Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Urban Farms Could Be Incredibly Efficient—But Aren’t Yet

In some ways, hyper-local food is a counterculture movement, focused on growing herbs and vegetables in the same dense urban environments where they will be eaten. It trades the huge efficiencies of modern agriculture for large savings in transportation and storage costs. But is urban farming environmentally friendly?

Casual Farmers Overwork, Buy Fertilizer, And Use Municipal Water.

JOHN TIMMER - 12/27/2018

The green revolution that transformed modern agriculture has generally increased its scale. There's tremendous potential for efficiencies in the large-scale application of mechanization, fertilization, and pesticide use. But operating at that level requires large tracts of land, which means sources of food have grown increasingly distant from the people in urban centers who will ultimately eat most of it.

In some ways, hyper-local food is a counterculture movement, focused on growing herbs and vegetables in the same dense urban environments where they will be eaten. It trades the huge efficiencies of modern agriculture for large savings in transportation and storage costs. But is urban farming environmentally friendly?

According to researchers at Australia's University of New England, the answer is pretty complex. Within their somewhat limited group of gardeners, urban agriculture is far more productive for the amount of land used, but isn't especially efficient with labor and materials use. But the materials issue could be solved, and the labor inefficiency may be a product of the fact that most urban farmers are hobbyists, and are doing it for fun.

Urban ag

The researchers—Robert McDougalla, Paul Kristiansena, and Romina Rader—defined urban agriculture as taking place within a kilometer of a densely built environment. Working in the Sydney area, they were able to find 13 urban farmers who were willing to keep detailed logs of their activity for an entire year. Labor and materials costs were tracked, as was the value of the produce it helped create. The energetic costs of the materials and labor were also calculated in order to assess the sustainability of urban farming.

The plots cultivated by these farmers were quite small, with the median only a bit over 10 square meters. Yet they were extremely productive, with a mean of just under six kilograms of produce for each of those square meters. That's about twice as productive as a typical Australian vegetable farm, although the output range of the urban farms was huge—everything from slightly below large farm productivity to five times as productive.

For the vast majority of crops, however, the urban farms weren't especially effective. They required far more labor than traditional farms and as a result the total value of the inputs into the crop exceeded the income from selling it. In other words, the urban farmers were losing money, at least by traditional accounting measures. And the farms weren't especially sustainable, with only about 10 percent of all the inputs coming from renewable resources. Again, labor was a major culprit, as it's not considered very renewable, and urban farming is very labor-intensive.

So that all sounds like a bit of a disaster, really. But as mentioned above, things quickly get complex. The urban farmers, as it turned out, bought compost and fertilizer, and used the municipal water supply. Cities, as the authors note, produce large quantities of organic waste that could be used to make compost. While it would require additional labor and land space, it would be easy to make the care of the crops far more sustainable. Combined with the use of collected rainwater, these could get the percentage of renewable contributions up to roughly 40 percent.

Laborious

Then there's the issue of the time spent on labor. The urban farmers don't seem to be especially efficient compared to regular farm laborers, and by all indications they don't necessarily want to be. For many of them, it's more a hobby than career; they put in more labor because they enjoy it or find it relaxing. If you start reducing the labor costs to reflect this, things start changing dramatically. If only the material costs of urban farming is considered (meaning labor was set to $0), then the apparent efficiency improves dramatically.

Not surprisingly, ignoring labor costs also makes a big difference financially, with the profit-to-cost ratio going from a mean of 0.62 up to 2.8, indicating that these urban farms would generally be quite profitable.

Labor also makes a big difference in terms of energy use. As they're now operating, these urban farms aren't very different from rural farms, which means they're not sustainable. Shifting to local sources of materials, like rainwater and compost, would drop the energy use dramatically, shifting the farms into territory that's typically considered sustainable. Eliminating labor considerations on top of that would make urban agriculture among the most efficient means of growing vegetables presently studied.

There are two obvious caveats to this work: the small number of farms sampled and the fact that they were all in a single urban area. This sort of study will obviously need to be replicated in other locations before we can start generalizing about hyper-local produce. But the role of labor in this sort of analysis makes conclusions difficult to generalize. Is it reasonable to discount some fraction of the labor costs when people are doing the farming for pleasure? Do we start considering a tomato plant on a balcony part of an urban farm?

While many of the details are unclear, the overall conclusion seems solid: while urban farms aren't yet there in terms of sustainability and energy use, the potential for them to outpace their larger urban cousins is definitely there. But it will take an entire sustainable support infrastructure for them to truly arrive.

PNAS, 2018. DOI: 10.1073/pnas.1809707115 (About DOIs).

Singapore Changi, The World’s Best Airport To Open A Valoya Lit Indoor Garden

For 8 consecutive years Singapore’s Changi airport has been dubbed the world’s best. It is a hub for 62 million passengers annualy and is known worldwide for its indoor greenery designed to promote Singapore’s reputation as a city of gardens. The extension which is to be opened in the first half of 2019 is a futuristic looking dome of curved glass and steel with the world’s highest waterfall (40 m) placed at its center.

Photo by Jewel Changi Airport

The dome will be populated with flora that consists of 2.000 trees and over 100.000 other plants. These will receive sunlight through the glass of the dome which will be supplemented by Valoya’s luminaires, custom made for the Changi Airport. Valoya is a provider of LED grow lights for the crop science, vertical farming and medicinal plants markets globally, known for their research driven approach and high quality, wide spectra. In addition to the standard product series, Valoya offers custom made solutions developed for large scale projects such as Singapore’s renowned airport. These custom solutions are typically made for projects that are demanding and need a high degree of engineering and photobiology expertise and support.

The form factor of the luminaires resembles a compact box designed to fade into the background and not distract from the plants. Valoya’s powerful LEDs are placed inside with a spectrum optimized for the entire growth cycle of the widest variety of plants. The spectrum’s color is a warm white designed to seamlessly fuse with natural sunlight. It is safe for and pleasant to human eyes.

The construction of this dome is a 1,7 billion dollar project. The order of Valoya luminaires is already delivered to the customer and is in the installation phase. In March 2019 the dome will open its doors to the visitors.

About Valoya Oy

Valoya is a provider of high end, energy efficient LED grow lights for use in crop science, vertical farming and medicinal plants cultivation. Valoya LED grow lights have been developed using Valoya's proprietary LED technology and extensive plant photobiology research. Valoya's customer base includes numerous vertical farms, greenhouses and research institutions all over the world (including 8 out of 10 world’s largest agricultural companies).

Additional information:

Valoya Oy, Finland

Tel: +358 10 2350300

Email: sales@valoya.com

Web: www.valoya.com

Facebook: https://www.facebook.com/valoyafi/

Twitter: https://twitter.com/valoya

Food Irradiation Technology Not Widely Used With Fresh Produce, But It Could Be

December 7, 2018

By Stephen Kloosterman Contributing Editor

Food irradiation technology has been around for more than 50 years as a way to kill pathogens, although it is not widely used in the food processing industry.

Now, a growing firm called ScanTech Sciences is marketing its irradiation services for use with fresh produce.

ScanTech Sciences is building its first facility in McAllen, Texas’ Rio Grande Valley ECP Center. It opened for commercial operations during the summer 2018.

The facility can process between 120-160 cases of produce per minute, said Lindsay Eierman, ScanTech Sciences’ marketing manager. The company plans to open other facilities in ports of entry, such as New York/New Jersey and Nogales, Arizona, she said. Eventually, the company’s plans are to expand to areas such as of secondary import and export markets. Savannah, Georgia, Houston and California are among its targets.

