Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

On Rooftops And In Tunnels, City Farms Lead Food Revolution

Salad plants are already being grown in old bomb shelters but floating dairy farms and 16-storey food towers could be next

Growing Underground produces food 33 metres beneath Clapham High Street in a wartime bomb shelter. Photograph: Roca London Gallery

10 February 2019

Only the Northern line tube trains rumbling through tunnels overhead provide any clue that Growing Underground is not a standard farm.

The rows of fennel, purple radish and wasabi shoots could be in almost any polytunnel, but these plants are 100 feet below Clapham High Street and show that urban agriculture is, in some cases at least, not a fad.

The underground farm has occupied a section of the second world war air-raid shelters for nearly five years, and Richard Ballard, one of the founders, is planning to expand into the rest of the space later this year.

“The UK is the hardest market for growing salad,” he said. “We’ve got very low prices in the supermarket, so if we can make it work here we can make it work anywhere.”

The Growing Underground experience is being highlighted at two exhibitions this year: Roca London Gallery’s investigation into “agritecture”, London 2026, which opened on Saturday, and the V&A’s Food: Bigger Than the Plate in May, which will also showcase micro-farming methods such as Grocycle’s hanging mushroom bags.

Urban commercial farming – as opposed to Britain’s 330,000 allotments – is a regular topic of interest at places like the World Economic Forum in Davos, where policymakers consider whether the world’s food system, blamed for causing both obesity and malnutrition, can be fixed.

There are already plenty of urban farming projects around the world, particularly in the US, Japan and the Netherlands, ranging from aquaponics – urban fish and plant farms – to vertical farming, where plants are grown in stacked trays, a method Growing Underground also uses.

ReGen eco-villages would power and feed self-reliant families. Photograph: Roca London Gallery

“It’s definitely becoming an expanding industry,” Ballard said. “There’s several other businesses starting up in London in containers, smaller projects, and there are several around the country now, other vertical farms.”

Growing Underground supplies herb and salad mixes – pea shoots, garlic chives, coriander, rocket, red mustard, basil and parsley – to Marks & Spencer, Waitrose, Ocado, Whole Foods and Planet Organic, as well as restaurateurs including Michel Roux. Being in London creates an advantage, Ballard says, as they can harvest and deliver in an hour.

He reels off other advantages. Being underground means temperatures never go below 15C – surface greenhouses need to be heated. They can do more harvests: 60 crops a year, compared with about seven in a traditional farm or about 25 in a polytunnel. Electricity to power the lights is a major overhead, but the firm believes renewable energy will become cheaper.

Similar British ventures include the Jones Food Company in Lincolnshire, while in the US AeroFarms has several projects in New Jersey, and Edenworks in Brooklyn uses the nitrogen waste from the tilapia and striped bass in its aquaponic fish farm to feed its herb crop.

For Clare Brass of Department 22, a sustainability consultancy which curated the Roca London exhibition, projects like Growing Underground are vital pointers to the future.

“We are living in the most ridiculously wasteful system,” she said, citing research that shows about a third of the world’s food is lost. “We need to transition to a circular economy. Business and government are not going to do it. These are people who are innovating, and we need these people to show us the way.”

Some of the ideas presented include rooftop bee-keeping, an insect breeding farm for roundabouts in Stockholm, home food recycling in 24 hours, and a floating dairy farm in Rotterdam that is due to open later this year – a real-life interpretation of the children’s book The Cow Who Fell In the Canal.

Futuristic food tech companies may look like a great investment, but when venture capital runs out, many businesses fold. Paignton Zoo in Devon was one of the first to try vertical farming in 2009, using a system known as VertiCrop to grow leafy greens such as Swiss chard and pak choi for its monkeys. Five years later, the system was gone. The company behind it, Valcent, which later became Alterrus and set up rooftop greenhouses on carparks in Canada, went bankrupt in 2014.

“Vertical farming makes sense for microgreens,” Carolyn Steel, a London-based architect and author of Hungry City, said. Herbs are about 200 times as valuable per kilo as grains. “But why farm grain in a city when it can grow 20 miles away and spend three years in a grain store. Grain stores are one of the reasons cities emerged in the first place.”

For Steel, urban farming should be encouraged as an important reminder for city dwellers where their food comes from. “We have become very remote from our food,” she said, pointing out that London’s geography shows how it was built on its food supply. Grains came along the Thames to Bread Street, chicken entered from the east to Poultry, while beef went to Smithfield.

“Ultimately we need to pay more for food,” Steel said. “Ever since industrialisation we’ve been externalising the true cost of food, and now we’re seeing the true cost of that in terms of climate change, mass extinctions, water depletion, soil erosion and diet-related disease. Where does vertical farming sit in that?”

A hydroponics unit for the home provides water and light for plants. Photograph: Roca London Gallery

'Superfarm' By Studio NAB Proposes A Vertical Farm Concept To Combat Land Shortage

in response to the growing global population, studio NAB, has developed the ‘superfarm‘ concept as an alternative to traditional farming methods. as the name suggests, the project creates a building that focuses on the production of foods with a high nutritional value that can be consumed in addition to a healthy diet. the ‘superfarm’ also strives to recreate an ecosystem within an urban environment. seaweed culture, beekeeping, insect farming, aquaponics and also various greenhouse cultivations and outdoor cultures are included in the scheme by the architect.

view of the project from a dock | all images courtesy of studio NAB

As a conceptual project, studio NAB‘s design has been imagined in the heart of a city on a river development in an effort to respond to scarcity of land. the 6 storey proposal is designed to occupy a small 12m by 12m surface, with a height of 34m. each level of the ‘superfarm’ is developed to increase in area as you ascend, therefore gaining the maximum floor area with minimum impact on the site. each floor will house different functions, with the top floor comprising of a greenhouse with beehives and planting spaces. on the roof, solar panels and wind turbines provide energy to power the building.

view from the access footbridge

in addition to producing a wide variety of highly nutritious foods, the ‘superfarm’ also aims to reduce travel distances of food and therefore restore the link between producers and consumers. inhabitants will also gain easier access to these products by coming directly to the farm. accessible from the footbridge, a direct sales area has been imagined as well as a storage area for dry goods and cold rooms for perishable goods.

view from the platform of the production of seaweed

studio NAB’s concept also aspires to combat unemployment and revive the local economy on a neighborhood scale. the scheme also aims to create a collective awareness of the inhabitants and local partners around a common project of innovative and healthy urban agriculture. thanks to the installation of wind turbines and solar panels, several kW/h can be produced daily to supply the heat production systems and to allow the ventilation and lighting of indoor production areas. therefore, the building will produce it’s own power to operate and be completely energy self-sufficient.

view of the production space in direct connection with the greenhouse

view of the greenhouse, on the roof, solar panels and wind turbines power the building

section through the building showing the functions of the farm and details of the food produced by floors

level 6 greenhouse

level 5 aquaphonics

level 4 algae culture

level 3 insect breeding

level 2 platform

level 1 offices

ground level

project info:

project name: ‘superfarm’

project status: concept

architect: studio NAB

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: lynne myers | designboom

architecture video competitions product library shop socialize

New Greenhouse Concept: Multispan, Foil and Semi-Closed

During this year's Sival, a new greenhouse concept was launched by CMF Groupe. The GreenPush BioActive is a semi-closed multispan concept. "We want to limit the pest pressure and offer a more homogeneous climate", Corenthin (Felix) Chassouant with CMF Groupe explains.

IPM

As shown at the Sival and in the video above, the GreenPush BioActive is equipped with insect nets, in the roof and windows. A constant airflow into the greenhouses creates over-pressure, making it impossible for insects to enter the greenhouse and thus creating favorable conditions for IPM.

The air entering into the greenhouse is controlled by a high-tech climate management system, offering extra control over the greenhouse air. "Temperature, humidity and CO2 can be optimized in an easy way, offering growers extra tools to control their climate", Felix continues. "Since the air is dehumidified before it enters the greenhouse anyhow, it offers opportunities to recycle the air various times and create a homogeneous, favorable climate for the crop while ensuring optimal heating conditions and using the energy to the best. In warmer periods and with the use of cooling pads, it's also possible to cool the outside air being brought into the greenhouse."

The GreenPush BioActiv is equipped with the oval tubes - like the GreenPush concept that was launched last year. The ovalized tube makes higher widths possible and thus more volume in the greenhouse. "This concept is for both glass as well as foil greenhouses", Felix tells us. "The larger widths & higher volume gives a better humidity and temperature control within the greenhouse, whereas the amount of shadow is significantly lower thanks to the larger distance between posts. With the GreenPush BioActiv we take the next step."

