Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

The Urban Farming Startup Created By Kimbal Musk — Elon’s Brother — Lets You Scan Your Produce To See Where It Came From. Take A Look Inside

Business Insider/Jessica Tyler

December 19, 2018

Square Roots farmers sell their crops to local customers.

Business Insider/Jessica Tyler

Elon Musk's brother, Kimbal, is on a mission to reduce the global food shortage and train the next generation of urban farmers.

His Brooklyn-based company, Square Roots, delivers fresh herbs that are grown inside 320-square-foot shipping containers.

In the wake of the romaine E. coli outbreak, Square Roots is determined to substitute the opaque practices of the industrial food industry.

The company now allows you to scan its crops and learn exactly when they were produced — and who made them.

While his brother, Elon, dreams up moonshot projects like colonizing Mars and building a tunnel for autonomous vehicles, Kimbal Musk's thoughts are rooted in a much more immediate crisis: the global food shortage.

Though he's on the board of both Tesla and SpaceX, he'd much prefer to talk about Square Roots, the urban farming startup that he co-founded with friend and entrepreneur Tobias Peggs.

Since 2016, Square Roots has been delivering fresh herbs to retail stores across New York City. The company also pioneered a training program that walks young entrepreneurs through every step of the indoor farming process, from planting seeds to selling crops.

Read more: Kimbal Musk predicts a movement of millennial workers fleeing desk jobs for farms

One of the advantages of indoor farms is that they can control climate conditions to reduce the risk of contamination in the water or air.

Square Roots is taking this a step further by offering customers some peace of mind about how, when, and where their food is being grown — adding in the kind of transparency that could one day prevent incidences like the recent romaine E. coli outbreak, which resulted in more than 50 reported illnesses across 19 states.

By scanning a QR code on the back of an herb, customers can learn the name of the Square Roots farmer who grew it, and exactly when the growing process started.

The new scanning system makes Square Roots an industry standout, even among the numerous vertical farms popping up across the nation.

Earlier this year, Business Insider took a tour of the Brooklyn-based indoor farming compound. Take a look.

Square Roots is headquartered in Brooklyn, but its non-GMO, pesticide-free herbs are also sold in Manhattan and Queens.

Business Insider/Jessica Tyler

The company is more than just a collection of indoor farms.

Business Insider/Jessica Tyler

"There's an incredible opportunity to re-envision the food system," said co-founder Tobias Peggs.

Business Insider/Jessica Tyler

In an interview with Business Insider, Musk said he expects a growing number of young Americans to join him in the local farming movement.

Peggs said Square Roots plans to have one of its farms in every city in America, before going global.

Business Insider/Jessica Tyler

Even on a rainy day, visitors crowded around the steel shipping-containers that house Square Roots' produce.

Business Insider/Jessica Tyler

Each shipping container has its own programmable climate, which is controlled by Square Roots farmers.

Business Insider was given a peek at the herbs being harvested inside.

Business Insider/Jessica Tyler

The company's hydroponic growing system uses 90% less water than conventional agriculture.

Business Insider/Jessica Tyler

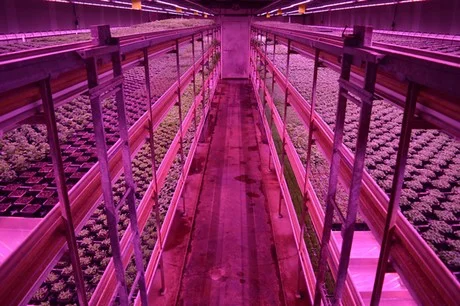

LED lights illuminate the crops, but they don't run 24-7 like some other vertical farms.

Business Insider/Jessica Tyler

Peggs said operating the farm is intuitive, like using an iPhone.

Business Insider/Jessica Tyler

"You press a few buttons and it's magic," he said. The company's software allows farmers to monitor the growth process, adjust temperature conditions, and conserve resources in real time.

Square Roots has access to historical records that can tell it when and where the best crops were grown.

Business Insider/Jessica Tyler

If you tasted the basil in Northern Italy in 2006, the company can research and replicate the temperature conditions to give you a similar product.

Peggs said the average apple takes nine months to get through the food system.

Business Insider/Jessica Tyler

The typical storage time for lettuce is around one to four weeks, but certain produce can be stored for up to a year.

To keep an apple from rotting, distributors often coat it in wax or treat it with a pesticide-active ingredient that slows down the growing process.

Business Insider/Jessica Tyler

In those instances, Peggs said, consumers think they're making a healthy choice, when "you're actually just eating a waxy ball of sugar."

Like apples (which are not offered by Square Roots) herbs begin to lose their nutrients if they're stored for too long.

Business Insider/Jessica Tyler

The company delivers its herbs to retail stores within 24 hours of harvest, which is critical to keeping them fresh.

Business Insider/Jessica Tyler

Square Roots let us try their freshly-grown chives, which were some of the yummiest we've ever tasted.

Business Insider/Jessica Tyler

"When people try real food, they don't go back to industrial food," Musk said. "It just doesn't taste good."

The company also produces herbs like mint, oregano, thyme, and basil.

Business Insider/Jessica Tyler

The scanning system gives a detailed timeline of the crop from seed to shelf.

Business Insider/Jessica Tyler

That may sound like simple information, but food labeling laws in the United States are notoriously lax.

Business Insider/Jessica Tyler

It was only after the latest E. coli outbreak that the Food and Drug Administration finally asked producers to label romaine with a harvest date and region of origin.

All you have to do is point your iOS camera at the bar code on the back of the package.

Business Insider/Jessica Tyler

From there, you'll gain access to more than just data.

Business Insider/Jessica Tyler

The timeline offers links to learn more about the farmers and their growing techniques.

"At the heart of everything we do are the farmers," Peggs said. "You have to love the arugula to make it grow better."

More: Features BI Innovation Indoor Farm Kimbal Musk

Superior Fresh At The Forefront Of Aquaponics Trend

By Noah Fish nfish@agrinews.com

December 8, 2018

Brandon Gottsacker, chief operations officer for Superior Fresh, describes the facility that grows salmon and greens in the middle of western Wisconsin countryside. | Chuck Rupnow/Eau Claire Leader-Telegram

“To grow what we have on about two-acres under glass, you’d need about 60-acres of conventional land,” said Kurt Wagaman, general manager of Superior Fresh. The fish house at the Superior Fresh facility, a Wisconsin-based aquaponics firm based out of Hixton, Wis.

HIXTON, Wisconsin

If you find yourself eating locally grown, organic lettuce this winter and wonder how that’s possible, it’s probably because of a Wisconsin-based aquaponics firm.

On a Native Restoration Sanctuary in the Coulee Region, about 60-miles from the Minnesota border, the company Superior Fresh has built a recirculated aquaculture facility and hydroponic greenhouse.

For those unfamiliar with aquaponics, the most basic definition is that it’s the combination of aquaculture (to raise and harvest fish) and hydroponics (to grow plants without soil). In even simpler terms, the fish waste feeds the plants and the plants clean the water for the fish.

The Superior Fresh facility uses nitrate-rich water from fish held in the aquaculture tanks to fertilize and water leafy greens in its greenhouse, which has recently doubled in size to 250,000 square-feet. The company is able to produce fresh products year-round, while maintaining a water-sustaining zero-discharge.

You’d be hard-pressed to find an organic, sustainable operation that can match the latitude of Superior Fresh.

“We have no chemicals, no antibiotics, no pesticides and are non-GMO — even our fish food is certified organic,” said Kurt Wagaman, general manager of Superior Fresh. “To grow what we have on about two-acres under glass, you’d need about 60-acres of conventional land.”

The company grows more than 100,000 pounds of leafy greens a month, Wagaman said. That ranges from several different varieties of head lettuces to salad greens.

“A good way to imagine that, is that it’d be the equivalent of roughly 32,000 heads of lettuce every day,” Wagaman said.

Inputs vs. outputs

Steelhead trout and Atlantic salmon are also raised under the same roof. Superior Fresh raises about one pound of fish for every 1.1 pounds of food that’s put into the system. According to Brandon Gottsacker, president of Superior Fresh, that’s a very efficient feed conversion ratio.