University of Georgia Center for Food Safety Director Francisco Diez-Gonzalez spoke about the potential of the technique at the Southeast Regional Fruit and Vegetable Conference in January 2018.

“It’s been proven it can reduce the count of salmonella and listeria by more than 99.99 percent,” Diez-Gonzalez said. “It’s capable of killing viruses. It also helps to reduce microorganisms that could have an influence in spoilage.”

The technology, however, isn’t widespread in its use.

“Although the technology has been around for quite some time, it was not economical for use as a commercial application until the early 2000s,” Eierman said. In 2004, Australia shipped half a ton of irradiated mangoes to New Zealand, which was the first international use of food irradiation.

Food irradiation is approved by dozens of reputable organizations, including the U.S. Department of Agriculture, the Food and Drug Administration, the Centers for Disease Control, the American Medical Association and the United Nations World Health Organization, Eierman said. It’s also currently used as a post-harvest food process in more than 40 countries.

Room to grow

“There are two primary reasons that food irradiation is not more widely used,” Eierman said. “The first issue is intellectual property and investment. The technology is very complicated and requires expertise in nuclear engineering, mechanical engineering, and food science.”

Food irradiation can include the use of gamma rays, X-rays or electron beams, called e-beams. ScanTech Sciences’ patented form of e-beam food irradiation is Electronic Cold-Pasteurization, so-called because it allows product to be kept cold throughout the process. Not breaking the cold chain of storage is an added value for food processors.

The second reason food irradiation is uncommon, she said, is simply capacity. The technology is expensive, and Eierman said there have not been very many successful food irradiation ventures.

But that isn’t to say that food irradiation is rare.

Eierman said about a third of spices imported into the United States are irradiated. Many imported tropical fruits, such as guava, dragon fruit, persimmons and mangos, are irradiated. Also, much of the food consumed by NASA astronauts are irradiated to prevent sickness, according to the FDA’s website.

Eierman said food irradiation could be a good fit for processing fresh produce.

“Electronic Cold Pasteurization is a great solution for fruit, vegetables, herbs, spices and ready-to-eat (fresh-cut) commodities such as sliced apples,” she said. “It is particularly beneficial for commodities with short shelf life (such as berries or leafy greens), commodities with a high incidence of pests (such as peaches, which have the plum curculio), and commodities that are susceptible to contamination with pathogens (such as Listeria monocytogenes in cantaloupe or E. coli in lettuce).”

Irradiation is useful for not only for sanitizing foodstuffs but also eradicating pests.

One example of this is U.S. blueberry exports. Blueberry maggot fly larvae in the eastern U.S., and their presence in blueberries restricts exports of the berries to some countries trying to avoid infestation by the blueberry maggot fly. As certain chemical fumigants are phased out, irradiation is among tools being examined in a project led the U.S. Highbush Blueberry Council.

Eierman said her company’s technique of e-beam food irradiation could serve as a chemical-free alternative to methyl bromide fumigation, which remains in widespread use despite known downsides.

“Methyl bromide is a chemical fumigant that has been used for decades on imported and exported commodities as a pest control mechanism,” Eierman said. “Unfortunately, methyl bromide is a harmful ozone-depleting substance. The Montreal Protocol of 1987 was an international treaty that attempted to phase out the use of methyl bromide. However, methyl bromide remains in use because it is one of the few substances that provides effective pest control.”

Her company also hopes to combine its food irradiation services with integrated logistics, transportation and information services.

“These services reduce compliance costs associated with the Food Safety Modernization Act (FSMA),” she said. The Produce Safety Rule allows an exemption for produce that is going to a kill-step process. Electronic Cold-Pasteurization is a viable solution for meeting this exemption.

“ScanTech Sciences is eager to transform the food industry by providing safer, higher-quality produce,” Eierman said.

FDA certified

The U.S. Food and Drug Administration has evaluated the safety of irradiated food for more than 30 years and has found the process to be safe. FDA does, however, require irradiated foods bear the international symbol for irradiation. Look for the Radura symbol along with the statement “Treated with radiation” or “Treated by irradiation” on the food label. Bulk foods, such as fruits and vegetables, are required to be individually labeled or to have a label next to the sale container. The FDA does not require that individual ingredients in multi-ingredient foods (e.g., spices) be labeled.

Tags: food safety, listeria

YOU MIGHT ALSO LIKE

PMA names Impact Award winners

Taylor Farms voluntarily recalls salads over potential salmonella

Sanitation issues in packhouse led to cantaloupe listeria outbreak, FDA says

CAN (SK): Herb Grower Talks About Switch To Marijuana

If everything goes according to plan, Brian Bain will convert his Saskatoon market garden to a marijuana nursery by next year.

He said it's a matter of economics.

"All of a sudden, you have a crop that comes along, that you can pay your employees better, you can pay yourself better and the business itself will do better," he told CBC Radio's Saskatoon Morning. "It's really hard not to make that switch."

Right now, Bain grows herbs like mint, chives, dill and basil and sells them to grocery stores across western Canada. He plans to convert his hydroponic garden to a nursery that will sell live pot plants to licensed stores.

Bain said margins in the produce business are tight and it can be difficult to make money.

Publication date : 12/13/2018

This Year Our Farms Went Where No Farm Have Gone Before!

We went oversees to Vietnam, cross-country to Alaska, and even underground in the Caribbean! We also launched a brand new managed farming service, set a record for fastest sale (18 hours!), and performed a container farming first by transporting a growing farm to NYC for the Future of Everything Festival

Freight Farms

We went oversees to Vietnam, cross-country to Alaska, and even underground in the Caribbean! We also launched a brand new managed farming service, set a record for fastest sale (18 hours!), and performed a container farming first by transporting a growing farm to NYC for the Future of Everything Festival.

We hosted five open houses, gave 150+ private farm tours, and trained 80+ new farmers…good thing we also added seven new employees to the team to help out!

Some of our notable new customers included: Ford Motors and Cass Community, NBA player Ekpe Udoh and his non-profit, SEFCU, AppHarvest, and IDEA schools… it was amazing to see how these organizations are adding a modern twist to what it means to farm.

Keep reading for ALL the stats

How The Farm Bill Impacts Greenhouse And Indoor Growers

December 28, 2018

Photo taken by Allison Kopf

When President Trump signed the Farm Bill last week, it was the first time that indoor farmers have been included in the act’s provisions since its birth in 1933.

The Farm Bill, which will allocate $867 billion of federal money over the next ten years came about in reaction to the dust bowl years of the 1930s. That era of climate variability and unsustainable farming techniques left American farmers vulnerable, which the first farm bill attempted to help with. Today, facing our own era of climate change, Congress has begun to take an interest in how it can help indoor farmers. Here are four parts of the bill that we’re really excited about:

Office of Urban Agriculture and Innovative Production

Section 12302 of the bill opens a new office to aid urban and indoor farmers. The newly created Office of Urban Agricultural and Innovative Production will “ encourage and promote urban, indoor, and other emerging agricultural practices.”

We’ll have to wait and see what that encouragement and promotion actually means, but it’s certainly a plus for indoor and greenhouse growers to have a federal office learning where it can have the government add value to the indoor ecosystem.

Micro-Grants

Good news for farmers in food insecure places: the government wants to help. In order to feed citizens with real, healthy foods, provision 12616 of the bill authorizes small grants for farmers who want to build hydroponic and aeroponic farms.