Like CMF's other options, the CMF’s GreenPush BioActiv turnkey solution can be adapted to all climatic conditions to obtain more homogeneous crops by reducing or even eliminating chemical products.

For more information:

Author: Arlette Sijmonsma

© HortiDaily.com

Statement From FDA on Investigation of November '18 Outbreak of E. coli In Romaine Lettuce

The U.S. Food and Drug Administration and the U.S. Centers for Disease Control and Prevention acted quickly to protect consumers from an emerging outbreak of E. coli O157:H7 linked to romaine lettuce by issuing a public warning this past November and recommending that industry and retailers voluntarily remove the product from the market. It was critical to provide this advice because it was believed that contaminated produce was still in the food supply at a time when Americans were preparing meals to celebrate Thanksgiving. By removing potentially contaminated products from the market, health officials and industry were able to reduce additional illnesses.

Evidence at the beginning of this outbreak showed that the genetic fingerprint of the pathogen obtained from patients impacted by the 2018 outbreak was similar to the strains associated with an outbreak previously linked to leafy greens in 2017. With help from this historic information, our staff worked quickly to initiate traceback from points of sale through the supply chain ultimately to the farms where the romaine could have been grown. Investigators were able to narrow down the growing region to California based on trends in the industry. Moreover, the supply chain pointed to specific California counties.

The traceback investigation identified multiple farms that may have been implicated in this outbreak. These farms became the focus of further evaluation. The FDA led a team of experienced federal and state investigators who were tasked with taking samples and inspecting these farms to try and find out where and how this outbreak happened. They collected samples of soil, animal feces, fertilizer, agricultural water and reservoir sediment. The CDC was able to find one positive match to the outbreak strain in the sediment of an on-farm water reservoir, used for irrigation, in Santa Maria, Calif.

The investigation teams made numerous visits to leafy greens farms in various counties and growing regions of California identified through traceback. The outbreak strain of E. coli O157:H7 was not detected in any other samples collected during this investigation. On December 17, 2018, the farm with the positive match to the outbreak strain in the sediment issued a recall of romaine lettuce and other products -- including red leaf lettuce, green leaf lettuce and cauliflower -- that may have also been contaminated due to use of agricultural water from the on-farm reservoir.

Given the critical nature of these activities, during the partial lapse in funding, the FDA and CDC continued work on this investigation. Thanks to this continued effort during the partial funding lapse, we were able to declare the outbreak over – just over two months after it was first announced – once we were confident that contaminated product could no longer be available for purchase and there were no new illnesses linked to romaine from the implicated California growing areas. Even though the outbreak was declared over, the FDA’s investigation continued. We wanted to understand the factors that allowed this outbreak to happen and provide information to help prevent similar outbreaks from occurring again.

Today, we’re announcing the findings of this investigation and our best hypotheses as to how this contamination could have occurred. In the case of the one farm with a positive sample previously referenced, the FDA believes that the most likely way romaine lettuce on a specific ranch on this farm became contaminated was from the use of water from this reservoir as agricultural water. It is believed that this water came into contact with the harvested portion of the romaine lettuce, since the outbreak strain of E. coli O157:H7 was found in sediment from the reservoir and in no other sampled locations. The water from the reservoir doesn’t explain how lettuce grown on other ranches or farms identified by traceback may have been contaminated. So, this one farm cannot explain the entire outbreak.

As part of our investigation, we determined that the farm had a procedure in place to collect and test reservoir agricultural water for generic E. coli and to treat the agricultural water with a sanitizer before use. However, the investigation team noted the verification procedure records did not document that sufficient sanitizer was present to adequately reduce any pathogens present in the water when this water was used for direct contact with romaine lettuce at harvest, during postharvest handling, and to wash/rinse harvest equipment food contact surfaces. It’s important to note that the farm reported that it did not use water from the reservoir for the dilution of crop protection chemicals. It also remains uncertain how the outbreak strain of E. coli O157:H7 was introduced into their on-farm water reservoir.

The finding of the outbreak strain in the sediment of the water reservoir is significant, as studies have shown that generic E. coli can survive in sediments much longer than in the overlying water. It’s possible that the outbreak strain may have been present in the on-farm water reservoir for some months or even years before the investigation team collected the positive sample. It is also possible that the outbreak strain may have been repeatedly introduced into the reservoir from an unknown source.

The teams did find evidence of extensive wild animal activity, including waterfowl, rodents, coyotes, etc., and animal burrows near the contaminated reservoir. This likely warrants consideration as a possible source of the human pathogen found in the on-farm water reservoir. It is another factor that we will work with the farm to address. Additionally, adjacent land use including the use of soil amendments, or for animal grazing on nearby land, may have had the potential to be contributing factors.

As explained in the Environmental Assessment of Factors Potentially Contributing to the Contamination of Romaine Lettuce Implicated in a Multi-State Outbreak of E. coli O157:H7, which provides the findings of the unrelated spring 2018 investigation into contamination that originated in the Yuma growing region, food safety problems related to raw whole and fresh-cut (e.g. bagged salad) leafy greens are a longstanding issue. The FDA and CDC identified 29 foodborne illness outbreaks of Shiga-toxin producing E. coli (STEC) with a confirmed or suspected link to leafy greens in the United States between 2009 and 2017. STEC contamination of leafy greens has been identified by past investigations, traceback, observation and sample collection results as most likely to occur in the farm environment.

To help ensure that leafy greens are safe and mitigate problems that might occur, it’s important to understand where leafy greens are grown and harvested and not simply the location of the business entity that shipped or processed the produce. It’s also important to be able to determine which farms and growing regions are responsible for supplying the contaminated product and the time frame when product was supplied. This information is crucial to the development of accurate public health messages to both protect consumers from exposure and empower retailers and consumers to take appropriate actions.

The FDA continues to recommend that leafy green growers, buyer/shippers and retailers be able to trace product back to the specific source in real time and make information about the source, such as harvest date and standardized growing regions, readily available for consumers on either packaging or point of sale signs, or by other means. We’re pleased to see many companies in the leafy green industry take voluntary steps to quickly respond to our previous recommendations. We believe this is the best approach to be able to inform consumers should there be any future risks to public health. Our first goal is working with federal, state and industry partners on implementing best practices to try and prevent these outbreaks in the first place. But when outbreaks occur, without the ability to identify the growing region or specific suppliers of suspected shipments, the public messages issued by the FDA and other public health partners during recalls or outbreaks will continue to be -- out of necessity -- broad and likely to include farms and growing regions that may not be responsible for the contamination. We know more needs to be done and there is a shared sense of urgency around these efforts.

The FDA recommendations based on this investigation are similar to, and reinforce, the changes recommended for the leafy green industry in the Yuma environmental assessment. We continue to strongly recommend that all segments of the leafy greens industry thoroughly review current operations, procedures, policies and practices taking into consideration the findings of this investigation report, the FSMA Produce Safety Rule, the FSMA Preventive Controls for Human Foods Rule and other relevant FSMA regulations. Other available science-based information relevant to the reduction or elimination of human pathogens on leafy greens should also be considered. In addition, industry should make the necessary modifications to operations, procedures, policies and practices to ensure safe products for consumers and minimize the likelihood of similar outbreaks in the future.

We’ll continue to work with industry to explore better ways to assure quick, accurate and easy access to key traceability information. The FDA believes that widespread industry adoption of existing and emerging technologies, which can be used to trace product from the field to the consumer in real time, is a critical piece of our ability to protect the public. In addition, the agency has already started special, microbiological surveillance sampling assignments for romaine lettuce that is grown for distribution throughout the country. If samples are found to be contaminated, the FDA will follow-up with the responsible farms and firms to assure that they remove contaminated products from the market. The agency will also work with responsible farms to determine issues and identify steps they can put in place to prevent contamination in the future.

Advancing the safety of fresh leafy greens requires ongoing collaboration. We urge all segments of this industry, from farm to table, and our government partners to review the findings of our investigation and make necessary changes. We recognize and appreciate the efforts that the leafy greens industry has taken to date. But together, we also know more must be done on all fronts to help prevent future foodborne illness outbreaks. We remain committed to further strengthening the FDA’s food program and applying our food safety expertise as we work to better safeguard the U.S. food supply.

Are You A Teenager Who Is Passionate About Technology And The Environment?

This is your time to shine!

Seeds&Chips and Fondazione Francesca Rava - NPH Italia Onlus

launch the Call for Teenovators

Applicants have the chance to speak at the next edition of the Summit and meet with the innovators and world leaders who are shaping the future of the planet

The deadline for applications is April 10th 2019:

https://seedsandchips.com/#call-teenovator

Milan, February 14th 2019 - Seeds&Chips - The Global Food Innovation Summit – the largest food innovation summit in the world – in collaboration with Fondazione Francesca Rava - N.P.H. Italia Onlus, a charitable non profit foundation that helps children in serious need in Italy and worldwide, is launching the Call for Teenovators.

