Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Hydroponics Gives Local Veg Production Further Boost

It is learnt that hydroponics systems, a technology suitable for Qatar’s environment even during the summer, can grow watermelons extremely well, producing big and sweet varieties.

September 28 2018 08:18 PM

Prominent Qatari agriculturist Nasser Ahmed al-Khalaf showing the watermelons in his farm near Al Khor.

Qatar’s aim for self-sufficiency in food production has got a major fillip as a local farm succeeded in growing and improving the quality of certain types of vegetables and fruits with hydroponics system.

Prominent Qatari agriculturist Nasser Ahmed al-Khalaf told Gulf Times that his farm will harvest in the coming weeks melons and water melons, grown for the first time in the country using hydroponics.

"We have as well increased the (production of various types of) herbs,” disclosed al-Khalaf, who is also the owner and managing director of Agrico.

A private Qatari agricultural development company established in 2011, Agrico produces organic vegetables and fruits year-round in Al Khor using hydroponics systems and aims to help Qatar achieve food security.

Al-Khalaf said that they will be harvesting between 800kg and 1,000kg of watermelons per week from next week while melons would take 30-45 days more. These types of fruits are grown separately in two greenhouses.

Agrico now produces large-size watermelons with hydroponics system

It is learnt that hydroponics systems, a technology suitable for Qatar’s environment even during the summer, can grow watermelons extremely well, producing big and sweet varieties.

While some local farms also produce melons, al-Khalaf pointed out that Agrico uses hydroponic system and aims to grow vegetables and fruits year-round.

“Any new item we introduce we try to make it sustainable in order to supply the market on a daily basis,” he stressed.

In the mushroom family, the company now added shiitake and oyster mushrooms in its production. By next year, it will also grow some hard vegetables such as carrots and beetroots.

Agrico also plans to experiment with growing bananas by the end of this year, apart from organic papayas and other fruits such as lemon and pomegranate.

Al-Khalaf noted that Agrico’s operations expanded substantially in the previous season to further increase its production and meet the growing demand for fresh produce. It is now exporting various vegetable items to Kuwait and Oman.

After proving it can produce year-round in the past years, even during the summer, he pointed out that they developed other greenhouse systems in a much economical price.

“Our aim in 2018 was to focus more in developing our agriculture system in other farms, which we did by developing over 20,000sqm of greenhouses under our own operation,” al-Khalaf said.

“Besides Agrico, we are also keen in developing other farms using our technology and transferring this know-how to improve the farms in Qatar to make production sustainable,” he observed.

Around 300 of the 1,400 farms are continuously increasing their production of various vegetables since last year and this number is also growing, according to al-Khalaf.

"Qatar residents will also see a huge difference in the quality of existing items this season, especially in tomatoes, cucumber, zucchini, capsicum, and eggplant," the agriculturist added.

Tesco’s CEO Calls On Food Industry To Tackle Food Waste

Every year, a third of the world’s food goes to waste.

Posted By: Martin White on: September 25, 2018

Tesco CEO Dave Lewis will today call on the global food industry to be more transparent and publish their food waste data, to ensure that no food goes to waste across the global food chain.

Lewis will announce his call for action at the Champions 12.3 conference in New York today, and a statement from the retailer said that 27 of Tesco’s major suppliers such as Müller Milk & Ingredients, Kerry and Arla will soon publish their food waste data for the first time.

The statement also claimed that major branded Tesco suppliers such as Mars, General Mills and Unilever will commit to measure and publish their food waste data within the next year.

Tesco published food waste figures for its Republic of Ireland and Central European operations for the first time last year, and the retailer claims that it is “70% of the way towards its target that no food, safe for human consumption, goes to waste.”

According to the statement, Lewis will say: “Every year, a third of the world’s food goes to waste. That’s the equivalent of 1.3 billion tonnes of food being thrown away and we think that’s simply not right.

“We hope every country, major city and company involved in the food supply chain publishes their own food waste data, so that together we can take targeted action to reduce waste.

“We believe that what gets measured gets managed. Ultimately, the only way to tackle food waste is to understand the challenge – to know where in the supply chain food is wasted.”

Champions 12.3 is a coalition of executives from governments, businesses and international organisations which aims to halve global food waste at the retail and consumer levels by 2030.