A Census

In order to get a grasp on the indoor farming landscape, the government will conduct a census of existing indoor, rooftop, greenhouse, and hydroponic farming operations in both urban and rural areas.

This is great news. We’ve been conducting our own survey for a few years now since the ag census previously didn’t do much for highlighting indoor growers. We’re excited to see where this goes.

Help From the Government

Information from that census will help the government aid farmers in a couple ways under section 11122 of the bill. One of them is that the Federal Crop Insurance Corporation will research insurance plans to help farmers, particularly those in small-scale production to offer policies that are most beneficial. Currently, the government offers subsidized insurance for farmers in case of drought or hail or if prices fall. The primary crops covered under insurance are the most basic staples of American agriculture, such as wheat and corn. For indoor farms, the elements would not affect yield as they would outside, but there are still plenty of variables, including the price of crops, the cost of electricity, and others, which could benefit from some type of federal insurance.

We believe that greenhouse and indoor farming is the future of farming, and we’re glad to see that the U.S. government is thinking ahead and moving in the same direction. The farming industry faces some challenges before it. With climate changes, the patterns of planting will vary more and more, and extreme weather will become more normal. As our cities continue to support more people, it’s becoming more of a challenge to provide fresh, wholesome food to the neighborhoods that need it. The provisions in the farm bill provide the beginnings of some solutions for meeting those challenges, and for leading to a farming industry that’s equitable, sustainable, and healthy!

Canadian Cannabis Company Enters Asia-Pacific Market with Australian Acquisition

Globalization of cannabis continues, and we are present in relevant markets, with Asia-Pacific now added to our international footprint.

Wayland Group is expanding into Australia, through entering into an agreement to acquire 50.1% of Tropicann, a newly formed, privately owned Australian company located in Darwin, Northern Territory. With this acquisition Wayland has positioned itself in the burgeoning Asia-Pacific market.

“Globalization of cannabis continues, and we are present in relevant markets, with Asia-Pacific now added to our international footprint. The Northern Territory is the ideal location for our new Asia Pacific hub. The location provides Wayland with ideal climate conditions in a globally respected and sovereign country with a large and fast emerging market of over 250MM people just 4 hours north. This acquisition accelerates Wayland’s growth strategy in becoming a truly global cannabis company,” stated Wayland Chief Executive Officer Ben Ward.

Michael Gunner, the Chief Minister of the Northern Territory, declared, “We have a plan to diversify our economy and create jobs. Medicinal cannabis is a growth industry for the Northern Territory, particularly after its legalization by the Australian Government. The Northern Territory Government, Tropicann, and Wayland are in discussions about Major Project Status. Major Project Status ensures priority Ministerial oversight to assist with ongoing project coordination and facilitation across different government agencies to secure timely project delivery.”

“This is a very real and exciting opportunity for the people of the Northern Territory to enter and participate in a new growth sector in the global economy. It also offers the possibility of creating value-added products through processing here in the Northern Territory,” stated Ken Vowles, Minister for Primary Industry and Resources.

Pursuant to the terms of the agreement the Company has agreed to make an initial payment of $4,800,000 Canadian dollars followed by a second payment of $24,000,000 CAD following certain milestones being achieved, including issuance to Tropicann of a license to cultivate cannabis in Australia.

For more information:

Wayland Group

www.waylandgroup.com

"Every Time We Are Surprised By The Ideas Of Our Clients"

Avner Shohet, TAPkit:

Why would you build a greenhouse on a roof in the middle of the city, with all the compromises and investments you have to make? Why not get out of the city, only 10 or 20 kilometers, to have a simple greenhouse with a smaller investment, and it gives the same solution.”

Indoor farming

With the TAP kit, Israeli company Teshuva Agricultural Projects Ltd. enables small farmers who cannot afford to invest one or two million dollars in a big greenhouse. They see themselves as a competitor of indoor farming. “We want to enable people to get into sophisticated farming without getting into big investments, so we are aiming to keep the price low”, says CEO Avner Shohet.

“Containers and other indoor farming ideas are nice, but we believe in a low cost greenhouse, just outside the city will be more efficient. Also, indoor farms like containers needs artificial light which costs energy. Our partner on lighting is the sun. It is providing us with very good conditions, not charging us at all. It seems the produce here is stronger and better than growing in a container, because of the natural light.”

Rapid expansion

Avner shows the greenhouse of one of his clients in Israel, who is growing a mix of lettuce and herbs. “He first started selling to his neighbors, then came the restaurants. They like the fact that they know the grower of the food they serve. They visit him regularly. In this 500 m2 greenhouse he produces 150-200kg a week. He grows by demand, which is the dream of every farmer.”

Currently the grower is supplying to seven restaurants. He supplies them every week so gradually planning is needed. A new unit is planned. “Only two months after the greenhouse was put in production, he came to me saying his clients wanted more production. Some of them are actually willing to support his investment of the second unit, in order for them to secure his supply.”

Climate system

To keep a constant climate in the greenhouse, a system of Roots is being used. “The temperature underground is stable and the average of summer and winter. They drill a hole in which they put two pipes, 6 meters deep. In summer we get cold, chilled water to cool down, and in winter it is a little bit warm. It is the perfect temperature year-round.” This climate system is not a must for every client of the TAP kit. “It is a valuable addition for places that have big difference between summer and winter. This month we started building two installations in South Korea. There we use the same system. They have even more extreme temperatures. In summer they reach 40 degrees Celsius, in winter below -15 degrees.”

Profitable solution

In a unit of 500 m2 the production of lettuce is 12 tons a year, or in case of herbs, 6 tons a year. This grower is mixing crops, so his production will be 8 tons a year. His turnover should be around 100- 120,000 euros per year. The cost of the unit, including a small plant nursery and packing equipment, is around 55,000 euros. The preparations for the unit will add another 10,000 – 15,000 euros. The return on investment is 1.5 years. This makes it a profitable solution for growers.”

Three modules

Depending on the climate, TAP provides three different modules. The one that is being used in Israel is suitable for sub-tropical countries. There is also one for tropical areas that has more ventilation. For cold countries double plastic is being used. “This unit will cost 80,000 Euros, because it has a different structure. Every three or four years the plastic has to be replaced, which costs a few hundred Euros. This is still a small investment in comparison to containers with automation and artificial lighting.”

Surprised by clients

When we started, we focused mainly on Africa and South America, thinking: ‘these people don’t have much money and with support of the World Bank they are able to grow in our self-assemble hydroponic greenhouse. But very soon we discovered our market was much bigger than that.

“Our first clients were from South Korea. There is one in the Philippines and 2 units are on the way to a resort in Mauritius. I think here in Israel we can sell a few dozen of them. There is also interest from USA, France, Ecuador, Mozambique and even from Gaza.” Most clients will have one or two TAP kits and they can supply the products to the supermarkets, restaurants and vegetable sellers in their neighborhood. “This way they really answer the need of local produce.” A small part of the greenhouse is usually for propagation.

“A client from Miami is to buy 3 to 5 units, which he aims lease to several people”, says Avner. “Another client from New York wants to put a TAP kit in a home for the elderly. There will be food for the kitchen and occupation for the people living there. It’s not a hard job. People don’t have to bend down. These are uses that we have never thought of before. Every time we are surprised by the ideas of our clients.”