“On top of that, we’re using all that nutrient-rich water that the fish pass on to grow an additional 10-pounds of produce,” said Gottsacker. “That’s 1 pound of input into the system and 10 pounds of healthy organic food out of the system. So that’s flipping the scales with agriculture inputs versus outputs, and it’s pretty special.”

Wagaman said Superior Fresh hopes to add an herb line and is investigating the production of microgreens.

If you’re looking for Superior Fresh lettuce, you don’t have to go far. Wagaman said the firm’s lettuce can be found at any Kwik Trip location. Superior Fresh living butterhead lettuce and baby spring mix also are available in more than 600 stores throughout Wisconsin and Minnesota, and the company’s washed leaf lettuce mixes are available at more than 30 stores throughout Wisconsin.

This summer, Superior Fresh sold its first batch of land-farmed salmon at Festival Foods stores in Wisconsin.

Wanek family investment

The state-of-the-art aquaponic center in rural Wisconsin was built in 2015 by the Wanek family, owners of the Arcadia-based Ashley Furniture. The Waneks invested more than $100 million in the facility.

Interested in sustainable agriculture, Todd and Karen Wanek recruited Gottsacker, a distant relative of theirs with a degree in biological sciences, fisheries and aquaculture from the University of Wisconsin—Stevens Point.

“We had a common interest, and felt there was a huge need for sustainable agriculture and raising sustainable protein,” Gottsacker said of his link to the Waneks.

To gain the knowledge he’d need to run a commercial operation, Gottsacker went to West Virginia to work as an aquaculture technician for the Freshwater Institute of The Conservation Fund. He credits Steven Summerfelt, the director of aquaculture systems research for the institute, for spending a year training him. Summerfelt now serves as the chief science officer for Superior Fresh.

“He took me more or less under his wing, and showed me the ropes,” said Gottsacker. “He showed me the landscape of aquaculture and we visited sites all over North America.”

Gottsacker returned to Wisconsin in 2013 to work with the Waneks on a business model, and how to approach the capital intensive startup. During that time they also decided to integrate hydroponics with aquaculture.

“With Todd and Karen’s help, assistance and great background and understanding in business, we were able to put together what we think is the best plan,” said Gottsacker. “To not only have a successful business, but to do it sustainably.”

Growing trend

This week, Gottsacker and Wagaman were in Miami for the annual Aquaculture Innovation Workshop, where leaders from the industry are able to network.

This was the sixth workshop for Gottsacker. He said it’s amazing to see how much the aquaculture industry has grown in that time. Six years ago, the workshop had about 50 attendees and just a few commercial companies. This year he said there were around 20 companies.

According to the Minnesota Department of Employment and Economic Development, there are now 40 aquaponics facilities in the state.

“We’re proud to be the first ones to really take that same model in aquaculture and integrate it with commercial hydroponics application,” Gottsacker said. “There’s a huge need for it, and this type of farming is going to continue to grow.”

Tags Hydroponics Agriculture Economics Sanctuary Fresh Product Greenhouse

Restoration Facility Aquaculture Gardening Greens Fish Romaine Produce Natural Food Ceo Karen Todd Wanek Steven Summerfelt Brandon Gottsacker Wisconsin

Commerce Company Botany Store Kurt Wagaman Food Superior Fresh Firm

Noah Fish - Agri News Reporter

Noah joined the Post Bulletin staff in 2018 as a regional and Agri News reporter, and has covered Southeast Minnesota as regional and sports reporter since 2016. He enjoys talking to farmers, playing basketball and watching HBO.

New Research Shows How Organic Farming Is Worse For Climate

Chalmers University of Technology in Sweden

One of the main aims of organic farming is to maximise the 'natural' aspects and minimise chemical interference when it comes to producing our food. But is it actually better for the environment?

A new study, published in Nature, looked at pea and wheat crops and it suggests the opposite. It claims that organic farms are worse for the climate, simply because they tend to take up more room. That means more deforestation, and less carbon getting pulled out of the air and stored in the ground, conclude the international team of researchers.

But to be clear, this research was limited to a couple of crops in just one region, so it's way too soon to make any broad sweeping statements about the entire industry. For their study, the team of scientists focused on the farming of organic peas and wheat in Sweden.

Primarily because no fertilisers are used, organic pea farming takes up more space than non-organic pea farming, and that can be a problem, depending on how that land would otherwise get used.

"Our study shows that organic peas, farmed in Sweden, have around a 50 percent bigger climate impact than conventionally farmed peas," says one of the researchers, Stefan Wirsenius from Chalmers University of Technology. "For some foodstuffs, there is an even bigger difference – for example, with organic Swedish winter wheat the difference is closer to 70 percent."

The team developed a "carbon opportunity cost" metric for assessing the carbon footprint of certain types of land use, charting carbon dioxide emissions against how much food is produced. For organic farms, that ratio lags behind non-organic farms. Few previous studies have considered how carbon storage in vegetation and soil affects the environmental impact of organic farming, according to the researchers.

And the team isn't suggesting organic farming should be shut down at the earliest opportunity – rather that its use should be carefully considered. That consideration could extend to biofuels too, which also need more land to produce than conventional fuels.

According to sciencealert.com, the issue is particularly topical in Sweden, with the government pushing for an expansion in organic farming. These policy decisions have an impact on the climate across the globe, the researchers point out.

Publication date : 12/17/2018

Swedish Retailers Are Starting To Grow Herbs Under Their Stores

William McGrath, Amsterdam Office, Bord Bia – Irish Food Board

As Ron Finley once said in his Ted Talk on Gorilla Gardening - “To Grow your own food is like printing your own money”. Urban Gardening is by no means a new phenomenon – it has been around for hundreds of years. Back in the 1800s urban gardening took up much of the space that we see in gardens and parks in modern day cities and towns. Back then urban gardening was not a past-time or a way to improve your social media followership but instead it was a way to survive. People didn’t have the luxury of popping down to the supermarket to fetch a fresh bag of rocket lettuce or freshly pickled beetroot, instead they had to put in the hard graft and grow the food from scratch.

We have come so far in the last 100 years in relation to food technology and production that we have become comfortable with where our food comes from and how it gets to our dining tables.

Recent years have seen a revolution in the concept of urban gardening. Not only can we see urban garden plots popping up in suburbs of most cities but we can also see people growing plants and herbs in their homes and on their apartment balconies. In Stockholm alone, people have turned their balconies into a miniature oasis of speciality herbs, vegetables, and flowers. With urban populations around the world forecast to grow over the next decade, we can begin to see that people are conscious of where their food is coming from especially in an urban setting.

A new initiative created by the leading Swedish retailer ICA Kvantum - Liljeholmen in cooperation with Urban Oasis, sees retailers in Sweden beginning to grow their own micro-herbs and vegetables in the basement of their stores. The system used is a Hydroponic system, meaning they grow the crops in a water solution as opposed to soil, making the crops less reliant on fertilizers, pesticides and fungicides. Joakim Haraldsson – Sales manager stated “We can use this technique to cultivate anything we want. We are just a small step away from sun-ripened tomatoes and ripe strawberries for Christmas”. The idea came from a group of four students, who created the concept of Urban Oasis as a pilot project in University. The idea has continued to grow momentum in Sweden, with ICA Maxi Lindhagen also creating plans to grow speciality herbs in their basement using the same concept.

Source: Bord Bia

Publication date : 12/06/2018

Ship To Plate, Food Grown Onboard Cruise Condo Ships

What else can you add to the cruise ship to make it more like home? A fresh produce farm. Storylines will have ship-to-plate food using some of the latest technologies in hydroponic food production. This will enable portions of the menu and indeed whole dishes to be grown right onboard the cruise condo ship.

Side benefits of this are better quality and better tasting food with a lower carbon foot print as food produced this way only travels a few feet, not thousands of miles.