City Roots Owners Talk About Their Decision To Downsize

Urban Farm Gets Back to Its Roots.

By Bach Pham

Sep 26, 2018

Bach Pham

There was a sense of calm between City Roots owners Robbie and Eric McClam as they worked on the field at the farm last week, preparing for the Glass Half Full Festival. After a busy first half of the year, the quiet moment was a welcome turn for the father and son.

The change came by choice.

Founded more than a decade ago, City Roots occupies a few acres in Columbia’s Rosewood neighborhood, near the Hamilton-Owens Airport. But recently, the community-minded urban farm began growing faster, expanding production at a second site.

“This past winter and spring we were scaling the farm from three acres to about an additional 30 acres to which we were planting a dozen or so acres of vegetables,” says Eric McClam. “We basically had five farms: a microgreen farm, a mushroom farm, a flower farm, a vegetable farm, and an agrotourism farm spread across two locations, 15-20 minutes apart. That was fun and exciting, but had its own new set of challenges.”

The size and scope of the changes was immediately felt. City Roots was branching in several directions with production, and struggling to make it all connect.

“We had over 200 different things we were growing between the farms,” Eric says. “No one can do 200 things well.”

The complexity of the farm’s rapid growth brought as many technical issues as it did benefits. City Roots was doing everything: growing, processing and delivering to local restaurants in Columbia and food hubs in Atlanta, Greenville and Charleston nearly every day of the week.

“We had three deliveries going on a day at one time on some occasions,” Robbie says. “We had vans in the shop, car repairs all the time.”

The breaking point hit over the summer when Eric fell ill and was forced to take some time off.

“What precipitated the scaling back and hard look at everything was I literally got shingles from stress this summer and had to stay home for a period of time,” says Eric. “While at home, I had time to take a hard look at what was holding that stress and recognizing that it was the diversity and scale of the farm. Everybody has a grounding moment in their life and says, ‘OK, what is important to me?’ The farm and family are important.

“So after making the hard decisions, we scaled it back to fit what works well for the farm. We recognized that getting better at what we do well and letting go of things that were painful to let go, especially reducing staff — some of whom had been here for many years — was something necessary for the direction of the business.”

Eric calls the decision to lay off employees “the hardest decision.” The farm went from 23 employees to about 15.

“We hope we are still in a good place with everyone. We just didn’t have the ability to retain them. We had to be nimble and change course. My role as the head farmer is to steer the ship. We were heading for a ditch, and we needed to get back on course.”

The McClams made several major changes in the past few months. Production at their second site was halted, and the community supported agriculture (CSA) program was cut.

“When we first started, the CSA was exciting and a good business model for us,” says Eric. “We never could quite get the volume of CSA we needed to make that diversified larger scale work, though. … We realized that we’re better suited to do a variety of things and bringing those to market and doing it that way.”

While the field side of the farm struggled to find the right identity, two parts of the farm actually have grown over the years: microgreen and mushroom production.

Microgreens went from being a small portion of the farm in the beginning to quickly becoming the biggest component of City Roots, seen not just in Columbia, but everywhere in the South from menus in Charleston to shelves in every Whole Foods in the Southeast.

“A lot of people grow organic vegetables, but not a lot of people grow microgreens and mushrooms,” says Eric. “Those are what we’re most known for, that’s our niche market and what works really well for us.”

City Roots plans to shift their focus to sharpening their microgreen and mushroom production, maintaining some small-scale flower production, and simply putting more time into the urban farm itself.

“We’re going to be putting more landscaping around the farm, more shrubs and trees, making the farm a prettier place and improving it as an event venue,” Eric says. “I’m excited about putting more emphasis here at the home farm and getting back to the roots at City Roots.”

Eric still plans to maintain the educational aspect of the farm. This year they doubled the number of school tours from last year, and plan to continue finding ways to share the farm with the community. They have also been exploring pickling, dedicating a portion of the farm to growing root vegetables and plants like ginger to contribute towards different recipes to sell at the farm.

There is still hope to do some large-scale gardening, especially with one particular product that has become a much-talked about agricultural item: hemp. The farm applied for the industrial hemp pilot program run by the South Carolina Department of Agriculture and is currently in the running to be one of the 40 farms certified to grow hemp in South Carolina.