The objective is to find the most passionate and dedicated teenagers (ages 13 to 19), determined to change the food system and address the most pressing global issues in accordance with the UN Sustainable Development Goals. These teenagers will inspire the current and next generation of leaders at the fifth edition of Seeds&Chips, from May 6-9, 2019 in Milan, Italy at Fiera Milano, Rho.

At the Summit, Teenovators will have the chance to open the conference sessions for our exceptional speakers – heads of state, entrepreneurs, opinion leaders and innovators – from around the world, and share their thoughts and experiences with them.

Giving a voice to young people has always been a priority for Seeds&Chips. As ambassadors for the next generation, they are spokespeople for the fundamental changes that we must undertake, and symbols of the incredible potential we have to meet these challenges. It is them, after all, who have the most influence on the future, not just from a food innovation point of view. In addition to involving many teenagers, Seeds&Chips 2019 is also calling for Young Pioneers (age 20-25) to share with the world their current projects and plans for the future.

“The world needs to take inspiration from young people,” says Marco Gualtieri, Chairman and Founder of Seeds&Chips. “In the years to come new generations will have to face great challenges: soil degradation, biodiversity loss, pollution, access to water and climate change pose very serious threats to the future of humanity as we know it. With their choices and efforts, new generations have the power to help humanity transition to a better food system and to reverse the environmental damages that are threatening life on Earth. Luckily, research shows that Generation Z is poised to become the most entrepreneurial generation ever, bound to influence the next big wave of innovation and fully achieve the United Nations Sustainable Development Goals.”

“We’re enthusiastic about the synergy with Seeds&Chips because an important part of the Fondazione Francesca Rava – N.P.H. Italia Onlus is educating young people about respecting themselves, others and the environment that surrounds them,” says President Mariavittoria Rava. “N.P.H. Nuestros Pequeños Hermanos, which represents the Francesca Rava Fouundation in Italy has been changing people’s lives for over 60 years, with the motto one child at a time, from the streets to the degree.

Through our work in schools and campuses, we listen to the motivated voices of many young people who don’t often get the chance to express themselves and be valued.

The partnership with Seeds&Chips, thanks also to the support of Eco Eridania, allows us to give many deserving young people the opportunity to bring their ideas to the world stage with and be influencers for a better tomorrow.”

Seeds&Chips and the Fondazione Francesca Rava – N.P.H. Italia Onlus are thus launching a worldwide call to all teen innovators who are motivated to shape the future of the planet and of humanity.

Are you ready to impact the future?

Complete and submit the application form available on our website https://seedsandchips.com/#call-teenovator no later than April 10th, 2019.

Seeds&Chips - The Global Food Innovation Summit, founded by entrepreneur Marco Gualtieri, is the largest food innovation event in the world. Every year since 2015, the Summit has brought together and expanded an ecosystem of startups, companies, universities, organizations, investors, accelerators and incubators, opinion leaders and policy makers from all over the world. It functions as an international meeting point for innovators, influential experts and global leaders from the public and private sector to develop and implement solutions for the most pressing issues in food production and supply.

It showcases the latest ideas and state-of-the-art technologies that hold the potential to transform our food system and help achieve the targets set by the Sustainable Development Goals. In 2017, Seeds&Chips’ keynote speaker President Barack Obama delivered inspiring remarks on the importance of food innovation and the impact of climate change and sustainable practices on our global food system. T

he 2018 edition saw more than 300 international speakers, among them former US Secretary of State John Kerry, President of IFAD Gilbert Houngbo, Minister of Agriculture of the Kingdom of The Netherlands Carola Schouten, former European Commission President and Italian Prime Minister Romano Prodi, Starbucks’ former CEO and Chairman Howard Schultz and Intellectual Ventures Founder Nathan Myhrvold.

Fondazione Francesca Rava Fondazione Francesca Rava – N.P.H. Italia Onlus is an independent, non political, charitable non profit foundation whose mission is to help children in serious need, in Italy and worldwide, through children sponsorship, fundraising projects, volunteers and educational programs. In Italy the Foundation represents N.P.H. (Nuestros Pequenos Hermanos – Our little brothers and sisters) a charitable organization for orphaned and abandoned children in Latin America, founded in 1954 by Father William Wasson, from Phoenix, Arizona. NPH philosophy was even studied by Doctor Erich Fromm, a renowned German social psychologist. In more than 60 years, more than 25,000 orphaned and abandoned children have been saved, nourished, raised with love and educated in the N.P.H. orphanages in Mexico, Haiti, Guatemala, Honduras, Nicaragua, El Salvador, Dominican Republic, Peru and Bolivia. The Francesca Rava Foundation was born in 2000 in the name of Francesca, a bright and generous young woman who suddenly died in a car crash, after her sister Mariavittoria, a lawyer, met N.P.H. and decided to dedicate her life to help children. Since then, an outstanding amount of projects were supported from Italy, accomplished in Haiti, where the Foundation is particularly committed, and in other countries in Latin America to support N.P.H. children.

The NYC Agriculture Collective: Third Annual Fresh In February Event

The NYC Agriculture Collective would like to invite you as a fellow farmer to our third annual Fresh in February event, hosted by us and taking place on Thursday, February 28th, 2019 from 6:00-9:30 pm at Project Farmhouse

Where else can you find fresh, local produce in 12-degree weather? Luckily, New York is chock full of urban farms, like yours, that grow all year round. We'd like to showcase your farm in addition to the NYC Agriculture Collective to celebrate winter harvests for the third year in a row at Fresh in February and observe why New York strives to become another large agriculture economy, second to California!

Together, our diverse collection of urban farms, urban agriculture service companies and NYC-based agtech businesses invite investors, academia, chefs, and the general public to taste fresh local food as part of a unique food experience at Project Farmhouse in Union Square.

The evening will consist of an exclusive venue where local, year-round farmers will display how they are making agriculture possible in the wintertime in NYC. See the technology in action, meet the farmer and indulge on local produce.

Enjoy hyper-local and delicious snacks, as well as one of a kind specialty cocktails - delicately curated with our Collective's produce, and products from other fine local purveyors.

