Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

This Farming Style That Skips Soil And Adds Fish Is Growing In Popularity

Aquaponic farming is not a widespread practice, but it is expected to grow. According to Future Market Insights, the global aquaponics industry is expected to grow more than 7 percent in the next 10 years. In 2018, the United States was home to about 40 percent of all aquaponics operations globally.

Courtesy of Tom McPherson

Springworks Farm, a commercial aquaponics operation in Lisbon.

By Sam Schipani, BDN Staff

February 22, 2019

Aquaponics sounds like the stuff of science fiction. Instead of crops’ roots reaching down into the soil, they are suspended in water that is filled with live, swimming fish that sustain the plants with their nutrient-rich excrement. The closed-loop system is generally less disease prone and more water efficient than soil-based gardening, and at the end of the day, its farmers can sell plants from above the waterline and the fish from below.

Aquaponic farming is not a widespread practice, but it is expected to grow. According to Future Market Insights, the global aquaponics industry is expected to grow more than 7 percent in the next 10 years. In 2018, the United States was home to about 40 percent of all aquaponics operations globally.

The innovative growing method has the potential to make a splash in Maine’s agricultural scene, but first, it has to overcome market roadblocks and a marred past.

The story of Springworks Farm

The only active commercial aquaponics growing operation in Maine is Springworks Farm in Lisbon. Trevor Kenkel, the company’s founder, broke ground on Springworks Farm five years ago, when he was just weeks into his freshman year at Bowdoin College. The 6,000-square-foot facility raises tilapia and grows five different types of lettuce. Kenkel said the farm provides produce and fish to about 25 Hannafords and several distributors.

Courtesy of Tom McPherson

Springworks Farm, a commercial aquaponics operation in Lisbon.

“Our system is about 20 times more productive per acre than a conventional farm,” Kenkel said. “We have this whole web of organisms that allows us to be a steward of that system rather than controlling it.”

Along with their eco-friendly bona fides, aquaponic systems can provide local produce year-round, even during Maine’s harsh winters.

“Maine has a really strong local food movement that I think is really supportive of an operation like this that can produce local food all year,” Kenkel said.

Growing local has an added sustainability benefit: reducing food miles. Most of the lettuce in the United States is grown in California and Arizona, whereas Maine-grown aquaponic lettuce does not accrue the carbon generated by a cross-country journey.

“In terms of carbon use, the amount that you save by reducing the 2,500-mile trucking journey to 200 miles is really incredible,” Kenkel said.

Kenkel said that Springworks Farm is still in “growth mode,” but the outlook is good. It recently broke ground on a second greenhouse.

Courtesy of Tom McPherson

Trevor Kenkel, founder of Springworks Farm, a commercial aquaponics operation based in Lisbon.

But promising aquaponics operations have failed in Maine before. Fluid Farms, billed as the first commercial aquaponics operation in the state, was founded in 2013 in Dresden following a successful Kickstarter campaign that raised more than $9,000. In 2016, it won the $50,000 grand prize in Gorham Savings Bank’s LaunchPad competition. The company was even certified organic by Maine Organic Farmers and Growers Association.

Now, only a few years later, Fluid Farms appears to be no longer operational. According to the Maine Secretary of State’s office, Fluid Farms administratively dissolved in 2018. Tyler Gaudet, one of the founders, declined to comment on what happened to the company.

Aquaponics in the classroom

Aquaponics is used primarily as a learning tool in Maine.

Maine Agrotech in St. Albans, designs, installs and provides technical support for small-scale aquaponic systems throughout the state. Jeff Giallombardo, Maine Agrotech’s founder, said most of its customers are universities and high schools, though he has installed a few at private residences as well.

“The interest now seems to be in the education sector,” he said.

Giallombardo started Maine Agrotech after using aquaponics as an educational tool for an alternative education program for Nokomis Regional High School in Newport.

“I got involved with aquaponics to try to deliver engaging and interdisciplinary instructions to students in my program,” Giallombardo said. “I got inundated with requests from people wanting to know how to do it.”

Education is built into the business model for Springworks Farm, too. Kenkel said the farm has been an educational operation “from the start,” conducting tours and selling small aquaponics kits for aquariums as a didactic tool.

Courtesy of Tom McPherson

Lettuce grown at Springworks Farm, a commercial aquaponics operation based in Lisbon.

“We have those now in something like 130 schools and a curriculum to match,” Kenkel said. “I kind of wish I had that growing up. A micro-farm lets you experience things the hands on way.”

University of Southern Maine is one of the schools that takes regular field trips to Springworks Farm. Theodore Willis, associate research professor at the university, started using aquaponics to teach a land-based aquaculture and research methods class in August 2017. The 10-tank aquaponics system — housed in a university laboratory — grows lettuce, celery, bell peppers and kale alongside tilapia, which is the fish most commonly used in aquaponic systems.

In Willis’ experience, aquaponics is a valuable learning tool, but can be challenging to manage. During the school year, Willis has a steady stream of students to help tend the system, and the school cafeteria and catering services use the produce grown in meals on campus. Summer vacation, on the other hand, proves challenging.

“It works well for nine months out of the year, but for three months we are trying to figure out what to do with the various things we are growing down there,” Willis said. “I’m relying on undergraduate volunteers to come in and clean things and feed fish.”

Roadblocks to aquaponics in Maine

On a larger scale, the small university scheduling issues could translate into real world roadblocks for commercial aquaponics operations.

“If you have any aquaculture system on a large scale, you have to have the financial backing and the personnel to keep it running,” Willis said.

Like at the university, having consumers for aquaponically grown products is also essential to the operation’s success.

“You have to be able to move product,” Kenkel said. “Lettuce has a very short shelf life.”

Unlike at the university — Willis said he is not looking to make money off of its system — consumer preferences matter for commercial operations. Aquaponically grown crops also tend to be more expensive than their soil-based commercial farmed counterparts.

“It is a relatively expensive way to grow food, so there is usually a premium price point on it,” Willis explained. “You have to get the consumer to recognize that head of organic romaine for $2.99 drove thousands miles and was grown with water mined from aquifers, whereas one from aquaponic operation that is $3.25 was grown locally with no added fertilizers.”

Courtesy of Theodore Willis

Associate research professor Theodore Willis growing aquaponics at the University of Southern Maine.

Finding a market for aquaponically grown food and fish in Maine is also going to be a challenge. American consumers have less of a taste for tilapia, the primary fish grown in aquaponic systems. Tilapia is, as Willis described, “a bulletproof teaching fish” because it is so hardy and forgiving. But it is difficult to sell.

“[Tilapia] is a not particularly strong-flavored white flesh fish, like flounder,” Willis said. “A lot of this is training the consumer to accept a different taste than they are used to.”

Not only is it challenging to turn a profit on aquaponically grown products, but also the upfront costs for the energy and infrastructure required for an aquaponics operation are steep. The extreme weather conditions throughout the year make keeping the system at relative stasis especially difficult in Maine.

“In Maine, you’ve got fairly hot summers paired with pretty brutal winters. Keeping things consistent in that kind of environment is difficult,” Kenkel said. “With the right kind of equipment and processes in place, it’s certainly achievable, but getting started is very difficult compared to other kind of agricultural systems.”

Overcoming challenges and the future of aquaponics in Maine

These roadblocks could have prevented commercial aquaponics operations from succeeding in the past in Maine.

“I don’t think anyone has quite figured out the energy equation in Maine in terms of lighting, heating and cooling,” Giallombardo said. “I’m not sure anyone has figured out the market yet either, and what crops are the most profitable.”

Giallombardo believes culinary herbs are an opportunity for aquaponic growers, as most of the herbs sold in supermarkets are grown in the southern United States.

“You can get a much higher quality product grown locally at a better price point right now,” Giallombardo said. “That’s really your best bang for your buck in my research.”

The educational interest in aquaponics across Maine could help with one of its biggest barriers to entry: knowledge.

“People just don’t know enough about aquaponics here,” Giallombardo said.

Giallombardo predicts that the aquaponics industry, as well as similar industries like recirculating aquaculture and indoor agriculture, will only continue to grow in Maine. The proliferance of aquaponics learning tools in classrooms, he said, will prove especially useful as job training.

“You can use these systems really to educate on all of these industries and prepare students for jobs that are no doubt going to be there soon,” Giallombardo said.