“We are excited about that potential,” says Eric. “It’s a new niche market that we see a lot of potential for growth.”

China's Scientists Observe Plant Growth in its Space Lab

They are trying to accomplish full-cycle of plant growth under microgravity.

CGTN 2018-09-27 20:13

Astronauts need a lot of food during their space expedition that sometimes takes nearly two years. Carrying dried prepackaged food takes up space in their spacecraft.

One solution is to send seeds that occupy less volume to cultivate them in the space. Recently, scientists have successfully grown vegetables and plants in the space shuttles.

However, microgravity makes it difficult to water the plants as they clump together. Space scientists at NASA started using hydroponics and aeroponics to grow plants in space stations.

While hydroponics delivers water to plant roots, aeroponics ensures misty air conditions for plants' growth.

Chinese scientists have taken this experiment to the next level at Tiangong-2, a space laboratory.

They are trying to accomplish full-cycle of plant growth under microgravity. Boxes containing rice and Arabidopsis, a small flowering plant, are on board the space lab.

"After the seeds arrive in space, they will grow and mature there, and finally yield seeds. This kind of long-term experiment is quite rare in the international community," Zheng Huiqiong, director of Tiangong-2's space biotechnology and the plant cell engineering research team said.

"It is of great importance because it can help solve one of the key problems to providing necessary food, water, and oxygen to humans," Zheng explained.

The research found that under the conditions of microgravity, the flowering of Arabidopsis occurs 22 days later than on the ground.

"If we need to eat leaves in the future, it is better to have plants that flower late. But for rice, late flowering will influence the yields, so we have to adapt it to the environment," said Zheng.

The research also found that rice is more active in guttation under the conditions of microgravity, meaning it exudes more and more significant drops of sap on its leaves.

"This phenomenon has advantages and disadvantages. On the one hand, bigger sap drops will influence the growth of the plant because it will increase the humidity. On the other hand, it offers us clues to establish an effective life-support system in the future, so we could provide water to humans via plants," said Zheng.

Economics of Urban Ag

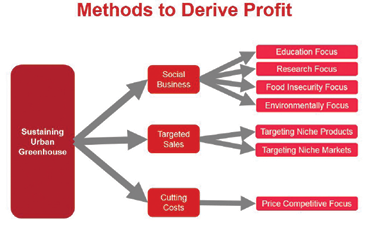

Targeting high-value, niche markets or products, and adapting a social business model can help urban greenhouses derive profit.

September 27, 2018

Robin G. Brumfield and Charlotte Singer

Editor's note: This article series is from the Resource Management in Commercial Greenhouse Production Multistate Research Project.

Urbanized agriculture is gaining momentum in response to increasing demands for locally produced fresh vegetables. Greenhouse or indoor vegetable production to meet local demands is the backbone for this evolving scenario. The viability of various indoor crop cultivation options demands proper documentation to guide appropriate recommendations that fit different production circumstances for growers.

Brooklyn Grange’s Brooklyn Naval Yard Farm

Photo courtesy of Brooklyn Grange

Recently a popular trend toward eating local, deemed being a locavore, evidenced by a growing social movement, has evolved (Osteen, et al., 2012). While the benefits of buying food locally are debated due to the economics of comparative advantages, consumer groups support urban agriculture for a number of reasons, such as to support local farmers; to provide local, fresh food in inner city deserts; to buy fresh food; to know from where their food is coming; and to respect the environment (Peterson, et al., 2015). Specifically, one study found that 66 percent of those surveyed welcomed more local food options because local food supports local economies (Scharber and Dancs, 2015).

Many consumers also cite environmental impacts as a reason to buy local, evidenced by one study finding that environmental factors were an important reason to buy locally grown food for 61 percent of those surveyed (Scharber and Dancs, 2015; Reisman, 2012). Another popular reason is to reduce food insecurity. USDA defines food insecurity as “a household-level economic and social condition of limited or uncertain access to adequate food” (USDA ERS, 2017). Buying locally grown food can reduce food insecurity in that having local farms provides consumers who might not have previously had access to fresh produce the opportunity to purchase it. Some urban farms make a point of targeting food insecurity, and having local farms allows a city to rely less heavily on external markets to feed its population. Despite debate of realized benefits, consumers eat local food to feel good about it (Scharber and Dancs, 2015).