Guests will be able to get involved in this process if they choose, so even the green thumbs in the community will be catered too. A big part of the Storylines offer is the fact that "anything you can do in your land based living, you should be able to do onboard our ships." This hydroponic garden is just an extension of that.

The garden itself will be over 2 levels and radiate a warm UV type light into the surrounding areas as it will be encased in glass. It will sit in pride of place right in the center of the main dining lounge so as guests are ordering their meal, the chef may be in the garden picking the ingredients to go on the plate. The lower level will be glassed in on a condo deck adding the feeling of a cosy home to those living nearby.

For more information:

www.storylines.com

Publication date : 12/11/2018

“Indoor Farming Is About Producing An Economic Product By Using Technology”

Bowery Farming raises $90 million

“Indoor Farming Is About Producing An Economic Product By Using Technology”

"The mistake in our industry is that many people tribute the soul success of indoor farming to LED. LED makes indoor farming viable. But if you want to make indoor farming scalable, you have to think in trends that are happening in robotics, automation, computer vision and machine learning." Speaking is Irving Fain, CEO with Bowery Farming. Yesterday the company announced a $90 million funding round, led by GV (formerly Google Ventures). Additional investors in this round include Temasek (the global investment company headquartered in Singapore), Dara Khosrowshahi (CEO of Uber), David Barber’s fund Almanac, First Round Capital, GGV Capital and General Catalyst. What's their secret? “Bowery Farming isn’t just about focusing on growing indoors, it is also about producing an economical product by using technology.”

Indoor farming

Indoor Farming is a hot topic these days. With on one hand companies going through the roof and on the other hand companies having to give up their activities, there's obviously both opportunities as well as major challenges in the industry. "Overall it has been an exciting time for our industry of indoor farming. We work in ways that ten years ago weren’t possible," Irving Fain with Bowery Farming explains. The company opened up their first farm in 2017 in New York. "Indoor farming is not just putting up four walls. It is controlling the environment to provide the growing population in cities with fresh food.”

To Bowery Farming, the line between techniques and producing food is a thin one. In totally controlled environments they are able to grow consistently, pesticide-free and year-round, regardless of the climate. “Given the level of control, we are not only growing twice as fast as the field, we are getting more yield of every crop cycle, as well as more crop cycles per year than the field does. We can grow a lot faster while saving over 95% of water.” Then there’s traceability, producing local and food safety – especially in these days an important reason to keep an eye out for indoor farms. Bowery’s farms are SQF certified, the highest level of food safety, and they implement stringent food safety policies so that retail partners and customers can be confident purchasing produce that has gone through the highest levels of food safety and quality testing.

Want to take a peek into the farm? Bowery's head of R&D and BoweryOS, Henry Sztul, sat down with Fluence Bioengineering to share how they are able to cultivate food 365 days a year in a highly productive and efficient way.

Software control

One of the unique points of Bowery Farming specifically is their own software control system: BoweryOS. “We are not only a farm, but also a tech company. We’ve built a proprietary software system that uses automation, machine learning and vision systems and sensors to monitor our plants 24/7 and collect millions of data points. This allows us to constantly iterate on each varietal, tweak flavor profiles, provide each crop exactly what it needs to thrive, and harvest each crop at the exact right time. BoweryOS will also tell the farmer what to do, when and how, which means that we don’t necessarily need to hire experienced farmers.” According to Irving, the lack of need for skilled labour is one of the points that will assure Bowery Farming of a future not touched by the troubles many indoor farms are in.

Viable indoor farming

“We honor the innovation that’s been going on for decades in places like the Netherlands. The Dutch growers have been innovators in agriculture for a long time. With what we are building here, we take the knowledge of all those years and innovate on top of that,” says Irving.

As an example, he recalls the developments in LED lighting, making indoor farming possible in a way that hasn’t been before. “Part of the indoor farming developments occurred thanks to LED. LEDS were expensive for a long time. In the last seven years they have dropped in cost by 85% and doubled in efficiency. And even more interesting: they are dropping again and will become twice as efficient as today,” he confirms. “The mistake in our industry is that many people tribute the soul success of indoor farming to LED. It makes indoor farming viable, that’s for sure. But if you want to make a solid business case, indoor farming has to be scalable. Therefore you have to think in trends that are happening in robotics, automation, computer vision and machine learning. These are the things that allow the economics of the business to change in various ways. Bowery Farming isn’t just about focusing on growing indoors, it is also about producing an economic product by using technology.”

Proof of concept

With the first Bowery farm, Irving has delivered his proof of concept in the last couple of years, both tech wise as in the market. The company supplies to a number of retail outlets like Whole Foods and has increased distribution with the opening of the new farm. “Together we’re expanding in the market: we deliver to a number of Whole Foods and Foragers in the area and continue to grow. We’ve also opened up some foodservice partnerships with Temple Court, sweetgreen and Dig Inn in the New York area.”

According to Irving, the growth isn’t ending. “Our biggest challenge is to get people to really believe in this industry and in the importance of what we’re doing.” This might be pretty easy with the current circumstances – the E.coli outbreak. But there’s more, Irving explains. “Thanks to our efficient use of supplies and nearby growing, we’re offering a product that’s premium in terms of quality, but pricewise equivalent to field produce.”

Selling the system?

Even though he’s currently occupied fully with the recent opening of their new farm, the eyes at Bowery are set on the horizon. “The opening of our second farm is just the beginning. The roadmap is enormous, we have plenty more opportunities. We have a lot of interest both from consumer and retailer. Although we focus on succeeding in the New York market, the growing popularity of people moving into cities is not only an issue in the US but everywhere. Ultimately I see Bowery Farming all around the world using our technology to provide fresh food to urban environments.”

The recent $90 million funding is to contribute to this. Prior to this round, Bowery raised $27.5 million from investors. Bowery plans to use the capital to scale their operation in new cities across the country and open multiple farms by the end of 2019. This funding will also enable them to continue growing the team, investing in technology and innovation across the company.

Does he consider expanding by selling their technique instead of opening up new farms on their own? For now the answer is no. “For now there is so much learning to be done. We fully focus on building and designing to put us in a better position.” He explains why that remains important. “We are a technology company, but our product is food.” It sounds simple, but to Irving it is important to not lose sight on that. “At the end of the day we are growing food for people. They bring it home to their families, are at the dinner table. That’s a topic we should never let out of sight. While we are developing all this great technology, the end result has to be good food.”

For more information:

Bowery Farming

https://boweryfarming.com/

contact@boweryfarming.com

Publication date : 12/13/2018

Author: Arlette Sijmonsma

© HortiDaily.com

Canadian Automated Vertical Farm Systems Developer Inno-3B Raises C$6m Seed Funding

Canadian vertical farming systems developer Inno-3B has completed its first seed round of financing at nearly C$6 million ($4.45m).

Located in Quebec and Ontario, the company provides turnkey vertical farming systems for a variety of customers, from researchers, biotechnologists, and small-scale farmers, to regional and multinational producers.

Inno-3B provides fully automated, controlled, scalable, and remotely monitored robotic growing systems with real-time support to help customers grow organic produce, berries, and herbs locally.

This week, the business benefitted from a seed investment round led by the Ecofuel Fund, with the participation of Desjardins Capital, the Fonds de Solidarité FTQ, Premier Tech, the Fonds de Solidarité FTQ Bas Saint-Laurent, Investissement Québec and the Ministère de l’Économie et de l’Innovation.

Inno-3B said that the C$6m will enable the business to implement a demonstration of its technology in the context of real-time operations, a move which is designed to accelerate product marketing and ensure constant support for customers. This will include creating 10 new jobs to advance the company’s design and manufacturing processes; the company already has 15 employees across its two locations.

“We are enthusiastic to start this new phase of development with such strategic investors dedicated to our success,” said Martin Brault, President and CEO of INNO-3B, adding that the Ecofuel Fund, Desjardins Capital and the Fonds de solidarité FTQ were, in particular, actively supporting the company’s growth.

Richard Cloutier, president and CEO of the Ecofuel Accelerator and managing partner of the Ecofuel Fund, said that Inno-3B’s innovative technology had the capacity to enable customers to produce vegetables with low production costs, high yields and low energy consumption, and to do so all in a small space.