Though Springworks Farm still stands alone, Kenkel is also hopeful about the potential for small-scale growers, whether in classrooms or their own homes, to branch out in the future.

“I think there’s a strong community of people who do it on a smaller scale,” Kenkel said. “I wouldn’t be surprised if more people struck out and built larger systems.”

Indoor Agriculture May Hold The Future of Food

Paris has meanwhile come up with its own urban agriculture model, dubbed “Pariculteur,” a series of town hall-mandated projects designed to cover as much of the capital as possible with greenery via a rise in urban farming. An initial 10 hectares for the project is set to grow to 30 hectares by next year

Published: February 24, 2019 AFP

AeroFarms co-founder Marc Oshima. AeroFarms of Newark, New Jersey, is the largest vertical farm in the world.Image Credit: AFP

Paris: In a world faced with the conundrum of mountains of waste and obesity for some and dire shortages and malnutrition for others the future of food is a main dish on today’s global menu.

A key ingredient is the trend in ever more imaginative forms towards urban agriculture, a multi-faceted recipe already being poured over by some 800 million people globally, according to the UN’s Food and Agriculture Organisation.

The trend takes many forms - from collective market gardens in even the most run-down of urban districts to connected vertical farms using indoor farming techniques to meet spiralling food demand in areas largely bereft of arable land.

Today, with our containers, we are 120 times more productive per square metre than on open ground.

- Guillaume Fourdin | Founder, Agricool

Yves Christol, of French cooperative In Vivo, has identified six models of the genre.

They include a key European variant, electronically managed without recourse to pesticide - or even soil or sunshine.

Green beans means ... Iceland

“That has allowed Iceland to become a major producer of green beans,” says Christol, thanks to geothermal heating.

Asian countries are also in on the act, not least Singapore, with the high density population city state bent on ensuring high-tech food autonomy.

Japan and China have sought to give new life to sites which once hosted electronics factories even if the strategy appears costly.

AeroFarms co-founder Marc Oshima. AeroFarms of Newark, New Jersey, is the largest vertical farm in the world.Image Credit: AFP

China has launched some urban farms even in areas where the soil has been polluted by heavy metals and would be too costly to clean up.

The US model, as cities including New York and Chicago seek to become sustainably hunger-proof, includes hydroponic gardens - effectively eschewing soil and using mineral nutrients in a water solvent, although profitability can prove elusive.

But scale is an issue and the concept will not be viable “so long as the price of the vegetables is not increased fourfold,” to cover energy costs, says Christol.

Strawberry containers for ever

The cost of transporting food is something which particularly exercises entrepreneurs such as Guillaume Fourdinier, a founder of French start-up Agricool in Paris and Dubai.

His firm produces strawberries year round in shipping containers fitted out with LED lighting. Urban agriculture’s raison d’etre, he says, comprises fighting against “the ecological disaster of transport”.

“Today, with our containers, we are 120 times more productive per square metre than on open ground,” says Fourdinier.

“We produce in decentralised fashion and closer to customers,” he adds of strawberries sold marginally cheaper than their organic equivalent.

Paris has meanwhile come up with its own urban agriculture model, dubbed “Pariculteur,” a series of town hall-mandated projects designed to cover as much of the capital as possible with greenery via a rise in urban farming.

An initial 10 hectares for the project is set to grow to 30 hectares by next year.

Urban ecologist Swen Deral, who oversaw a pan-European urban agriculture project last year, says if the concept is to be financially viable in cities it has to go “beyond production”.

“Either they recycle, or else they create services linked to urban agriculture, educational activities, restaurants and the like,” he explains.

Researchers point to urban agriculture’s additional benefit of fighting against the effects of climate change as its proponents seek to reinvent urban existence.

Francois Mancebo, researcher at France’s Reims University, summed up the challenge in an article published by peer-review open access publisher MDPI and entitled “city gardening: managing durability and adapting to climate change thanks to urban agriculture.”

Mancebo says the concept must become an integral part of urban planning with local politicians underlining the need for active participation of city dwellers.

Simple Secrets To Start A Vertical Farm

Talking to people just like you, it’s clear that the first step is always the hardest on the road to building a vertical farm. The plunge into the unknown where your own time, capital, and dreams are at risk stops a lot of entrepreneurs from fulfilling their ambition. Fortunately, Matt Farrell took that step for you and tells all in this exclusive interview on the Urban Vertical Project. Keep reading because Matt talks about:

Location, location, location (where to put your vertical farm)

The honest truth about Zip Grow Towers

How much money can you actually make when you start a vertical farm (what restaurants will pay you)

The simple secret of getting customers who pay

I know why taking that first step to start your farm is scary; it means taking a big chance with your time and money to do something that doesn’t really have a standard set of procedures.

I am right there with you. Chances are, if you’ve found this article, you’ve thought about what it takes to make one of these bad boys a reality. Maybe you’ve done some daydreaming or vision boarding, or maybe you’ve even built a small system. In the end, we’ve all probably come across or conjured within our own imaginations an idea for a vertical farm that works, but that’s a far cry from actually making it a reality.

How do you go about doing that? For me, I’m going to follow the process for starting a vertical farm I modeled off another entrepreneur in an earlier article:

Set up a proof of concept

Secure a buyer

Execute

Even knowing a structure like that one exists, transforming that to reality is a different story. But, as my favorite (and legendary, if you can believe such a thing) street performer says “It’s better to go out and do something than to stay home and plan something.”

So, I went out and did something. I helped my father buy a bunch of IKEA products and convert them into a hydroponic system for less than $100. It was a start.

Now I’m working on another prototype, and I hope to actually maintain this one. My goal with this next system is to collect and analyze a bunch of data to project future results like yields, energy costs, and calories/square foot. Maybe that will turn into an open source project that people can turn to for up-to-date information, or perhaps it will evolve into a farm in its own right. In addition to that prototype, I’ve been doing tons of research for different people that’s helped them to think about their own, personal businesses and projects.

Even so, if all of my work turns out perfectly, it still exists in a vacuum. Simply put, there isn’t enough information out there to for people to make realistic comparisons or projections for their own farm. Other websites and news articles have featured fantastic farms, ideas, and projects, but there aren’t a lot of actionable numbers. That partly comes from being in an industry that’s too scared to share (something we’ve mentioned before and that projects like MIT CityFarm is working to overcome). That’s why we work so hard to bring you these exclusive interviews and why we get down and geeky – getting the nitty gritty numbers. I want you to have a successful urban vertical farm.

All of that is to say, I’m working on my first step and outlining that process for you. But this article isn’t about just the first step; it’s about revealing the simple truths real farmers know that can help you think more realistically abut your project.

And that’s where Matt Farrell comes in. Matt has been into hydroponics for awhile, but he doesn’t come from any sort of traditionally agricultural background.

He was studying in the School of International Service at American University where he got hit with the idea to help the school build a small hydroponic system. Though the school has taken it down since, his dedication to the idea of local, high efficiency farming has persevered. Now, he’s out on his own running Stag’s Leap Produce. Their tagline:

“Always Fresh. Never From A Shelf.”

The site goes on to explain their goals a bit more: “We want to connect the community to a local source of fresh, organic produce at an affordable price. Come try the freshest, healthiest produce around.”

I’ve known Matt personally for awhile now and he was generous enough to take time out of his busiest growing season to give me some exceptionally candid answers about his experience getting his farm up and running.

Location

In this section, we’re going to take a quick look at why the location of Matt’s farm is so important and why it means you might have more flexibility than you thought in where to put your vertical farm.

Matt is the owner operator of Stag’s Leap Produce in Mullica Hill, New Jersey. Another New Jersey Farm, huh? Just like Freshwater Greens (from an earlier interview), Stag’s Leap produce illustrates a perfect lesson for aspiring vertical farmers to internalize; take advantage of local market access. In addition to supplying local restaurants and businesses (see below for a list Matt shouts out in addition to a local farmers market and customers that come to him directly), being in New Jersey means they potentially have access to the much denser populations in New York and the surrounding cities.

