Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

We Are Excited To Announce Our Partnership With Seneca College To Bring Our First "The Vertical Farming Bootcamp"

Want to learn more about Vertical Farming, Aquaponics and the technology behind it? Please Click Here

Want to learn more about Vertical Farming, Aquaponics and the technology behind it? Do you have a business model in mind and need to learn the components to execute it? Now is your chance! Sign up for our Vertical Farming Bootcamp!

June 1, 2019 - 9:00 am to 5:30 pm

Seneca College Newnham Campus

Please Click the link to sign up:

https://www.eventbrite.ca/e/vertical-farming-bootcamp-tickets-60711365328

UCD Sells Surplus Land To Rooftop Greenhouse Company

The 33.6-acre agricultural parcel that UC Davis sold to Gotham Greens in Dixon abuts I-80 and is zoned A40, which means it is suitable for rural residential, with an existing agricultural well and ample irrigation water. Courtesy photo

By Tanya Perez

A recent story in the Sacramento Business Journal about the sale of UC Davis-owned land inspired some questions — namely, how does UCD ever have surplus land?

The April 4 story noted that “Brooklyn, New York-based indoor farming company Gotham Greens Holdings LLC has bought 33.6 acres of (agricultural) land just west” of the campus. The sale price, which went to the highest bidder, was $954,000, or approximately $28,400 per acre.

The Sacramento Business Journal said the land had been donated to UCD “decades ago.”

The property, at 9113 Olmo Lane in Dixon, is described by Realtor.com as “Nearly 34 acres of prime irrigated row crop land with a two acre mature homestead, enclosed by chain-link fencing. … Within the fenced-in yard is an old boarded-up dwelling (circa 1920), an old storage shed and an occupied office building.”

It is zoned A40, which means it is suitable for rural residential, with an existing agricultural well and ample irrigation water.

The Enterprise talked with UCD’s Grant Rockwell, the executive director of real estate services to understand how and why land such as this would be sold.

In a nutshell, this land had been gifted to UCD, with any proceeds from the rental or sale of it allocated to benefit Intercollegiate Athletics, or ICA.

“When properties like that are gifted to the university,” Rockwell said, “there are key beneficiaries.” In this particular case, “Rental or sale income is funneled to ICA.”

A boarded-up and uninhabitable house, circa 1920, comes with the property, as well as an office building and an old shed. Courtesy photo

He continued, “(This property) didn’t generate a lot of rental income,” because the house was uninhabitable and the leased farmland and office building were not bringing in much revenue. “Selling it was more lucrative, and the endowment goes back to ICA.”

Rockwell noted that the money was “earmarked for specific scholarships for ICA — off the top of my head, for men’s football, men’s and women’s basketball, and women’s volleyball.”

While Rockwell’s office is involved in this type of transaction, he said that the UC Office of the President “technically runs the process.”

In the case of the Olmo Lane property, sealed bids were opened on Jan. 15, and Gotham Greens was the highest bidder.

Rockwell explained that “If we think the property could sell for over $1 million, it goes through a sealed bid process.” When the university has properties such as single family residences that are expected to sell for less than $1 million, “They don’t go through a bid, and it’s a more traditional” sale process.

Gotham Greens might seem like an unusual choice to buy prime ag land. The company touts itself as growing “pesticide-free produce … using ecologically sustainable methods in technologically sophisticated, 100% clean energy powered, climate-controlled urban rooftop greenhouses.” As well, it says they are “farmers that live in apartments. We see green fields where others see rooftops.”

Rockwell said he believes that “Gotham Greens is trying to make inroads in to this market.”

As for UCD’s real estate services office, it handles “a full spectrum of real estate activities,” Rockwell said, which ranges from acquiring land and buildings to property management and off-campus tenant improvement coordination.

His goal for his team is “Effective asset management, (with consideration) of what the campus needs.”

Rockwell added, “When donors gift property to the university, they are often very specific with regard to the recipients. … With the current real estate market, there are opportunities to provide proceeds to the (beneficiaries).”

— Reach Tanya Perez at tperez@davisenterprise.net or 530-747-8082. Follow her on Twitter at @EnterpriseTanya

Italy: Thirteen Hectares of Lettuce Grown On A Floating System

All types of lettuce are grown with the floating system on an area of 13 hectares. The whole system is automated to produce salad marketed under the brand name Ninfa. The location is Standiana, (Ravenna), near the large amusement park Mirabilandia, famous in Italy. "Here we also have fun with water - and we produce lettuce with water", entrepeneur Gianluca Rossi says.

The owner Gianluca Rossi

High quality

A production site of this size, with these technologies is not often seen in Europe. According to Rossi he gets positive responds on his systems, even from the major seed companies in the world.

"The 13 hectares are part of a 100-hectare farm. The design took more than six years to complete and I did it myself together with the leading experts. I made many trips abroad before it was done", he recalls.

Here is how the roots appear in the support, just removed from the water

On the track, oriented in the direction of the processing warehouse, the panels with the lettuce.

Gianluca shows how everything is done with utmost care. "Our greenhouses only serve as protection, not to anticipate cycles. The production runs from mid-April to December, while in the winter months it is suspended."

The cultivation takes place with floating panels certified for contact with food. The roots are immersed in water. Nutrition is carried out with the classic triad of elements N, K, P and microelements. Weed killers are not needed, of course. Defence follows the technique of integrated control.

Watch the video!

The positioning of the panels with lettuce on the railroad.

180 hectare land

"With traditional methods, adds Rossi - considering also the rotations, in the open field - it would take 180 hectares of land to produce what we can do in 13 hectares of floating system. In our case, the rotation is nothing more than the replacement of the "old" water that is not wasted but returned to the fields of the remaining 87 hectares of our company".

No water waste

At first glance, it might seem that there is a waste of water, but that is not the case. "Careful management allows for prolonged and waste-free use. With the same number of plants produced, the reduction in water consumption varies between 70 and 80% compared to a traditional method".

Here are some other numbers: 9 million cultivated plants expected in 2019, 4000 tons of products and 169,000 floating support panels. "Our history goes back a long way, Rossi points out, because it was my father, from a very young age, who dedicated himself to the trade in vegetables. At a national level, we are already known for our activity as traditional producers, and now we want to make ourselves known for this new reality".

Aerial view of the Standiana farm. There are 13 hectares of greenhouses with lettuce grown in floating systems

Minerals

Water, like the earth, does not of itself, contain enough nutrients, but they are both a means of mixing, holding and conveying them. Unlike traditional methods, in the tank, the mineral salts are available only to plants that absorb according to their daily needs, excluding leaching, waste and dispersion into the surrounding environment or in the aquifers.

"More yields, less waste of nutrients, less water consumption, no forcing, concludes Rossi. There is a difference, even from an organoleptic point of view. The panel tests carried out on the Ninfa salad have shown a higher percentage of mineral salts than traditional crops, with a significant increase in shelf life.

Swedish Supermarket Opens Onsite Container Farm

It's The Third Container Farm Made By US Manufacturer

US container farm manufacturer Freight Farms has built and opened a new container farm at a Swedish supermarket through their Scandinavian distributor Futufarm. Located in Halmstad Sweden, Freight Farms customer ICA Maxi Högskolan is one of ICA Gruppen's 1,300 grocery stores in the country. This month, the store began harvesting a range of hydroponically-grown greens for shoppers from the 'Leafy Green Machine' container farm, bringing the number of Freight Farms' container farms in Sweden to three.

"We're excited to be the first ICA Maxi store to implement an onsite farm," said Rikard Hillarp, owner ICA Maxi Högskolan. "By growing crops just steps from our shelves, we're able to offer our customers what are truly the freshest greens possible."

On March 29, the group kicked off its launch with a Harvest Festival for customers, selling produce and offering free samples of the newly-harvested greens and a Q&A with store employees Max Rydberg and Douglas Klang, now the newest onsite farmers.

ICA Maxi Freight Farm exterior

Transport to the store and capacity

The Leafy Green Machine destined for the Swedish supermarket began life in the United States where it was built by Freight Farms in Massachusetts. It was trucked to New York City from where it was shipped to Europe, before making its journey to the ICA Maxi store by truck and placed into position by a crane. The company says this farm can produce up to two acres worth of produce.

"Freight Farms' containerized farming technology allows ICA Maxi Högskolan to create and maintain the optimal growing conditions to harvest produce year-round using less than 5 gallons of water per day," Freight Farms said in a release. "Beyond the store's initial offering of butterhead lettuce, spinach, and herbs, the farm's integrated IoT data platform, farmhand, will also allow the store to grow non-native crops otherwise unavailable in the region, regardless of seasonal limitations in Sweden's Nordic climate."

ICA Maxi Högskolan is Freight Farms' third container farm in Sweden, and the company said there is anticipation to scale.

ICA Maxi store employees

Scandinavia ideal setting for container farms

With winters being rather cold and offering limited daylight, Scandinavia is restricted in what it can produce locally, especially outside the summer months. Freight Farms also noted that consumers in the region are known for their penchant for sustainable and environmentally-friendly solutions to a range of situations. In fact, IKEA made an announcement last month, stating that it would begin growing lettuce on site for its staff soon, suggesting that it may later sell it to paying customers if all goes well. However, this trial is only for lettuce and ICA Maxi's new farm is fully operations and consists of several varieties which are all available to customers. Therefore, Freight Farms wants to highlight the benefits of having food grown locally.

"Freight Farms' technology is especially helpful in Sweden, where our short growing seasons can limit crop availability throughout the year and increase our reliance on imported produce," added Hillarp. "We're now able to shorten the distance food travels to get to our customers from 2,000 kilometers to just 30 meters."

Max Rydberg and Douglas Klang - the new "onsite farmers"

Futufarm's Chairman, Harrie Rademaekers, noted that the potential for container farms in Nordic countries is great, pointing out that much of the produce consumed in the region originates from overseas. "Even though we have access to greens all year round, only 50 percent of the crops we consume are grown in the region," he observed. "In general we are very dependent on imported crops from Holland and Spain, which is not very sustainable. Nordic consumers are very focused on locally-grown and this fact builds a strong case for local container farms serving local food stores, restaurants, hotels, schools and so forth. Our climate is changing and water supplies are becoming more precious, which will force us to find new methods of farming. Food tech solutions will helps us, and in this case, Freight Farms' hydroponic technology can provide a climate-controlled farming solution that helps us save 95 percent more water than traditional agriculture."

Some leafy greens produced in the container farm

"By removing the miles between the food source and consumers, produce maintains nutrient density and stays fresh for far longer, significantly reducing food waste for both retailers and consumers," said Freight Farms' CEO Brad McNamara.

"Our team innovated the technology to empower individuals and businesses all over the world to decentralize the food system in meaningful ways specific to their local community or environment," he concluded. "We're thrilled to work with industry leaders like Rikard Hillarp and retailers like ICA Maxi, who together have the forward-thinking vision and reach to disrupt the grocery industry internationally."

For more information:

www.freightfarms.com

Will The Urban Agricultural Revolution Be Vertical And Soilless?

Over the last seven years, New York City has become an epicenter for urban CEA, offering planners an in-situ setting in which to evaluate its impact

A case study of controlled environment agriculture in New York City

Controlled environment agriculture (CEA) is an emerging form of farming increasingly found in cities worldwide. Advocates promote CEA as the future of food production, arguing for its potential to address challenges ranging from climate change to food insecurity. Detractors state that CEA’s narrow focus on high-end produce, along with its intensive capital and energy needs, limit its meaningful contribution to the urban food system.

Over the last seven years, New York City has become an epicenter for urban CEA, offering planners an in-situ setting in which to evaluate its impact. A new case study examines the current state of CEA in New York City, its composition, requirements, and future. The authors identify CEA’s relative contributions, which include providing a small number of green-sector jobs and increasing access to produce in low-income communities. In parallel, they question if CEA provides sufficient benefits to warrant public-sector support.

Recommendations for cities considering CEA include critically analyzing its purported benefits; evaluating the environmental, economic and social potential of projects located on publicly-owned rooftops and land; and focusing incentives on nonprofit and institutional production that show clear community benefits.

Access the full study at ScienceDirect.

Publication date: 4/18/2019

These Calgary School Kids Think They've Found A Way To Grow Food On Mars

A group of budding outer space social innovators from Calgary think they've found the secret to growing food on Mars

Stephen Hunt · CBC News

Posted: Apr 18, 2019

Calgary's Nanosharks in Houston on Thursday. (Alex Gubski)

A group of budding outer space social innovators from Calgary think they've found the secret to growing food on Mars.