For more information:

Teshuva Agricultural Projects

60 Nof Harim St., Olesh, 42855 Israel

+972-9-8940507

+972-50-7922579

+1-201-5803003

office@taprojects.com

www.taprojects.com

Publication date : 12/12/2018

Author: Jobke den Hertog

© FreshPlaza.com

New York City School Opens Greenhouse Classroom

On a snowy November morning Manhattan Borough President Gale Brewer, students, teachers, School Construction and other community members celebrated City As School High School new Greenhouse Classroom.

The fundraising efforts were led by City As School teacher and Alum Naima Freitas who will be using NY Sun Works curriculum with experiments and research that connect science to math, social studies and art. “I am especially excited about using this classroom as a demonstration site for local elementary and middle schools,” said Freitas, “and will be working with my students to plan Pay What You Can Farm Stands and Cooking Demos with their hydroponic harvests”

Guests enjoyed fresh mint tea, kale chips and pesto made by the students using their first harvest.

The greenhouse classroom will expand far beyond the educational auspices of the Urban farm: Students will learn about the science of sustainability and how to grow food with cutting edge technology. They will also learn about contamination, pollution, biodiversity, and conservation while understanding how their actions have an impact on the environment.

“In-school hydroponics labs are a great innovation that make real-life, hands-on, project-based science education a day-to-day part of students’ lives,” said Manhattan Borough President Gale A. Brewer. “Research and common sense both tell us that experiential education opportunities produce deeper learning and more meaningful experiences for students, and I’m thrilled we could fund and complete this project through my office’s urban agriculture initiative. Whether it’s hydroponics, aquaponics, greenhouses, kitchens, media labs, or recording studios, giving our students the facilities they need to do more than just memorize and recite is always the right thing to do.”

The Borough Presidents funding allowed for a complete gut renovation by NYC School Construction Authority to transform the previous space into a fully functioning urban farm in collaboration with NY Sun Works.

Canadian Cannabis Company Expands In Australia And Portugal

Flowr, a Canadian Licensed Producer of cannabis products, has acquired a 19.8% interest in Holigen Limited (Holigen). Flowr will provide, among other things, its cultivation, facility design and construction IP for use by Holigen in the construction of its facilities in Portugal and Australia and for obtaining its final licenses in those territories.

Significant cultivation facilities, potential low-cost production

Holigen is a European-based cannabis company in the process of developing large-scale cannabis cultivation facilities and Good Manufacturing Process (GMP) compliant production facilities that are expected to provide finished medical cannabis products, pharmaceutical ingredients, and plants and seeds to medical cannabis markets globally. Holigen is in the final stages of obtaining one of the largest cultivation licenses in the developed world for outdoor and greenhouse facilities on 72 hectares (7.8 million square feet) in Portugal. This project has been designated a Project of National Interest by the Portuguese government, which ensures special handling and prioritization by government agencies and access to low cost financing.

Benefitting from Portugal’s climate, cost-effective land and labour, and the high crop yields it expects to generate by employing Flowr’s cultivation IP, Holigen could be among the lowest cost producers in the world.

“The combination of Holigen’s strong management team and incredible assets along with our cultivation, design and construction IP will create what we believe will be a worldwide leader in production” said Tom Flow, Co-CEO of Flowr.

Licensing near completion, GMP certification expected

Holigen expects to complete its licensing process for its first site in Portugal by mid-2019 and expects to be one of the few licensed producers in Europe that will produce products in GMP-compliant facilities.

Holigen has applied for licenses to cultivate, manufacture, distribute, import and export medical cannabis and derived products at two sites. These applications were considered compliant with local regulations by the health authorities in Portugal (INFARMED). Both sites are pending inspections to complete the licensing process. Holigen anticipates licenses to be granted for site 1 by Q2 2019 and site 2 by early 2020. Its Australian facilities have already achieved GMP certifications with respect to the relabeling and release of products. As the fit-out of the facility progresses, Holigen expects to arrange further GMP inspections.

In Australia, Holigen has strong ties to the country’s largest distributor of medical cannabis and holds the following medical cannabis licenses: Cultivation, R&D and Manufacturing from the Office of Drug Control and Drug Control Section Australia (Therapeutic Goods Administration) and GMP License from the TGA. Holigen is in the process of obtaining a New South Wales Schedule 8 pharmaceutical manufacturing license, which is the remaining license it requires.

Development details

Holigen currently is developing four cultivation facilities in Portugal and Australia along with production and R&D facilities. These sites include:

A 65 hectare (seven million square foot) outdoor cultivation site in Portugal that is expected to be partly operational in the second quarter of 2019 and fully operation in the first quarter of 2021 with potential production of more than 500,000 kg annually;

A 294,000 square foot greenhouse facility in Portugal that is expected to begin operating in the first quarter of 2020 with potential production of 110,000 kg annually;

An indoor facility in Portugal expected to begin production in mid-2019 with a potential capacity of approximately 3,500 kg annually and the potential capacity to extract up to 49 tons of dried product;

Approximately 90,000 square feet of planned GMP-compliant production facilities integrated into the Portuguese cultivation centers; and,

A 2.4 hectare site in Sydney suitable for cultivation and manufacturing, which includes a 3,500 square foot indoor cultivation facility with a potential capacity of over 1,000 kg annually.

“We are delighted to be working with Flowr to develop these valuable properties and licenses into one of the leading cannabis franchises in Europe and Australia,” said Pauric Duffy, Holigen’s Co-Founder. “In addition to developing the cultivation facilities, we are hard at work developing medical cannabis brands in our key markets, preparing to leverage the distribution partnerships we are forming, and evaluating alternative product lines like infused beverages.

“Flowr has the high quality, high yield growing technology and experience that we believe will quickly allow Holigen to execute on the very significant licenses we hold and are obtaining in both Portugal and Australia,” said Peter Comerford, Holigen’s Co-Founder. “With the partnerships we are developing, we believe we will be positioned perfectly within the Australian government’s ambitious strategy for significant export of medicinal cannabis announced in January. With the licenses we are obtaining, combined with Flowr’s proven cultivation technology, we believe this transaction places both companies in a unique position to act as a true medicinal cannabis multinational.”

For more information:

Flowr

flowr.ca

Publication date : 12/24/2018

A Greenhouse In The Eternal Ice: Vegetable Gardening In The Antarctic

Paul Zabel from the German Aerospace Center is operating a greenhouse in the Antarctic, where tomatoes, lettuce and cucumbers flourish. For future space missions, plant cultivation is to be tested under difficult conditions.

Photo: DLR

In the past few months, Paul Zabel had to cope with bad weather conditions. For a whole polar winter, he was responsible for the research greenhouse of the German Aerospace Center. This is located in a large container, 300 meters from the German Neumeyer Station.

"We had the lowest temperature in August, with minus 43.4oC. There were a few days where there were stronger storms, and I did not go out because that was just too dangerous. "

Through a satellite connection, the situation in the greenhouse, 13,500 kilometers away from Europe, is monitored continuously.

Photo: DLR

"We can not touch any of the plants, but we can say for example: The container should be two degrees warmer. Let's make an adjustment and then the container would be up two degrees. We can control the lighting and we can also give a different mix of nutrients to the plants. We can control everything from here."

The complete remote control of vegetable cultivation in a hermetically sealed container is a prerequisite for its application to future interplanetary space missions.

"The scenarios demand that the greenhouse system could fly to Mars in advance, unpacking there automatically and making sure that plants would grow automatically there. When the first humans arrive on Mars, they would find an almost fully functioning greenhouse. That's the theory."