I talk a little bit more about the importance of these population centers combined with available space in the Rust Belt Hypothesis (you guys remember that, right? Probably not, I wouldn’t either, so here’s a link), but Stag’s Leap might demonstrate an alternative, or even start to unravel that hypothesis. Remember, the Rust Belt Hypothesis is the idea is that declining industrial cities are perfect environments for vertical farms because of the inherent socioeconomic conditions there. Those conditions include: population density, existing infrastructure (usually in the form of abandoned warehouses from the manufacturing golden age), cheap energy, local community support (jobs!), and legislative support to revitalize a struggling economy.

But check this out!

Mullica Hills New Jersey is definitely not a Rust Belt City. So, if Stag’s Leap demonstrates that a vertical farm can work in less dense populations like there, that means the demand for these products (fresh, local vegetables available year round) and the expertise required to produce them is even higher than we expected. It means that if farms like Stag’s Leap become the norm, or even just more common, vertical farms will have demonstrated that they can fill needs beyond urban centers. That opens up huge swaths of the country that would otherwise wouldn’t have been considered; well beyond what’s normally considered the Rust Belt as seen below.

And according to Matt, that fits in perfectly with their mission: “We believe you should have the ability to purchase fresh, healthy, produce straight from its source. Without harmful chemicals or pesticides, at an affordable price.”

How is Matt growing food?

But how exactly is Matt meeting this demand? “I grow lettuce, basil, kale and arugula. I have two types of growing systems, Bright Agrotech’s Zip Grow Towers and custom made shallow water floating rafts.”

Image from Bright Agrotech

Essentially, he is using two types of growing systems inside of one 3000 sq ft greenhouse. Zip Grow towers utilize a wicking medium to deliver water and nutrients to plants.

Here’s a video directly from Bright Agrotech that explains in more detail how the Zip Grows work.

The floating rafts Matt describes to me seem like a conventional deep water culture (DWC) setup, though he’s modified this idea a bit by making the reservoirs shallower. I’ll let the folks at Boswyck Farms in New York City describe what that is as they have one of the few hydroponic certifications around and are really knowledgeable growers in general.

[DEEP] WATER CULTURE

Water culture systems are the simplest form of active hydroponics. Plant roots grow directly in the water reservoir and are supplied oxygen with an air pump. Water culture systems can be built from repurposed glass mason jars, plastic buckets, or tubs as the reservoir container, with the plant suspended from the lid in a net pot, letting the roots grow through the holes into the water below.

In larger, commercial scale designs, several plants are placed in a sheet of buoyant material that floats on nutrient solution like a raft. Water is generally held in a separate, larger reservoir and pumped up to the floating grow bed and then drained back down to the reservoir in a constant cycle.

Deep Water Culture Example From Epic Gardening

The combination of the Zip Grow towers and his tables allows Matt to maximize the efficiency of all the space in his 3000 sq ft greenhouse. That efficiency comes from incorporating the principles of vertical farming we talk about in this blog.

Remember, the definition of vertical farming is growing on multiple levels. The Zip Grows achieve this by having multiple plant sites on a vertical access hanging down from supports running above the ground. Additionally, Matt stacks his DWC beds to double his production/sq ft when compared to a set up like the one in the photo above. Below is a photo of Matt’s stacked system, which, even in its simple form, doubles his production/sq foot! That’s the power of vertical farming!

I was immediately intrigued about Matt using Zip Grow Towers. Bright Agrotech seems like a great company, but I’d struggled to find an account of using their product that wasn’t tied to their marketing material. I didn’t, and don’t, have any suspicions, but I just wanted to check things out. I’d even flirted with buying a few towers myself to test them out, but Matt’s review of the Zip Grow Towers based off his experience running a real business is even more helpful.

“In the zip grow towers I can plant 6-7 heads of lettuce. But lettuce heads grow much better in raft systems than NTF systems, so we grow our heads in our raft beds now. Each bed is around 4’ by 8’ and we grow 50 lettuce heads in each bed, we also stack our beds twice.“ But, as you can see in the video below (no making fun of the flipped video), those Zip Grows are not wasted.

“Basil, kale and arugula grow well in our Zip Grow towers. We plant 7-8 basil and arugula per tower and 6 kale. In a 10′ by 10′ space we can house about 30 towers. We get around half pound of basil and arugula per tower and we count kale by the leaves so we get around 12 or more mature leaves per tower. We pick our towers continuously so that we are always harvesting from our plants and doing little replanting. With Zip Grow towers the majority of the work is in planting and hanging the towers.“

That breaks down along these lines:

Harvest/Tower (Lettuce)Harvest/Tower (Basil)Harvest/Tower (Kale)7 plants½ pound12 leaves

So Matt is growing through a combination of Zip Grow towers and vertically stacked deep water cultures. We’ve looked at a few different ways to grow produce on this site, but what it really comes down to is how much money you can make off of what you grow. Remember, the incentive to go vertical is to produce more calories/square foot at a lower cost. To quote from our introduction to LEDs:

“In vertical farming, it comes down to producing calories people want to buy (assuming your product is food of course). To make money, you need to produce those calories efficiently.”

How much money can you actually make when you start a vertical farm?

Let’s assume you are producing those calories efficiently.

I asked Matt how he set his price points for the different restaurants he sold to. “So originally we followed bright agro’s models for crop pricing. They host a number of blogs and videos talking about how to price your basil and how to sell you produce and offer very large price points for their crops.” Off the top of his head, he cites “$2.00 an oz for their herbs and I think $3/pound for vegetables.”

Bright Agrotech Farm Wall (more info here)

If you remember when I talked about actual restaurant pricing here, you’d understand that I had some doubts that these price points were attainable. Matt agreed. “They like to highlight how restaurants will be happy to pay that price in the winter but all of the restaurants I went to were really turned off by these type of high prices.”