The Nanosharks, a science team from JunioTech Kids Academy in Calgary are in Texas this weekend, competing in the FIRST (For Inspiration and Recognition of Science and Technology) Lego League Championship.

That's the name of an annual science competition, where teams of young people from around the world research real-world problems in areas such as energy or food-safety, then pitch a solution by navigating a Lego robot through a course.

The Nanosharks were one of two Canadian teams selected to compete in Houston, with a pitch to grow food on Mars by turning the nutrient-deficient soil of the Red Planet into growing fields that one day might sprout field peas.

That's what 12-year-old David Krutik told Calgary Eyeopener host David Gray in a Friday interview.

"We're planning to kind of make this type of fertilizer where we're going to place it in the [Martian] soil, and when it mixes with the soil it's going to be like Earth soil," Krutik said.

So where will all that fertilizer come from? Gray asked Krutik. "Humans," said Krutik.

Two members of the Nanosharks. (Alex Gubski)

Growing food on Mars

That was expanded upon by Alex Gubski, the Nanoshark's robotics coach and mentor.

"They are obviously carrying the water for hydroponics projects," Gubski said.

"That was a little bit bulky and more on the expensive side, so the kids decided, 'OK, how we can augment the idea of growing food for Martian colonies versus hydroponics?'

"So they thought, 'we'll just analyze different cultures and see which ones will improve their quality of soil better."

That's when they came up with the idea of turning poop into fertilizer.

"That will be in abundance," Gubski said. "Travel to Mars will be a few months, so they're going to bring a few hundred pounds of that."

That pitch will be part of the Nanoshark's presentation in Houston, which Gubski said is a three-pronged competition.

"It's the core values — how they operate as a team," he said.

"It's the project, which is the scientific part of the competition," he added.

"And the third one is a robotic game. So teams get to build a robot, program it, and try to score as many points as possible in 2.5 minutes.

"All teams are judged in all three areas. In general, a score depends on their good performance in all three, and they're scored and awarded, based on that."

The Nanosharks from Calgary. (Alex Gubski)

Whether the Nanosharks ever get the opportunity to test out their ideas on the Red Planet remains to be seen,. But what's not debatable is that an event such as this helps engage young people in STEM (science, technology, engineering and mathematics), at the same time encouraging the core values of FIRST, such as teamwork and innovative approaches to real-world problem solving.

Don't tell Krutik — who is back for the second time — or any of the rest of the Nanosharks all that stuff, however.

They have their own reasons for promoting Martian agriculture.

"It was fun," Krutik said. "Every day we had like two hours on the weekends to work on it. It didn't take too much time out of my day. Sometimes, we'd go to each other's houses to work on it — and then we'd also play."

With files from the Calgary Eyeopener.

Acquisition of Manufacturing Assets

Cobotix is the current manufacturer of the Company’s Patented Vertical Farming Technology

Vancouver (Canada), April 17, 2019

Affinor Growers Inc. (“AFI” or the “Company”) (CSE:AFI, OTC:RSSFF, Frankfurt:1AF) is very pleased to announce that it has entered into a letter of intent to acquire manufacturing assets that make up the Cobotix Manufacturing Inc.’s (“Cobotix”) business, undertakings and goodwill in Port Coquitlam (the “Acquisition”). The Company and Cobotix will have thirty (30) days to complete the due diligence process and determine a closing date for the Acquisition. In consideration for the assets, the Company will pay to Cobotix up to $2,900,000, subject to a valuation of the assets (the “Consideration”).

The Consideration will be satisfied by certain cash payments and the issuance of up to 38,000,000 common shares (the “Common Shares”) in the capital of the Company at a deemed price of $0.05 per Common Share. Upon completion of the Acquisition, it is anticipated that Ron Adolf will be appointed to the board of directors and become an officer of the Company. No additional changes will be made to the Company’s board of directors or management based on the Acquisition.

Cobotix is the current manufacturer of the Company’s Patented Vertical Farming Technology. As a result of the Acquisition, the Company will be able to consolidate the intellectual property associated with the manufacturing and design aspects of the Vertical Farming Towers, and will be able to extend its reach, diversification and stability, which are fundamental to the growth and profitability of the Company going forward. Cobotix is currently developing multiple cell manufacturing opportunities throughout North America, building on the success of current operations. The Company and Cobotix act at arm’s length.

Cobotix brings over 30 years of expertise to the design and manufacturing of the Vertical Farming Towers. Over the past six months, Cobotix has been working directly with the Company to develop and test the new designs that were unveiled at the 2019 BC Tech Summit.

Randy Minhas commented “This is a great opportunity for the Company to move to the next level with its Vertical Farming Towers and to be involved directly with design and manufacturing going forward. We will now be in a position to capitalize on the extremely talented team at Cobotix, who have been instrumental in our new tower designs.”

Ron Adolf commented “We’re excited to be joining AFI and collectively working to commercialize the new Vertical Farming Towers while continuing to work on new designs and technologies in the vertical farming industry. Over the past six months, we have been very pleased with the great strides AFI has made in advancing their technology. Our business model of collocated manufacturing cells is a great fit in the evolution of Cobotix and AFI.”

Randy Minhas

President and CEO

About Affinor Growers

Affinor Growers is a publicly traded company on the Canadian Securities Exchange under the symbol ("AFI"). Affinor is focused on developing vertical farming technologies and using those technologies to grow fruits and vegetables in a sustainable manner.

Neither Canadian Securities Exchange nor its Regulation Services Provider (as that term is defined in the policies of the Canadian Securities Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release may contain assumptions, estimates, and other forward-looking statements regarding future events. Such forward-looking statements involve inherent risks and uncertainties and are subject to factors, many of which are beyond the Company's control that may cause actual results or performance to differ materially from those currently anticipated in such statements.

Could The Future of Farming Be Urban?

BY NIC CHA KIM

April 22, 2019

CARSON, Calif. -- According to the United States Department of Agriculture, roughly a third of food produced for human consumption is lost either through pesticides, bad weather, transportation, and various other factors.

“These guys are ready,” said Deanna Kennemer of GP Solutions, referring to a row of vegetables grown vertically inside a shipping container.

Urban farming has been on the rise and with good reason. It takes less land, less water, and farmers can grow year-round.

“These greens are called fusion romaine and we planted them about eight weeks ago,” said Dennemer. “They’re ready to be harvested today.”

Cultivated inside modular and stackable shipping containers, these grow pods are designed with the backyard farmer and local restaurant in mind. With much of our food harvested outside of the country and transported hundreds of miles, urban farming can provide locally sourced organic food to city centers as well as disaster areas.

“Okay, it’s all ready to go. Back in its slot,” said Dennemer as she fitted a slot of vegetables under a water drip.

Farming could be as easy as plug and play.

“This is a soil-based pod,” said Shannon Illingworth as he showed us around an urban farm fitted for organic farming instead of hydroponics.

He got interested in urban farming when he was infected with E. coli after eating at a restaurant. Not knowing where the food came from, he decided to create a system where the origin of food can be traced with an app on your phone.

“What you see here today is really evolving indoor growing environments to a soil-based product that’s already nutrient enriched,” said Illingworth. “So new growers and existing growers can make it real simple.”

No need for sun or seasons, pesticides or manure.

“As you can see, the plants love it,” said Illingworth.

Farming in the future is looking bright.

Call For Videos: 2019 Greenroofs & Walls of The World Virtual Summit

Linda Velazquez on April 19, 2019

Greenroofs & Walls of the World™ Virtual Summit 2019

The 2019 Greenroofs & Walls of the World™ Virtual Summit – Greenroofs.com’s 5th completely online conference – will be held Live in September.

Held biennially since 2011, the Mission of the Greenroofs & Walls of the World™ Virtual Summits is to inform, share, and create a global social media experience online for learning and networking via the power of the Internet.

The theme of the 2019 Virtual Summit:

“Cooling a Warming Planet with Living Architecture”

The climate crisis is now and we need to embrace bold solutions and address it in many ways, especially with nature-based design and projects that promote green infrastructure as well as those with social and socially equitable benefits.

Encompassing a broad range of design solutions and a diverse community of multi-disciplinary professionals are crucial in our effort to mitigate and reverse the cataclysmic effects of human induced global warming.

Unique in our industry, the Greenroofs.com Virtual Summits are community destinations that allow you to connect with everyone and experience greenroofs, greenwalls, and green living infrastructure online. Participants have an incredible opportunity to learn about innovative site-specific, cultural, and climatic approaches in living architecture and – this time around – some transformative climate policy.

And with our social media and live events, you can connect and meet awesome experts and practitioners – all with with no carbon footprint!

#VirtualSummit2019

Earth. Image: NASA

Call for Videos

New this year and for the first time, we are issuing an Open Call for Videos! Do you have something unique and interesting to share with the world regarding “Cooling a Warming Planet with Living Architecture?” We’d love to hear from you!

What

Think of your video as an interactive live presentation that is prerecorded by you. We are looking for creative videos about 10 – 30 minutes in length of ideas, people & projects talking about how design can and does address climate change. We are open to videos from both individuals and multi-speakers either in a panel-type or multiple interview format.

Watch previous speaker videos on our Albums / GreenroofsTV channels: 2017, 2015, 2013 and 2011.

Send us an Abstract of your proposed video, either in writing or short under 1-minute video format (much more fun!). But it’s up to you.

Please include: Video Title; Primary Presenter(s); Contact Info; Type(s) of vegetated LID (Low Impact Development) Living Architecture (for example greenroof, greenwall, green street, bioswale, bioretention pond, storm barrier, etc.); Abstract (300 word maximum); and Biography: (100 word maximum).

We need engaged speakers: you MUST be available to participate in social media and make time for a Live Q & A!

By submitting your video, you grant Greenroofs.com permission to share your work with our readership via website, email, and on social media channels.

What Not

We are not looking for:

General information on green roofs and/or green walls/living architecture/green infrastructure – we have a pretty sophisticated audience!

Simply narrated PowerPoint presentations – sure you can show a few narrated slides, but overall it has to be lively and dynamic. Go outside and film your subject or film inside with people discussing and actively engaging with each other.

Your entire video – please only send us What is listed above for now!

Just Another Day on Aerosol Earth. Image: NASA/Joshua Stevens/Adam Voiland

How

Send Abstract and/or Video Abstract to: virtual@greenroofs.com

Our distinguished 2019 Advisory Board and I will review all Video Abstracts to determine a diverse group of sustainability and living architecture professionals.

Key Dates

Upon acceptance of your video, specifics will follow but these are the Key Dates to keep in mind:

Call for Videos: April 19, 2019

Call for Video Abstracts Due: May 31

Notification of Accepted Videos: June 7

Completed Videos Due: July 26

The 2019 Virtual Summit is Open with Scheduled Live Happenings & Social Media Events: September 1-30

Earth. Image: NASA Earth Observatory by Robert Simmon, using Suomi NPP VIIRS data from Chris Elvidge (NOAA National Geophysical Data Center)

#VirtualSummit2019

Join Us and the World in September

The 2019 Greenroofs & Walls of the World™ Virtual Summit will be a fun and interactive experience for all.

We hope you join us online in September to learn and share your vision for a healthier planet enveloping living architecture with the world!

For additional info, contact me at:

Linda S. Velazquez, ASLA, LEED AP, GRP

Greenroofs.com Publisher & Greenroofs & Walls of the World™ Virtual Summits

Host

linda@greenroofs.com

o: (770) 772-7334 | t: (888) 477-1326

ARCHITECTURE, CLIMATE CHANGE, GREEN INFRASTRUCTURE, GREEN ROOFS, GREEN WALLS

Hydroponics To Aquaponics: How University Students Are Learning To Master Sustainable Food Production — On The Roof

PSU

April 18, 2019

Pittsburg, KS

Fish soon will be living on the roof of the science building at Pittsburg

State University.

And those fish will be helping to grow plants.

It’s a forward-thinking project by Students for Sustainability (S4S), a student organization at PSU, in cooperation with Enactus, another student organization, and the PSU Biology Department.

S4S has gained a reputation for its recycling efforts: each Fall, members collect as much recyclable material as they can during the move-in process at the residence halls. At each Spring, they collect reusable items students don’t want to take with them when they leave campus to head home — hair dryers, brooms, microwaves, you name it. Those, they sell at the SEK Recycling Center.