TICKETS ARE AVAILABLE HERE

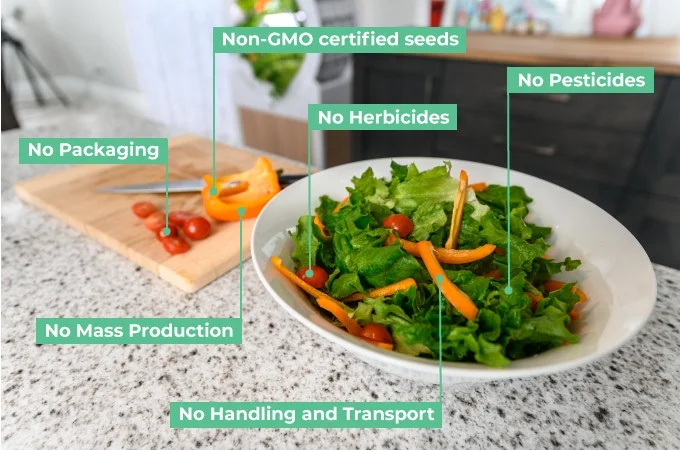

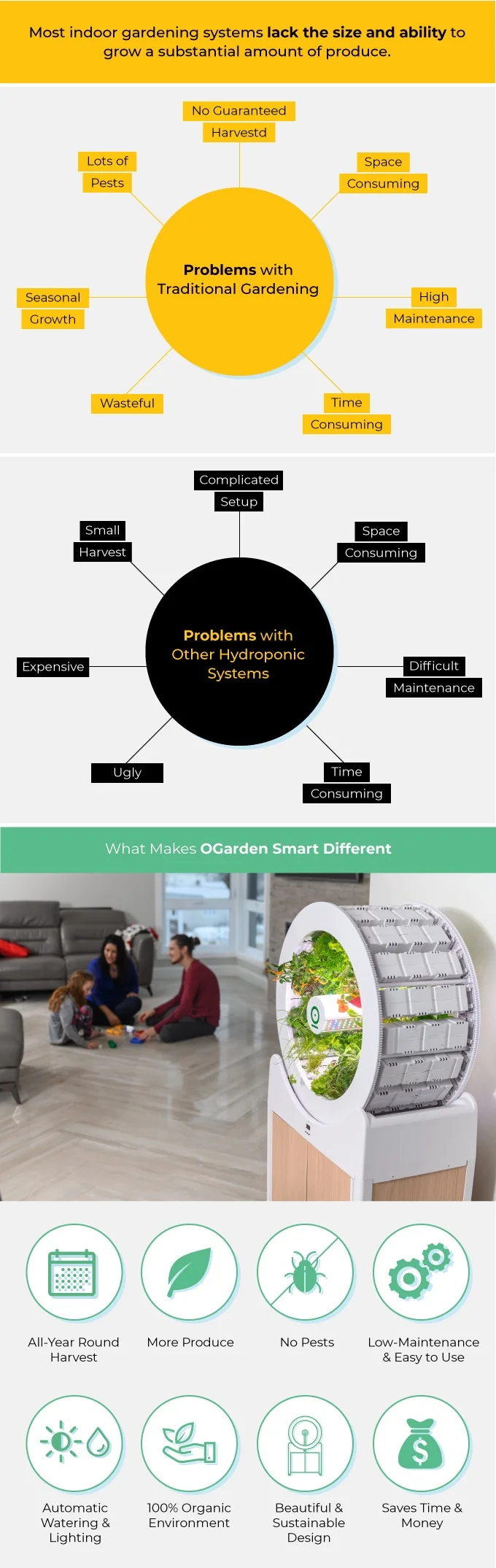

OGarden Smart: Grow An Indoor Garden of 90 Fruits & Veggies

The OGarden Smart can grow up to 90 fruits, veggies and delicious aromatic herbs at once, so you can enjoy an abundance of super fresh food.

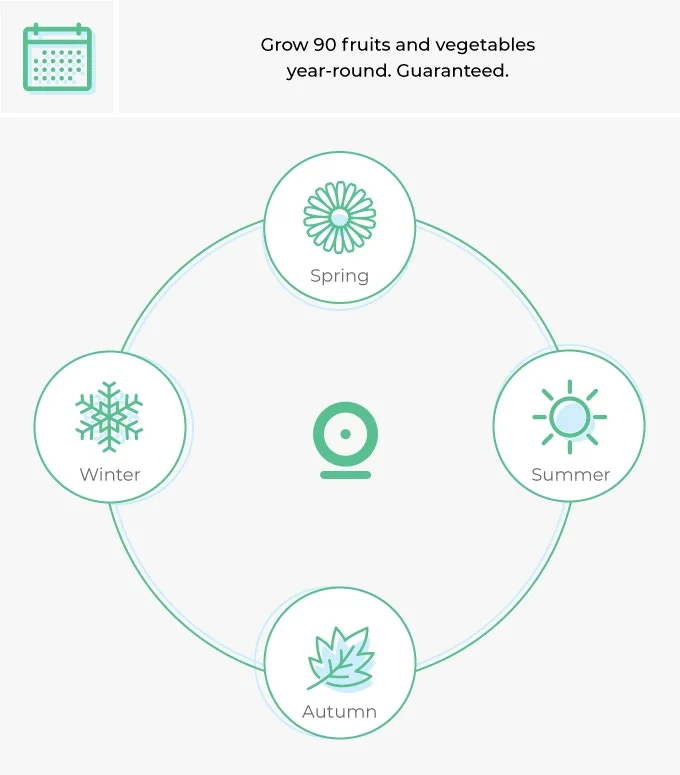

Automatic watering makes using OGarden Smart virtually effortless, and the automatic low energy consumption LEDs simulate the perfect amount of sunlight, offering optimal year round growth (and will automatically turn on and off for convenience and energy conservation)

All you need to do is plant a seed, make sure there is enough water in the tank (only once a week), and you can harvest your produce 30 to 40 days later, that’s it! And don’t forget to send the roots to the compost bin and start the life cycle again.

There are 90 available spots, so with a good rotation, you can have 2-4 large vegetables a day, every day.

Why is OGarden’s growth so efficient? And why is it so easy?

The key is in the cup of seeds. Made with organic soil and fed with all the organic fertilizer it needs, our seed cups create the perfect environment for the plant to grow. they’re also super clean! No spilled dirt or fuss. With a 100% biodegradable membrane, the seed cups stay in place without any mess.

OGarden Smart’s LEDs simulate the perfect amount of sunlight that your produce needs to thrive. No more worrying about which seasons to grow your produce in. No matter the conditions outside, OGarden Smart will grow up to 90 fruits and veggies at once, with 20 different varieties to choose from.

Is your favorite vegetable or fruit not on the list? No problem! With the Empty seed cup, you can sprout your own seeds. Have fun and grow your own original plants. We'd love to see what you grow! Take photos of your harvest and share them with the Ogarden Smart community.

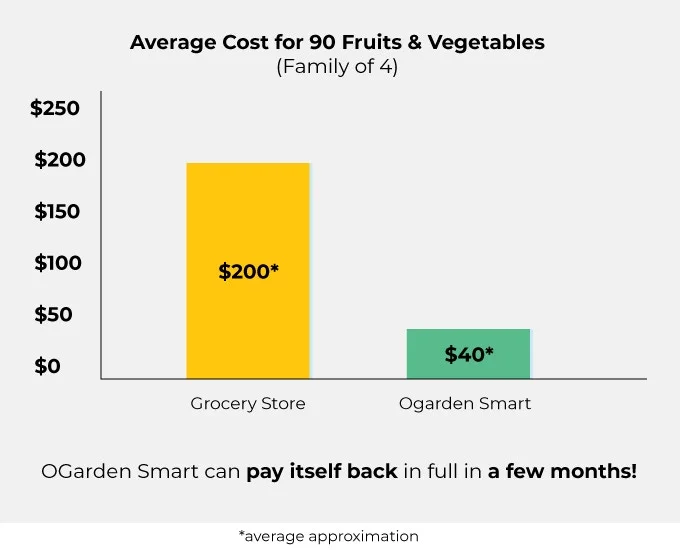

According to the U.S. Department of Agriculture, it costs a family of four an average of $850 per month for groceries*. OGarden Smart can save you up to 80% on your veggie expenses - allowing you to cut down your grocery bill.

*Official USDA Food Plans: U.S. Average, November 2017

With OGarden, you can get fully grown, pesticide-free veggies for as low as $0.45 cents!

By producing your vegetables, fruits, and herbs directly at home, you know the quality of the air, the water and environment they grow in. Have peace of mind knowing that all of your fresh produce is grown in a 100% organic environment.

WHAT COMES IN THE BOX:

● The Ogarden Smart (disassembled) ;

● 30 Empty seed cups;

● 3 packs of seeds (Basil, Chinese cabbage Tat-soi, Lettuce Green Oak Leaf)

Additional Empty cups and multiple varieties of seeds are available on the online shop.

NOW ON KICKSTARTER (Feb.12th)

We Need To Prioritize Urban Farming In City Planning

The new faces of farming — millennials, career changers, refugees — are all looking for opportunities, and many of them want to farm in urban places, next to their customers

January 31, 2019 By Mary Kimball

Last November, I stood on the stage of the Meeting of the Minds Summit in Sacramento, sandwiched between a panel led by energetic Stockton Mayor Michael Tubbs and his vision for economic prosperity, and a talk on the future of autonomous delivery vehicles. My talk? To encourage city planners, developers and urban architects to bring agriculture back to cities and urban spaces, and what this addition can do for the future of their communities’ resiliency, job creation, healthy citizens and carbon footprint.

Stay with me here. I know, agriculture is not “the new wave.” It’s not even close. I mean, we’re talking something that started about 10,000 years ago when eight of the Neolithic founder crops, like emmer wheat, hulled barley, lentils and chickpeas, were first cultivated. Fast forward to the late 1800s in the Sacramento Valley, when Yolo County was the largest producer of wheat in the entire United States.

The new faces of farming — millennials, career changers, refugees — are all looking for opportunities, and many of them want to farm in urban places, next to their customers.

Things have changed quite a bit since then. In 1900, 60 percent of the U.S. population consisted of farmers — so around 45 million — and most, if not all, lived and farmed in rural areas. Today, only 1.8 percent of our population is a farmer, or about 6 million. Today, we don’t just have fewer farmers than we did then (for a much larger population), we also have an age issue. The average age of the American farmer is just under 60. The only occupation with an older average age is truck drivers. A more critical statistic is the age distribution. For every farmer under the age of 25, there are five over the age of 75.

While you might not feel this threat every day, it’s very real — it’s a threat to our food supply and health, and to the resilience of our communities and nation. As former Agriculture Secretary Tom Vilsack said, if left unchecked, this shortage of farmers and farmer succession could threaten our ability to produce the food we need.

What can you do about it? For one thing, recognize that your cities, towns and new developments not only have room for farming, but should welcome it with open arms. The new faces of farming — millennials, career changers, refugees — are all looking for opportunities, and many of them want to farm in urban places, next to their customers.