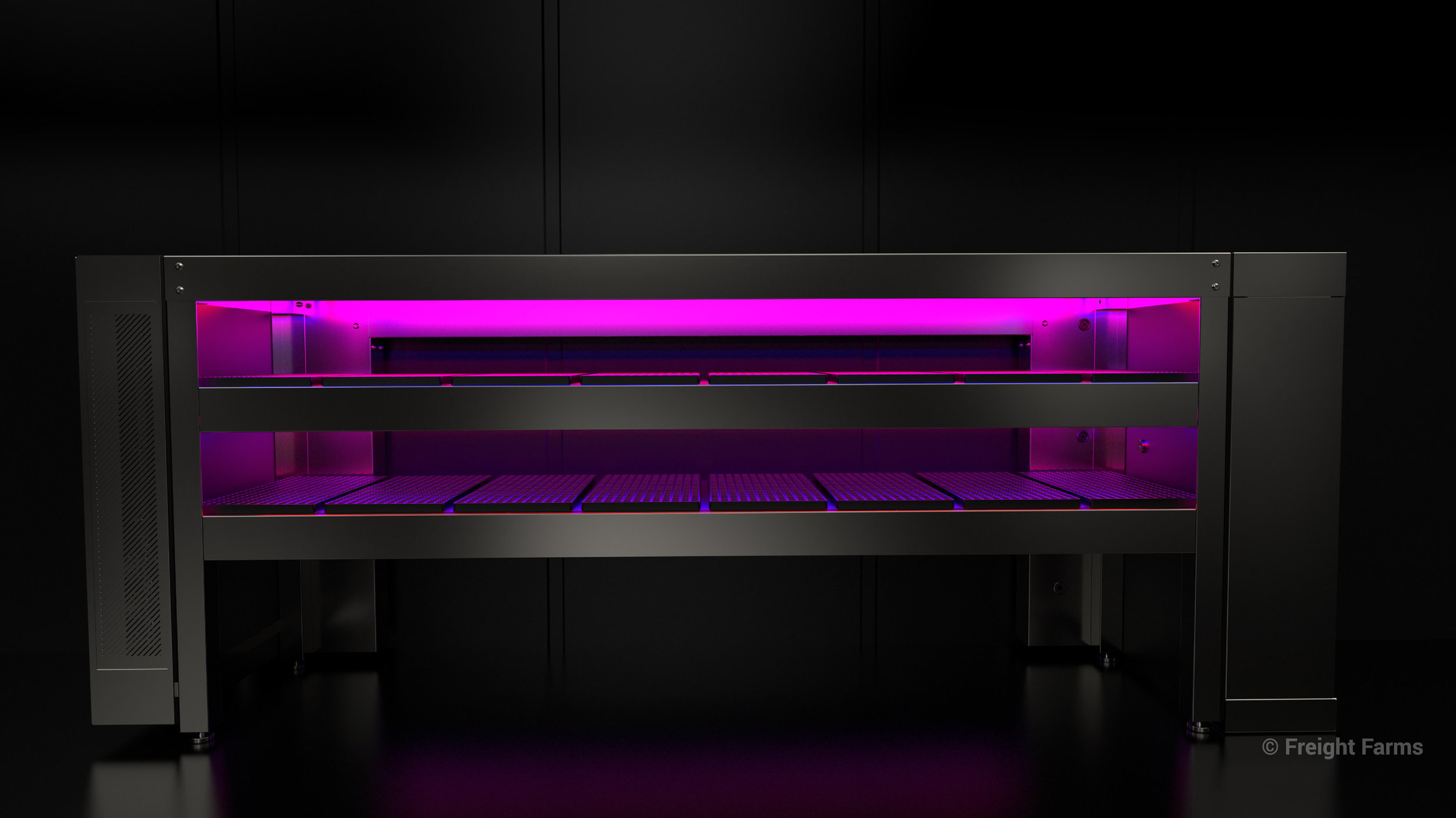

This is the main problem I have with purchasing ready-made systems from companies like Bright Agrotech or Freight Farms. This is not to disparage the actual products; not only have I never grown with them commercially myself, all testimony and evidence points to the fact that they work as intended and are examples of superior craftsmanship. However, it is completely fair to challenge the financial information they provide. They are incentivized by increasing sales of their product to use higher-than-realistic prices when they provide which gives the impression that you can pay off the initial investment in their product faster than is actually possible.

Here’s the table from above with Matt’s harvest per tower again.

Harvest/Tower (Lettuce)Harvest/Tower (Basil)Harvest/Tower (Kale)7 plants½ pound12 leaves

Let’s compare those numbers with those that Freight Farms shares. Real quickly, Freight Farms is a buy and farm as-is shipping container modification that also uses Zip Grows. I will note that I reached out to Freight Farms some time ago when I was originally considering investing in one of these and not for the purposes of an article. They were extremely helpful, but I ultimately decided the product was not for me at a $75,000 price point.

Image from Freight Farms

Here is the nice spreadsheet that they initially sent along for help with financial and crop planning. For full sized lettuce, they are saying that you can fit slightly more than what Matt was able to fit into one tower, but that may just be attributable to variety. They are also saying you can get 35 lbs/week of basil from a single tower. That doesn’t quite seem to stack up, though it could be the difference between a continual harvest like Matt uses, and harvesting a whole tower at once.

Anyways, as I said before, the company is super helpful and if you have any concerns, I’m sure they would be happy to address them. We’re going to look a little more at their financial models in a second too, so stick around.

I’m sure that there are examples of farmers getting the price that they advertise or even higher. However, in the interest of giving you an appraisal of the actual options out there for starting your farm, it’s fair to point out that it might always be the case. I definitely do not intend to disparage these companies or their products, and I’m happy to open up a space for them to respond to anything I’ve written.

As my research shows and Matt confirms “At these prices you’re [or a restaurant is] paying $30 a pound for herbs and twice or three times the industry standard for vegetables. Most restaurants simply can’t do those kinds of numbers. For example, most restaurants will pay around $8-12 dollars a pound for basil that they get from Cisco or other big food providers and while their willing to pay a small mark up for basil, the highest I got was $20, it is hard to get business owners to dish out to much money on basil and lettuce if it is breaking the bank.“

Based on that information, you’d be able to pay of the $75,000 investment in a Freight farm in just 2 years. Not only does that seem a little too good to be true, but if we plug in Matt’s numbers, we get a very different picture. Here are the price points Matt actually advertises when he sells direct to consumers:

Of course, neither Freight Farms nor any other supplier can be expected to anticipate market variance for the entire country. However, I want this information to be out there so you can more accurately make the decision on whether or not these products are right for you to start your business with.

Getting Customers Who Pay

Remember, the three steps to starting your vertical farm are

Proof of concept

2. Secure a buyer

3. Execute

I outline them in more detail here, but I wanted to include them here again to point out getting people who will pay you happens before most of the physical farming at a commercial level begins. Matt didn’t blink when I asked him how he did that and his unflinching attitude is probably one of the reasons Stag’s Leap is still chugging along.

He kept his answer short, too. “I literally just went around to everywhere I could find with a business card and told them I was doing locally grown high value crops. Some people didn’t call me back and others did.“ I can shorten it even more. How do you get people to pay? “Elbow grease.”

Original Photo of Mirai in Japan

A google search is going to blast your screen with thousands of marketing books, articles, blog posts, and everything else that’s going to tell you about building a brand, marketing, and sales tactics. Trust me, I’ve read most of them. But what they all really boil down to is just putting in the work, it’s as simple as that.

Hydroponics versus Soil-based Produce

That work is made a lot easier when you have a quality product to back it up. I still can’t believe how closed minded people still are to hydroponic products. They insist that the best produce comes from soil because it’s natural. Honestly, I just think they have a preconceived picturesque notion of farming in their mind that they are too stubborn to get rid of.

Look, my uncles have owned a restaurant my whole life, and that’s impressive considering most restaurants close within 90% of restaurants close in their first 12 months of opening. I started working there when I was 6 years old and didn’t stop until I went to college. I’ve been cooking my own meals since then (shoutouts to the ginger scallion sauce in the Momofuku cookbook) and gardening for almost that long too. I know what good produce tastes like. I know that it even smells and feels different. And I know that you can get good produce with hydroponic crops because I eat them all the time.

Yet…just try and bring up the idea of vertical hydroponic farming with an organic or permaculture extremist. Even though the ideas are super compatible, it’s still awful.

Click for the article

And frankly, people don’t agree with them. As Matt says “I haven’t come across anyone that has said we can’t grow superior produce with hydroponics, and if I were, I would probably refer them to a number of studies that suggest hydroponics can grow healthier, more flavor produce. [I’d] also give them some of our lettuce to try.”

That’s not just regular Joe-schmoes vouching for Matt’s product either. “The chefs that we work with really like our produce and would probably pay a lot more for our produce if they ran their restaurants. We constantly get great remarks about the lettuce we produce and the quality and flavor of our basil. We have a number of repeat customers that come for our salads and lettuce heads that say we have the freshest and best tasting lettuce around. And that definitely has to do with the fact that we are growing inside and with hydroponics. It really makes the whole production a lot easier and since we are selling locally this allows us to grow lettuce for flavor instead of shipping and shelf life.”

Since Matt is focusing on local food, his produce is so much fresher than anything consumers would be able to buy in a grocery store.

Obviously I’m a fan of holistic farming and permaculture techniques. I’m also a general fan of the USDA Organic Label, even if I think it could be improved. I just think that people need to really think about the type of farming Matt is doing beyond writing him off for trying something new, even if he’s using a manufactured product or, “heaven forbid;” PLASTIC. Especially in comparison to USDA Organic, something as simple as plastic doesn’t have as bad of an environmental impact as the pesticides already in use– natural or not.

Matt and I talked about this as well: “So I think its interesting when people like to contrast holistic farming with vertical farming, or holistic farming with hydroponic farming. When I think about what does holistic mean, I think about what is healthy for the consumer and what is healthy or sustainable for the planet. I think that vertical and hydroponic farming are great in both of those ways. Vertical farming really saves on land, which, as we are having a serious land crisis in terms of farming and are losing a lot of farm land to urban sprawl, is a really sustainable and positive for the future of farming. Hydroponics also allows us to recycle about 70-80 percent of the water we use, reduce the fertilizer we use, and eliminate any runoff from fertilizer. We can also do a lot of traditional holistic methods like companion planting and natural pest control using beneficial insects.”

Those are just a few of the ways to merge ideas that both philosophies espouse.

Conclusion

We wandered through a few different areas in this post. We touched on why vertical farms, if Matt’s is any example, might not be so limited in location than I was writing earlier. We also looked at how Matt is growing his food. He is using a combination of Zip Grow Towers and a custom built, stacked water culture system that allows him to maximize his production in the space.