The group’s latest initiative, hydroponics and soon to be aquaponics, is one that’s trending: they’re promoting sustainability by developing a sustainable food production project they have installed in a greenhouse on the roof of Heckert-Wells Hall.

“Trial phase”

One recent afternoon saw a group of students there tending plants; they're growing without soil in a “garden” built of PVC pipe and covered with mosquito netting to diffuse sunlight.

Among them was Charlie Beetch, who moved his family from Hutchinson, Kansas, to Pittsburg to pursue a bachelor’s degree in Sustainability, Society, and Resource Management (SSRM); it’s the only program of its kind in Kansas.

“We’re still in the trial phase,” Beetch said. “Th fish ought to be here next week. Then, it will be a full system.”

As he checked the health of the plants, a classmate, Cecily Stephens, a non-traditional graduate student from Pittsburg, harvested greens she considered using in a salad later.

“We’re growing arugula, red kale, romaine, collard greens, and butter lettuce,” said Stephens, who dreams of becoming an environmental journalist. “I’m pushing for starting herbs, and we could use them for fresh pesto!”

“Perfect fit”

The project was borne of conversations between S4S advisors and students during last year’s Earth Day celebration in the Overman Student Center. Enactus member Dodge Mattingly was displaying a booth that described his group’s trip to Haiti to set up a hydroponic system at an orphanage to help them grow fresh produce.

S4S members had been dreaming of a food production project — especially one that would provide a learning laboratory experience. Enactus was wanting to give away their prototype hydroponic set-up. And S4S

President Erin Kruse, a Girard, Kansas, native, had experience with aquaponics, hydroponics, and farm-to-table production at Johnson County Community College before transferring here.

“It seemed like a perfect fit,” said Jim Triplett, who volunteers as the Special Assistant to the President for Sustainability — a position created last year as part of the university’s focus on sustainability.

Enactus also gave S4S the fertilizer, seeds, and other supplies needed, and offered to share what they had learned to help S4S get up and running.

“Enactus had worked out the hydroponic side of the project, but the aquaponics portion is a new dimension, because it involves growing fish,” said Triplett, who for decades taught in the PSU Biology Department and served as its chair.

“The waste from the fish will break down and provide nutrients for the plants that will use the nutrients to grow, cleaning the water before it’s returned to the fish,” he explained. “When properly balanced, the system provides extremely efficient food production in terms of resources, energy and space.”

The biggest challenge? Fitting the PVC pipes and other supplies into the elevator.

Networking

Last month, their project took another step forward with a visit to Nile Valley Aquaponics, in inner Kansas City, Missouri, where they toured the facility and gained insight into its closed loop system.

The trip was organized by Kruse, who works at the Student Assistant for Sustainability in the President’s Office, and is majoring in SSRM.

Joining her on the trip were several S4S members, SSRM majors, faculty members including Catherine Hooey (Geography), June Freund (Economics), Tim Bailey (Geography), and staff including Jesse Briscoe (Housing), Elliott Rowland (Physical Plant).

Nile Valley provided inspiration: it features three, six-foot deep, lined trenches that house more than 60,000 tilapia. The water from the fish-rearing troughs is pumped up to the top of a stack of four growing beds that sit on top of the trenches and run their full length, Triplett said.

The nutrient-laden water travels through each bed and drops to the bed below until it is returned to the fish trough. In addition to plants and fish, the facility raises soldier flies to feed the fish and goats to eat the vegetative leftovers from production.

The trip also included a visit to Johnson County Community College, which created a Center for Sustainability in 2003.

“A composting operation there takes in all of the food waste from the facility and runs it through a hot tumbler and, with the addition of wood chips and sawdust, it develops into a compostable mix in about 10 days,” Triplett said.

The mix then is moved to aeration piles and is used as a soil amendment on the campus farm.

A greenhouse there houses the aquaponics project, which features a fish tank that holds 60 tilapia. They provide the nutrients for the hydroponic production of leafy greens and larger plants in media beds. All of the material grown from the system is used in JCCC dining services.

“It’s an amazing system and is reflective of future sustainable food production. We hope some of these ideas can be applied to future projects at PSU,” Triplett said. “There is a lot more to do before our system is fully operational, but this project has caught the imagination and interest of an active and enthusiastic group of students who are investing their time and energy to forge a new path in sustainable food production."

Learn more about the SSRM degree at https://bit.ly/2Og4STx

Early Bird Tickets Are Available For The September Conference

Early Bird Tickets Are Available For The September Conference. Tickets

Are Limited, Get Yours Soon!