Source: Deutschlandfunk Kultur

Meet The Designer Putting Rooftop Gardens On Cars in NYC

By placing lightweight “green” roofs composed of plant life on the tops of cars and buses, Marco Castro Cosio’s Bus Roots aims to unlock an extra 1,000,000 square feet of green space in New York City

Following up on their NYC Is Green content series, Mercedes-Benz EQ and arts-focused media production company Created Here are placing the spotlight on sustainability advocate and NYC-based interactive designer Marco Castro Cosio. After taking us behind-the-scenes with visual artist Zaria Forman, who creates large-scale paintings of arctic and ocean landscapes to raise awareness for climate change, and highlighting Dan Barasch, a community developer building a fully underground park in NYC, Mercedes-Benz EQ is capping their content series by featuring the innovative work of Castro Cosio.

As an innovation consultant with residencies at Columbia, NYU, and TED, and as the mind behind Bus Roots, an initiative that installs “green” roofs on the tops of vehicles, Marco Castro Cosio represents the environmental ingenuity NYC Is Green stands for.

By placing lightweight “green” roofs composed of plant life on the tops of cars and buses, Marco Castro Cosio’s Bus Roots aims to unlock an extra 1,000,000 square feet of green space in New York City. Castro Cosio’s contribution would generate more plant life in NYC – which helps to provide refuge to the city’s wildlife and pollinators – and his green roofs would serve as a natural coolant for the sweltering New York summers. Watch the video above to learn more about Marco Castro Cosio’s green roofs, his commitment to NYC sustainability, and more.

US (MA): Lettuce Grower Decreases Crop Cycle by 30%

Fresh Roots Greenhouse is a hydroponic lettuce, herb and leafy greens grower based in Chelmsford, Massachusetts. After 40 years in the pharmaceutical industry, Fresh Roots’ owner Bill Evans wanted to give back to his community during his retirement years. He found himself drawn to how cooperative-run greenhouses like Evergreen Cooperatives and WellSpring Cooperative created jobs for underserved members in addition to providing local produce, which inspired him to build Fresh Roots Greenhouse. Fresh Roots’ state-of-the-art Harnois greenhouse uses an AmHydro Nutrient Film Technique (NFT) system to grow arugula, kale, basil, and several varieties of lettuce.

The potential to direct plant growth

Since Bill’s goal is to run his greenhouse year-round, he needed the most energy-efficient lighting system possible. His experiences growing with HPS and fluorescent lights at other facilities had been suboptimal. While the fixtures grew plants, Bill could tell that the plants were not growing as quickly and that the red varieties were not coloring up as expected. Bill felt that LEDs were the most practical financial choice – while LEDs cost a bit more up front, they would save him money on electricity and labor in the long run. After Bill learned about spectrum and LumiGrow through Melanie Yelton, Vice President of LumiGrow Research, at a hydroponic tomato growing course at the University of Arizona, he was eager to learn more and stayed in touch. He was impressed with LumiGrow Research’s depth of knowledge and hands-on approach to helping customers implement the latest lighting strategy research. As a result, LumiGrow was top of mind for Bill when he began to search for the right LED lighting system for Fresh Roots Greenhouse.

“I really believe in the promise of spectral science,” says Bill, “From the time I met Melanie [at University of Arizona] and learned about LED lighting’s potential to direct plant growth, I’ve wanted to work with LumiGrow.”

Extending photoperiod to maximize growth

Bill implemented LumiGrow fixtures across the Fresh Roots entire greenhouse. He uses them for all NFT stages of plant growth. Bill was eager to start growing and immediately began using the lights to extend his plants’ photoperiod to 21 hours.

“Keeping the light on for 21 hours keeps the plants awake,” explains Bill, “If they’re kept awake, we maximize their growth period.”

Fresh Roots lettuce varieties reach harvest size about 30% faster than their typical light exposure seen in soil farming. The seed manufacturer reports a typical harvest after 50-55 days, whereas the LumiGrow-lit lettuce is ready after about 35-40 days. Bill has had success growing a wide variety of lettuces, from green butterhead to green leaf to romaine. Depending on the variety, the finished lettuce heads weigh between 7-10 oz. Each variety grows a bit differently under the LumiGrow lights.

Bill has also successfully reduced his basil’s crop cycle by over 35-40%. The basil plants reach harvest size in 35-42 days – unlit greenhouse-grown basil can take up to 56-68 days as reported by the seed manufacturer.

Additional savings using smartPAR Light Sensors

Bill has moved past simple daylight extension and is using LumiGrow fixtures to automate his lighting strategy to improve production. Bill is using LumiGrow smartPAR Light Sensors to constantly monitor the light levels inside the greenhouse and adjust the fixture intensity to achieve a daily light integral (DLI) of 17 μmol·m−2·s−1 over the course of each 21-hour photoperiod. Once the target DLI is reached, the LumiGrow smartPAR Wireless Control System turns down the fixtures’ light intensity to minimize electricity use while keeping the plants awake for the full photoperiod. Bill is happy to see that his plants are thriving under the LumiGrow fixtures.

Bill was even happier to discover that in addition to consistently reaching his lighting goals, the smartPAR Light Sensors are maximizing his LumiGrow fixtures’ energy efficiency. After Fresh Roots’ smartPAR Light Sensors were installed, Bill noticed that his electricity bill was significantly lower than when he was simply turning the fixtures on at the end of the day to extend photoperiod. Bill can rest easy knowing that he can rely on his smart lighting to deliver the appropriate amount of light every day while saving him money each month.

Bill also appreciates the flexibility that LumiGrow adjustable spectrum offers. While Bill prefers to use his LumiGrow smartPAR Light Sensors to automate his greenhouse’s lighting, he likes that the LumiGrow smartPAR Wireless Control System also gives him the option to adjust each spectral channel to create custom spectral strategies. His LumiGrow fixtures’ versatility and user-friendly software make it simple to fine-tune his spectral programs as leafy greens research continues to develop. Bill likes that smartPAR enables him to easily create new lighting zones, which opens the possibility of growing new varieties of leafy greens under different ratios of light spectrum

In the meantime, Bill will continue to provide high-quality, locally-grown leafy greens to the local community in Massachusetts and share his passion for LumiGrow technology.

“I love sharing the many properties of these lights with people, particularly the science and engineering behind them,” says Bill, “Year-round supplemental lighting is not something a lot of greenhouses in this area have yet.”

For more information:

LumiGrow

800-514-0487

info@lumigrow.com

www.lumigrow.com

Why It’s Critical For Food Companies To Choose Sustainable Packaging

Photo courtesy of Sustana

December 5, 2018

Every day, 2.2 million pounds of waste paper converge on Sustana recycling mills, where we sort and process it into more than 230,000 tons of post-consumer recycled fiber per year.

The U.S. is in the midst of an increasingly sophisticated and urgent conversation about environmental damage from single-use plastics and containers. Restaurant operators and food distributors, in particular, are thinking more about how sustainable packaging can help to address food-related social and environmental issues while delivering a positive brand impact.

While plastics and plastic packaging are an integral part of the global economy and provide it with many benefits, their typically linear value chains entail significant drawbacks that are becoming more apparent by the day. In a business-as-usual scenario, projected growth in plastics production could lead by 2050 to the oceans' containing more plastics than fish, and the entire plastics industry could consume 20 percent of total oil production and 15 percent of the annual carbon budget.