Then, and perhaps a little controversially, we looked at pricing produce. While Matt is able to get a premium for his product’s freshness and sustainability, he still has the feeling that he’s not hitting the marks companies set for their pre-fabricated products. Not all of the numbers we included were exactly comparable, but they still make the point that you need to do your own market research before basing any business plan on those figures.

Next, we looked briefly into how Matt got customers for his produce before wrapping up by focusing on one of my pet-peeves; the rejection of hydroponic growing techniques by soil fanatics. I think this, along with location planning, is a significant challenge to the adoption of vertical farming technology. Though by no means the most important, it would be great to start doing taste studies along those lines.

This post was jam packed, and I hope you enjoyed it. Besides the great discussion about some of the challenges in vertical farming, I think the biggest take away is the detailed look at potential pricing. “Trust, but verify” as the saying goes.

Six Spectral Channels: Osram Unveils Grow Light System For Horticulture Research

Phytofy RL is already being used by NASA and Michigan State University. Osram is using it to carry out research of growth, anthocyanins and taste, conducted in a climate chamber at the TU Munich.

Osram has developed a research luminaire to meet the growing demands of researchers at universities, private institutes and plant production in greenhouses and vertical farms. Researchers and modern agriculturists can use the LED-based plant luminaire system Phytofy RL in the lab or in climatic chambers in order to develop new plant-specific light and growth recipes. These recipes can lead to desired outcomes in plant quality, yield and flavor.

Each of the six spectral channels can be addressed individually with Phytofy RL and the intensity planned and managed precisely in real time.

Selective intervention

"Various light wavelengths and intensities allow selective intervention in the metabolic processes of agricultural crops and ornamental crops", Claudia Zehnpfennig, Global Product Manager with Osram explains. "Yield, coloration and taste as well as other features can be influenced in this way. The latest research shows that not only is this process impacted by photosynthetically active radiation (PAR) – in the range of 400 to 700 nanometers (nm) – but that shorter and longer wavelengths also influence plant development."

With Phytofy RL, six spectral channels – from a natural far-red end-of-day light to UV light – can be addressed individually and the photosynthetic photo flux density (PPFD) planned and controlled precisely in real time: 385 nm, 450 nm, 521 nm, 660 nm, 730 nm as well as a warm white channel with 2,700 Kelvin. At the same time, the large number of LEDs in the fixture allows a higher photosynthetic photon flux (PPF).

Claudia Zehnpfennig & her colleague Kelcey Trecartin last year on the Cultivate

Light recipes

According to Claudia, the highly uniform light distribution is a special feature of the system. "The calibrated system furthermore supplies a precise irradiance map, calculated by the software with no quantum flux measurements required. Use of Phytofy RL allows for evaluation of the most varied light recipes, without having to change luminaires between individual tests. Diverse combinations of wavelengths also can be programmed, in different light profiles and across the entire photoperiod." In addition, users get five light recipes following registration, which have been specially developed by Osram.

Use of Phytofy RL allows the researchers to evaluate the most varied light recipes, without having to change luminaires between individual tests.

Climate chambers

The system software was developed by Osram together with plant biologists and can be used intuitively via the graphical user interface. Manufacturers of climate chambers benefit too, with integration possible in their systems. "The flat and robust design (667 x 299 x 44 mm, just under 9 kilos) is optimized for vertical farms, rack systems and growth chambers."

Phytofy RL is already being used by NASA and Michigan State University. Osram is using it to carry out research of growth, anthocyanins and taste, conducted in a climate chamber at the TU Munich.

For more information:

Claudia Zehnpfennig

horticulture@osram.com

Osram

Marcel-Breuer-Strasse 6

80807 Munich, Germany

Phone +49 89 6213-0

Fax +49 89 6213-2020

www.osram.com/phytofy

Publication date : 2/27/2019

Pushing The Boundaries of Creativity In Fresh Produce

These days image is everything in the fresh produce industry, as consumers become more brand conscious and aware of what they are eating and where the product comes from, not to mention how sustainable it is. Specialists agree that the brand stories and images conveyed on the packaging are of paramount importance.

Igor Moulder, Creative Director at Virtual Hub design agency has been in the business for many years and has seen how much things have changed. “When I started in the fresh produce industry in 1996 it was run by big companies who were slow to move on global consumer developments. Around 15 years ago things changed rapidly when growers started to market their produce.”

“It used to be only the technical qualities of the carton which growers had to think about. However, when growers became more aware of marketing their own products it really opened up the market, and the brand story and end packaging became really important. Modern consumers need to trust a brand and trust the quality that goes with it. They also like to know the story behind the product – where does it come from, is the supply chain transparent, what is the situation with regards to ethics and sustainability, etc.?”

Originally from South Africa Igor has worked with some of the best-known companies designing logos, website, brochures etc. One of his long-standing clients is Cool Fresh.

“Cool Fresh has built a credible story behind their fruit and are also strongly promoting corporate responsibility by supporting large-scale educational, sport and community development projects in South Africa. This gives back to the communities and gives the consumer a good feeling when buying the product.”

“Today, digital marketing and fresh produce need to get together, as there is a big gap to fill. Most people use mobile phones to search these days, so the fresh produce industry needs to become mobile friendly. The fruit sector has been slow to move but things are changing. Having said this, we cannot just rely on digital - print and old-fashioned networking are still important. You can have 1000 friends on facebook but it means nothing if it cannot be turned into sales. People are still people and need to see things and feel emotions. There is lots of emotion behind buying fruit and we need to give this to the consumer while still providing price and quality to the retailer.”

According to Igor it is a case of juggling time and money when designing a new brand. The grower has to like it, it has to be within budget, it has to be acceptable to the retailer and it has to be appealing to the consumer.

Corporate identity is very important, and most companies like to stick to the same logo and style. This year Igor worked on a new concept with Cool Fresh where communicating the company’s strategy was given a whole new look, whilst keeping the old logo but almost hiding it under the new corporate message. “The idea was that if nothing changes, people stop seeing ‘the real message’ after a while. Cool Fresh wanted to create something different and create a talking point, while still maintaining a very clear corporate and strategic identity and message. This was certainly the case with the company’s ‘Connecting Fresh’ approach to this year’s Fruit Logistica in Berlin.”

Igor admits that his ‘out of the box’ style does not fit every company. Yet, in the very competitive retail and consumer world it is important for any brand owner to stand out amongst the competition. Igor believes that innovative fresh produce companies should look at how branding and marketing is done in the fashion business. Igor closes: ‘The Dutch call it ‘gluren bij de buren’. Take a look at how other sectors are managing their marketing. Do not be scared of trying new things!’.

To view Igor's portfolio click here

Igor may be contacted on igor@virtual-hub.net

Publication date : 2/22/2019

Author: Nichola McGregor

© FreshPlaza.com

Plant Factory With Artificial Lighting: Toyoki Kozai's Brilliant Research On An Interesting Practice

According to AgriGarden, 'Plant factory is a highly efficient agriculture system which uses high precision control facilities in the continuous production of crops."

1/9/2019 9:16:19 AM

(MENAFN - GetNews) Dr. Toyoki Kozai's research work is on ' Opportunities and Challenges for Plant Factory with Artificial Lighting (PFAL) (or vertical/indoor farming). Dr Kozai graduated from Chiba University, Japan in 1967. He obtained a Master's degree in 1969, and a PhD degree of Agricultural Engineering in 1972 from the University of Tokyo in 1972. He served as Dean of Faculty of Horticulture and Director of Center for Environment, Health and Field Sciences of Chiba University. He was inaugurated as the President of the prestigious Chiba University in 2005. He resumed his career in research as a professor emeritus in an endowed chair position at the Center for Environment, Health and Field Sciences during 2009-2012. He established Japan Plant Factory Association (non-profit organization) in 2010 together with his colleague, and served as the president until 2018, and is serving as the honorary president to date.

Furthermore, Kozai's academic excellence and his scientific interest can be gauged from the multiple books he has written, namely, 'Smart Plant Factory: The next generation indoor vertical farms (2018), 'LED Lighting for Urban Agriculture (2016), 'Plant Factory: An indoor vertical farm for efficient quality food production (2015), and 'Photoautotrophic (Sugar-free) Micropropagation as a New Micropropagation and Transplant Production System (2005).