“Innovation makes it possible for the company to respond to the growing needs of consumers for fresh quality products while also reducing greenhouse gases significantly,” he said.

In addition to accelerating Inno-3B’s marketing push, the new funding will also be used help to intensify R&D activities within the business.

“Thanks to the technological advances made in recent years, we have managed to position ourselves among the leaders in automated vertical farming,” said Brault, revealing that the company was also exploring certain ‘interesting synergies’ relating to artificial intelligence (AI) as part of its future development planning.

The Ecofuel Fund is a C$30m venture capital investment fund and accelerator offering customized training programs for clean technology companies. Powered by Cycle Capital, Ecofuel works with entrepreneurs to assist them in starting businesses to breakthrough internationally.

Ecofuel is funded by Investissement Québec, BDC Capital, Fondaction, the Fonds de solidarité FTQ and the Centre québécois de valorisation des biotechnologies (CQVB).

Desjardins Capital, working with a background of nearly 45 years expertise, is committed to the promotion and support of small and medium-sized businesses in Quebec, having assets under management of C$2 billion. The fund contributes to the sustainability of 460 businesses, cooperatives and funds operating in various sectors of activity and from all regions of Quebec.

The Fonds de solidarité FTQ is a capital development investment fund that is financed with Quebec savings. With net assets of C$13.7 billion as at November 30, 2017, the fund contributes to the creation and maintenance of 186,440 jobs, partnering with more than 2,700 companies and with more than 645,000 shareholders.

Related Stories

AeroFarms ‘Always in Capital Raising Mode’ as Vertical Farming Group Raises $20m

How Canadian Vertical Farming Company TruLeaf Aims to Prevent Disease Through Nutrition

Circular Economy and True Sustainability: the Next Phase for Vertical Farming

Association for Vertical Farming to Reveal Sustainability Certification Scheme at Summit

4 Things Every Investor Should Know About Vertical Farming: Lessons Learned From AVF Summit

What Do Investors Need to Know About the Future of LED Grow Light Technology?

Ag Industry Brief: FBN Makes Moves in Canada, Bayer Sells Digital to BASF, more

Efficiency Is Key In Medicinal Cannabis Cultivation

The worldwide demand for medicinal cannabis increases and production facilities become larger and more automated. Efficiency in the cultivation of medicinal cannabis is key and this starts with automation and process planning. Codema has been providing automation to a few of the top 10 cannabis growers in Canada and the U.S. They are involved in a large number of medicinal and legalized cannabis projects in these countries. Codema provides automation on every essential part inside the greenhouse for growers, such as cultivation systems, logistics, water treatment, irrigation and software. Meanwhile, Codema has gathered quite some knowledge about the critical success factors in the cannabis world.

Cannabis cultivation has to meet high hygiene standards. The concentration of CBD and THC in the medicinal oil is very important. Medicinal cannabis must therefore not contain pesticides, heavy metals, fungi or bacteria. It is also extremely important to have as little airflow as possible, since cross-contamination is something that really needs to be avoided with this crop. Besides, great importance is attached to the uniformity of cultivation, where automation comes in.

Whitepaper

Codema presents this knowledge in the whitepaper: Technology for medicinal cannabis: 10 critical success factors for achieving the best results. Go to: https://codema.nl/products/medicinal-cannabis/ and download the whitepaper for free.

For more information:

Codema Systems Group

Oosteindsepad 8

2661 EP Bergschenhoek

The Netherlands

+31105212755

info@codemasystemsgroup.com

www.codemasystemsgroup.com

Walmart’s E-Commerce Chief Marc Lore: Food Delivered ‘Right Into Your Fridge’ Is The Future

“How about just being able to keep you in stock on everything you need and not even have to think about it? That’s the future.”

Walmart is about to take food delivery to a whole new level, Walmart’s e-commerce chief told CNBC. Marc Lore, the president and CEO of Walmart’s U.S. e-commerce business, stated in an interview that “delivery right into the fridge” could be in the cards as Walmart expands its delivery services.

Lore, who co-founded Walmart subsidiary Jet.com, envisions consumers getting a “one-time code” at the start of the process.

Then, the delivery person arrives “with a camera on their chest. You can watch it on your iPhone and see them come in, put it in your fridge and leave, to sort of build confidence and trust in these Walmart associates doing it. So, ... imagine going out to work, coming home, and there it is. The stuff’s in your fridge already.”

The next step beyond that would be “not even having to order” the food you’re getting, said Lore, who has served as the head of Walmart e-commerce since September 2016. “How about just being able to keep you in stock on everything you need and not even have to think about it? That’s the future.”

Walmart has been investing heavily in its e-commerce platforms, acquiring a host of websites. Lore said 4,700 of the big-box retailer’s stores, which the company is leveraging as “hybrid warehouses” to compete with Amazon’s rapid delivery services, are within 10 miles of 90 percent of the U.S. population. The company is planning to roll out same-day delivery to 40 percent of the population by the end of this year, and to 60 percent of the population by 2019.

On November 2018 MG Magazine Published An Article Written By Chief Strategist of D Branding - Dino H Carter

As someone with extensive experience, Dino knows how important brand thinking is for an industry that grows so rapidly like the Cannabis industry.

Here are some of the highlights:

The foundation of every company is its brand. No matter how booming the industry or what a company produces, if its brand is not solid the business will find surviving—much less thriving—in a competitive environment difficult. Make no mistake: The cannabis industry is becoming more competitive by the day.

So, what is a brand? Is it the company’s logo? A product’s name?

It’s neither.

Brands are intangible. Logos, product names, packaging, marketing, advertising, and customer service are some of the tangible assets that help build a brand. The brand itself is much more: a “feeling” customers associate with a service or product; a concept, an idea…an experience.

For your business to become a brand, it must develop a personality beyond its products and services, and that personality must align with consumers’ wants and needs. Who are your customers? What benefits do you deliver to them? How do your products and services make them feel about themselves? As you consider your brand, focus outward; see your brand from consumers’ point of view. Remember: They have all the power. They probably can buy products very similar to yours whenever they want, wherever they want, and for a price with which they feel comfortable. What—besides the nebulous and ubiquitous “high quality”—makes your brand so special they should buy from you? Even the smallest companies can build a strong brand with devoted customers simply by creating an identity that resonates with their target market.

Your brand isn’t about your company—it’s about who your customers want to be. Nike’s brand, for example, has less to do with shoes than with excellence in sports. Check out the company’s ads sometime. You won’t find the benefits of the product in big, bold type. In fact, you may not even notice the product at all. Instead, you’ll see action shots of professional athletes doing what they do best. Nike’s customers don’t buy shoes—they buy a dream.

(to read the whole article click here)

Business Owner:

If you don't get good results from your marketing activities

If you don't get the business results you desire

If sales are down

If you are launching a new product in 2019

You should work on your brand strategy. Book a free consultation call with Dino H Carter, Chief Strategist of D Branding.

Click here to book your free session now.

Developer Plans $33 Million Indoor Farm, Microgrid Project In Former Paper Mill

DECEMBER 20, 2018

Arcadia Energy Corp. wants to transform the former Florelle Tissue Corp. plant, pictured here in 2010, into an up to $33 million indoor farm and energy complex.

WATERTOWN DAILY TIMES

BROWNVILLE — A Rochester microgrid developer plans to build an up to $33 million indoor hydroponic farm and energy complex in a former paper mill on the Black River.

Acadia Energy Corp. wants to repurpose the 100,000-square-foot mill that once housed Florelle Tissue Corp., which closed in 2013, for a vertical farm and a microgrid.

John Bay, CEO of Acadia Energy, said for the farm, which would occupy only 10,000 square feet, he envisions growing produce like lettuce, tomato and arugula in bins of seven to 15 feet with rotating trays. The microgrid would produce electricity and thermal energy using natural gas, although Mr. Bay said he wants to transition to using hydroelectric and solar to generate power down the road.