The City of West Sacramento did something about this need for new farmers. As city officials learned that the two largest obstacles to starting a farm are access to land and access to capital, they also realized they had one of these critical resources at their disposal — land. In 2014, my organization, the Center for Land-Based Learning, partnered with West Sacramento to begin the first urban farm on a site that was formerly a gas station and had sat an idle dumping ground for almost 20 years. Today that farm is flourishing — literally. A graduate of our California Farm Academy training program, Laurie Gates of Flourish Farm, is growing a half-acre of fresh flowers for u-picks, farmers markets and local farm stands.

Lake Washington Farm, a privately-owned site next to a fire station and across from Nugget Market, is another innovative West Sacramento example. Not only do the three farmers at this 3.5-acre site have an onsite farm stand, but they sell to Nugget and to local restaurants.

Just down the road from Lake Washington Farm sits the West Sacramento Housing Development Corporation farm site, formerly an under-utilized half-acre lawn in the middle of a low-income senior housing complex. Now it’s a thriving farm that provides acreage for three farmers who grow everything from fresh veggies sold to residents and neighbors, to the Sacramento area’s first Saffron crop. The farmers even take time to educate the students at the elementary school across the street.

These revitalized, formerly unused urban spaces are growing much-needed healthy food. All of these farms are in food deserts. Several of our farms grow food for school lunch programs in local districts. They completely change the look and feel of a neighborhood, inviting new development and businesses to connect and grow with them. These urban farms can be a critical carbon sink and have been prioritized in the newly released California 2020 Natural and Working Lands Climate Implementation Plan. They provide local markets and food access to people who haven’t had it in generations. Local businesses support these projects by bringing employees out for volunteer days and buying produce they then donate to food banks. These farms provide opportunities for people of all ages to learn about where their food comes from and how it’s grown.

So, what is holding you back from unleashing this economic and community building engine? Whether you’re a landowner, developer, city or regional planner, or elected official, I challenge you to do what you can to promote urban farming. You can tear down the fences surrounding vacant lots. Create citywide policies that encourage and even incentivize urban agriculture, and perhaps even more importantly, incentivize institutions like hospitals and schools to purchase locally grown food. Prioritize updating zoning policies that restrict or constrict urban farming. Seek out your local and regional beginning farmer training programs and ask them to join you. Stop saying, we can’t do that here, and instead take action to include urban agriculture in your city planning.

Use of Coco Coir To Grow Substantially Over The Next Decades

Since its introduction, over 20 years ago, coir has gained ground rapidly in North, Central and South America, as well as Asia.

With a history of only 25 years, coco is a relatively new product in the horticultural industry. Its popularity has been on a continuous rise and is expected to keep on growing over the next couple of years. “The European growing industry was very peat minded, but this has changed. Nowadays peat and coco are fully compliant raw materials being used in the production of potting soil”, Geerten van Eldik with Fibredust tells us. That’s why the company recently joined Growing Media Europe – the first coco producer to do so.

The global substrate market is always on the move. Since its introduction, over 20 years ago, coir has gained ground rapidly in North, Central and South America, as well as Asia. Making it possible for growers to start hydroponic cultivation in an affordable way, and therefore offering higher yield levels and the possibility to avoid diseases while still mono cropping, the use of coco grew alongside the use of hydroponics. In Europe, the rise of coir hasn’t been as mad, as many growers were already familiar with substrate growing when coco entered the industry.

“Currently about 12.5% of global growing media being used is coir, as researched by Wageningen UR and RHP”, Geerten continues. This percentage is expected to grow further. Wageningen UR researcher Chris Blok estimates the amount of coco being used, currently 5 million m3, might even multiply by seven over the next couple of years. With both the production and the use of peat being limited more and more, an alternative is needed. And coco could be it.” Nowadays soft fruit is changing the industry. “In America, the market for coco slabs is growing thanks to the popularity of the product in crops such as soft fruit and cannabis. In Europe, bulk is key and since peat is a complete raw material, it's of good use in this industry. The use of slabs could grow in the next couple of years, but nowadays we see coir is being used as an alternative to peat in the mix of potting soils”, Geerten explains."

FibreDust India production location Anar Coir. About 40 hectare drying and processing facilities.

Team Fibre Dust India - Anar Coir - visited by Geerten

The USA sales team

Challenges

Being a reusable product, a product of nature and an easy to use substrate, coco is favored by more and more growers. However, coco is facing challenges as well. As a product of nature, the residual product from the coconut growing industry, coir had to deal with supplying issues due to climate circumstances in production regions in India and Sri Lanka.

By spreading their production over various Indian and Sri Lankan facilities and investing in the production chain, Fibredust has been able to solve the issues and secure their supply for the future. “Drying the raw material is an important topic. We’re testing this thoroughly and are nearly there, but it’s a complicated matter: you do not want to adjust the internal quality of the material. We’re looking for the perfect way to ensure our buffering quality whilst maximizing the output and keeping an eye out on the energy costs.” In the production chain, water and transport are also of concern. “With a special system we collect a lot of rainwater, which can be used in the process. By using a reverse osmosis system, we are able to re-use the water and since the buffering process is optimised, we can buffer large amounts of peat in a short time. With investments like these we want to keep investing in the sustainability of the industry. We expect this will result in an RHP certificate in 2019 as well.”

The USA sales team

Geerten with Satheesh Rao

Coco is bought based on trust

“Coco is bought based on trust”, Geerten continues. “On the outside, you cannot see if a product is good or bad, and since the delivery time is four weeks, the problems are big when there’s something wrong with the product. That’s why to us, trust in the company is valued highly.” Certificates like SA8000 and ISO14000, ISO9001 and OMRO are examples of this – but there’s more. This year Fibredust joined Growing Media Europe, the body representing the growing media industry and known for being a rockwool-peat organization.

“The European growing industry was very peat-minded, and peat and coco were even competing, but this has changed. Peat and coco are fully compliant as raw materials being used in the production of potting soil, and the choice is for the grower to make.” With the importance of coco growing, the interests of the coco industry have grown as well. “The industry needs to be represented”, says Geerten.

For example, the import of coco material into Europe has attracted interest from the European Commission. “With coco being officially a plant waste, it was said every consignment had to be tested separately before it could be imported. With thousands of containers being imported, that would be an immense setback. Thanks to the effort made by the coco industry and the network and support of Growing Media Europe, this plan was torpedoed. We’re proud to be a part of this. Of course we’re Fibredust and are a commercial company, but the major issues of the industry concern us as well. If the industry flourishes, we flourish as well.”

For more information

FibreDust LLC

T: 860-613-0077

Heritage Crops That Feed on Sea Water Could Feed the UAE's Growing Population

Scientists are looking to genetically modify crops that were grown here in ancient times to help solve the region's food security issues.

Scientists are hoping to tackle the region’s food insecurity by reintroducing heritage crops that have been genetically modified to grow using saltwater straight from the sea.

Poor soil coupled with a scarcity of fresh water has led the UAE, and much of the region, to rely on importing food to feed its populations.

Euro-centric methods of agriculture are ill-suited for the hot and dry land, and some vegetables require 30 or more times the water in the UAE than is needed to grow the same plant in cooler environments.

Importing sufficed for decades as little consideration was given to environmental impact. But today, with the threat of global warming and the food industry being one of the biggest culprits, the way we eat has become one the most important frontiers for sustainability.

Dr Ismahane Elouafi, director-general of the International Centre of Biosaline Agriculture, does not agree with the idea that deserts are barren environments. Instead, she believes that although regional appetites have veered away from what the land naturally provides, they must be brought back.

“Sixty per cent of our food comes from only four crops. There are only 150 crops available on the market out of the 7,000 our ancestors used to grow,” Dr Elouafi said.

Wheat, maize, rice and potatoes feed the majority of the world’s population. But all four of those crops, which were genetically engineered to sustain people during the European industrial revolution, are unsuitable for growth outside the Northern Hemisphere.

Instead, she says that crops such as millet, which some historians believe was among the first seeds grown in the Fertile Crescent – an area of the Middle East where agriculture and some of the earliestcivilisations began – can fulfil food demand.

Pearl millet is among the crops the ICBA are hoping to reintroduce to the UAE. Photo by Showkat Nabi

Dr Elouafi is now seeking other plants that can grow in the UAE, adding thousands of species of ancient crop seeds to ICBA’s gene bank. Her scientists are digging through time to find some of the 7,000 crops our ancestors used and, from those, identifying species that are saline-resistant, nutrient-rich and, of course, tasty.