TICKET INFORMATION

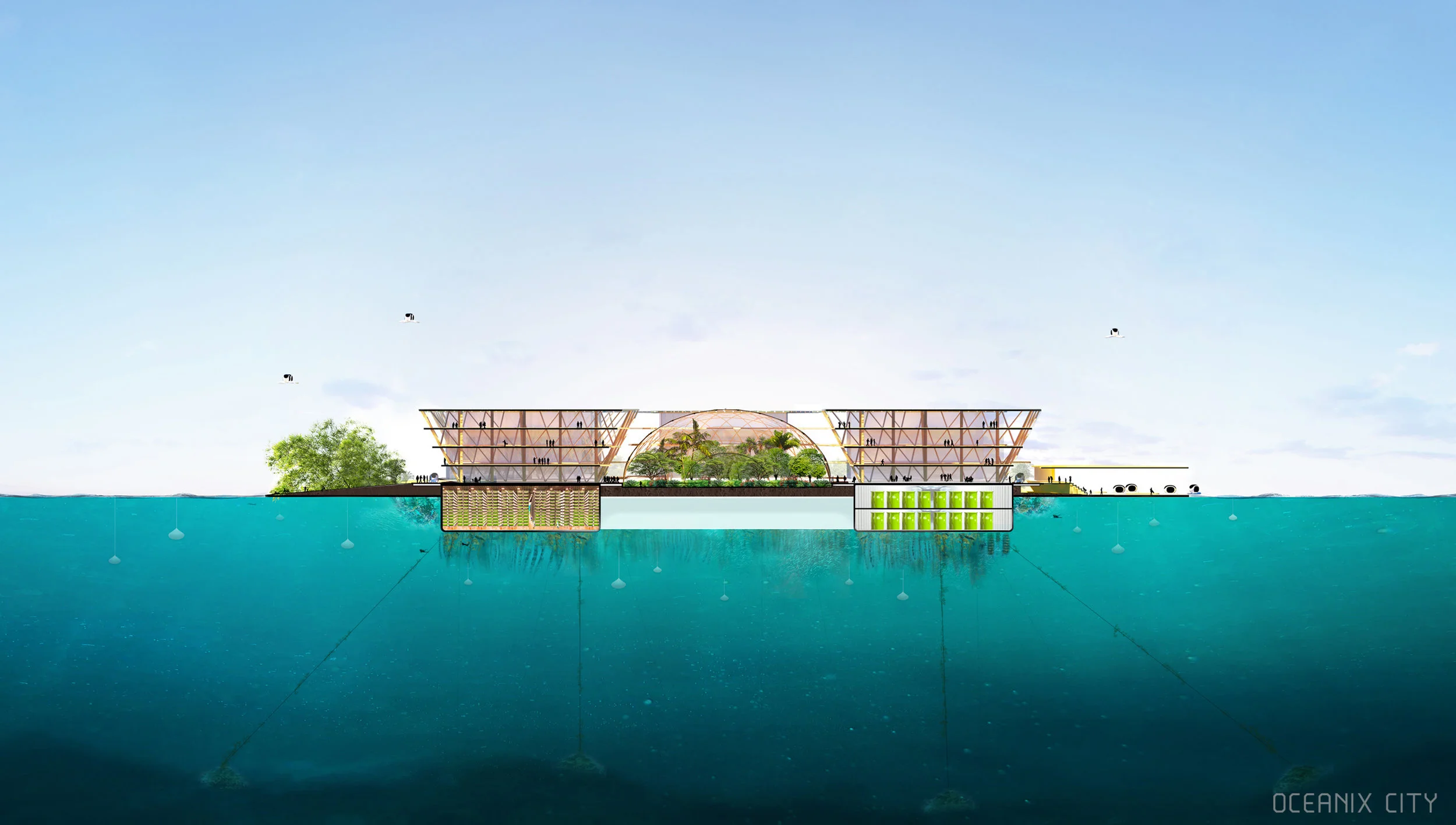

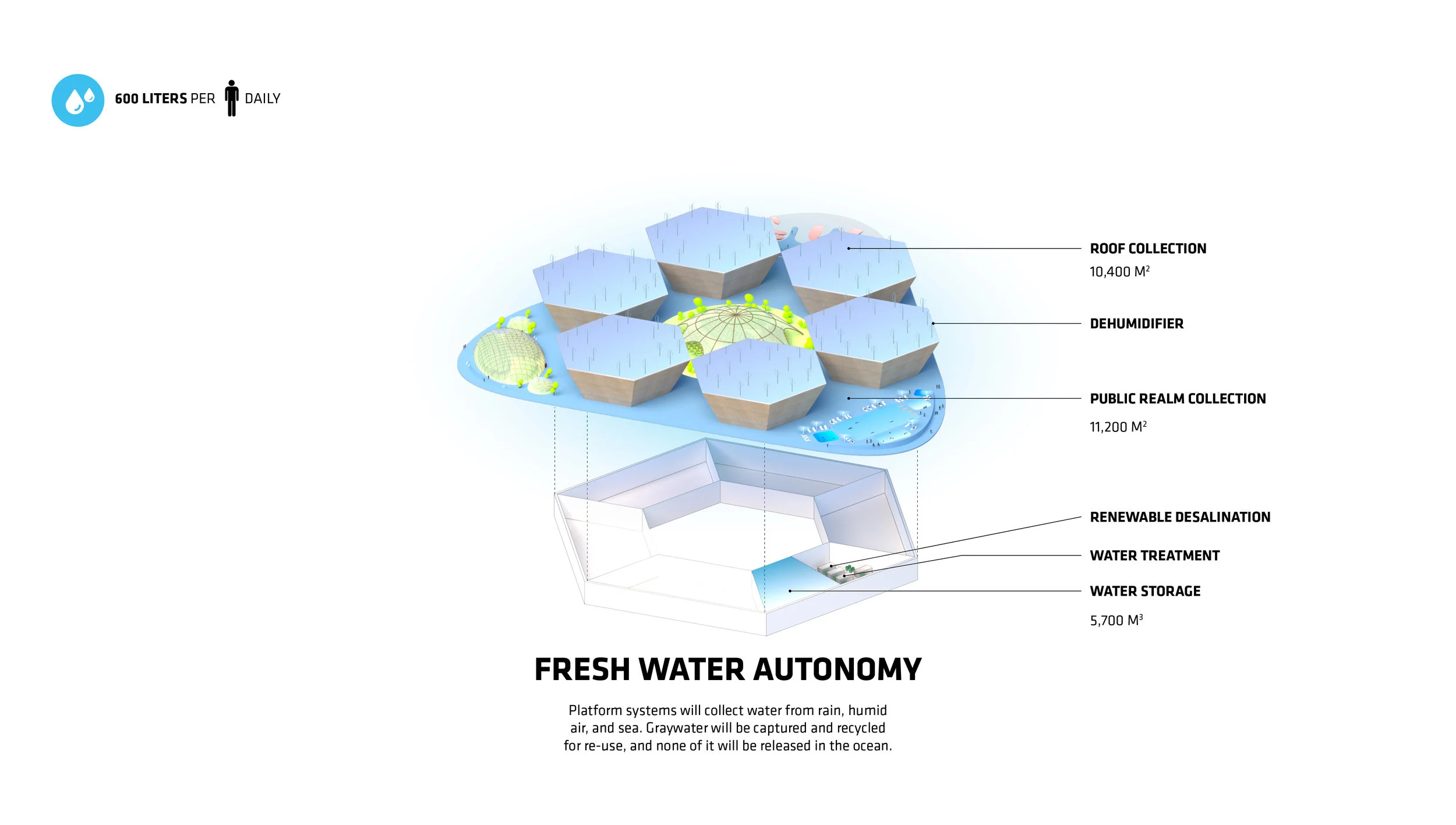

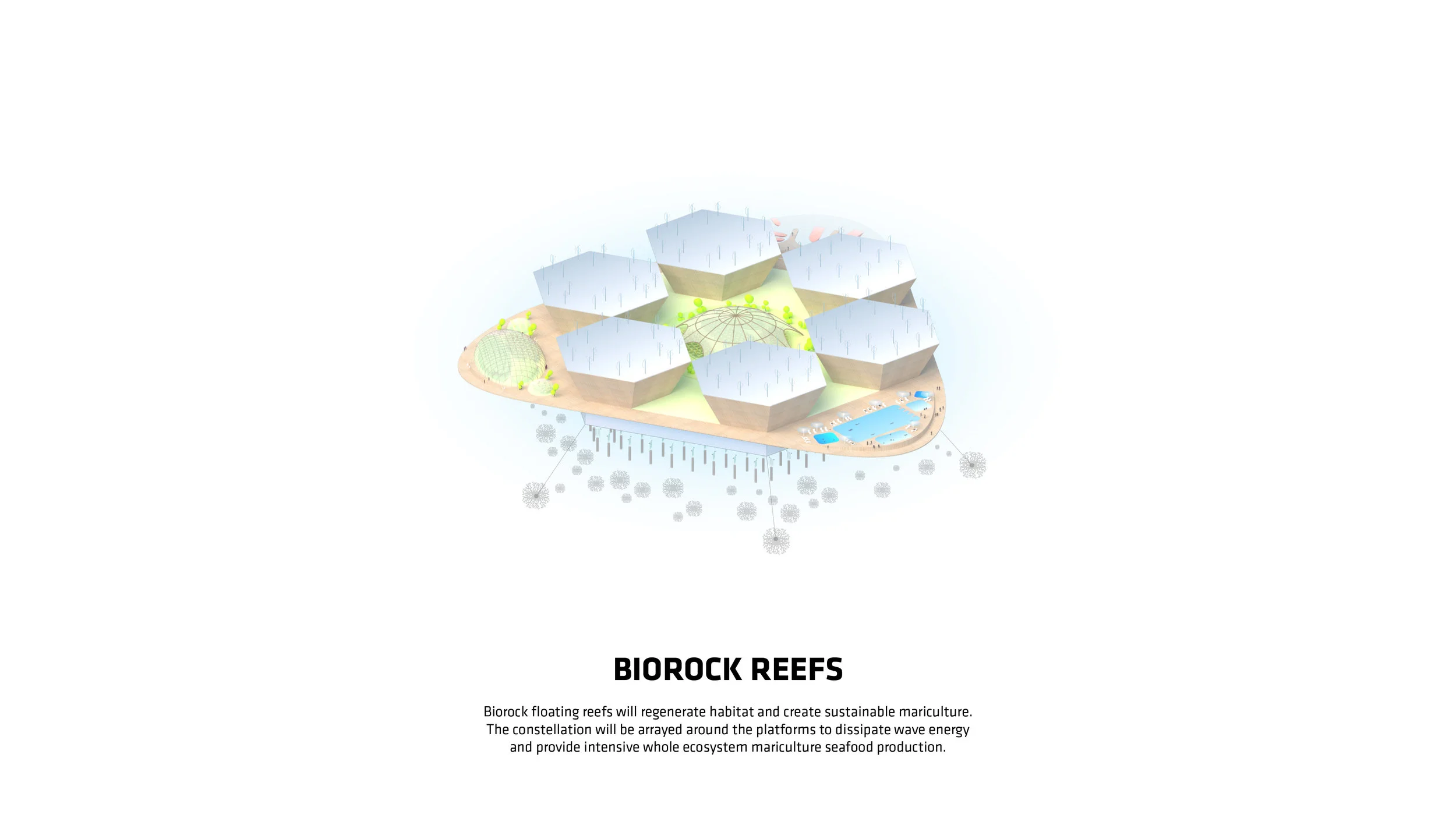

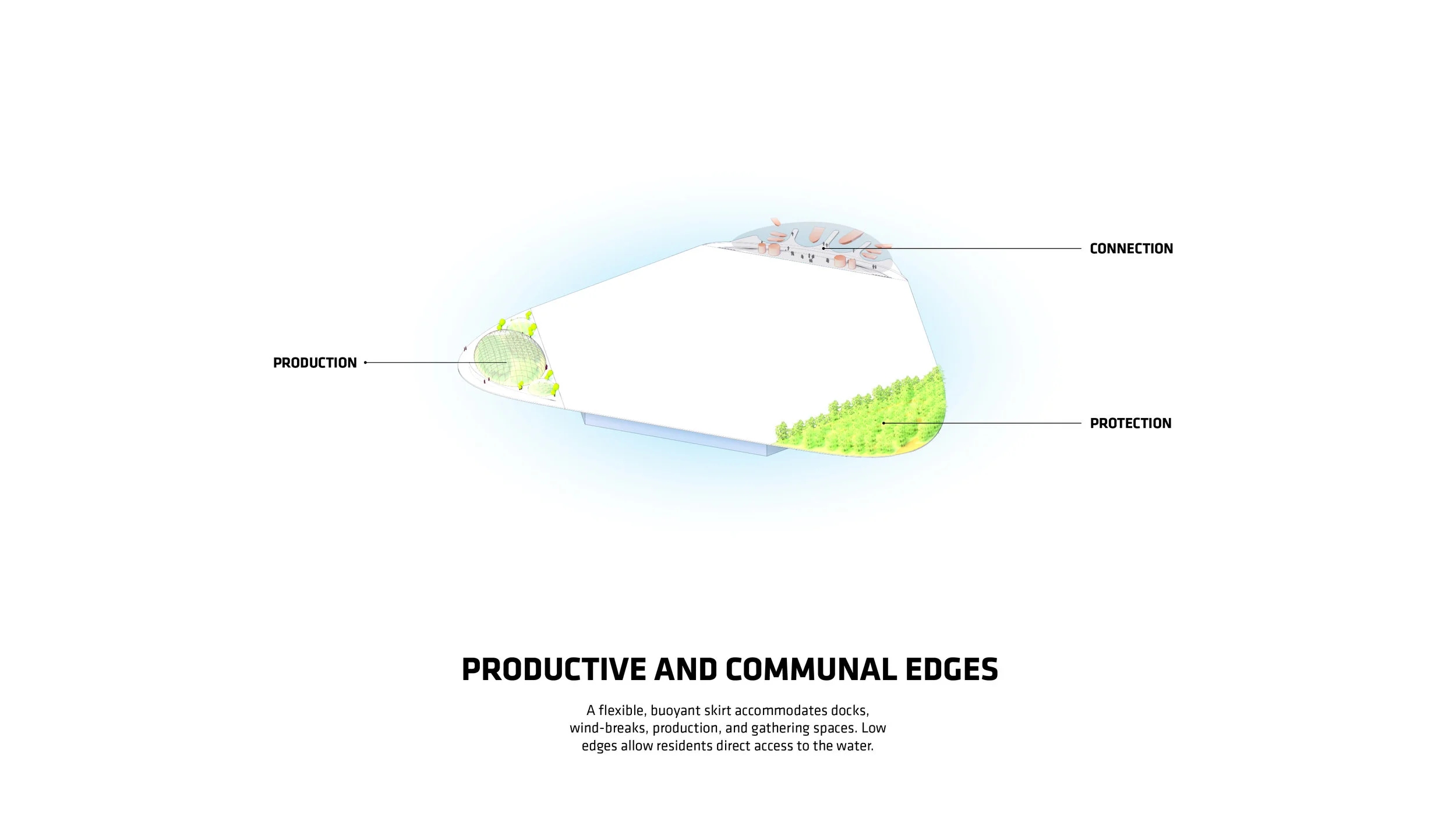

Oceanix City: This Concept Of Floating City Includes Food Production And Farming

Linked by Michael Levenston