His early work on greenhouse light environments, energy savings, ventilation, computer control, knowledge engineering, integrative environment control using a heat pump, fogging and null-balance CO2 enrichment systems, and closed systems with artificial lighting for transplant production in the fields of greenhouse horticulture earned him great recognition in his field.

Kozai has recently been working on 'plant factory with artificial lighting (PFAL) and has been leading the R & D of PFAL. His continuous quest in this field allowed him to dive deeper into this subject. He has been invited as a keynote speaker on the PFAL to more than 20 international symposia during 2015-2018.

According to AgriGarden, 'Plant factory is a highly efficient agriculture system which uses high precision control facilities in the continuous production of crops."

According to Kozai, it is believed that PFAL is expected to contribute to solving the food-environment-resource-health issues concurrently. Kozai has further described the six major components of the PFAL viz., thermally well-insulated, almost closed structure, multi-tier unit with lighting and hydroponic cultivation devices, air conditioners and fans, CO2 supply unit, nutrient solution supply unit and environmental control unit. Furthermore, he has mentioned that relatively large automated PFALs have been built in Japan in the year 2018, and the number of profit-making PFALs has been increasing in Japan since 2016. Besides, there are ongoing large-scale projects in the world hence stressing the fact that this concept is gaining prominence not only in Japan but globally as well.

In addition to the above, Kozai's study throws light on the essential benefits of PFAL as well. First, that PFAL offers a high degree of freedom of environment control and that any environment can be created at minimal costs, thereby making it highly cost-effective. Second, all rates of resource supply, plant production and waste production can be measured and controlled. Then, Resource Use Efficiency (RUE) (amount ratio of resource fixed or kept in plants to the resource supplied to the PFAL) can be estimated online for each resource element including electricity, water, CO2, fertilizer and seeds. This shows the convenience and the hassle-free process.

Currently, compared to the greenhouse, the PFAL can save water consumption for irrigation per kg of produce by 95% by recycling use of transpired water vapor from plants (The transpired water vapor is condensed and collected at the cooling coil of air conditioners and returned to nutrient solution tank). The productivity of leafy lettuce per unit land area is more than 100 times higher in the PFAL than in the open field. Thanks to this high productivity per unit land area, the PFAL can be built in urban areas with non-fertile or contaminated soil, resulting in the reductions of CO2 footprint, loss of produce during transportation, and delivery time of fresh vegetables to citizens.

However amongst all the benefits, there is one issue which still remains unresolved i.e., a methodology to find an optimal set of environmental factors automatically to maximize the CP (or productivity) under given conditions is yet to be developed. To maximize the CP, unit economic value, plant growth rate, percent marketable portion, cost of each resource element, consumption and RUE of each resource element needs to be measured or estimated online, and be integrated to calculate the CP.

Kozai's excellent research suggests how the CP can be more than doubled and the impact and the expected increase this will have on the PFAL market. He has therefore proposed the reduction in cost per kg of produce, an increase in sales per m2 of cultivation space by introducing recent advanced technologies such as artificial intelligence. Currently, costs for electricity, labour and depreciation for the initial investment account for about 20%, 20% and 30%, respectively. The rest (about 20%) is for seeds, fertilizer, water, containers, maintenance, etc.

Further, Kozai has the discussed the idea of next-generation PFAL (n-PFAL) and the associated requirements, scheme for R & D, challenges and opportunities. According to him, n-PFAL needs to create unique environments for plant production to produce high-quality plants with high yields using minimum resources and minimum emission of waste by introducing advanced but inexpensive technologies. He has suggested different technologies, which can be of great use in the same. However, he has submitted some challenges and opportunities, for example, smart LED lighting, phenotyping (plant trait measurement), production management including seed processing and circadian rhythm, efficient use of resources with minimum waste, breeding using DNA markers of plants suited to PFALs, et cetera. He has defined plant phenotyping and has given a detailed account of its usage in n-PFAL. Plant traits include plant architecture, chemical components, physiological status and response, etc.

In the n-PFAL, a huge time-series dataset of plant phenotype (traits), environment and management (human and machine interventions including seed processing) is automatically accumulated in a data warehouse. The data warehouse is connected with a related genome database and other n-PFALs' data warehouse via Internet. This global and local network of n-PFALs each with semi-open database will bring about a paradigm shift of plant/food/agricultural production and breeding of plants suited to PFALs. For example, breeding of plants suited to PFALs can be speeded up using the n-PFAL. Kozai has further recommended four types of models to be implemented in the PFAL: 1) mechanistic models for photosynthesis, respiration, transpiration and growth, and for substance, energy and monetary balance, 2) multi-variate statistic models, 3) behaviour (or surrogate) models, and 4) AI (or deep learning) models.

Kozai's study has won great acclaim amongst the researchers and his brilliant research on PFAL, an upcoming innovation will be of great use not only nationally but internationally as well.

The Investment Company The World Needs

March 9, 2019

Kyle Baldock

Setting a Higher Standard in AgriTech Investment

Neon Bloom is a venture capital firm that focuses on acquiring innovative agriculture and ancillary technology products and services across the globe. With a suite of flagship investments in Holland and one in South Korea, Neon Bloom has made a strong start for a company that only began in January of this year. Of central importance to their investment strategy is a keen understanding of the holistic nature of the industry: they invest in complimentary companies in order to bring various parts of the value chain under a single umbrella. I interviewed Company Director Werner Huisman about this “Seed to Sale,” approach to investing. He told me:

“The big advantage is bringing knowledge together from many different parts of the world. Having the opportunity to bring so many talented individuals under one brand with the same mission and vision empowers each company within the portfolio.”

Read on to learn more about Neon Bloom’s mission to advance the industry for the betterment of mankind.

Getting to know: Neon Bloom

When did Neon Bloom start operating and why is it focused on AgriTech?

WH: Neon Bloom started the operation beginning this year. We are focused on the three pillars of water, power and food. We believe in “the zero hunger” mission and want to be a part of this mission. After learning about the importance of technology to improve sustainability and reduce the cost of goods we realised the importance of innovation to help with “The Zero Hunger” mission.

What technologies and trends are you most interested in for the coming decade?

WH: I believe in technologies based on natural and sustainable solutions. By the year 2050 the world population is expected to grow to 10 Billion people. This is over a 56% increase of food needed compared to 2010. It is going to take innovative technologies and a group effort to meet the demand. Looking at the solutions we bring in from Holland, they are all natural and sustainable.

Within HollandPlug we produce 100% organic substrates based on jute and PLA. This should replace the environmentally-unfriendly stonewool substrates.

Within Holland Pulse Light we are able to extend the expiration date for food by generating an enormous amount of energy through our pulse light technology- the pulse light flash has a power of 1850 Joule. With the electronic magnetic field and the enormous number of photons we are able to generate we are able to flash the food with the light and eliminate bacteria, fungi and viruses with all-natural products. Our machine utilises mainly UV-A which is able to rupture the cell membranes; whereas UV-C light impacts the DNA which changes the texture and taste of the food.

Within Holland2O we sell water machines which are able to produce HOCl water with a very low ppm value! (<30 ppm). This water has a redox value of around 1000 Orp(V) and an pH of 6.6 which is able to remain stable for a long period of time. With this water, we are able to kill all sorts of bacteria, fungi and viruses using only natural substances.

Where in the world are you seeing the most innovation in your three pillars of power, water and food?

WH: In principle, all around the world. In each part of the world there is a shortage of water; in each part of the world they grow fruit and vegetables and in each part of the world there are problems with fungi, viruses and bacteria. We believe that it will take a global effort to help meet the needs of the world over the next several decades.

Which volume are you in the market for- what is a normal project volume?

WH: Depends on which product you are talking about, but talking about % in the substrate market, we think we can take over 30% in 3 years’ time. We also believe our other technologies will have the capabilities to capture a significant amount of the market share. It is important to us that sustainable technologies lead the way in vertical farming.

What does Neon Bloom look for in potential acquisitions/investments?

WH: The requirements are in general as follows:

Product should have a relation to power, water or food;

The product should have a sustainable character;

It should have international potential;

The company must share our core values and vision

Does your company do VC or corporate finance? Debt or equity financing? Does Neon Bloom invest its own money?