“We’re only focusing on a few for now because breeding is extremely expensive. That’s why most of the countries to the south [of the Northern Hemisphere] still use crops from the north – they are put on the market by multinationals,” she said.

But now, breakthroughs in genetic coding technology can tremendously reduce the cost of breeding, meaning that it may be possible to engineer endemic crops to become easier to grow and better suited to mass cultivation in the region.

The shortage of water, she said, is one of the main constraints to UAE food production. Water scarcity has been offset in the country by some of the world’s most substantial desalination plants – an energy-intensive practice.

But instead of desalinating seawater for crops, Dr Elouafi wants to engineer crops so they can be irrigated with water straight from the sea.

“It is possible – there are crops that have salinity tolerance already. We’re looking at these crops and into using either gene editing or hybrids to get crops on to the market that take more saline water and are more nutritious,” she said.

Omar Al Jundi is the founder and chief executive of Badia Farms, the region’s first vertical farm, in Al Quoz, Dubai. Reem Mohammed/The National

These innovations could be used in conjunction with developments such as Omar Al Jundi’s vertical farm, the first commercial one to launch in Dubai. It could be used to grow ICBA’s regionally-suitable crops to disrupt current energy-intensive agriculture in the Arab world.

“Our water bill for August was Dh1,500. That is lower than my home water bill. We’re able to harvest the majority of the water we use, recycle it and use the humidity to nourish plants,” said Mr Al Jundi, the founder and chief executive of Badia vertical farm, which produces 1,000 heads of lettuce at a time.

Vertical farming uses hydroponic systems to yield crops. Being indoors, vertical farms seldom need pesticides and the technology is progressing at a rate that could allow it to grow anything, including ancient or heritage crops.

He said using his technology to grow sustainable plants, such as the ones ICBA is rediscovering, is completely achievable and part of his vision for the future of urban agriculture.

“You can grow as high as you want, but going up 10 to 20 storeys produces a lot – it could feed thousands, if not more. This is the future.”

Updated: January 16, 2019 08:35 AM

What Type of Solar Kit Do I Need To Run My Grow Lights?

For most people, the main purpose of going solar is to offset the cost of electricity. However, solar power systems come in two general types, grid-tied and off-grid

Q: What Type of Solar Kit Do I Need To Run My Grow Lights?

Quick question on solar. I want to run eight, 1,000W adjustable double-ended bulbs along with a five-ton AC unit and a Quest 205 dehumidifier. Along with fans, lights, and AC on 240V and the rest 120V. On an average of 18 hours a day. Around 150 amps to be safe. Is that a sufficient amount of info to receive an idea of what type of solar kit I can buy?

A: For most people, the main purpose of going solar is to offset the cost of electricity. However, solar power systems come in two general types, grid-tied and off-grid. This is generally one of the first decisions to make when it comes to solar panel installation.

Grid-tied means that the solar panels are directly tied to the conventional power grid and may provide some or all of your power needs. When unused power is created by your solar panels it is automatically delivered to the grid, earning you credits on your power bill.

Off-grid systems are not connected to the conventional power grid and operate independent of your local power company, and requires that 100 percent of your power comes from your system. Also, unused power must be stored in a battery bank until it can be used at a later time. A truly off-grid system will greatly increase the cost per watt of your solar system and also cost more to maintain over time.

I will assume you are most interested in a grid-tied system. Because of the sensitive nature of the equipment, I would recommend having a licensed electrician pull four circuits from your supply of power. Subpanel No.1 will be for the eight lighting fixtures. Each double-ended fixture is capable of 1,150 watts, so we will estimate maximum power consumption at 9,200 watts. At 240V the total draw is approximately 38.3 amps (38.3A). For safety and load ratings I always add 20 percent which makes the correct choice for Subpanel No. 1 a 50A double pole 240V breaker.

Subpanel No. 2 will be for the five-ton commercial grade A/C which will use about 32A or less at 240V, so that makes the correct choice for Subpanel 2 a 40A double pole 240V breaker.

Subpanel No. 3 is for the commercial-grade 205-pint dehumidifier that will require a dedicated 120V 20-amp circuit with a NEMA 5-20 plug. Lastly, I would have your electrician pull a final 120V 15-amp circuit for all of your additional fans and accessories.

The total wattage of the major appliances is around 18,325 watts. Assuming all the major appliances are running at maximum for 18 hours a day, that is approximately 330-kilowatt hours (kWh) per day or 10,030 kWh per month. However, although the lights will operate for 18 hours a day continually, the A/C and the dehumidifier will not, so your actual consumption will be less.

Because of the complexity when it comes to selecting the right size solar system, I would recommend you to consult a local company to determine the number of solar panels you will need. Local factors such as geographic location, weather, positioning, and line of sight blockages in your horizon all play a factor into how many kilowatt hours you can produce per day. Also, local laws, permits, and regulations will apply, which makes consulting a local solar expert worth the time and money to ensure a smooth purchase and installation.

Ozone Technology For Greenhouse Water Treatment

"Proper Greenhouse Water Recycling Is The Key To Increasing Your Profitability"

“Proper greenhouse water recycling is the key to increasing your profitability, year after year. Without adequate control of your nutrient feed solution, the entire process of fertigation can prove harmful for your crop’s steady growth.” Speaking is Christopher Labbate with Climate Control. The company offers ozone water treatment to eliminate pathogens spreading through water. “Water recycling has become a popular trend in the agricultural industry. As more greenhouse operations are in need of treating their nutrient wastewater on site. Growers are recognizing that using quality water has substantial benefits in many areas of production, including plant health and quality control.”

Although using a hydroponics system may eliminate soil borne pests, there are other pathogens that spread through water. Pathogens and other water bacteria are a cause for concern in water quality. Most greenhouses today use some type of recycled water treatment in their irrigation systems or use chlorination. Sometimes multiple solutions are combined to answer the problem of crop management.

Climate Control offers Ozone solutions. “Ozone is a powerful oxidant gas that is injected in the water to kill microorganisms, bacteria, and break down other plant pathogens by oxidation. This occurs immediately at point of contact and continues to disinfect your nutrient solution. Some of the ozone reverts back into oxygen in the treated storage tank and this can be a large advantage to growers as it is beneficial to growth”, Christopher explains.

Ozone generators create ozone through an electric discharge of sparking Oxygen (O2) to create Ozone (O3). This can be controlled by software to increase or decrease the concentration of ozone, to output the desired amount for optimal plant health.

“Monitoring and control of pH and Electrical Conductivity (EC) have become standard practice, for improving plant health and quality throughout growers. By measuring these two simple factors, most nutritional problems can be avoided.”

According to Christopher, the measurement of Dissolved Oxygen (DO) is also proving to be just as critical to plant growth. “Minimum levels of dissolved oxygen are also required for a healthy plant. Most growers do not have the sensors to read this important quality of the water. Ozone water treatment not only kills 99.9% of bacteria in your irrigation water, but also gives added benefit. By providing dissolved oxygen for the root zone of the plants, you will see a 10% increase in crop yields.”

Ozone is effective in getting rid of odors in the water as well, like from iron and manganese. “It's the gold standard for drinking water, and used in many municipal water treatment plants around the world.”

Currently many growers might doubt between UV Sterilization. This technique inactivates microorganisms and stunts pathogen growth with UV light. Christopher believes this is not sufficient. “This happens while the water is in the UV chamber only, and as long as the water has sufficient contact time. And it’s also interesting to note that UV disinfects the water by sterilizing the contaminants so they can no longer replicate. Whereas ozone will destroy the contaminants completely by breaking them down. Then Ozone dissolves back into oxygen, which is very beneficial to the rootzone of the plant.”

Christian concludes: “Our mission at Climate Control Systems has always been, to help growers stay profitable by offering cutting edge automation and control technology. You can also expect to save 35% on water costs and 40% on fertilizer expenses with this industrial grade ozone water sterilization equipment.”

For more information:

Climate Control Systems

Christopher M. Labbate

1-519-322-2515

Chris@climatecontrol.com

www.climatecontrol.com

Publication date : 2/5/2019

Italy: Phosphonic Acid In Organic Crops

Sicural, a laboratory authorized by the Ministry for Agricultural Policy for the analysis of samples taken during checks on organic crops, is currently performing analyses on phosphonic acid, produced by Fosetyl aluminium degradation. This is because of technical regulation RT 16Accredia, which entered into force a few weeks ago.

At work with LC MS/MS

"Fosetyl aluminium is the active principle of many fungicides and it is widely used, although it cannot be employed in case of organic cultivation. Often, however, analyses detect phosphonic acid, which is the degradation product of said active principle," explain Maverik Bezzi, Silvia Zuccherelli and Giusy Riciputi from Sicural.

