesses

In the middle of an industrial building in the Andheri East neighbourhood of Mumbai is a farm. It is spread across 1,000 sq ft and grows 2,500 plants. It is no ordinary farm. The hum of an air conditioner greets visitors into the room, tube lights replace sunlight, and there’s no soil on the patch

Urban hydroponic farmers are making it possible to eat fresh, pesticide-free produce, with no soil use

BY JOANNA LOBO

PUBLISHED: Jul 13, 2019

Herbivore Farms, in Mumbai's Andheri, is spread across 1,000 sq ft and grows about 2,500 plants

In the middle of an industrial building in the Andheri East neighbourhood of Mumbai is a farm. It is spread across 1,000 sq ft and grows 2,500 plants. It is no ordinary farm. The hum of an air conditioner greets visitors into the room, tube lights replace sunlight, and there’s no soil on the patch.

Herbivore Farms is an example of a newly popular and successful type of urban farming—hydroponics. Simply put, it is growing plants in water. Soil is replaced by a water solution that is rich in macronutrients like nitrogen, potassium, phosphorous, calcium nitrate and micronutrients like manganese, zinc etc. A ‘grow system’ controls the balance of nutrition, humidity and temperature, uses less water than soil-based farming and increases yield without chemicals or pesticides.

“There are many advantages to urban farming. The land requirement is quite low, water consumption is 80 percent less, the water is recycled and saved, it is pesticide-free and in cases of high-tech farms there is no real dependency on the weather,” says hydroponic farmer Ajay Naik of Letcetra Agritech in the Sattari district of Goa.

Hydroponic farming is setting up roots all across India. Sakina Rajkotwala and Joshua Lewis, of Herbivore Farms, have come into focus in the last year. In Manori, Linesh Pillai started Terra Farms as a pilot project before taking the idea countrywide. Delhi has Triton Foodworks; Noida has Nature’s Miracle; Chennai has Sriram Gopal’s Future Farms and Rahul Dhoka’s Acqua Farms; and Gurugram-based company, Barton Breeze, has six farms across Haryana, Rajasthan, Uttar Pradesh, and Uttarakhand.

Sakina Rajkotwalla quit her job at Magic Bus to start Herbivore Farms;

Image: Ronit Sarkar

“Hydroponics and other soil-less farming techniques can help us take our agriculture and farming industry to the next level,” adds Naik.

The new farmer

The path to hydroponic farming is paved with good intentions: Sustainable farming and the desire to eat fresh, organic, zero-carbon food.

Rajkotwala and Lewis’ journey began after they quit their jobs at Magic Bus and Directi, respectively, and decided to seek out their purpose in life. The question of ‘who we are’ led them to examine what they eat and how to grow it, and a stint at an Auroville farm, and eating fresh produce, turned out to be the change they sought. “It was a revelatory experience, as it opened our minds to the importance of food,” says Lewis. “We wanted to replicate that farm model—pluck vegetables and eat them fresh—in the urban space.” Hydroponics made the most sense, and they started with a small farm on Rajkotwala’s terrace in Juhu in 2017 and moved to Andheri in 2018.