Sustainable food packaging and brand identity

Sustana aims to be a part of the solution. We promote and apply sustainable manufacturing and business practices to deliver premium, eco-friendly recycled fibers to customers across North America. One such product is EnviroLife, the only 100 percent post-consumer recycled fiber in North America that is FDA-compliant for use in direct food contact packaging under all conditions of use.

For restaurants looking to differentiate their brand and attract environmentally conscious consumers, packaging is an excellent way to demonstrate concern for the earth while materially reducing environmental impact. Sustana recognizes that food packaging is becoming another way to articulate a company’s values, and to show its commitment to the environment and to the communities in which it operates.

Projected growth in plastics production could lead by 2050 to the oceans' containing more plastics than fish.

As we dialogue with end users, we see how successful food and beverage companies know that customers develop a relationship with their product packaging. A customer will have half an hour with that coffee cup, for instance. It might have their name on it with logos and design. This provides a tangible way for a customer to look at that and feel good about the choice they made. They’ll notice that it’s not disposable, it’s reusable. This object transmits the company’s values in a very real way. The customer will feel good about having contributed.

McDonald’s recent announcement that it will source all packaging from recycled, renewable or certified sources by 2025 highlights the significant shift underway in the market. Starbucks’ announcement earlier this year that it aims to launch a fully recyclable and compostable coffee cup within three years further emphasizes the transition.

Packaging for a circular economy

According to a third-party Life Cycle Analysis, EnviroLife’s environmental impact is much lower than that of generic North American virgin fiber. Our patented manufacturing process eliminates optical brightening agents, resulting in a product that is suitable for food contact with no need for a barrier or coating. Because of this treatment, EnviroLife is free from contaminants that are present in most other post-consumer fibers.

Straight from production, EnviroLife is ready to be used in all food packaging applications, including takeaway containers, soup containers, coffee and tea cups, coffee bags, cheese-and-meat interleaving paper and bread bags. EnviroLife is also certified by the Forest Stewardship Council.

EnviroLife is free from contaminants that are present in most other post-consumer fibers.

Sustana’s Chairman and CEO, Fabian de Armas, speaks to EnviroLife’s unique environmental benefits: “EnviroLife is the only 100 percent recycled fiber in North America that provides a zero-fluorescence solution and meets FDA requirements for direct food contact without the need for a barrier. Sustana provides its clients with premium products and environmentally sustainable solutions whose impacts are measurable. We conduct a third-party-verified analysis of the impact of using our products on the environment in terms of overall carbon footprint; it’s an entire life cycle analysis for our products. Sustana is the only producer that does this, and we’re proud of that.”

Shrinking environmental footprint

Sustana transforms post-consumer waste paper into premium recycled fiber, with state-of-the-art recycling mills in De Pere, Wisconsin, and Lévis, Quebec. Every day, 2.2 million pounds of waste paper converge on Sustana recycling mills, where we sort and process it into more than 230,000 tons of post-consumer recycled fiber per year. By recycling waste paper, the mills save enough energy to power 85,000 average U.S. homes for one year.

EnviroLife’s low environmental impact helps food-serving brands meet their sustainability goals, and answer the growing consumer demand for environmentally friendly products. We recognize that when it comes to packaging, how it’s created and where it originates have become just as important as looks and function.

Topics:

FDA Names First Source In Ongoing Investigation of Romaine Lettuce Outbreak

A Santa Maria, California farm—run by a county supervisor—is the first to be identified as a source of E. coli contamination.

December 17th, 2018

by Sam Bloch

Just before Thanksgiving this year, the American public was warned to steer clear of all romaine lettuce due to an ongoing, multi-state outbreak of E.coli O157:H7, a particularly deadly strain of the bacteria that had sickened 32 people and prompted kidney failure in at least one person. In the weeks since, government agencies, including the Food and Drug Administration (FDA) and the Centers for Disease Control and Prevention (CDC), have narrowed down the source of the outbreak, and given the okay to make salads again—provided, of course, that shoppers check where the lettuce is coming from.

Because FDA, which regulates 70 percent of the country’s food supply, was only recently granted the power to force mandatory food recalls, companies have, in the past, voluntarily pulled their products from stores when contamination was suspected. This romaine outbreak, however, led to a landmark agreement with lettuce producers to label their products with harvest dates and locations, so in the event of another outbreak of this scale, retailers and especially clued-in eaters who love breaking food news—trust me, you’re a rare breed—will know exactly which lettuces to avoid.

Now, there’s a new development in the ongoing investigation. The FDA on Thursday publicly identified one California farm as one of eight linked to contaminated lettuce: Adam Brothers Family Farms in Santa Maria, where sediment from a local irrigation reservoir tested positive for E. coli 0157:H7. The farm—which FDA stresses is not the sole source of the outbreak—has voluntarily agreed to recall its lettuces and cauliflowers. Because the traceback work is is still ongoing, FDA recommends avoiding romaine lettuce harvested in Monterey, San Benito, and Santa Barbara Counties.

Adam Brothers is owned and operated by Peter Adam, a Santa Barbara County Supervisor representing the fourth district, and his brothers Dominic, Kieran, and Richard, according to The Santa Barbara Independent. In a 2016 profile of Peter, a fifth-generation family farmer, the paper describes his farm, located in a floodplain, as a sprawling, 3,400-acre operation where he raises broccoli, cauliflower, celery, and cattle, employing 400 workers.

Adam, who the Independent calls the county’s “leading antigovernment protestor,” rose to prominence over 15 years ago, during a long, public fight with county planners, who designated part of his farm as an environmentally sensitive wetland, and thus, protected from any agricultural activity. He sued to overturn a stop-work order and was awarded nearly $5 million for lost profits, $892,500 for the depreciated land value, and an additional $130,000 in punitive damages.

Adam also faced a minimum three-year prison sentence for a federal Clean Water Act violation, according to the Independent, which was the result of an investigation launched by the U.S. Army Corps of Engineers and the Environmental Protection Agency (EPA). In that case, Adam settled for $1 million. “In the end, Adam lost millions, but the wetland designation was reversed,” the paper wrote. “He could farm the land.”

Representatives from FDA and CDC told The New Food Economy that it’s “too soon to speculate” on how the bacteria, which lives naturally in the intestinal tracts of healthy animals like cows, goats, sheep and deer, could have ended up in the reservoir. Adams Brothers said in a statement that filtered, treated water from the reservoir, which “may have come in contact” with harvested produce, has tested negative for E.coli. It’s worth noting that lettuce growers aren’t required to test their irrigation waters for pathogens.

Waterway protection rules, such as the recently-revised Waters of the United States (WOTUS), are designed specifically to protect rivers, streams, and tributaries from use by farms. Adam, the county supervisor, has been public in his antipathy for rules that govern water and land use for farming. “We level the earth here. We irrigate. We extract water and spread it over thousands of acres to grow crops,” he told the Independent. “We’ve been drilling holes up here since Jesus was a lieutenant.”

US Kansas: America's First Industrial Hemp Classes For Farmers

Part of the new US Farm Bill approved in Congress makes industrial hemp legal across the country

By: Alex Meachum

December 28, 2018

Kansas - Part of the new US Farm Bill approved in Congress makes industrial hemp legal across the country.

Nick Starling shows us the classes now offered to help farmers learn about growing industrial hemp.

This is America's Hemp Academy, the first of its kind in our area where future hemp farmers can come here and learn the nuts and bolts of the crop that's used for thousands of different purposes including the flour that's in this cookie.