State-of-the-art equipment

When it comes to organic produce, RT16 establishes that a level of phosphonic acid above or equal to 0.010 mg/kg is not enough to rule out the use of inadmissible or admissible but irregular technical means. This leads to further analyses by the Certifying Body to identify the potential cause of the positive result.

Makerik Bezzi

"A specific warning level must be defined and the fact that the phosphonic acid may derive from natural plant components or foliar fertilization."

"The new detection limit is rather critical and needs sensitive tools such as LC MS/MS, which we are not equipped with. The analysis method and experience in using the tools is also just as important."

"Analyses and checks of organic crops are very strict. We are at full disposal for any clarification."

Contacts:

Sicural

Via Dismano 2855,

47522 Cesena (FC)

Tel.: +39 0547/377303

Email: laboratorio@sicural.it

Sito: www.sicural.it

US, Illinois - Hydroponics Bill Introduced In House

High-impact businesses will receive tax credits, according to the bill. Hydroponics is the method of growing plants and produce using only water with mineral nutrients and without soil.

by Kyla Asbury | Feb 12, 2019

Rep. Stephanie A. Kifoweit (D-Aurora) introduced a bill created to drive business for hydroponics on Feb. 1 to the House of Representatives.

The bill's first reading was Feb. 1 and it was then referred to the Rules Committee.

House Bill 1636 amends the Illinois Enterprise Zone Act and provides that businesses that intend to establish a newly qualified hydroponics facility or expand their current qualified facilities to include hydroponics will be considered "high-impact businesses."

High-impact businesses can lose their designation if they fail to comply with a set of terms and conditions in the bill. High-impact businesses are those intending to make a minimum investment of $12 million and plan to create 500 full-time jobs involving hydroponics, according to the bill.

The bill doesn't state what "high-impact" businesses actually mean, other than the amount of money they make or employees they will have. The bill doesn't state why it is needed.

High-impact businesses will receive tax credits, according to the bill. Hydroponics is the method of growing plants and produce using only water with mineral nutrients and without soil.

The bill, if passed, is effective immediately.

Heatwave Conditions Takes A Toll On Australian Fruit And Vegetable Growers

The hot weather has taken a toll on Australia's farmers, with many regions still in drought, and for Australia's fruit and vegetable growers, many are battling through these conditions still getting the fruit to market, although it is still having an effect.

Most parts of Australia have sweltered through a heatwave over the past fortnight, with daily temperatures regularly in the high-thirties to mid-forties.

On Thursday, South Australia's Port Augusta reached 49.5 degrees, just 10 days after it created international headlines for reaching around 49 degrees at the same time as temperatures were below minus 56 degrees in parts of Russia. It is a similar picture across all states, with conditions topping 45 degrees plus in nearly all areas.

The hot weather has taken a toll on Australia's farmers, with many regions still in drought, and for Australia's fruit and vegetable growers, many are battling through these conditions still getting the fruit to market, although it is still having an effect.

Picture: Temperatures taken on Jan 15 (source:Weather Obsessed/Jamie Lyons)

The Australian Mango Industry Association reported: "We have had the extreme heat in North Queensland and some rain that brought forward some of the harvesting in North Queensland and resulted in some fruit becoming ripe on the trees and unable to be marketed. But overall, growers have managed those ups and downs."

Further south, in Central Queensland's Rockhampton region, Lush Lychees were expecting production to be nearly double on last year, although there were some issues with the weather this summer.

"We had periods of drought, which made watering difficult with our river system, and we had high temperature days which lasted for a week," co-owner Krystal Caton said. "So that was a bit difficult on the fruit causing heat stress and fruit drop. But other than that, we got through and got them all picked this week. The high temperature and heat it caused a lot of fruit drop - so we lost a lot of fruit and it caused some heat stress on some of our varieties. But that's farming - working with the weather."

Brisbane Produce Market report also noted: "This week, the heatwave continues to impact supplies on vegetables. We’re seeing a limited supply of broccoli, cauliflower and celery but tomatoes are bouncing back, particularly the grape and cherry varieties."

Photo: Vegetable crops in East Gipplsand

While it is the same story for vegetables in Victoria. The East Gippsland Food Cluster says that this year production has been variable due to the weather conditions.

"It depends on the crop and we have had a few hot, above 40-degree days, and naturally that takes a toll," Industry Development Officer Shayne Hyman said. "With baby leaf (lettuce) there has been some tip-burn. There has been early beans and they are pretty good. But it is all weather dependent, meaning this week's crop is good, while next weeks could be tipped-in. People are wanting broccoli, and brassicas are a winter crop. But because people don't follow seasonality of vegetables, they want it now, so broccoli production has been down, and that has been because of the weather - not very much rain and long hot periods. I was talking to the biggest cauliflower producer, and they are going to turn it all in (for the season), because it was coming along beautifully, and on that particular crop the heads burst, which meant it was un-sellable."

Production wise, Budou Farms, in Merbein in the Victoria’s south, is behind harvest time slightly between a week to 10 days. But the table grape grower is looking at a slightly above average year in terms of volumes, despite some issues with the weather.

"With the weather we have had a few heatwaves and the next few days are meant to be very intense," co-owner Enrique Rossi said. "From tomorrow we have two days of 45 degrees, which is not good. We are a little down on rainfall throughout the year. In winter, during one month we only got 4 millimetres of rain, which is very worrying. But we have to take the good out of the heatwaves - and this extreme weather we have got in Australia, makes the fruit have exceptional flavour."

Publication date : 1/25/2019

Author: matthew@freshplaza.com

How GLASE is Blazing A New Frontier in Lighting

By Erico Mattos | January 25, 2019

Primary organizers of the GLASE consortium are Tessa Pocock of the Rensselaer Polytechnic Institute (left) and Neil Mattson (center) and Erico Mattos of Cornell University.

Lighting control is the last frontier in controlled environment agriculture (CEA). Well-designed horticulture lighting systems can reduce energy use in greenhouses and indoor farms, thereby increasing production and profitability. Light-emitting diode (LED) technologies have the potential to improve energy efficiency and therefore energy costs of greenhouses, but in many ways the hardware capabilities are further ahead than our understanding of how to best operate these systems.

Working in the rapidly growing CEA industry, the Greenhouse Lighting and Systems Engineering (GLASE) consortium is a public-private partnership to develop, transfer, and implement advanced energy-efficient LED lighting systems with improved environmental controls for more efficient and sustainable greenhouse production. Formed by Cornell University, Rensselaer Polytechnic Institute (RPI), and Rutgers University, GLASE is supported by the New York State Energy Research and Development Authority (NYSERDA). The consortium’s mission is to advance CEA through a holistic approach, bringing together different areas of expertise from academia and the marketplace, and creating a hub for technology and information exchange among industry stakeholders and key players.

First-Year Focus: Research and Participation

The combination of engineering practices with plant science is being recognized as valuable, if not critical, to the field of horticultural lighting. During its first operational year in 2018, GLASE developed a series of multidisciplinary activities aimed to optimize CEA systems. Recent technologies developed by consortium researchers include:

• The use of a remote chlorophyll fluorometer to monitor plants relative growth rates

• A proposed standardized horticultural lighting label to facilitate the comparison of lamps across manufacturers

• Improvements to the Lighting and Shade System Implementation (LASSI)

• A control system to optimize lighting control and reduce greenhouse energy consumption

• Light-spectrum optimization for plant growth

The participation of industry stakeholders is paramount in guiding GLASE research and bringing the innovations to market. GLASE is working with industrial partners to commercialize and accelerate the adoption of new energy-efficient technologies nationwide. Since April 2018, 21 industrial members have joined the consortium. The participants are a combination of commercial greenhouses, indoor farms, lighting manufacturers, and service providers. With $5 million secured for research and outreach for the next five years, GLASE will continue to work with industry partners to further develop and implement new energy-efficient technologies to achieve energy-related improvements in greenhouse system operations by optimizing energy efficiency, crop yield, and quality.

What’s Next for GLASE

Future GLASE activities include:

• The development of automated lighting and shade control systems integrated with control of wavelengths for optimal crop growth

• The use of CO2 enhancement in greenhouses

• Investigation of LED use to alter plant physiology and morphology to increase yield or the production of chemical compounds that increase crop value

• The design of novel prototype luminaires for greenhouses

• The development of software that includes whole greenhouse systems management to synergistically control lighting, ventilation , and humidity.

GLASE also works with commercial pilot facilities to test technology adoption in real-world production settings. To ensure the development and implementation of effective technologies, GLASE is supported by a scientific advisory board (SAB) and an industrial advisory board (IAB). The SAB identifies new areas of research and vets GLASE-developed technologies, whereas the IAB offers the consortium guidance on the optimal path to market and provides a source of technical and market intelligence.