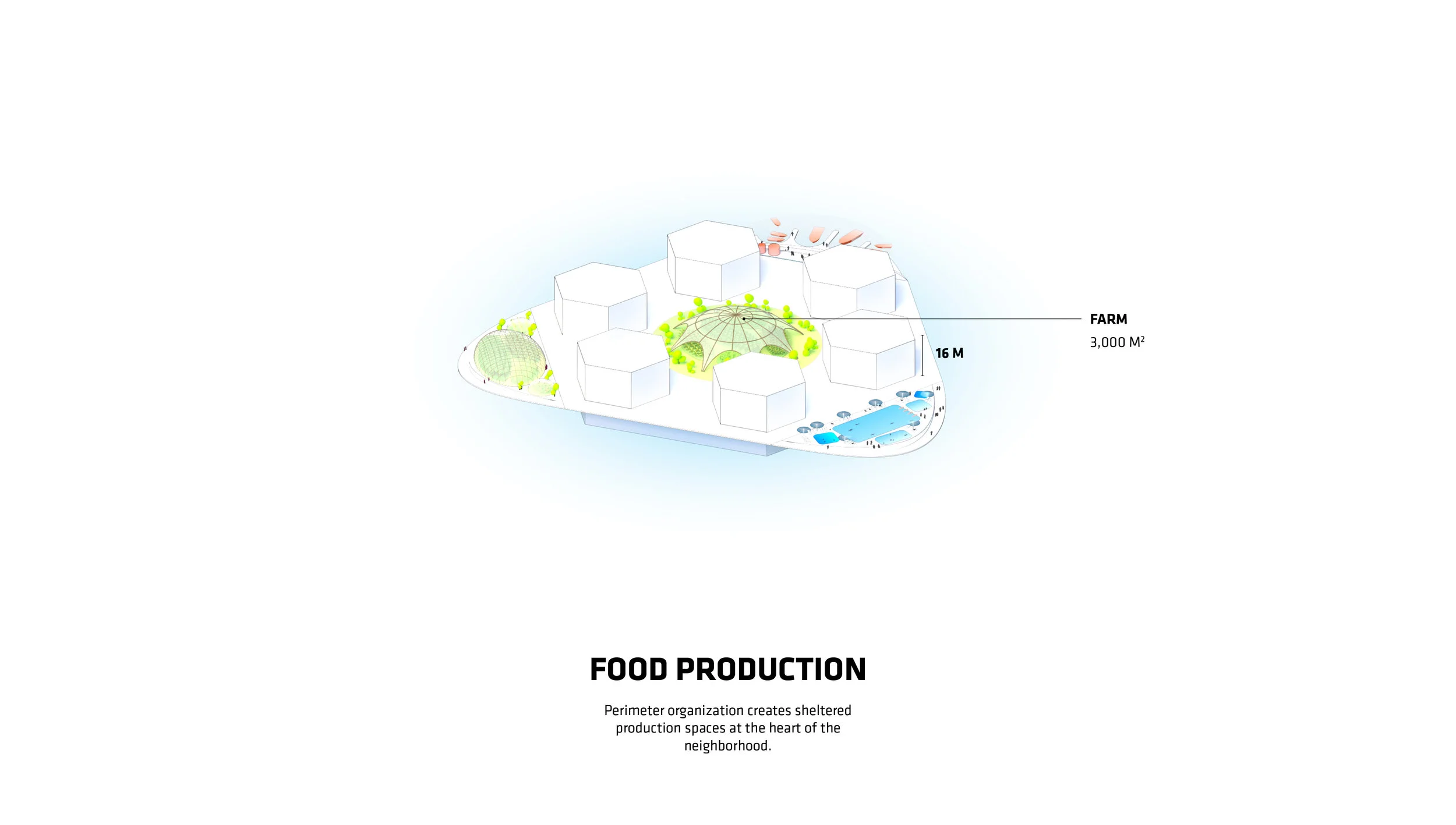

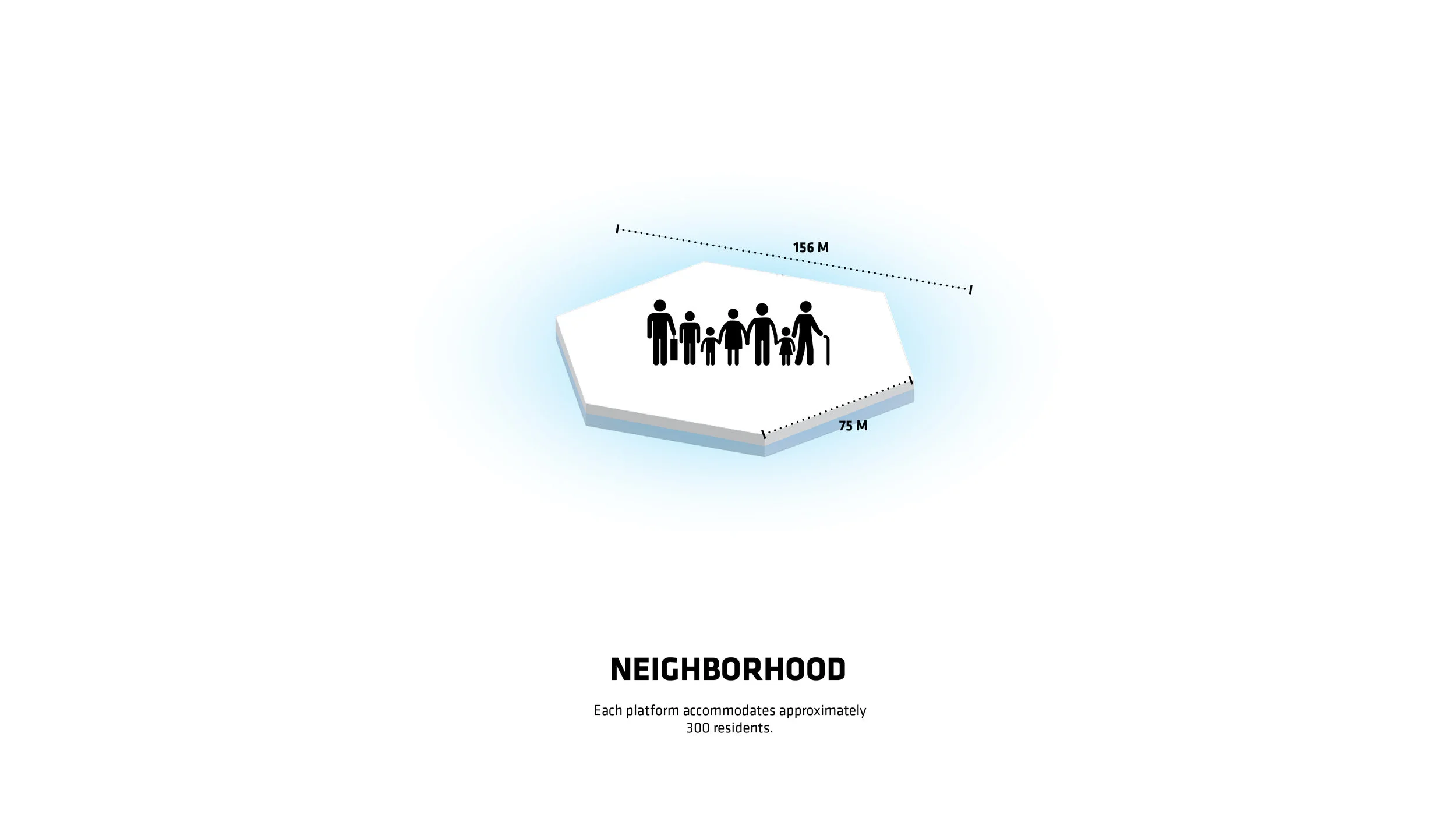

“Every island has 3,000 square metres of outdoor agriculture that will also be designed so that it can be enjoyed as free space,” said Ingels.

By Katharine Schwab

Fast Company

Apr 4, 2019

Excerpt:

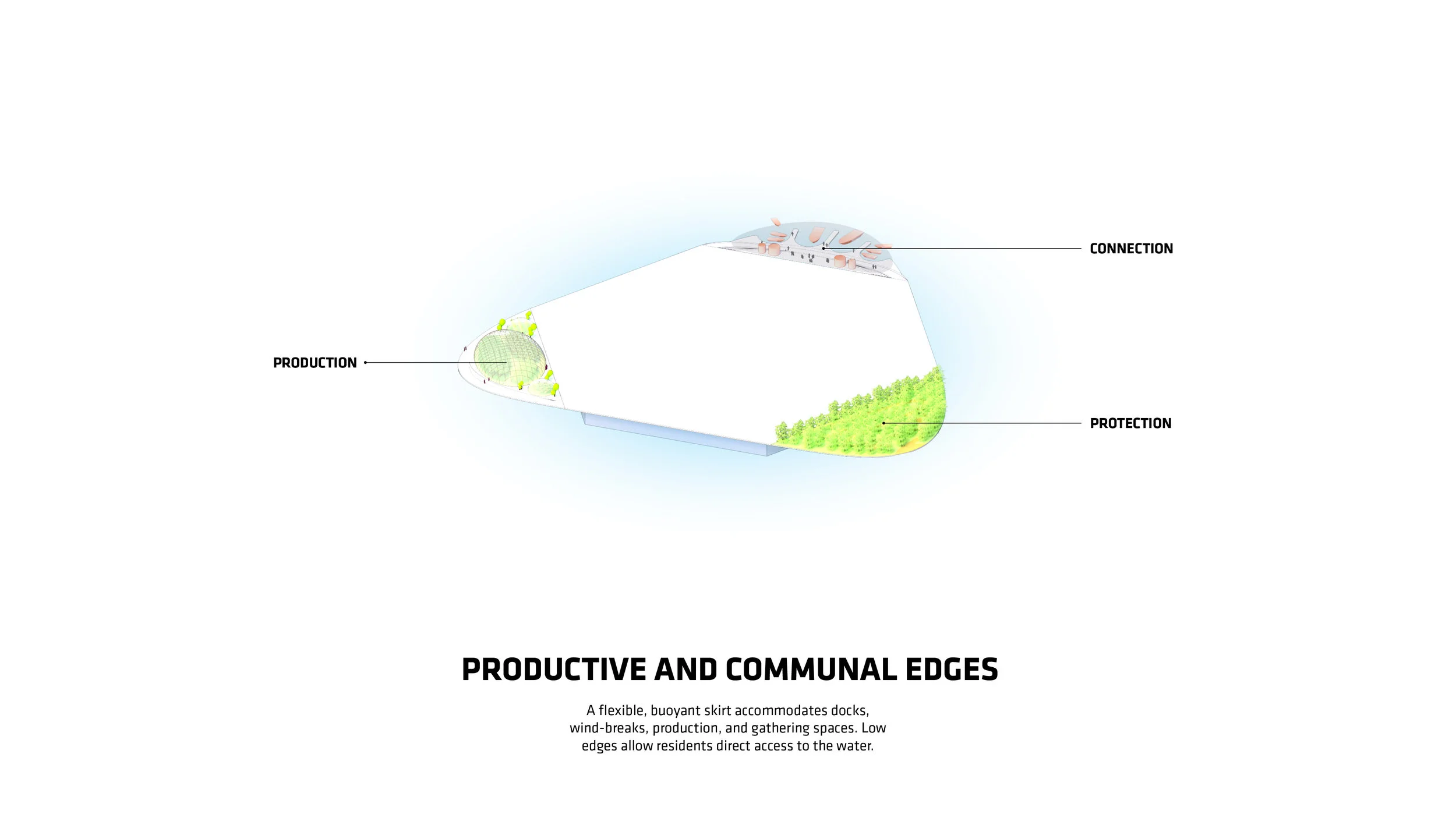

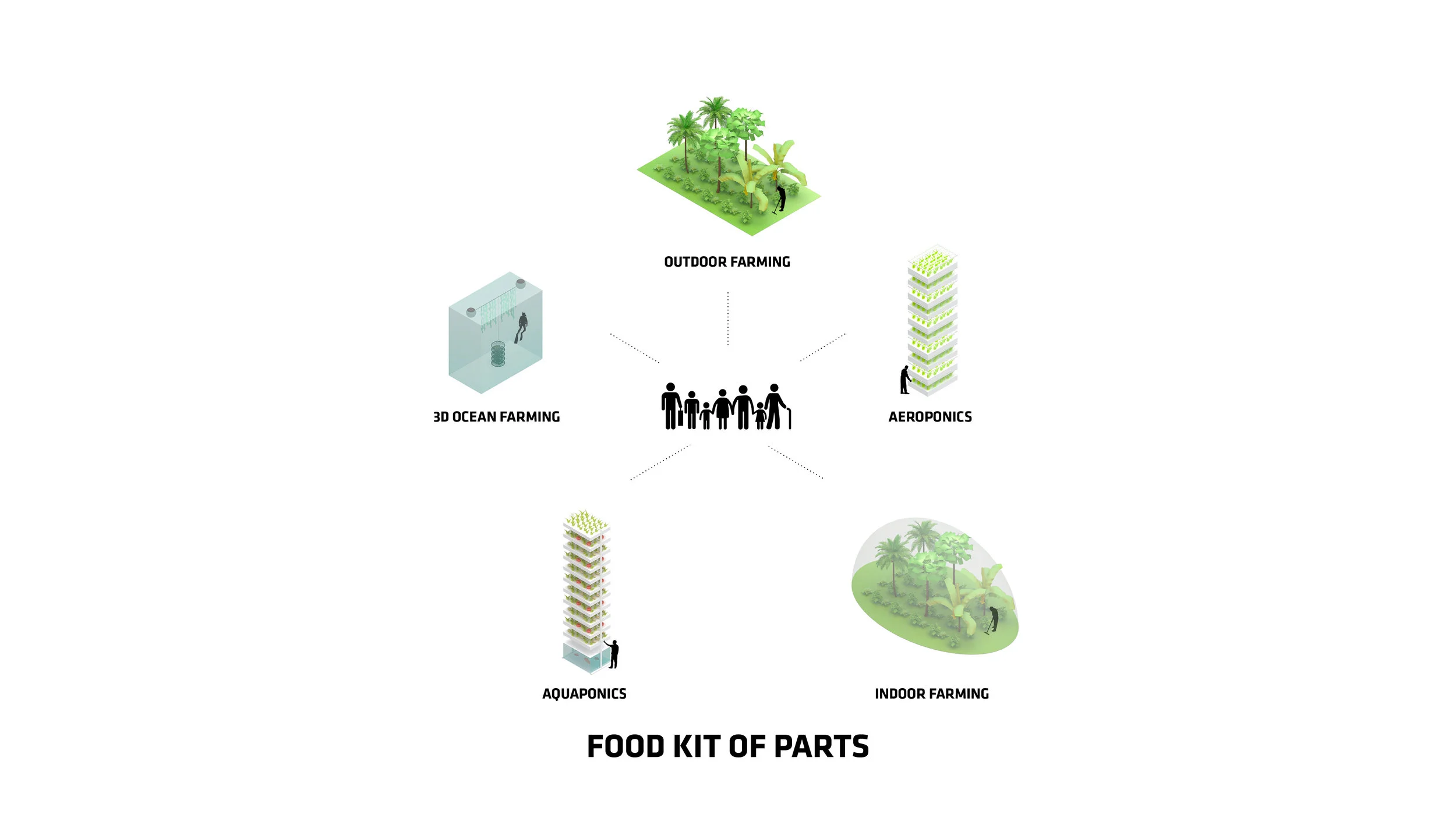

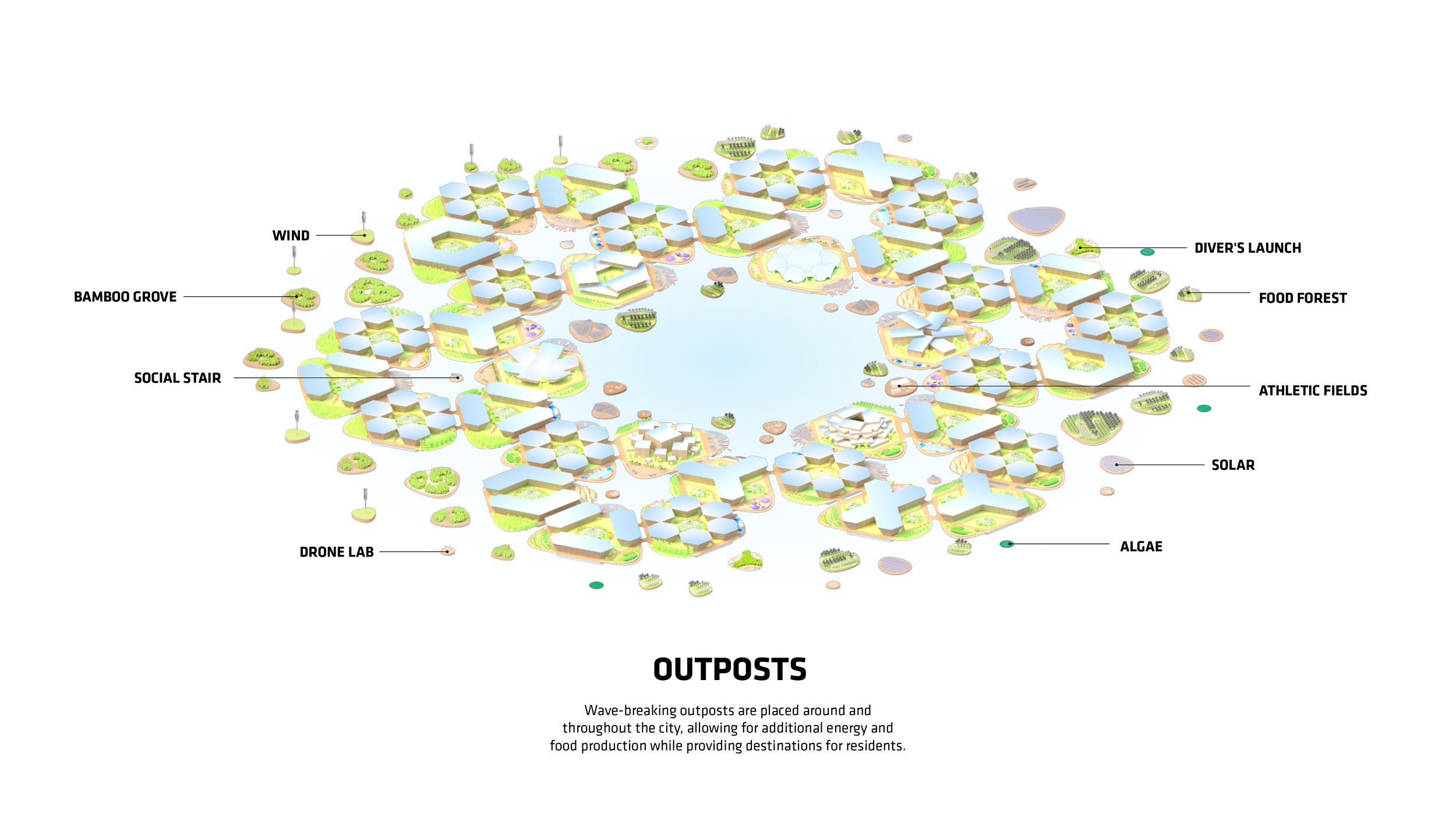

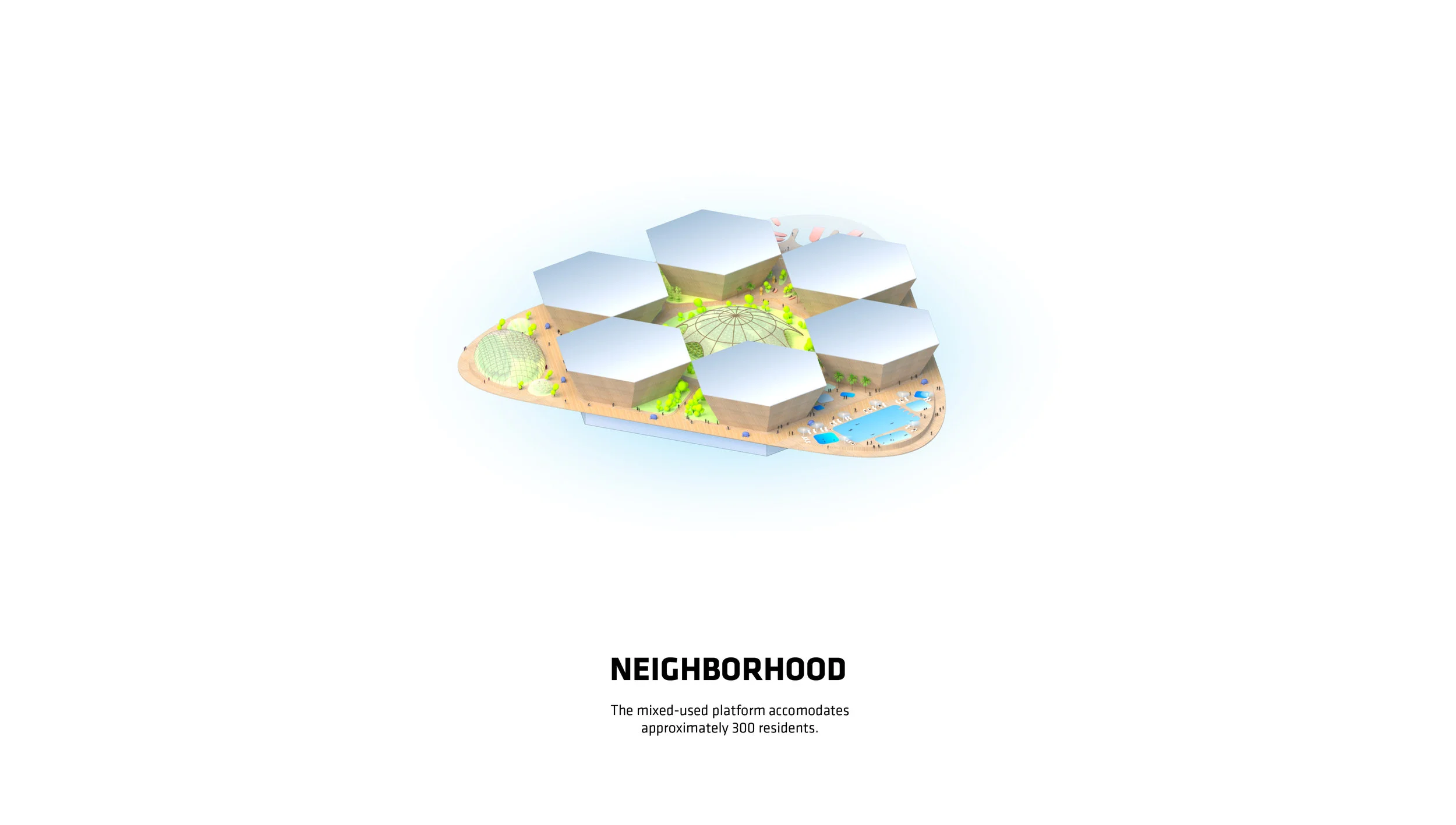

For Oceanix’s idea to work, all the food needed to feed every person living in the floating city would need to be grown there. What does that mean? There’s certainly no meat involved, mostly because beans are a far more efficient way of getting protein. Some crops would be grown outdoors–an estimated 32,000 square feet on each hexagon would be devoted to food cultivation. Much of that would be outdoors, since the sun uses the least amount of stored energy, and the crops would double as green space for residents.

But according to Clare Miflin, the cofounder of the Center for Zero Waste Design, a floating city would also need to experiment with other ways of growing food. One possibility: outdoor vertical farming for crops like lettuce. Then there’s hydroponics and aeroponics, the latter of which uses 10 times less water than traditional farming simply by spraying plant roots with mist. Aquaponics, in which plants grow hydroponically and are fertilized with fish waste, has a deep precedent–the Aztecs used aquaponic farming on their own floating agricultural islands many centuries ago.

With food comes food waste. Miflin wants to create a circular system where all food waste is turned into nutrients for the soil through composting. Food waste would go through a pneumatic system of pipes directly to an anaerobic digester to start the composting process. But there’s also the problem of packaging. Miflin believes that it would be crucial for the floating city to only use reusable food containers, with centrally located drop-off points for people to put their empty containers; from there, they could be cleaned centrally and reused.

Read the complete article here.

Singapore Makes Room For Allotment Gardens As Urban Farming Takes Root

Singapore now has more than 1,000 allotment gardens in a dozen of its national parks. Each is a raised planter bed measuring 2.5 meters by 1 meter, and can be leased for three years for S$57 ($42) annually

Linked by Michael Levenston

Singapore now has more than 1,000 allotment gardens in a dozen of its national parks. Each is a raised planter bed measuring 2.5 meters by 1 meter, and can be leased for three years for S$57 ($42) annually.

By Rina Chandran

Reuters

Apr 15, 2019

Excerpt:

Rain or shine, every day for the past year, Kanti Kagrana walks a short distance from his son’s flat to Singapore’s HortPark, a national park where he grows chillies, eggplant and spinach in his allotment garden.

Kagrana, a 60-something native of India, is among a growing community of urban farmers in Singapore, which introduced allotment gardens in November 2017, modeled after England’s program which dates back to at least the 19th century.

“I enjoy gardening, but there is not enough space in my son’s flat,” said Kagrana, who has two plots.

“This gives me something to do, and I take the produce home so we save some money, as well,” he said as he turned the soil with a spade.

Agriculture makes up only about 1 percent of Singapore’s land area, but urban farming – including vertical and rooftop farms – is fast becoming popular.

Singapore last year topped the Economist Intelligence Unit’s (EIU) Global Food Security Index for the first time, scoring high on metrics such as affordability and availability.

Hong Kong Industrial Building Champions Green Spirit By Funding Rooftop Farming Through Recycled Cardboard

20 Apr, 2019

Jeff Chan (left) from Jones Lang LaSalle and farming expert Michelle Hong from Rooftop Republic. Photo: Jonathan Wong

YKK Building In Tuen Mun Boasts A 9,000 sq ft Farm That Workers Say Boosts Interaction With Clients And Promotes Bonding And Cohesiveness

At an industrial building in northwest Hong Kong, funds from selling piles of cardboard have been used to seed an unlikely endeavour on a 9,000 sq ft site on its roof – farming radishes and beans.

Workers at Tuen Mun’s YKK Building can choose to grow what they love according to the seasons, and freshly picked harvest are cooked at a staff canteen next door or given to charity.

The aim of the project – which was set up in September 2018 – goes beyond food production. Jones Lang LaSalle, the company which manages the building, launched the farm under expertise from agency Rooftop Republic to bring cheer to an otherwise dreary industrial district and for staff to bond.

Chu Oi-lan (left) enjoys rooftop farming with colleagues. Photo: Jonathan Wong

Jeff Chan Ka-chu, a senior director at the firm, said it wanted to create a relaxing work environment for tenants and foster exchanges between them and building management staff.

“In the past, when property owners and tenants come to the office, it’s mostly about complaints,” Chan said. “But through this project, with a softer touch, we can share experiences with our customers, such as on farming.”

Through this project, with a softer touch, we can share experiences with our customers, such as on farming, Jeff Chan, Jones Lang LaSalle

In the spirit of being environmentally friendly, the money for maintaining the farm comes from paper waste, alongside cans and plastic bottles, sold for recycling for about HK$20,000 to HK$30,000 monthly. The amount of waste each month, collected from tenants, can be up to 10 tonnes.

According to Chan, the farm was set up with more than HK$400,000 saved from over a year of selling waste material. The monthly operating cost now is a sustainable HK$4,000.

Hong Kong urban farmers find bliss in rooftop gardens

Chu Oi-lan, 38, a clerk who has worked at YKK for 19 years, said she loved the leisure activity of farming. Chu and her colleagues visit the rooftop garden during their off hours. She spends about 20 minutes each lunchtime tending to the plants.

Experts have called on the government to recognise the social benefits of rooftop farming. Photo: Jonathan Wong

“I have been waiting for this for a long time,” she said. “We can play and eat. I take watering the plants as an exercise.”

Chu said she bonded with colleagues through the project, and friends were also envious about her company’s farming perk after seeing her posts on social media.

Hong Kong has more than 60 rooftop farms, involving more than 1,500 people, according to Mathew Pryor, an associate professor and head of the landscape architecture division at the University of Hong Kong.

As Singapore runs out of room, rooftop farms offer solution to concerns about food security

In his study in 2016, Pryor estimated that there were some 600 hectares of farmable rooftop area across the city – about 32 times the size of Victoria Park.

“The primary benefit of rooftop farming was not food, but social cohesion and social interaction,” he said. “It’s not adding to the food supply of the city. But they are producing a huge amount of happiness.”

Pryor also noted the affordability of rooftop farms, and called on the government to view such projects as bringing social benefits, especially amid the ageing population.

“Older people who have a lot of time on their hands and particularly in the low-income areas [may not have good living conditions]. The idea of participating in a social [rooftop project] just for a bit of recreation and interaction ... That’s a powerful idea.”

Officials should give more recognition to rooftops farms by offering legislative and regulatory support, he said, while adding that technical help should be offered to people who want to take part in it.

“We can see the whole thing as a social project, rather than a food production project.”