“We’re very excited about this opportunity. This marketplace is an up-and-coming marketplace,” Mr. Bay said. “We’re excited to work with and serve people in the greater Watertown area.”

The state awarded Acadia Energy $415,000 through the Regional Economic Development Council program Tuesday, which will help fund the vertical farm.

The firm has already secured preliminary commitments from banks to finance the overall project, which would include about $3.5 million for the farm and $20 million to $30 million for the energy complex. Mr. Bay said, however, the firm must take several more steps before opening the complex, including purchasing the building, updating it and finishing the engineering designs.

“It’s been probably three years in the process and we’re probably another 12 to 18 months before we bear fruit,” Mr. Bay said. “We’re not certain at this point if we’re going to own the hydroponics (farm) or put somebody in as a tenant.”

Building the farm and energy complex inside the former Florelle Tissue mill is not Arcadia Energy’s first north country project. The firm, which has an office in the Watertown Center for Business and Industry, has also been designing the Jefferson County Industrial Development Agency’s microgrid to supply electricity to tenants in the Jefferson County Corporate Park.

“One reason we’re down there is the welcome we got from the county and town” of Watertown and Hounsfield, Mr. Bay said about his project in the mill.

"Mushroom Growth As An Early Precursor Of What Is Now Vertical Farming"

Those who drive onto the property of Johan van Namen in Hoenzadriel, a small village in Gelderland, Netherlands, do not expect to find a vertical farm

Berjelle van Namen, son of mushroom grower, fascinated by vertical farming

Those who drive onto the property of Johan van Namen in Hoenzadriel, a small village in Gelderland, Netherlands, do not expect to find a vertical farm. Yet in one of the cells no longer are mushrooms being grown, but herbs and micro vegetables. Berjelle van Namen, son of Johan, has started vertical farming with a growth surface of 160 square meter. "The first growth results are positive. The plants are feeling fine, just like me actually."

Preparations for the growth started two years ago. Berjelle, now a fourth year student Business Administration & Agribusiness at the HAS Hogeschool, was doing an internship in Finland in the spring 2017, where he saw a vertical farm, Robbe's Little Garden, where lettuce, herbs, and micro vegetables were grown. "I was made responsible for the optimization of the growth by means of LED-lighting."

Mushrooms as an 'early example'

Vertical farming in Finland was not to be expected, particularly not in a country where the price per square meter is relatively low. "The total growth area of the company was 500 square meter, with the intent of expanding. By growing in layers, the company was able to guarantee an even better product quality, and higher turnovers were achieved."

Berjelle now has the same goal in his own vertical farm. Back in The Netherlands, the plan took shape. End 2017 the moment came, and one of the cells in the mushroom nursery was transformed slowly into a vertical farm. "The mushroom growth could be seen as an early precursor of what is now vertical farming. The racks used for mushroom growing, turned out to be well suited to multi-layer growth."

Growth adjustments

Still, a lot had to be figured out before the first growth could finally start in September. "For example, I have spent a full week on realizing the optimal water dosage. I also worked on the ideal light recipe. Light spectra contain small differences, which do have a surprising effect on the appearance, the taste, and the health of the plant. Ultimately, everything depends on what the grower wants for his product, and for the growth methodology. By now there is a lot of variation worldwide in how vertical farms are constructed. I have underestimated the work involved a little, to be honest. But now the first results are in, I want to continue."

Berjelle hopes to finish his study as soon as possible to spend more time in the 'pink cell'. The software for the cell, in which around 20 herbs and micro vegetables are grown, has been supplied by Green Simplicity of Wessel van Paassen. The lamps are by Hortilux. "CO2, lighting, and irrigation are not required when growing mushrooms. Actually, besides the adjusted settings, I only use the climate control that controls the temperature, just like it did for mushrooms."

Golden mean

From the back to the front, various tests from young to old can be found in the cell. "This growth was a test. Not everything is optimal, but the results are good. Basil of course requires a bit warmer climate, and coriander a bit cooler on the other hand, but in one cell you have to choose the golden mean, make compromises. That went okay, I think."

Berjelle bought the seeds for the herbs and the micro vegetables at Enza Zaden. He preferred the lesser known herbs, such as lavas, savory, and pizza herbs, but also the more known types such as thyme and parsley grow under the red glow. "Ultimately, with especially bred seeds for vertical farming, much more profit can be made, I expect."

Farming with a sustainable and healthy product

But before you are ready, you can already continue fine tuning. The ultimate goal of Van Namen Specialties, as Berjelle wants to call his young project, is expansion to multiple cells. "At first I think of a warm and a cooler cell. Still, the herbs and micro vegetables are already of good quality without special climate adjustments."

Berjelle will be soon starting his first harvest. "I am going to try to sell the herbs and micro herbs to local shops, and I will offer my products to clients I already know from the mushroom trade, whom I can offer something extra. The beauty of vertical farming is that it exudes sustainability. You do not need heat, because the lamps already give off sufficient heat. And the electricity for the lighting is generated by the solar panels on the roof of the nursery."

But Berjelle does not only want to distinguish himself on sustainability. "I have much faith in research that shows that vegetables and herbs from multi-layer growth contains more anti-oxidants."

For more information:

Van Namen Specialties

Berjelle van Namen

berjelle@xs4all.nl

06-25420255

Publication date : 12/20/2018

© HortiDaily.com

US: Take A Peek Inside One Of The Country's Biggest Aquaponics Academies

HARRISBURG, Pa. (WHTM)

Commonwealth Charter Academy has opened one of the largest public educational aquaponics facilities in the country.

The 6,100 square-foot center is located at the cyber charter school's campus in Harrisburg.

CCA students are managing nearly 3,000 plants and about 400 fish in the facility.

ABC 27 took a look inside. Check it out here:

Hemp Farming Coming To Alabama But Still Months Away

The Alabama Department of Agriculture and Industries will work with the federal government, the governor’s office, law enforcement and others in developing a plan to authorize hemp farming and processing in the wake of the decision by Congress.

December 17, 2018

A display about products made from hemp that was shown at the Alabama State House in 2016 when lawmakers passed a bill authorizing research on growing hemp for industrial uses. (Mike Cason | mcason@al.com)

Alabamians should be able to grow and process hemp as an agricultural commodity because of the farm bill approved by Congress last week, but there are still governmental hurdles ahead before they can get started.

The Alabama Department of Agriculture and Industries will work with the federal government, the governor’s office, law enforcement and others in developing a plan to authorize hemp farming and processing in the wake of the decision by Congress.

Agriculture Commissioner John McMillan said it will take months to get the regulatory framework approved but said there’s strong interest and potential for hemp as a cash crop.

“Without a doubt this opens the door for I think great potential for our producers in Alabama to add another cash crop to their options,” McMillan said. The commissioner said hemp farming on a significant scale probably can’t happen in Alabama before the 2020 growing season.

On Dec. 12, Congress passed the 2018 Agriculture and Nutrition Act, usually called the farm bill. The law, which still awaited President Trump’s signature on Monday, changes the legal status of hemp from a controlled substance to an agricultural commodity.

Hemp is related to the marijuana plant. But hemp contains far smaller amounts of THC, the intoxicating substance in marijuana, and is valued for the use of its fiber. Hemp stalks and hemp seeds are used to make a wide array of products, including fabric, fiber board, carpeting, insulation, livestock feed and automobile components such as door panels and insulation.

McMillan said the reclassification of hemp was widely expected in the agriculture community, partly because Senate Majority Leader Mitch McConnell supported the change because of the industry’s potential in his home state of Kentucky.

The commissioner expects the federal government to require states to submit a regulatory plan that passes muster with law enforcement.

“Even though the farm bill makes it a commodity, it’s still different from these other commodities because of the illegal potential,” McMillan said. “So, we anticipate for sure that the Board of Agriculture is going to require us to have the known locations where it’s being grown, testing procedures to be sure it’s legal, and then procedures on how it will be disposed of if the tests determine it’s not legal.”