Working toward industry standardization, GLASE has established a partnership with Intertek to offer its industrial partners a complementary lighting test to characterize horticultural lighting fixtures following the proposed lighting label published by A.J. Both, et al. This is an effort to provide growers with a reliable comparative platform to select among the available lighting technologies that best fit their unique needs.

Through the development of strategic partnerships and increased industry participation, GLASE is expanding its activities in 2019. In addition to having the opportunity to work with other GLASE partners, members of the consortium receive the benefits of a seat on the GLASE Industrial Advisory Board, early notice of invention disclosures (IP), quarterly technical reports and industry meetings, access to Cornell University and RPI research facilities, networking, marketing, and educational and training programs.

How You Can Participate

As part of the consortium outreach activities, GLASE is developing a national greenhouse energy benchmark database. The aggregated data will be used to support the development of new energy incentive programs, guide national funding opportunities, and allow GLASE researchers and other academic institutions to identify new areas of improvement in Controlled Environment Agriculture systems. Participating greenhouse and indoor growers will have the opportunity to benchmark their production systems against a national database to identify areas of improvement to increase operations’ profitability.

To learn more about GLASE and how to join the consortium, go to Glase.org.

Erico Mattos (em796@cornell.edu) is the Executive Director of GLASE. See all author stories here.

"Fresh Lettuce Even With Snow On The Ground"

CubicFarms is growing again

CubicFarms has completed its latest CubicFarm System near Edmonton, Alberta. Located in Weslock, AB, Swiss Leaf Farms founder and CEO David Pfaeffli is now selling his CubicFarms produce under the Thriiv Local Garden brand to a variety of stores and restaurants. Swiss Leaf Farm’s 14 machine CubicFarm System is capable of growing over a million and a half heads of lettuce a year, along with microgreens, basil and more.

Even though snow is on the ground, and temperatures are dipping below -20 oC, fresh, crisp, local lettuce and microgreens are now available.

David and Alyssa Paeffli and family in front of one of their CubicFarm Machines

DelFresco Pure installation has begun

Ontario CubicFarm customer Del Fresco Pure has completed their building, and 14 CubicFarm growing machines have been delivered to one of Ontario’s largest greenhouse operators. Del Fresco and CubicFarms are partnering together on several exciting projects and were recently together at the CPMA in Orlando where they featured a fully functional “Demo CubicFarm” complete with live produce. Passers by were memorized by the lettuce, basil, and microgreens growing before their eyes. The booth featured Del Fresco’s wide range of greenhouse crops, including strawberries. The ice cream machine was a hit and we featured Del Fresco strawberries and Cubic’s “Microbasil” as toppings.

Del Fresco expects to bring their CubicFarms grown produce to the Ontario market in the next 2 months, including lettuces and microgreens.

The Del Fresco Pure and CubicFarm Systems teams at the Orlando PMA

CubicFarms is working on its public listing on the TSX V

CubicFarms was approximately 40% owned by Bevo Farms, but in late 2018 that ownership was spun out as a one-time special dividend to shareholders. CubicFarms expects to be listed as a publicly traded company in the next month or so, making it one of the first publicly traded vertical farming companies.

For more information:

CubicFarms

1-888-280-9076

info@cubicfarms.com

www.cubicfarms.com

Publication date : 2/1/2019

Stop & Shop Sending Produce In Self-Driving Grocery Vehicles

The vehicles will bring a selection of Stop & Shop produce as well as meal kits.

JANUARY 16, 2019

Stop & Shop will launch driverless grocery vehicles in the greater Boston area beginning this spring. The vehicles will bring a selection of Stop & Shop produce as well as meal kits and convenience items directly to customers so they can shop right at their doorsteps.

Part of an engagement with San Francisco-based startup Robomart, the vehicles will address consumers’ growing interest in selecting their own fresh produce when shopping via online or mobile and will deliver an even more convenient grocery shopping experience for Stop & Shop customers in the Boston area. The new service will also offer the potential for the brand to expand beyond its existing brick-and-mortar stores.

“This is one way in which we’re leveraging new technology to make shopping easier for our customers – by essentially bringing the store to them,” said Mark McGowan, Stop & Shop president. “We also recognize that many of our customers want the opportunity to make their own choices when it comes to fresh produce, and we're proud to be the first retailer to engage with Robomart to address our customers’ needs with their cutting-edge solution.”

Stop & Shop customers in the Boston area can summon a Robomart vehicle with a smartphone app. Upon the vehicle’s arrival, they head outside, unlock the vehicle’s doors and then personally select the fruits, vegetables and other products they would like to purchase. When finished shopping, they simply close the doors and send the vehicle on its way. The vehicles’ RFID and computer vision technology automatically records what customers select to provide for a checkout-free experience, with receipts emailed within seconds.

“For decades, consumers had the convenience of their local greengrocer and milkman coming door to door, and we believe that by leveraging driverless technology we can recreate that level of convenience and accessibility,” said Robomart founder and CEO Ali Ahmed. “We’re extremely excited to bring our vision to life with Stop & Shop, one of the most pioneering and forward-thinking grocery chains in the world.”

All Robomart vehicles are autonomous, electric and remotely piloted from a Robomart facility. Throughout their delivery journey, these refrigerated vehicles will be restocked with fresh Stop & Shop goods to ensure customers are provided with the best selection.

The collaboration with Robomart is the latest example of Stop & Shop’s efforts to tap technology to enhance the grocery shopping experience and increase efficiencies. The brand recently opened a mechanized micro-fulfillment center in the Hartford, CT, area in partnership with Takeoff Technologies and, along with Giant/Martin’s, is introducing hundreds of robots in its stores.

Other Ahold Delhaize brands are investing in innovation as well, including Albert Heijn with the upcoming launch of the first fully automated distribution center in the Netherlands. Further, Ahold Delhaize is partnering with universities through its Artificial Intelligence for Retail Lab to accelerate research in AI and robotics.

Hanging Gardens of Steel & Glass

Vertical farming is conceptually simple. Instead of spreading out a farm over the land, you stack it into the air using shelves and multi-storey buildings

By: urbanagnews

February 11, 2019

Article by Lunacy Now

Long spires of steel and glass stretch up towards the sun. Within, teeming billions go about their busy lives, like ants in a kilometer tall nest. But every human in this vast metropolis needs to eat. And the solution is all around: towering vertical farms. Precise algorithms calibrate the exact amount of water and other nutrients required for optimal growth, and deliver it on a pre-determined schedule to ensure optimal growth.

That’s the sci-fi hive city dream, right? So how far are we from being able to produce that density of food production? And can you start producing enough food to feed your family in a regular suburban home?

We spoke with Dr. Joel Cuello, vice chair of the Association of Vertical Farming and Professor of Agricultural and Biosystems Engineering at the University of Arizona to find out.

What is Vertical Farming?

Vertical farming is conceptually simple. Instead of spreading out a farm over the land, you stack it into the air using shelves and multi-storey buildings. That’s how a company like Bowery Farming is able to produce 100 times more food on the same footprint of land as conventional agriculture, according to its statistics.

But it’s not just about horizontal versus vertical. Controlled Environment Agriculture (CEA) technology allows farmers to measure every aspect of their plants physical surroundings. The type and level of light, the temperature, and humidity are tightly controlled. Furthermore, farmers can supply the exact amount of water and nutrients a plant needs at the right time. Complex data analysis programs and AI enable a farmer to track progress and further optimize efficiency.

Types of Vertical Farming

There are two main technologies underpinning indoor farming.

Hydroponic: The plants are grown in a solution of water and nutrients.

Aeroponic: The plants are grown in a nutrient-infused mist.

Subcategories like fogoponic, deep water hydroponics, or aquaponics where fish are added to create an entire ecosystem also exist.

When Cuello spoke with us he had a clear vision that this industry could be the future of agriculture. He identifies three primary types of vertical farms, depending on the buildings.

Skyscrapers: This is probably what most people think of when they imagine a vertical farm. Although the technical capacity to construct them is there, Cuello says the economics don’t necessarily add up. Real estate is at such a premium in urban centers such as New York that it makes no sense to use it for agriculture, even if densely organized. Some architects such as Ken Yeang favor mixed-use skyscrapers which grow plants as part of a broader set of purposes.

Warehouse: Cuello sees this as the most viable for large scale commercial operations. You either build a new warehouse and fill it with vertical farming equipment or buy an existing building and convert it.

Modular: This is the most efficient and practical way to scale out vertical farming, according to Cuello. The beauty of modular farms is you can put them anywhere, in the desert, in Antarctica, it doesn’t matter.