WH: Neon Bloom is a VC with a focus on sustainable companies operating in power, water or the food industries. Our firm will provide debt or equity financing depending on our clients need. Yes, Neon Bloom invests its own money and is always searching for innovative companies to help us meet the “Zero Hunger” mission.

What advice would you give to AgTech companies that are looking to attract capital?

WH: You can attract capital from anywhere, so I would advise them to take a substantial amount of time defining their mission and vision statements. If your company’s core values and mission don’t align with an investment partner; then I would recommend finding a better fit. Secondly, see how their network and skill set can help grow your company’s footprint as well as impact in the world.

Why did Neon Bloom choose to become a member of the National Cannabis Industry Association?

WH: We decided to become a member of the National Cannabis Industry Association because of our first-hand experience of seeing the medical benefits the plant provides. This can help veterans dealing with PTSD or individuals with serious diseases. Cannabis is grown naturally and we believe it is a much better medicine than the drugs provided from pharmaceutical companies. It also has had a huge impact on slowing down the opioid crisis.

Why is there no visible investment in any cannabis related tech or producer?

WH: Our substrate technology can be utilised directly when growing cannabis along with our water. Both of these innovative technologies will allow for a product that is free of pesticides. It is the company’s goal to begin working with hemp producers this year. This will help provide food to the world as well as numerous other benefits to other industries.

Why did Neon Bloom join AVF?

WH: We don’t define success based on how much money a company is able to generate. Our firm determines success based on the impact and legacy we can leave on the world. It is crucial for humanity that we begin to implement many of the policies and beliefs of the AVF if we plan on having a sustainable future and to be able to meet the food demand for the ever-growing world population.

Want to find out more?

Visit Neon Bloom on the web: neonbloominc.com

KYLE BALDOCK

Dean Foods Explores 'Strategic Alternatives,' Including Sale

Amid the increase in options and consumer interest in plant-based milks and other dairy alternatives, Dean Foods has struggled

Feb. 27, 2019

Dive Brief:

Dean Foods is exploring "strategic alternatives to enhance shareholder value," according to a release. The options include an outright sale, pursuing a joint venture or merger, shedding assets or continuing on the company's current business plan by focusing on strategic initiatives.

The company has not yet set a timeline for the review of these options, but Evercore Group LLC will serve as financial advisor to Dean. CEO Ralph Scozzafava said in a statement that Dean is "taking vital, transformative actions to maximize the benefits of our scale and position the company for the long term."

Dean — which owns more than 50 dairy brands, private labels and legacy products including Oak Farms and Lehigh Valley Dairy Farm — reported a net income loss of $260.1 million in fourth quarter earnings Wednesday.

Dive Insight:

The announcement of this potential sale came the evening before Dean Foods reported its quarterly earnings. The country's largest milk producer posted losses for the fourth consecutive quarter and suspended dividends. For the full year, Dean reported a net loss of $3.63 per share. Announcing a review of its options before the release of this poor earnings report makes sense. And given the company's recent issues in the category, it shouldn't come as surprising news.

Amid the increase in options and consumer interest in plant-based milks and other dairy alternatives, Dean Foods has struggled. Plant-based and even lab-created milk has been sweeping the industry, hurting farms and milk producers. U.S. non-dairy milk sales were up 61% over the past five years, while dairy milk sales plunged 15% from 2012 to 2017, according to Mintel.

Adjusting to the change in demand, Dean has been working to diversify its investments in waters, juices and plant-based products. Dean bought a minority stake in Good Karma Foods, which sells non-dairy milk and yogurt, and later announced it was taking majority stake in the company. The dairy manufacturer also purchased Uncle Matt's Organic, a maker of probiotic-infused juices and fruit-infused waters. In 2016, it expanded its reach into other dairy segments, buying the manufacturing and retail ice cream business of Friendly's Ice Cream, a Northeast-U.S. restaurant.

In previous years, the company divested some of its plant-based and organic lines, including WhiteWave Foods and Morningstar.

The moves to diversify Dean's portfolio haven't been enough to avoid plant closures and layoffs. Late last year, Dean Foods closed two milk processing facilities and laid off 207 workers. Earlier in the year, the company shuttered three facilities. Dean also terminated more than 100 dairy contracts with the company to curtail how much milk it was purchasing.

Despite these measures, Dean Foods' earnings have continued to disappoint. Last quarter, profits dropped 12% from the same time a year ago. But that decline hasn't just been a result of plant-based competition. The company has battled with an oversupply of milk and tariffs. Since 2014, dairy prices have been falling consistently. Private label brands have also hurt Dean's business, as stores like Walmart and Amazon have launched store-branded milk that bring even more competition to the crowded space.

It seems that the company's cost-cutting measures haven't been enough and an outright sale could be likely. However, it's unclear who will want to buy Dean Foods. JPMorgan analyst Ken Goldman predicted that there won't be many interested buyers, according to Seeking Alpha.

"If Dean Foods does happen to find a buyer (unlikely, in our view), the stock will probably be purchased at a discount to the current price," Goldman said. "Dean is a levered company with a fast-deteriorating business and numerous out-of-date production facilities."

Farming On The Roofs of Shopping Malls In Singapore

Agriculture, takes up only about 1% of its land area.

Amidst the luxurious commercial setting of Singapore's Orchard Road, filled with fancy malls, department stores and food courts, there is a farm.

Reuters reports that the 6,450 sq ft Comcrop farm utilises vertical racks and hydroponics to grow leafy greens and herbs such as basil and perppermint, which are sold to nearby bars, restaurants and stores.

Allan Lim set up the rooftop farm five years ago, and recently opened a 4,000-square-metre farm with a greenhouse on the edge of the city.

The goal, in Singapore where land is at a premium, is to tackle food security.

“Agriculture is not seen as a key sector in Singapore. But we import most of our food, so we are very vulnerable to sudden disruptions in supply,” Lim said.

“Land, natural resources and low-cost labor used to be the predominant way that countries achieved food security. But we can use technology to solve any deficiencies,” he said.

In the country where 5.6 million people are densely packed in, land reclamation, moving transport utilities and storage underground, and clearing cemeteries for homes and highways have been undertaken.

Agriculture, takes up only about 1% of its land area.

Last year, Singapore topped the Economist Intelligence Unit’s (EIU) Global Food Security Index of 113 countries for the first time, scoring high on affordability, availability and safety.

However, importing more than 90% of its food, food security is susceptible to climate change and natural resource risks.

As climate change makes its impact felt across the world, the scarcity of water, shifting weather, and population growth will require better ways to feed the people.

A study published last year, cited by Reuters notes that urban agriculture currently produces as much as 180 million metric tonnes of food a year - up to 10% of the global output of pulses and vegetables.

From what was once an agrarian economy that produced nearly all of its own food, from pig farms, vegetable gardens and durian orchards and chicken in the kampongs, to government is now pushing to relocate over 60 farms in the countryside by 2021, to reclaim land for the military.

Speaking to the publication, Chelsea Wan, a second-generation farmer who runs Jurong Frog Farm said: “It’s getting tougher because leases are shorter, it’s harder to hire workers, and it’s expensive to invest in new technologies.

“We support the government’s effort to increase productivity through technology, but we feel sidelined,” she said.

Korean Company Starts Building Hydroponic Greens Houses in Northern Tajikistan

The use of the hydroponic system will help increase productivity, according to the Sughd regional administration.

8 January 2019 14:39 (UTC+04:00)

South Korea’s Myung Sung Placon Ltd has begun building hydroponic greenhouses in the northern Sughd province. The hydroponic system has an ancient history and was reportedly used for building of the Hanging Gardens of Babylon, Trend reports referring to news.tj.

The use of the hydroponic system will help increase productivity, according to the Sughd regional administration.

The building of the hydroponic greenhouses began in the Somgor area of the Bobojon-Ghafourov district on January 7.

An official source at the Sughd regional administration says local “Bars” Company is a contractor and specialists from South Korea are implementing the project.

Sughd authorities have invited Myung Sung Placon Ltd to build greenhouses in the province, taking into account the company’s experience of work in the neighboring Uzbekistan, the source added.