New York Passes Mandatory Green Roof Legislation

Linda Velazquez on April 18, 2019

Javits Convention Center. Image: Aramis Velazquez

Green Roofs for Healthy Cities Celebrates Historic Passing of The Climate Mobilization Act in New York City – Green Roofs Required on New Buildings

Green Roofs for Healthy Cities shares the historic win for all New Yorkers as well as the larger green infrastructure community: Today, April 18, 2019 at 1:30 pm EST time the New York City Council passed The Climate Mobilization Act, a suite of measures to reduce greenhouse gases released from buildings in New York City, including a requirement for green roofs and/or solar panels on newly constructed buildings.

Brooklyn Grange. Image: Linda Velazquez

The package of bills includes three pieces of legislation from New York City Council members Rafael Espinal, Donovan Richards and Stephen Levin.

“For the past two years Green Roofs for Healthy Cities has been advocating for new measures to grow the green roof market in New York City, and we are very pleased with the passage of this new legislation”, said Steven W. Peck, GRP, Honorary ASLA, Founder and President, Green Roofs for Healthy Cities. “New York now joins cities like Denver, San Francisco, Toronto and Portland, Oregon in making green roofs a requirement.” he added. “Through direct lobbying efforts from Green Roofs for Healthy Cities members and other partners, New York City will quickly become a leader in reducing the effects of climate change from its buildings. Thanks to all of the individuals involved!” he added.

Rafael Espinal, NYC Council Member, 37th District, who has been at the forefront of this push for a greener New York City said,

“Today, we are passing a bill that won’t just make our skyline prettier – it will also improve the quality of life for New Yorkers for generations to come. My legislation will require green roofs to be installed on new residential and commercial buildings, making New York the largest city in the nation to pass such a law. We’ve already seen the revolutionary benefits of green roofs in action thanks to places around the city like Brooklyn Steel, the Barclays Center, the Javits Center, the USPS Morgan Processing and Distribution Center, and many others. They cool down cities by mitigating Urban Heat Island Effect, cut energy costs, absorb air pollution, reduce storm-water runoff, promote biodiversity, provide sound-proofing, and make our cities more livable for all.”

“I want to thank the advocates who were instrumental in pushing this forward, Council Members Donovan Richards and Stephen Levin for partnering with me on this effort, and Speaker Johnson for his leadership. These bills show that New York will not be idle in the face of an existential threat like climate change. At a time when the federal government is taking us backward, it is up to cities to lead us into a sustainable future. The time to act is now.”

Kingsland Wildflower Rooftop. Image: Kingsland Wildflowers Green Roof & Community Space

The Climate Mobilization Act covers eight initiatives and two resolutions, among which includes:

• Int. 1031 – Green Roof Information

• Int. 1032 – Green Roofs for New Construction

• Res. 66 – Green Roof Tax Abatement increase

The Climate Mobilization Act is the largest single act to cut climate pollution of any city. In a densely packed metropolitan of over seven million residents, commercial and residential buildings are the largest source of emissions and sit at the center of the policy change. The Act will set emission caps with the goal of reducing emissions by 2030. Depending on the size and property assessments of the buildings, owners will be able to meet targets, ranging from a cut of emissions by 40% by 2030 and 80% by 2050 for larger buildings. Smaller buildings will reduce emissions in more modest measures.

Also see today’s article from Brooklyn Eagle.

Congratulations to New York City and to all whose hard and persistent work made this important Climate Mobilization Act happen!

Ikea Harvests First Hydroponically-Grown Lettuce

Courtesy of Ikea & Bonbio

4th April 2019

Ikea has harvested and served its first “home-grown” lettuce as part of a year-long trial exploring how food can be served more sustainability.

The Swedish furniture giant is growing lettuces in containers outside its department stores in Malmö and Helsingborg, Sweden, working alongside circular farming expert, Bonbio.

Each container conceals a high-tech growing operation comprising 3,600 lettuce plants in an area of 30 m2.

The container has four levels and is full of different sizes of lettuce. The seeds are sown in batches, so there is always lettuce available for harvesting.

No pesticides are needed during the growing process because the farming takes place in a closed system.

The lettuce is grown hydroponically in water containing liquid plant nutrients extract from organic waste – including food waste from Ikea’s restaurants.

This, Ikea said, means the lettuces require 90% less water and less than half the area than those that have been conventionally growth.

“It is not every day that we have a harvest celebration at Ikea and it is really fun for us to finally be able to serve our own lettuce. It is fresh, crisp and has a bit more taste than regular lettuce,” said Ann Holster, responsible for Ikea Sweden’s restaurant operations

“We will start serving the lettuce in our staff canteens, but hope to soon be able to offer it to our customers.”

[Going Green 2] How Samsung is Helping To Take Healthy Food From Farm To Table

April 25, 2019

As awareness of environmental issues grows, the impacts of the agricultural industry and our own personal food consumption are of increasing public concern. The use of pesticides, herbicides and other resources are falling out of favor and more efficient methods of food production are being explored as we strive to cultivate healthier food. Samsung Electronics is contributing to these efforts, developing technologies that can reduce the environmental impact of growing healthy food.

Horticulture LED Driving the Future of Farming

On the industrial scale, indoor farms are increasing in popularity, since they are better equipped to overcome spatial constraints and extreme climates. In such indoor farms, artificial light plays a crucial role in efficiently managing the rate of plant growth.

Drawing upon its LED technologies developed for other lighting markets, Samsung launched its Horticulture LED lineup in May of last year to provide advanced lighting solutions to indoor farms. LED lighting is more efficient and has a longer lifespan than previously existing artificial lighting solutions. It is also easy to control the light spectrum of LED lighting and LED solutions are becoming a more attractive option for indoor farms.

Samsung’s Horticulture LED Package and module

Different wavelengths of light can affect plants in different ways. For example, wavelengths of 430 to 700 nanometers are required for photosynthesis, a wavelength of 450 nanometers promotes germination, 660 nanometers stimulates growth, and 730 nanometers or more helps plants to bloom and produce fruits. It’s thanks to these properties that red wavelengths (about 600~750 nanometers) and blue wavelengths (about 400~450 nanometers) have been the prevailing trend in indoor farms.

Recent developments have also emphasized the importance of green light with a wavelength of 550 nanometers, with findings that it can penetrate the lower canopy and thus increase the photosynthesis in plants found there. Since this was observed, interaction with a blue wavelength is now actively being studied also.

Based on this research, Samsung released its White LED package last November, with an extensive spectral range, including growth-boosting blue and red wavelengths. Full-spectrum LED lights can increase the nutritional value of plants and deter disease and pests. The bright white light can also create a more pleasant work environment than narrow spectrum alternatives, allowing farmers to monitor growth and inspect for disease with relative ease.

The package is designed to deliver strong reliability, even alongside the use of chemical fertilizers or under hot and humid conditions. The package is also competitive in price when compared to red LED products, helping to reduce the cost of establishing lighting systems in indoor farms.

Samsung raised the photon efficacy level of white LED packages to the highest in the industry, thus reconfirming the company’s leadership in this field. As a result, lighting manufacturers can use 30 percent fewer packages in each luminaire to achieve the same efficacy level as other lighting equipment, ultimately reducing the costs for indoor farms.

Packages can be selected according to the types of plants and the facility’s requirements. Samsung Electronics offers five white LED packages and one white LED module. The company has also designed one blue package and two red packages with a single wavelength.

As Will Chung, a researcher in the company’s Lighting Marketing Group (LED), explained, “Although it’s been less than two years since Samsung Electronics started its horticulture LED business, we’ve already received lots of positive feedback from the market for developing high-quality LED technologies. “We’re committed to developing more innovative products that support convenient food production, and will continue to enhance our offerings with testing, studies, and experts’ advice.”

Grow Your Own

In the homes of the future, it will be possible to grow your own vegetables no matter the climate. Samsung recently showcased Chef Garden at KBIS 2019, an AI farming platform that integrates with the next generation of Family Hub. The smart indoor garden uses seed capsules, allowing people to grow small fruits, vegetables and herbs with only a small part of the plant. Chef Garden controls light, temperature and humidity to optimize plant growth. The system also utilizes fogponics technology, which creates a nutrient fog that delivers water and nutrients directly to the plants so that they can grow without the need for pesticides. With water kept to the minimum required, the inside of Chef Garden always remains clean. Chef Garden can also inform users when plants are ready to harvest and recommend recipes thanks to smart integration with Family Hub.

Fruitful Investments and Research

Samsung is supporting research and development in fields such as basic sciences, materials science and ICT through the Samsung Science and Technology Foundation. Samsung has funded 500 project grants for the Korean scientific community to explore since 2013, amongst which are technology research projects examining vertical farming and the acceleration of plant growth. In addition, it is expected that further discoveries garnered from ICT projects involving AI, IoT and LEDs will foster synergy between Samsung’s technology and industrial farming’s efforts to produce healthy food.

“One of the main objectives of this support project is to consider how technology might solve the environmental and food shortage problems society faces today,” said Doochan Daniel Eum, Head of the Samsung Research & Incubation Center for Future Technology. “It’s our intention to contribute a total of 1.5 trillion Korean Won (approximately 1.3 billion USD) by 2023, investing in technologies that can effect real change for future society.”

Artificial Lighting Solutions Going Green Healthy Food horticulture LED Indoor Farms LED lighting LED Solutions White LED Package

What Is The Impact of LED Grow Lights On Indoor Horticulture Crops?

Posted on 01/29/2019 by David Kuack, HortAmericas.com

Michigan State University researchers are studying the effects of sole source LED grow lights on edible and ornamental crops.

Michigan State University opened its Controlled-Environment Lighting Laboratory (CELL) in 2017. The 400-square-foot vertical farm research facility is being used to study the indoor production of high-value specialty crops, including edibles and ornamentals with LED grow lights.

“The two major crops that we are studying are leafy greens, including red and green leaf lettuce, and floriculture transplants, specifically seedlings,” said horticulture professor Erik Runkle. “We are fairly new to leafy greens. We started performing research with them about three years ago, whereas, we’ve been working with indoor lighting of floriculture plugs since 2011. What has been interesting is to compare and contrast responses among the different crops. Not surprisingly there are a lot more similarities than there are differences.”

The indoor lighting research being conducted in the lighting laboratory is only with LED grow lights. The LED fixtures that are being used were designed by OSRAM. A similar OSRAM LED product is now being marketed as Phytofy.

“The OSRAM fixtures we are using in our studies deliver seven different wavebands and each one can be independently controlled,” Runkle said. “We are using the OSRAM fixture in all of our indoor lighting studies. This fixture features a sophisticated lighting system that enables us to deliver an infinitesimal number of combinations of light intensities and different wavebands.

“Some of studies being conducted could relate to greenhouse production, but more often the research results we learn indoors won’t apply to greenhouses. In greenhouses we are supplementing sunlight. What we have found is the light spectrum has less of an effect in the greenhouse because there is all the background sunlight compared to indoor production. The ability to control these different growth and quality traits is significantly greater with indoor lighting than in a greenhouse.”

Using light to manipulate plant growth

Runkle said working with different crops, the indoor lighting research being conducted is trying to elicit some very different quality traits.

“Seedlings are typically grown economically in greenhouses,” he said. “To produce anything indoors is going to be more expensive. The challenge and the reason that we are looking at ornamentals in indoor production is that there is still a lot of seasonal variability.

“If there is a period of extended cloudiness or period of sunny weather that normally doesn’t occur, these unpredictable weather conditions can result in plants that finish too early or too late. Growing plants indoors takes a lot of those issues out of the picture because the environmental conditions can be completely controlled.”

Runkle said the research with leafy greens will look at the impact light can have on different attributes of the plants.

“With leafy greens, growers are more concerned with consumer preferences for flavor and texture, as well as the yield and the biomass of the plants,” he said. “In part, light can be used to manipulate these different attributes. With floriculture crops, growers are typically trying to produce a small, compact plant, and in some cases trying to develop flower buds early. In other cases, growers are trying to delay flowering.”

Leafy greens research at Michigan State will focus on the impact light can have on different attributes, such as texture and yield.

Photos courtesy of Erik Runkle, Mich. St. Univ.

Runkle said with floriculture crops the focus is on flowering and the growth aspects for compactness.

“A lot of time can be taken out of production through lighting edible and ornamental crops,” he said. “For leafy greens, the production time can be cut in half compared to the field crops. For floriculture crops, production time can be reduced by a week or two depending on the crop.”

Another area of research Runkle is interested in studying is to determine how light interacts with other environmental parameters, especially temperature.