Federal law had previously allowed states to authorize research on hemp farming and the Alabama Legislature passed a bill to do so in 2016. McMillan said no hemp is being grown in Alabama as part of such a research project because of the long process of getting regulations approved by the federal government. But he said that process is finished and should be applicable to creating a regulatory framework for hemp production under the new authorization in the farm bill.

McMillan said he has recommended to the staff of Gov. Kay Ivey that the governor put together a working group or task force to make sure Agriculture & Industries, law enforcement and other agencies and groups have a part in crafting a uniform state plan.

Hemp is also a source for cannabidiol, a substance some people take to as a treatment for physical ailments. Cannabidiol can also be derived from marijuana and the Alabama Legislature has carved out limited exceptions to the law against marijuana possession for the use of cannabidiol.

Last week, Alabama Attorney General Steve Marshall put out an updated public notice on the legal status of cannabidiol in the wake of the farm bill and the change in the designation of hemp by Congress.

McMillan said he expects a request to the Legislature for additional funding and resources to administer a hemp program.

McMillan is completing his second term as agriculture commissioner and will take office as state treasurer in January. McMillan said incoming Commissioner Rick Pate will be up to speed on the hemp program and said he does not expect the changeover to delay the process.

Curwin Steps Down As CEO of TruLeaf

Peter Moreira

December 17, 2018

Gregg Curwin is stepping down as president and CEO of Nova Scotia-based TruLeaf Sustainable Agriculture. - Contributed

Gregg Curwin has stepped down as CEO of AgTech company TruLeaf Sustainable Agriculture, paving the way for McCain Foods to steward the company through a phase of expected “exponential” growth.

In an interview last week, Curwin said it was his decision to step down and he did so with the full support of the TruLeaf board and major investors. All decided the company’s ambition and the complexity of its machine learning-driven vertical farms required a larger management team and access to more capital. Curwin left the post late last month.

Halifax-based TruLeaf aims to be the North American leader in vertical farming, which combines hydroponic technology, LED lighting and reclaimed rainwater with machine learning to produce vegetables year-round indoors. Vertical farming is nearly 30 times more efficient than traditional agriculture, uses as much as 95 per cent less water, and takes up less land.

“Startups are like kids — they’re your baby, and with that comes a lot of hard work, cost and emotional attachment,” said Curwin in the interview. “But ... as founders, it’s prudent to understand when to let go.”

Having taken on investment over the years, TruLeaf now has four major shareholders, none of which has a majority stake. McCain Foods invested an undisclosed amount in TruLeaf earlier this year, and will now manage the company. As well as Curwin, the other major shareholders are Toronto-based investors Mike Durland and Jeff Watson. Innovacorp, the early-stage venture capital agency owned by the Nova Scotia government, is also a small investor.

Curwin described the decision to step down as the hardest of his life and it is coming at a critical time for the company. TruLeaf plans next month to open its $16 million plant in Guelph, Ont., which will supply its Goodleaf Farms brand produce to the Toronto market.

The company already has a farm in Truro, which produces greens for the Maritime market and is experimenting using machine learning to optimize nutrition, taste and growing times.

But the Guelph plant will be far more sophisticated, with more sensors and a greater capacity for its systems to learn from the data it collects.

The next step for TruLeaf is to open farms in Montreal and the Prairies with the eventual goal of becoming the largest indoor farm operator in North America. Calling the projected growth rate “exponential”, Curwin admitted such ambitions will require a lot of capital but did not go into how much money is needed.

Curwin has been working for nine years on TruLeaf, and said that by the end of his run he was “physically, mentally and creatively spent.” He will continue to sit on the TruLeaf board and serve as an adviser, but otherwise will take some time off before getting involved with other endeavours.

Looking back on his time with the company, he noted several social and economic factors combined to propel the company forward. TruLeaf’s low-energy, local production of greens meets the demands of buy local, environmental and pro-nutrition movements.

Said Curwin: “I never imagined in my wildest dreams that we’d have this perfect storm.”

Peter Moreira is a principal of Entrevestor, which provides news and data on Atlantic Canadian startups.

BREAKING NEWS: Heliponix Wins Second Stage Investment From Purdue University Venture Ag-Celerator Fund. Midwest AgTech Investments On The Rise.

Midwest indoor agriculture startup, Heliponix (Evansville, IN) has won a second stage investment of $50k from the Purdue Ventures Ag-Celerator fund in West Lafayette, IN

By iGrow News | December 19, 2018

Midwest indoor agriculture startup, Heliponix (Evansville, IN) has won a second stage investment of $50k from the Purdue Ventures Ag-Celerator fund in West Lafayette, IN. The company, Heliponix provides consumers rotary aeroponic™ appliances called GroPods®. Although the appliance is the size of a dishwasher, it is capable of yielding a full head of leafy green vegetables on a daily basis by staggering harvests. These unprecedented yields are achieved by constantly replacing the non-perishable seed pods supplied by a monthly subscription. Not only is the appliance is able to grow CLEAN plants faster and more reliably than outdoors, but it only uses $7 of energy per month, and 6 gallons of water per month! It can even be configured to grow fruiting plants, or dwarf varieties of specialty crops.

The advanced IoT algorithms completely automate the farming process for consumers who have no previous knowledge or time to spend catering to the needs of plants. “We turn black thumbs green by collecting an incredible amount of data from the sensors in the GroPods deployed across the USA which is then fed into our machine learning algorithm”, siad CTO and Co-Founder Ivan Ball. “We then use this data to simulate and maintain environmental conditions for specific plants over WiFi without any additional maintenance from the user”.

Time lapse video generation included in the mobile application of each GroPod user.

This is only possible through the former NASA student engineers’ multiple utility patents which were filed after Co-Founders Scott Massey and Ivan Ball began prototyping designs in their apartment as undergraduate students at Purdue University. They had met while previously designing hydroponic growth chambers researching the optimal light spectrum to grow plants using LEDs with the least amount of energy. This research study was sponsored by a NASA grant across several universities to advance interplanetary, agricultural technologies under Dr. Cary Mitchell. However, Massey and Ivan went against the graduate route of most engineers in this position, and co-founded the company on a theory that the evolution of agriculture is on an irreversible trajectory towards consumer aeroponics appliances.

Young farmers inspecting their harvest of genova basil in their GroPod.

“If you wanted ice in the 1800’s, you needed to wait until winter when the climate allowed freezing temperatures. This was the status quo until the invention of refrigeration allowed ice to be made in centralized, ice factories that could produce year round. Ice factories defined the ice industry until personal ice factories, or refrigerators eventually became the standard means to produce ice, said Massey. “Much like the ice industry, agriculture is completely dependant on a stable climate in a world with a climate less stable than before. This was true until micro controllers and LEDs needed to farm indoors made recent, giant leaps in efficiencies/cost, so vertical farming could be more profitable than ever before. Despite the overwhelming amount of capital being invested into massive vertical farms, there are few instances in history where a decentralized version of a technology did not greatly disrupt the market share for centralized business models. By overcoming the knowledge gap that regular people lack about farming with sensors, IoT software, and automation; we have opened a new frontier for Agriculture, and we will take a giant leap into the future of food”.

GroPod at Forbes AgTech Summit in Indianapolis.

The aeroponic appliance, consumer business model has many inherent advantages. The nonperishable seed pods are manufactured in an automated k-cup packaging facility that drop ships directly to consumers to consolidate the entire supply chain through their proprietary software. Paying consumers invest into the hardware as opposed to institutional investment dollars for large vertical farms that are capital intensive with employees on payroll needed to maintain operations. There are no building or construction permits required for this business model that can be scaled to potentially millions of Americans without extensive capital investments beyond initial tooling, operating capital for inventory, and marketing needs. Although these benefits are all welcomed in the age of toxic outbreaks, the appliance is still listed at $2k which Massey explains is normal for any new product launch.

“The toxic Ecoli outbreak that killed too many people is symptom of a much larger problem in our current food system. Consumers are demanding transparency and accountability as the trust in organic labeling continues to fall with more scandals, and these toxic outbreaks become more common. This reactionary food system is only alerted after a death or ailment has been linked to a plant which often times goes unnoticed as the cause of the illness. We believe farming is a basic human right that every individual is entitled to, and we have a proactive solution for this global problem. When our farmers calculate the return on their investment (typically 1-2 years depending on the crop), they often find an immediate return on their investment when including the health benefits of eating safe and fresh produce that tastes better for themselves or their families”, according to Massey.