Hydroponic growing is growing a plant without using soil - usually in an inert substance like rockwool or perlite, which hold the roots for easy water and nutrient absorption. Hydroponics systems back several hundred years, and there is evidence that ancient civilizations grew plants in water. Nutrients are vital to hydroponic success: there are sixteen essential elements that a plant needs to grow, and the right balance of these nutrients must be maintained for each specific variety of plants. Equally as important as nutrition are the factors of light, temperature (heating and cooling), and carbon dioxide. Insects play a key role in pollination and pest management.

The Hanging Gardens of Babylon were one of the Seven Wonders of the Ancient World and were described as a remarkable feat of engineering with an ascending series of tiered gardens containing a wide variety of trees, shrubs, and vines, resembling a large green mountain constructed of mud bricks, and said to have been built in the ancient city of Babylon, near present-day Hillah, Babil province, in Iraq. Its name refers to trees being planted on a raised structure such as a terrace.

According to one legend, the Hanging Gardens were built alongside a grand palace known as The Marvel of Mankind, by the Neo-Babylonian King Nebuchadnezzar II (who ruled between 605 and 562 BC), for his Median wife Queen Amytis, because she missed the green hills and valleys of her homeland. The construction of the Hanging Gardens has also been attributed to the legendary queen Semiramis, who supposedly ruled Babylon in the 9th century BC, and they have been called the Hanging Gardens of Semiramis as an alternate name.

Edeka and Metro are Joining the Growers

In the farm, seedlings of various plants are being used. They are not growing in soil, but have been dipped in a thin layer of liquid that provides the necessary nutrients.

Vertical farming is a way to put an end to the climate-compromising import of vegetables from all parts of the world. Fruits and vegetables can also be grown in the supermarket, some manufacturers promise. But we are not there yet.

There is a large black box with Plexiglas windows, standing in the middle of the vegetable department of the Edeka market in Oberhausen. This is the "greenhouse of the future," explains Pascal Gerdes. In fact, it is a digitally networked herbal farm in which plants are to grow under optimal conditions.

After a critical appraisal of the plants and a smell test, a customer decides to buy some of the coriander, which she places in her almost empty shopping basket. Price: 1,29 Euro. The Gerdes family is not pleased with the customer's choice. This lady is the first buyer of the plants that are grown in the supermarket.

Only a few weeks ago, the futuristic-looking farm was set up in the store of the Gerdes family. It came from Berlin start-up Infarm, which is one of the major suppliers in the field of vertical farming. Infarm also cooperates with other retailers. The 'farm' is to be tested in the Edeka market for a whole year. If the mint, Greek basil, mountain coriander and the like prove to be worthwhile, the farm may remain there. It is, however, still too early to do away with the entire vegetable counter - that would be relying too much on this nascent technology.

Digital farms in Oberhausen, London and Paris

In the farm, seedlings of various plants are being used. They are not growing in soil, but have been dipped in a thin layer of liquid that provides the necessary nutrients. From above, LED lamps provide continuous lighting. Everything can be individually adjusted so that the optimal climate conditions can be created for every plant. Vertical farming promises efficient and, above all, rapid growth.

"Temperature and light intensity are adjusted completely autonomously," explains Martin Weber from Infarm. "We control the state and the growth of the plants via infrared cameras." An employee from Infarm will go to the Edeka stores to harvest. He or she will set the plants that are ready for sale apart, immediately inserting new ones in their place. Supermarket operators like the Gerdes family do not have to worry about anything. But that should change over time. With more experience, sowing and harvesting can be taken over by the supermarket operators.

Until now, Vertical Farming is limited to herbs, as in the Edeka store in Oberhausen. But one can grow any kind of fruit and vegetables, promises Infarms CFO Weber: "We would like to offer everything, without exception."

This optimism has apparently convinced some retailers: The incubators of Infarm are there at numerous German Edeka markets, including stores in the Swiss supermarket chain Migros and in metro markets - including a metro market in the suburb of Nanterre, Paris. And the internationalization is to go on: "In Paris and Zurich, we have already inaugurated the first farms outside Germany. And in early 2019, London will follow," said Weber. In the USA there is potential for the Berlin start-up as well.

Source: Wiwo.de

Publication date : 1/4/2019

Urban Farms Could be Incredibly Efficient—But Aren’t Yet

Casual farmers overwork, buy fertilizer, and use municipal water.

JOHN TIMMER - 12/28/2018, 3:45 AM

The green revolution that transformed modern agriculture has generally increased its scale. There's tremendous potential for efficiencies in the large-scale application of mechanization, fertilization, and pesticide use. But operating at that level requires large tracts of land, which means sources of food have grown increasingly distant from the people in urban centers who will ultimately eat most of it.

In some ways, hyper-local food is a counterculture movement, focused on growing herbs and vegetables in the same dense urban environments where they will be eaten. It trades the huge efficiencies of modern agriculture for large savings in transportation and storage costs. But is urban farming environmentally friendly?

According to researchers at Australia's University of New England, the answer is pretty complex. Within their somewhat limited group of gardeners, urban agriculture is far more productive for the amount of land used but isn't especially efficient with labor and materials use. But the materials issue could be solved, and the labor inefficiency may be a product of the fact that most urban farmers are hobbyists and are doing it for fun.

Urban ag

The researchers—Robert McDougalla, Paul Kristiansena, and Romina Rader—defined urban agriculture as taking place within a kilometer of a densely built environment. Working in the Sydney area, they were able to find 13 urban farmers who were willing to keep detailed logs of their activity for an entire year. Labor and materials costs were tracked, as was the value of the produce it helped create. The energetic costs of the materials and labor were also calculated in order to assess the sustainability of urban farming.

The plots cultivated by these farmers were quite small, with the median only a bit over 10 square meters. Yet they were extremely productive, with a mean of just under six kilograms of produce for each of those square meters. That's about twice as productive as a typical Australian vegetable farm, although the output range of the urban farms was huge—everything from slightly below large farm productivity to five times as productive.

For the vast majority of crops, however, the urban farms weren't especially effective. They required far more labor than traditional farms, and, as a result, the total value of the inputs into the crop exceeded the income from selling it. In other words, the urban farmers were losing money, at least by traditional accounting measures. And the farms weren't especially sustainable, with only about 10 percent of all the inputs coming from renewable resources. Again, labor was a major culprit, as it's not considered very renewable, and urban farming is very labor-intensive.

So that all sounds like a bit of a disaster, really. But as mentioned above, things quickly get complex. The urban farmers, as it turned out, bought compost and fertilizer and used the municipal water supply. Cities, as the authors note, produce large quantities of organic waste that could be used to make compost. While it would require additional labor and land space, it would be easy to make the care of the crops far more sustainable. Combined with the use of collected rainwater, these could get the percentage of renewable contributions up to roughly 40 percent.

Laborious

Then there's the issue of the time spent on labor. The urban farmers don't seem to be especially efficient compared to regular farm laborers, and by all indications they don't necessarily want to be. For many of them, it's more a hobby than career; they put in more labor because they enjoy it or find it relaxing. If you start reducing the labor costs to reflect this, things start changing dramatically. If only the material costs of urban farming are considered (meaning labor was set to $0), then the apparent efficiency improves dramatically.

Not surprisingly, ignoring labor costs also makes a big difference financially, with the profit-to-cost ratio going from a mean of 0.62 up to 2.8, indicating that these urban farms would generally be quite profitable.

Labor also makes a big difference in terms of energy use. As they're now operating, these urban farms aren't very different from rural farms, which means they're not sustainable. Shifting to local sources of materials, like rainwater and compost, would drop the energy use dramatically, shifting the farms into territory that's typically considered sustainable. Eliminating labor considerations on top of that would make urban agriculture among the most efficient means of growing vegetables presently studied.

There are two obvious caveats to this work: the small number of farms sampled and the fact that they were all in a single urban area. This sort of study will obviously need to be replicated in other locations before we can start generalizing about hyper-local produce. But the role of labor in this sort of analysis makes conclusions difficult to generalize. Is it reasonable to discount some fraction of the labor costs when people are doing the farming for pleasure? Do we start considering a tomato plant on a balcony part of an urban farm?

While many of the details are unclear, the overall conclusion seems solid: while urban farms aren't yet there in terms of sustainability and energy use, the potential for them to outpace their larger rural cousins is definitely there. But it will take an entire sustainable support infrastructure for them to truly arrive.

Why Mindfulness Is Essential For Farmers And Their Health

March 8, 2019 in Eco-Living & Health, Health