"This is right up our ally, it's going to give our family a new opportunity," said Margit Kaltenekker-Hall, future hemp farmer.

This field of opportunity is exactly what farmer Kaltenekker-Hall needs.

"We had a very successful oriental greenhouse business and then 2009 recession knocked that out, pretty much from right under our feet," Kaltenekker-Hall said.

She hopes growing hemp will turn their family's fortunes around.

"This has potential for our family to restore some of the productivity of this incredibly fertile soil," Kaltenekker-Hall said.

She's one of 12 farmers who already tried out the America's hemp academy.

"The amount of product from one seed is mind-boggling," said Jo Bisogno, founder and CEO of America's Hemp Academy.

Founder Jo Bisogno says he see this as Kansas's next big crop.

"I see an industry that's been around for 100's of years that went away now coming back," Bisogno said.

Bisogno says the demand for these classes is high-as they teach everything from seed to sale and connect them with suppliers.

Farmers say hemp is not as easy to grow as other crops.

"It is a very difficult, delicate plant and so it's not something you're just going to put in the ground and forget about it, it's going to require a lot of attention," said Ron Keith, Shawnee.

Shawnee farmer Ron Keith hopes to start planting in April.

"I have trees in my fields now so converting some of these tree farms into hemp farms is what I'm looking at," Keith said.

While it's not a new crop-they hope hemp's restored presence will mean more green in their wallets.

"Now that we can grow it again here, it has huge potential," Kaltenekker-Hall said.

Classes start on January 14.

Glenn Behrman, Robert Colangelo and Erik Runkle Reflect And Look Ahead

To kick things off, we ask our guests how they would describe indoor agriculture's 2018 in five words or less.

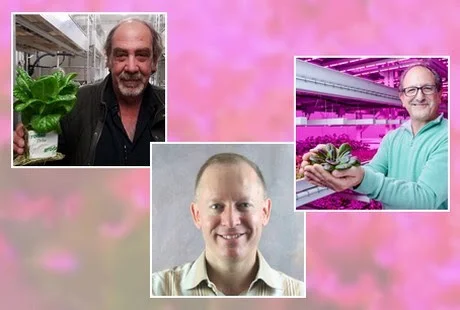

From left to right: Glenn Behrman, Erik Runkle, Robert Colangelo

An Indoor Ag Year Of Investments And Innovation

2018 is almost over. That means it's time for relaxation, exchanging gifts, and eating way too much (and not just veggies). It's also a time to reflect on the past year, and to look forward to what's on the horizon. That's exactly what we'll do now. Joining us at the holiday table to discuss the state of the indoor agriculture industry are Glenn Behrman, Founder & President of GreenTech Agro and CEA Advisors, Robert Colangelo, Founding Farmer/CEO of Green Sense Farms, and Erik Runkle, professor in the Department of Horticulture at Michigan State University.

To kick things off, we ask our guests how they would describe indoor agriculture's 2018 in five words or less.

Glenn: "Exciting but still not there."

Robert: "Dynamic, disruptive, transformative."

Erik: "Continued industry investment and expansion."

For Glenn, 2018 was a good year, with the successful pilot and subsequent expansion of the Store Grown program with their major US grocery retail partner, Central Market. "Hyper-local produce grown behind the actual supermarket in Growtainers and available for sale in the Produce sections, sometimes only minutes after harvest."

Robert sees the increased amount of capital going into the agtech market as a sign the controlled environment agriculture sector is being taken seriously. Erik, meanwhile, points to an increase in knowledge, having learned more about how green light influences leaf expansion and increases growth of lettuce. Yet much more research is needed in 2019 and beyond, he says.

Hyping, pricing, and working together

The biggest challenge for the industry in 2019, according to Glenn, is that there are "too many newcomers entering the industry that have been lured by 'likes', 'followers', hype, VC money and the promise of unrealistic returns. We need more people that truly understand what indoor ag is and what it isn’t and are not afraid to take chances and think outside the box. Those that understand that the technology available today is only a tool to produce more outputs with less inputs."

Robert says the biggest challenge for the coming year will be increasing the unit price of produce. "In part it can be done through branding, marketing and educating the consumer on the nutritional value of locally grown produce."

Those challenges are of course best tackled through cooperation within the industry, which itself could be seen as a bit of a challenge. According to Erik, developing a unified indoor farming industry association will be another challenge in the year ahead. At the individual firm level though, he thinks profitability will continue to be the greatest challenge.

Disruption, automation, innovation

Looking forward, Robert is particularly excited about new advancements in indoor growing technology. At the moment, at Green Sense Farms they are working on conveyance automation systems to optimize production and a robotic ventilation system to minimize micro climates.

Erik is focused on continued sole-source lighting research in combination with other environmental factors to increase yield and quality attributes of leafy greens. "I have several projects in mind, but the scale and scope will depend on the funding we can obtain to support the research."

After 45+ years in global horticulture, including the past 10 years laser focused on indoor ag and technology-based production, Glenn sees a future that capitalizes on the highest and best use of the available resources.

He sees 2019 as the year that he'll be able to "blend all the experience, wisdom and instinct that I possess and perfect a game changing strategy that totally disrupts the fresh produce supply chain. I’m 68, I've been doing this since I’m 21. It’s time for me to concentrate on the legacy I wish to leave behind."

Publication date : 12/24/2018

Author: Jan Jacob Mekes

© HortiDaily.com

France: "Local Cultivation Is More Than The Right Postal Code"

Le Maraîchers du Mont Saint-Michel

"The French market is a very good market to cultivate for. There is a demand for a clean, sustainably cultivated quality product: the tomatoes must be red and of good taste." This is what Jean Marc Paimblanc from the French tomato nursery Le Maraîchers du Mont Saint-Michel is saying. Recently, Havecon completed the company's 17 hectare greenhouse.

Upscaling

The greenhouse is up and about, the heating system and the water systems are completed. At the end of January, the first plants will be moved into the greenhouse and next year Le Maraîchers du Mont Saint-Michel (the growers of the Mont Saint-Michel) hope to get the first tomatoes from their new greenhouse. There will be quite a lot of them: already in their first year, there will be cultivation on 17 hectares. "That's new for the French market, where the average nursery has an acreage of a few hectares," confirms Jean Marc Paimblanc, director of the company. "Customers would like to cooperate more intensively with cultivation companies. That is where this size fits: it allows you to deliver in a customer-specific way."

Diffuse glass

The greenhouse is divided into three blocks of almost 6 hectares each and is equipped with diffuse glass to make optimum use of the available sunlight. The construction photos of Havecon, which is realizing the entire project in collaboration with the French CMF, show very well how the light is spread. At the company a processing room has been realized to have the tomatoes packaged to size and delivered to the customer. Also a number of CHPs have been installed.

"The people in France remain very modest but this really is a state of the art construction project in beautiful Normandy", according to Ramon Bol, responsible for the sales in Europe within Havecon.

Location

Le Maraîchers du Mont Saint-Michel are focusing on the local market. "The demand for local product is rising", says Jean Marc. "It is not only about the postal code of the company. A French tomato also ought to have the right quality and provide the right experience: the consumer wants a cleanly grown, red and tasty tomato, cultivated by a company from the region. All this gives value to the concept of local."