Harvest of a customer’s romaine lettuce, red russian kale, arugula, spinach, and genova basil.

Massey attributes their success in fundraising, team building, and sales through the resources available to entrepreneurs in the state of Indiana. The Purdue foundry, Agrinovus Indiana, CoWork Evansville, the Indiana Small Business Development Center, Purdue WestGate, Centric Indiana, Techpoint, the Vectren Foundation, the Mandela Washington Fellowship, and Elevate Ventures among many other entities have given exposure, capital, and industry introductions needed to not only start, but scale an AgTech company. The convergence of these resources in Indiana’s AgBioScience sector have amounted to an entrepreneurial hotbed throughout the state, and it’s Time To Tell

CEO, Scott Massey (center) speaking at the recent Agrinovus Innovation Summit.

Here’s A First Look At The Label That Must Appear On All GMO Foods By 2022

On Wednesday night, the United States Department of Agriculture posted its long-awaited GMO label law, which will require food companies to label foods that have been genetically modified, or “bioengineered,” by 2022

Images: USDA, Canva. Graphic: NFE

All GMO foods, that is, with a couple big caveats.

December 20th, 2018

by Sam Bloch

On Wednesday night, the United States Department of Agriculture posted its long-awaited GMO label law, which will require food companies to label foods that have been genetically modified, or “bioengineered,” by 2022. The law will affect a wide range of foods, from mass-market snacks, cereals and freezer meals made with ubiquitous GMO crops like corn, soybeans, and sugarbeets, to new fruits, vegetables and seafood that will soon be sold to consumers directly, like the rosé pineapple, Arctic apple, non-browning potato, and the AquAdvantage salmon.

How widespread will that label be? In the coming years, you’ll start to see the government’s new logo popping up on items in the grocery store. After proposing several potential design options back in May, the government unveiled its final choice on Wednesday: a stylized landscape with an indeterminant crop sprouting under a blue sky, ringed by a green circle and the word “bioengineered.”

This labeling rule won’t apply to gene-edited foods—those containing ingredients modified by techniques like CRISPR, which do not contain DNA from other organisms, and could have otherwise been obtained through conventional breeding

The label will soon be a familiar sight, but the government’s criteria for foods that can evade the label are already causing confusion and controversy.

The new rule, for instance, exempts products that come from animals fed with bioengineered ingredients, like milk, meat and eggs—but not, for example, foods like cheese or yogurt that are made with bioengineered yeasts or rennet. It exempts ingredients that have an “inadvertent or technically unavoidable” amount of bioengineered substances—a threshold that would allow food supply companies to use the same equipment on BE and non-BE crops alike. And it exempts highly refined ingredients, like sugars and oils—but we’ll get to that in a second.

In a move likely to rile some consumer advocates, the rule won’t apply to gene-edited foods—those containing ingredients modified by techniques like CRISPR, which do not contain DNA from other organisms, and could have otherwise been obtained through conventional breeding. Advocates of gene-editing technology say that the process merely speeds up the process of natural gene selection, unlike the first wave of genetically modified products that have genetic material transferred transgenically from other species.

“The message it sends is confusion.”

It’s not just what gets labelled that’s stirred criticism. The question of howlabels will appear has also been a hot topic. Though manufacturers will have several more traditional disclosure options, including a “prominent” disclosure text, the circular, semi-pastoral bioengineered symbol, they have other tools at their disposal: methods that include text messaging, or electronic or digital links, including the QR code that many, including Senator Bernie Sanders, have decried as a confusing method that lacks transparency.

The law was initiated by Congress back in 2016, as an effort to preempt Vermont’s own GMO labeling law that was causing consternation among food companies. Biotechnology experts I contacted, including Greg Jaffe of the Center for Science in the Public Interest, a consumer advocacy group, said the law was never intended to address food safety or nutrition—about 90 percent of scientists say GMO foods are safe—but about giving consumers information about the production process. (As I’ve reported, disclosing that information was shown to increase consumer acceptance.)

But if the law’s truly about production, as Jaffe says, it stops short of covering highly processed ingredients that are derived from genetically engineered crops, such as corn syrup, vegetable oil, and “refined” sugar from sugar beets. Last year, 94 percent of soybeans, and 92 percent of corn grown in the United States were genetically modified; at last count, so were 95 percent of sugar beets. But oil and sugar derived from these crops don’t have to be labeled, because it’s impossible to distinguish them from their conventional counterparts. Despite what the Castrol commercials would have you believe, oils are just oils, and sugar is just sucrose. Neither substance contains DNA. The only way to distinguish the two would be through supply chain verification.

The question of how labels will appear has also been a hot topic.

Instead, the USDA is encouraging companies to voluntarily disclose that information through a nearly-identical symbol that contains the words “derived from bioengineering.” For Jaffe, that doesn’t go far enough. He feels manufacturers should be required to say when they’re using those oils and sugars.

“The message it sends is confusion, because there are many food manufacturers who want to disclose this information, because they believe that there are consumers who want to know this information,” he says. “You could have similar products with similar ingredients, where one discloses, and one doesn’t, and consumers may not understand that those products could be identical.”

The law is not nearly as stringent as the approach in other countries, such as those in the European Union, where most products are sourced to be non-GMO, obviating the need for any kind of label that would support “consumer choice.” Back in America, manufacturers may choose to continue to bear the voluntary Non-GMO Verified label, which is granted by a third-party certifier. Additionally, organic foods, which must be GMO-free in their supply chains to be certified in the first place, are exempt from the disclosure law.

The rule, which will become effective early next year, sets an initial date for manufacturers of January 1, 2020.

Sam Bloch has written about arts, culture, and real estate for publications including The New York Times, L.A. Weekly, and Artnet. His essay about Los Angeles' "shade deserts" will be published by Places Journal this winter. Reach him by email at: samuel.bloch@newfoodeconomy.org

Brooklyn's Diversity Shines Through Urban Agriculture And Retail Trends

As part of the 2018 New York Produce Show schedule, FreshPlaza attended the Brooklyn Retail and Urban Agriculture Tour on December 13. The tour visited five different places in various parts of the borough, showing the diverse range of produce activities happening now in Brooklyn. From an urban greenhouse to an open air market, there are a lot of dynamic developments here, which could make Brooklyn a barometer for the future of the American produce landscape.

Urban greenhouse strives to attract young people into agriculture

Urban greenhouses are becoming less of a novelty and more of an accepted option for locally-grown produce. This is certainly the case in Brooklyn, with a number of urban greenhouses popping up in recent years. One of these is Square Roots, which was the first stop on the tour. Square Roots is located in a former Pfizer factory in the Williamsburg district and grows primarily herbs along with other greens in shipping containers that have been climate controlled and fitted out with grow lights, water systems and atmosphere control.

The company uses plenty of technology to help it operate and delivers within the local area to stores and restaurants. One of the primary drivers of the company is to draw in more young people into agriculture. "The average age of the American farmer is 58," noted tour leader Karsten Ch'ien of Square Roots. "Growing produce in an urban greenhouse attracts more young people with a passion for farming. A combination of high-tech equipment, the fact that more young people live in large cities with limited land area, and the interest in healthy and locally-grown food has helped drive the growth of urban greenhouses. Square Roots offers training programs and skill building in agriculture to give young people with a passion for fresh produce an opportunity to be a farmer."

On-the-go and convenience prominent

As a busy metropolis in its own right, the trend of convenient, on-the-go produce has established itself firmly in Brooklyn. Two of the stores visited as part of the tour, City Acres in Williamsburg, and Brooklyn Fare in the downtown area, were heavily stocked with a range of pre-packaged salads, healthy meals as well as juices and other healthy drinks.