“Right now we are focused on lighting and that is what a lot of my colleagues are doing as well,” he said. “But we also need to consider temperature effects on the growth rate of plants. By manipulating temperature and light we can probably reduce the production time even more than we have been able to achieve.”

The effects of different wavebands

Most of the LED grow light research that has been done with leafy greens has studied the effects of red and blue light.

“We have a fairly good understanding of the interaction between red and blue light and how that affects leafy greens,” Runkle said.

“The two wavebands for which much less information has been collected are green and far red. The most recent work that we have done is to look at both of these wavebands in independent experiments. Far red is a little more predictable and better known. We probably know the least amount about green light. Our group is focusing on some of these lesser used wavebands and trying to evaluate whether there is a fit, a need or a benefit to including them in a lighting fixture vs. sticking with a white light fixture or red/blue fixture.”

Researchers at Michigan State will study the impact of adding far red wavebands to the light spectrum on floriculture crops.

For the floriculture crops Runkle is studying, the focus is on collecting more details on the benefits of adding far red to the light spectrum.

“We know that there are benefits to far red, but how much far red needs to be delivered to get the positive benefits, which would be early flowering without the drawback of growth extension,” he said. “It’s really trying to dial in that waveband, particularly how much far red is needed.

“One of the things that we have learned is that inclusion or addition of far red light accelerates flowering of some long-day plants. What we are trying to determine is in which crops the far red promotion of flowering occurs and how much is needed to accelerate flowering. We’ve also been investigating how far red light interacts with other wavebands, particularly blue light, as well as how it interacts with total light intensity.”

Quantifying different growth responses

One of the studies being done by Runkle’s research team is comparing the effects of different light spectrum wavebands to white light LEDs.

“Some white LED grow lights are relatively inexpensive,” he said. “We want to determine if there is a benefit to the customized spectrums, which would probably make them a more expensive product. Growers could decide whether to purchase fixtures with a fairly unique spectrum and receive their benefits.

“Is it worth the extra cost to get these benefits? We don’t have specific numbers now, but the goal is to be able to quantify different growth responses under different light treatments. Information from our research, as well as from others working in the area, could help growers choose between a general inexpensive LED grow light to produce moderately good plants or spend more on fixtures to produce plants that flower earlier or have some other attributes that are desirable.”

Runkle said some companies are manufacturing customizable fixtures for growers.

“The major downside of these customizable fixtures is that they are often times more expensive than fixtures with a fixed spectrum,” he said. “Then the question for the growers is whether having the ability to tailor or adjust the spectrum worth the added cost. That is a hard question to answer at this point. It’s going to be situational. I’ve seen general fixtures marketed for the lighting of plants. I haven’t seen fixtures marketed yet for specific crop types.”

Can Indoor Farming Solve Our Agriculture Problems?

April 15th, 2019 by Erika Clugston

Food is central to our lives – that’s a given – but our relationship with it is problematic: agriculture is one of the leading causes of climate change. With the world’s population growing rapidly in the next few decades, the global demand for food is expected to increase by 70%. However, the production of this food is costly: meat and dairy have the highest global carbon footprint and agriculture uses 70% of the world’s freshwater, to name just a few problematic aspects. This coupled with a higher demand and pressure from the effects of climate change creates a vicious cycle. How do we break it?

Photos courtesy of Bowery Farming

Bowery Farming believes it has a solution. The company’s high tech, indoor farms use a hydroponic system, requiring 95% less water than traditional agriculture to grow produce. Additionally, vertical farming requires less space, meaning that Bowery is 100 times more productive than a traditional farm on the same amount of land. Because the farms are indoors, in closely controlled environments, there is also no need for pesticides. These are just a few of the ways that Bowery is rethinking contemporary agriculture systems.

We wanted to know more, so we reached out to Bowery CEO and co-founder, Irving Fain, to discuss his vision for today’s farming practices and the role that technology can play in improving our relationship to food.

Bowery CEO and Co-Founder Irving Fain

What was your inspiration and mission for founding Bowery?

I’m a big believer in technology’s ability to solve difficult problems. After building my last company, I wanted to spend my time working on an area that I was personally passionate about and a set of problems that were broadly important. Agriculture sits at the epicenter of so many global issues today. Over 70% of our global water supply goes to agriculture, we use over 700 million pounds of pesticides each year in the US alone, and industrial farming practices have caused a loss of over 30% of the arable farmland in the last 40 years. At the same time, our global population is growing to 9-10 billion people by 2050 and we will need 70% more food in order to feed a population of that size, meaning that more food will need to be produced in the next 30 years than has been produced in the last 10,000. After becoming obsessed with the question of how to provide fresh food more efficiently and sustainably to urban environments, I teamed up with my co-founders David Golden and Brian Falther to build Bowery. Bowery combines the benefits of the best local farms with advances made possible by technology in large-scale commercial indoor farms to grow produce consumers can feel good about eating.

What sets Bowery apart from traditional farming?

While traditional farming methods waste resources and endanger our future food supply, indoor farming allows us to grow more efficiently and with fewer resources. Bowery farms use zero pesticides, 95% less water, and are 100x times more productive on the same footprint of land than traditional agriculture. We’re also able to grow a wide variety of crops twice as fast, more crop cycles per year, and more yield per crop cycles than the field, regardless of weather or seasonality. BoweryOS, our proprietary software system, uses vision systems, automation technology, and machine learning to monitor plants and all the variables that drive their growth 24/7, while combining software and automation with industrial process management to optimize production, fulfillment and distribution. By applying proprietary machine learning algorithms to millions of points of data collected by an extensive network of sensors and cameras, BoweryOS can make automatic adjustments to environmental conditions to improve crop quality, health, yield, and flavor.

Since we’re able to provide consistent conditions for crops (many which are tough to grow outdoors, especially with changing global climates), there are truly endless possibilities to what we can grow at Bowery. And because we’re close to the point of consumption and don’t have to worry about growing crops to withstand long travel distances or shelf life, we can grow more flavorful, less commodified crops.

Additionally, because we grow in a completely closed environment, we drastically minimize the risk of contamination from foodborne illness. Unlike outdoor farms, which are vulnerable to contamination from animal waste, tainted groundwater or irrigation run-off, Bowery produce is grown in a closed-loop indoor system that recirculates filtered municipal water free of contamination. And because we control the entire process from seed to store, our greens aren’t matriculated through large distribution and fulfillment centers that often lead to additional exposure to contaminants.

Technology and agriculture aren’t often thought of together. Do you see them as natural counterparts?

Agriculture and technology are historically deeply intertwined. While many people think of technology as purely digital, agriculture is actually one of the first major human technological breakthroughs, and is the basis for the creation of towns, cities and civilizations. Over the years, there has been constant innovation in agriculture, and it’s supported the growth of human populations through today. So tech and agriculture have always had a close relationship.

Today, agriculture is at the epicenter of many of our global challenges. At Bowery, we began with the fundamental conviction that technology is critical to developing both a scalable and sustainable solution to those global issues.

What kind of produce do you grow?

Our proprietary technology BoweryOS allows us to grow a dynamic portfolio of different crops on a smaller footprint of land. We currently offer 9 SKUs at retail partners, including spring blend, kale mix, baby kale, arugula, butterhead lettuce, romaine, bok choy, sweet & spicy mix, and basil. Beyond that, we’ve experimented with over 100 varieties. Right now we’re focused on delivering the best leafy greens and herbs possible to our retail and restaurant partners, but we’ve already started experimenting beyond leafy greens with root vegetables such as turnips, and plan to expand our offerings in the future.

How did you finance the company – which VCs or companies invested?

With Bowery, we were fortunate to have a number of world-class investors excited about Bowery’s mission, the technology we’re creating, the team we’re building and most importantly, the food we are growing. When we built our first farm, we were fortunate to work with Rob Hayes and First Round Capital who led our seed round, along with a number of other fantastic investors. To date, we’ve raised $122.5M from leading investors such as Google Ventures, General Catalyst, and GGV. Bowery has also welcomed noteworthy thought-leaders in the culinary industry as investors, including Chef Tom Colicchio, Chef José Andrés, Chef Carla Hall, David Barber, co-owner of Blue Hill, and the founders of sweetgreen, among others.

Where are you currently located? Plans for expansion?

We currently have two farms located in Kearny, New Jersey. This past December, we announced our Series B funding round of $90 million and we plan to use the capital to scale our operation in new cities across the country and expand our network of farms in 2019.

As CleanTechnica has already covered, Bowery has announced plans to use a microgrid that will run in part off of solar power to support an indoor farm year round. Can you talk a little bit about the benefits and challenges of using the microgrid and when this project will be underway?

We are working to incorporate a proprietary hybrid microgrid system that uses distributed energy resources, including a rooftop solar array, a natural gas generator equipped with advanced emissions control technologies and lithium-ion battery energy storage system. These solutions will help cover a meaningful amount of our energy consumption needs for this farm and will set us up with the knowledge and experience to install significantly more sustainable solutions in future farms. We will continue to meaningfully increase this percentage over time as we innovate on our electrical energy distribution efficiency.

What are the costs of urban farming like in comparison with traditional produce?

The existing food supply chain has a lot of inefficiencies. Because we’re located near the point of consumption, we cut out much of the waste and cost in distribution while delivering a fresher, better product. At the same time, the technology we’ve developed allows us to grow in a way that is 100x times more productive than traditional farming on the same footprint of land, which enables us to keep the cost of our produce competitive with organic products grown in the field.

Do you foresee urban farming as the solution to issues caused by growing populations, climate change and increasingly limited resources?

Yes, we view urban farming as one of the solutions to issues caused by growing populations, climate change, and increasingly limited resources including food and water supply as well as environmental degradation.

For one, there simply is not enough arable land in the world to feed the growing population using today’s conventional methods, and fresh produce loses 45% of its nutritional value when shipped. At Bowery, we solve for this by reappropriating previously unusable industrial space to grow crops indoors, closer to the point of consumption, at a rate that is 100x more productive per square foot of land than that of traditional agriculture. Produce is also typically grown in one central area, shipped to cold storage, then driven via long-haul across the country, and finally transported by last mile shippers to stores. In the U.S. alone, food trucking is responsible for 12.5% of total emissions. By locating close to the point of consumption, we drastically minimize the carbon footprint of food distribution. Additionally, while the agriculture industry uses 70% of the world’s freshwater and over 700 million pounds of pesticides in the U.S. alone, we use 95% less water than traditional farming and absolutely no pesticides.

What are your goals for Bowery in the next few years?

Our goal is to open more farms in new cities to give people access to fresher, safer, more sustainable produce. And, from a macro level, in order to provide food for a growing population, we need to feed the world with more than just lettuce and herbs. Getting these right is an important first step, but in order to keep up with current customer demand, we’re working on growing more types of produce as we build more farms, with an eye toward greater access for more people. There’s a huge opportunity to deliver a vast variety of fresh, delicious produce to people around the world with Bowery’s technology.

How much money can a solar roof save you in Var?

Profit from your roof space: find local deals on solar in your area, eliminate your power bill, and join the solar revolution.

Tags: Bowery Farming, indoor agriculture, vertical farming

About the Author

Erika Clugston Erika is a writer and artist based in Berlin. She is passionate about sharing stories of climate change and cleantech initiatives worldwide. Whether it’s transforming the fashion, food, or engineering industries, there’s an opportunity and responsibility for us all to do better. In addition to contributing to CleanTechnica, Erika is the Web and Social Media Editor at LOLA Magazine and writes regularly about art and culture.

Students Compete For Plant Growth Chamber

Plantae and Conviron have collaborated to launch the Seeding Discovery Competition.

The competition is aimed to equip a successful university or college student with a high-performing GEN1000 plant growth chamber that will enable them to fulfill a meaningful research program in the field of plant sciences, biology, and biotechnology.

The Seeding Discovery Competition provides students with the opportunity to define and submit a proposal for a study that:

Aligns with personal and departmental objectives

Enables them to work with faculty and administration on planning and logistics

Contribute to their institution’s infrastructure with new research equipment at no cost

To be eligible, applicants must be students enrolled in a post-secondary program related to plant science. For further eligibility criteria and competition rules visit www.plantae.org/seedingdiscovery.

For more information:

Plantae

plantae.org

Conviron

Publication date: 4/10/2019

![[Going Green 2] How Samsung is Helping To Take Healthy Food From Farm To Table](https://images.squarespace-cdn.com/content/v1/57c8695d5016e11e71be1d83/1556172575017-JOO4JU04IDLYDU13K3NE/index.jpg)