Although the postal code of the company may not be the most important for the sales, the location is of course important: the company is unique in the region, has a strong sales market here and even has the metropolis of Paris, at less than 300 km distance in a straight line. The fact that this location is less than twenty kilometers away from the well-known Mont Saint-Michel, is really a great advantage. There is a reason why they have incorporated the French icon into their company name. "The Mont Saint-Michel is a household name domestically and outside of France", Jean Marc concludes. "They receive thousands of tourists a day - only the Louvre and the Eiffel Tower attract more visitors. And in this region, no comparable tomato nursery has been established yet, so that is a great opportunity. In the coming years we hope to supply regional parties with our local production."

For more information:

Havecon

Lorentzstraat 8

2665 JH Bleiswijk

Netherlands

Tel. +31(0)10 266 32 70

Fax +31(0)10 266 32 71

info@havecon.com

www.havecon.com

CAN (ON): Aquaponic Cannabis Grower Expands With Two New Facilities

To meet the demand of a growing patient-base, Green Relief, a licensed producer of medical cannabis, has officially acquired possession of a new facility in Stoney Creek, Ont., that will significantly boost the company's production capacity.

The 100,000-square-foot facility is located at 565 Seaman St., and is zoned commercial-industrial to accommodate cannabis production. Once the Stoney Creek site is at full capacity, Green Relief, which operates out of a 30,000-square-foot facility in the rural community of Flamborough, Ont., will increase its annual output from 2,800 kg to a total of about 17,800 kg.

"The acquisition of the Stoney Creek facility will allow our team to provide a growing number of medical cannabis patients with the products they need to improve their quality of life," says Warren Bravo, Chief Executive Officer, Green Relief Inc. "As a bonus, the new facility will generate job growth, while also providing ancillary activities to drive the local economy."

The Stoney Creek facility, which formerly housed a sporting complex, will require a $9-million retrofit to become operational in compliance with Health Canada regulations. To get the job done, Bravo says Green Relief is committed to sourcing Hamilton-based engineering firms and contractors.

Bravo anticipates the retrofit to commence in January 2019, with the facility up and running by March 2019, and a first harvest slated for mid-to-late summer.

As well as installing top technology for cannabis production, the Stoney Creek site will receive electrical upgrades, and be equipped with state-of-the-art security and HVAC systems. The latter will ensure cannabis production odours do not impact the surrounding neighbourhood.

In the coming months, Bravo says Green Relief will be hosting an on-site community event to address questions the public may have about the Stoney Creek facility, and introduce the neighbourhood to the company. This event will be coupled with a job fair to attract talent.

Once operational, the Stoney Creek facility will generate about 100 full-time jobs for the local workforce. Through Green Relief's partnership with the Ontario Disability Employment Network, these roles will provide people of all abilities with meaningful work.

"Our growth in a rapidly developing sector means employment opportunities at the Stoney Creek facility will cover a range of roles, from frontline production technicians to environmental scientists, and everything in between," Bravo says.

In addition to the Stoney Creek site, Green Relief's expansion plans include construction of a 240,000-square-foot production facility at the company's Flamborough site. A 25,000-square-foot facility on an adjacent property in Flamborough is also underway, and will be used for research and development.

Similar to Green Relief's facility in Flamborough, which uses LED lights in its grow rooms and is earth-sheltered for efficiency, the Stoney Creek site will adopt the company's sustainable production practices. This includes the use of aquaponics as a growing method.

Once the system's fish reach market size, Green Relief donates the protein source to Second Harvest, a food rescue service that delivers meals to those in need. Over the last three years, Green Relief has donated more than 40,000 fish through this initiative.

"At Green Relief, we do more than provide patients with safe and effective medical products to support their health and well-being," Bravo says. "Creating jobs, being a good neighbour, and giving back to the community is at the heart of everything we do."

For more information:

Green Relief

www.greenrelief.ca

Barbados: Government To Start Veggie Project ‘Early Next Year’

December 19, 2018

Article by Barbados Today

A high-tech farming project is set to kick-off early next year that could slash demand for imported vegetables by over 80 per cent.

The Government project to be set up in the new year, comes as a private firm owned by young farmers uses technology in an agricultural project that is intend to eventually feed the entire country while withstanding the threat of natural disasters, said Agriculture Minister Indar Weir.

Operating out of a 40-foot shipping container at Hastings, Christ Church, the directors of Ino Grow have developed a hydroponic farm, which currently produces lettuce, herbs and other leafy greens.

The company is producing non-genetically modified organisms (non-GMO) and herbicide-free crops, which can be grown every day of the year.

After a tour of the small facility, an excited minister for food security revealed the project had won the support of Government. Weir has invited Ino Gro directors Warren Kellman and Rishi Pajwani to be part of a similar programme, to be rolled out by Government at the beginning of the New Year.

“We are going to get together and we’re going to pull all of the costing together… and take agriculture to the next level. But more importantly, we need the scale,” said Weir.

Government’s ultimate goal is to produce almost 80 to 90 per cent of some of the vegetables currently being imported, Weir declared.

Minister Indar Weir (left) under the artificial sunlight provided by the agricultural farm, being schooled by Ino Gro co-directors Rishi Pajwani (left) and Warren Kellman (second from right) as mentor Ayub Kola looks on.

“I speak of tomatoes and lettuce of all varieties, and then we are going to look at broccoli as well, because broccoli is one of the vegetables that we import and we have to address that. If I am able to pull all of this together in short time, we then start looking at reducing our food import bill,” he said.

Amid the worldwide threat of global warming, Weir praised the new technology for responding to the growing need for “climate-smart” initiatives.

“We have to look at what climate change is doing to the Caribbean islands and indeed Barbados is vulnerable to climate change and if we’re going to get into climate smart agriculture, then this is the way we have to go,” according to the agriculture and food security minister.

“So that if we get a climate event, we don’t find ourselves without food for extended periods of time . . . . We have to be able to protect the amount of food that we are going to need to get through a climate event. We have to protect the seedlings to make sure that we have them at our disposal so that we can continue to grow,” he stressed, while indicating that the use of green energy will also be key to the development of similar initiatives.

Weir is particularly excited about the promise of climate smart agriculture for youth. “It excites the younger mind; those people who are coming out of school, who would have traditionally stayed away from agriculture, because they didn’t see it as a career option. But if we could replicate this right across Barbados, all of a sudden we are addressing a 21st century need, where we can create entrepreneurs, through having young people now graduating from university and getting involved in projects like these as businesspeople,” he said.

Ino-Gro co-director Rishi Pajwani thanked Weir for giving them a platform to show off the young farm initiatives. He also assured Barbadians that his company is up to the task of reducing the country’s “enormous” food import bill.

“We wanted to cut that down as well as educate the youth here in Barbados about agriculture – Traditional agriculture. Agriculture is no longer outside, hot sun and breaking your back. It’s now become labour efficient and easy, so we wanted to inform everyone and the youth to re-innovate the industry and get back into agriculture, because this is where Barbados was born,” said Pajwani.

But the new private sector initiative has not come without obstacles. As co-director Warren Kellman put it, the idea was so peculiar to Customs officials that they were sceptical when equipment started coming in.

“Customs had never seen something like that before. So when they saw certain pieces of equipment . . . they said they’ve never seen something like this attached to farming. We had to work closely with Customs as well, and actually create new entries in their system, so that people who are interested in this type of innovative farming, when they do bring in systems like this in the future, they wouldn’t face issues that we faced, because we tried to pave the way,” he said.

Making the process easier is the knowledge that they have the backing of Government in their quest to revolutionise Barbadian farming, Kellman said.