In City Acres, along with a significant range of organic options, was a section devoted to fresh-cut fruits and vegetables in clamshells. They were all common produce items such as watermelons, cantaloupe, broccoli, cauliflower, and many others, cut up in store to serve the busy patrons. Brooklyn Fare offered cut vegetables and prepared salads by the pound. Each store had a large organic section as well as offering a diverse range of exotic and on-trend fruits and vegetables.

Traditional style open-air markets still have a place

After visiting the gentrified Williamsburg area, the tour continued to the southwest of Brooklyn to one of the few remaining open-air markets in New York City - Three Guys From Brooklyn. Established in 1975, the store never closes and despite the wintry conditions, the array of fruits and vegetables displayed brought a burst of color into the grey day. Here the owners have kept their traditional method of selling high-volume, low-cost fruits and vegetables to serve the local community, from which many nations are represented.

"This is a very diverse neighborhood and our customers prefer the traditional feel and experience of purchasing fruits and vegetables," explained Philip Penta of Three Guys. "Although the cut and prepared market is a growth point, we also focus on growing our wholesale business with local restaurants and hotels. When modernizing, we are careful what we add to make sure we retain the character of the market while also keeping up with modern trends like loyalty cards and home deliveries."

Running this type of market comes with its challenges, but Penta said it is working well for them. "It's very difficult to remain open 24/7 every single day of the year. However, we need to have staff overnight to accept deliveries so we might as well stay open. 25 percent of our business occurs between 10pm and 6am which is remarkable to think about."

New York City's only mushroom farm

After having lunch at Wholefoods and observing the Gotham Greens greenhouse on the store's rooftop, the tour continued towards the Navy Yard to a simple red brick building with no other sign than "No Parking" on the garage. Inside was an entirely different world as we stepped into not only the only organic farm in New York City, but also the only mushroom farm - Smallhold. Not only that, but this farm operates very differently to the traditional grow and sell method. As the name suggests, Smallhold sets up micro-mushroom farms on customers' premises, to offer what is described as "hyper-local" produce. From there, Smallhold maintains control of the farms from its Brooklyn office and workshop.

"We provide a service whereby stores and restaurants can grow their own mushrooms right on the premises," explained co-founder Adam Carter. "If it's a store, they can sell the mushrooms to customers, or in the case of a restaurant, use them in dishes. We nurture the mycelium from which the mushrooms grow until they are ready to grow, then deliver them to the customer's climate-controlled mushroom farm which we set up. Smallhold maintains control of all systems, including airflow, CO2, and temperature. We currently grow ten different mushroom varieties, with oyster being the most popular."

Brooklyn's diversity offers many opportunities

With modern produce trends, customers are seeing more convenience and on-the-go offerings in stores. But Brooklyn is home to many different cultures and backgrounds and therefore the traditional high volume, low-cost, open-air markets are still thriving. The tour also demonstrated there are many young people and other urban dwellers with a passion for agriculture and they have embraced urban farming as a way in which "locally-grown" will have a viable future in big cities.

SOUTH KOREA: Smart Farm At Industrial Site Grows Future Foods

Miraewon’s container-shaped vertical farm is run by a robot that adds and removes seed trays on its own. The climate, including temperature and humidity, is automatically controlled. [LIM HYUN-DONG]

December 18, 2018

PYEONGTAEK, Gyeonggi - Miraewon, a farming company, is in an unlikely place, an ordinary industrial site in northern Pyeongtaek, Gyeonggi. But that’s because it’s a smart-farming company.

On Dec. 3, senior government officials, including the Ministry of Science and ICT’s first vice minister, gathered at Miraewon as it hosted a conference for experts as the government looks to establish research and development reform measures in search of new industries.

The company is at the forefront of smart urban farming, which utilizes technology to grow produce on vertically-stacked layers within a contained environment. Traditional methods rely on vast tracts of arable land. The fledgling smart farming sector is bringing agriculture indoors and promising high-density production without the use of chemicals.

While the company’s building seems like a manufacturing facility from the outside, the 1,160 square meters (12,486 square feet) inside are protected from external contaminants and produce 80 tons of around 20 different types of agricultural goods annually, including herbs and lettuce.

The company not only grows vegetables but also packages the produce, as, for example, salads ready to be sold on store shelves. Combining agriculture and manufacturing, the facility is a model smart farm for the future.

Last year, Miraewon supplied products it grew and packaged to 25 retailers, such as Lotte Mart, Hyundai Department Store, Samsung Welstory and CU, generating 35 billion won ($30.9 million) in sales.

“We reached the break-even point two years ago,” said Kang Dae-hyun, vice president of Miraewon. “For this year, we expect to record around 42 billion won in sales.”

“We plan to expand the vertical farming facility to a size of 700 pyeong [24,908 square feet] and push out full-scale automated lines,” Kang added.

A laptop monitor with details of the controlled environment is placed at the entrance of one of Miraewon’s cutting-edge container-shaped smart farms.

The laptop displays the current temperature, humidity level, pH level and carbon dioxide level, among with other essential climate details required to maintain an ideal environment to grow vegetables.

The smart farm, which specifically grows leafy vegetables such as lettuce, requires no human intervention.

Seed sowing is automated and trays with the sowed seeds are placed under LED lighting in 10-tray shelves stacked 20 centimeters (7.87 inches) apart by mobile robots. Lettuce sprouts are grown for 15 days, and in that period, they are fed with nutrient fluid and carbon dioxide.

All humans need to do is replenish the nutrient fluid and set the climate.

Miraewon’s container-shaped urban farm supplies young leafy plants, while other existing urban farms ship out vegetables.

High-tech farming has advantages over traditional methods.

“Smart farming can steadily supply vegetables through the four seasons. And because it is completely sealed from the outside, there is no need to use pesticides. We produce completely chemical-free food,” said Son Geum-joo, a researcher at Miraewon’s Agricultural Food Research Institute.

“Although the environment is limited, the farm will become price competitive with time as it will generate consistent high-density production,” Son added.

Smart urban farming is now reaching the state of industrialization, going beyond the laboratories of government-funded facilities or universities.

In addition to Miraewon, other companies in the country make use of urban farming. The list includes Agronics and Insungtec. Notable examples abroad include U.S.-based AeroFarms and Japan’s Akisai.

Urban farming is presented as a defense against the dangers of population growth and could help if food shortages are the result. The International Space Station currently operates a vertical farm for astronauts.

“Urban farming was chosen as one of the top 10 urban innovations of 2015 by the World Economic Forum,” said Seo Kyung-choon, the head of the bioscience technology division at the Ministry of Science and ICT.

“As all industries incorporate a form of intelligence and undergo a paradigm shift, urban farming, which combines biology and information and communication technologies, is currently in the spotlight as a promising new industry,” Seo added.

BY CHOI JOON-HO [chae.yunhwan@joongang.co.kr]

Uber CEO And Alphabet Invest In Urban Farming Startup

December 12, 2018

The two-year-old company raised $90 million in funding

Bowery Farming is part of a new wave of ag-tech startups

Farmers work at the Bowery Farming Inc. indoor farm in Kearny, New Jersey. Photographer: David Williams/Bloomberg

Bowery Farming Inc., a two-year-old startup that uses robotics to cultivate crops indoors, is on track for more growth. The New York-based company plans to announce on Wednesday that it raised $90 million from investors including Alphabet Inc.’s GV and Uber Chief Executive Officer Dara Khosrowshahi, said Bowery’s co-founder and CEO, Irving Fain. The company declined to provide its valuation.

Bowery is part of a new crop of agriculture technology startups growing leafy greens in controlled environments near cities. Last year, Plenty, a San Francisco-based vertical farming company, raised $200 million from the Japanese conglomerate SoftBank Group Corp.’s Vision Fund. Bowery grows its veggies in layers of sensor-rich trays that move and react to humidity, carbon dioxide and light. One square foot of Bowery’s indoor farm is 100 times more productive than an equivalent plot of arable land, Bowery says. Plenty makes similar claims.

Rows of produce grow in trays at the Bowery Farming Inc. indoor farm in Kearny, New Jersey. Photographer: David Williams/Bloomberg