High capital costs

The low supply of special varieties such as these microgreens can drive a higher price to help cover the high costs of running a greenhouse.

Photo courtesy of Robin G. Brumfield

Regardless of the strength of their consumer base, the number of urban farms is still low due to the high costs that urban farmers face compared to rural farmers. Not only is the land more expensive, but also the limited plot size and probable contamination of the land with lead and toxins essentially necessitates the use of a greenhouse with high investment costs. Cost challenges that many urban greenhouse farmers face include securing funding, finding economies of scale, and facing high capital and operating costs. The energy necessary to heat a greenhouse through the winter makes utility costs high, the most productive greenhouse technologies are expensive, and land is of much higher value in cities than in rural areas (Reisman, 2012). Not to mention, the initial infrastructure cost involved in building a greenhouse is much higher than the costs that farmers growing in a field face. The costs of urban greenhouses vary greatly depending on size and type. The construction of, for example, a hydroponic greenhouse entails costs for site preparation, construction, heating and cooling equipment, thermostats and controls, an irrigation system, a nutrient tank, and a growing system (Filion, et al., 2015).

Another problem with growing in cities is shade from tall buildings and skyscrapers. Jenn Frymark, chief greenhouse officer at Gotham Greens, cites this as the primary reason that the business built rooftop greenhouses. This creates its own set of problems and increases costs compared to standard greenhouses on the ground. Other urban producers address the shade problem in cities by producing in buildings using vertical agriculture and artificial lights. However, this increases the costs even further because of the need for light all year. These high costs keep the number of urban farms small.

Marketing: quality optimization, high-value plant products, year-round production

Due to these high costs, urban greenhouses must derive profit in creative ways, such as targeting high-value niche products or markets, and producing year-round. Targeting niche products and markets allows urban farmers to charge a premium that covers the added costs of operating in the city. Targeting a niche product could entail producing special varieties of vegetables, like how Brooklyn Grange, a successful New York City-based greenhouse, grows microgreens and heirloom tomatoes. The low supply of these special varieties can drive a higher price to help cover the high costs of the greenhouse. To increase profitability, farmers can also find a high-end market (Sace, 2015).

Targeting a niche market could entail selling produce to high-end restaurants and supermarkets, such as Whole Foods, whose customers are already expecting to pay a premium price, or it could entail marketing produce specifically to locavores. In fact, one study found that, for example, consumers were willing to pay a $1.06 price premium on one pound of locally grown, organic tomatoes. In the same study, the researchers also found that urban consumers were more likely to buy locally grown produce, compared with rural consumers (Yue and Tong, 2009). The high costs associated with living in a large city means that cities have a high concentration of people who can afford to eat local in this way, and the demographics of large cities translate to a high concentration of people who also see value in eating locally produced food. Together, these create a market of locavores willing and able to pay a premium for locally grown produce.

By targeting niche products and markets, urban greenhouse farmers can take advantage of existing high-end markets to cover their relatively high costs. Since these producers use greenhouses, and a few use indoor facilities, they can produce year-round, thus providing a constant supply and a steady demand for their products.

Harlem Grown in New York gives students the opportunity to learn about agriculture and the food system in a hands-on nature.

Photo: Instagram: @harlemgrown

Agricultural jobs in urban settings and other social values

Adapting a social business model can open urban farmers up to alternate sources of funding. They may want to provide jobs to disadvantaged groups such as low-income inner-city dwellers, or people with autism. Some of these businesses have reduced labor costs through volunteerism, as individuals may be willing to volunteer on a farm that supports a social issue (Reisman, 2012). Some examples of causes that urban greenhouse social businesses focus on include education, research, the environment and food security. Harlem Grown in New York adds an educational component to the greenhouse, namely the opportunity for students to learn about agriculture and the food system in a hands-on nature, allowing the greenhouse to become eligible for funding from schools, governmental programs or donors particularly interested in education.

Targeting niche markets or products, adopting a social business model and finding inexpensive plots of land can help urban greenhouses derive profit.

Graphic: Charlotte Singer

Other urban greenhouses can, for example, pitch themselves to city dwellers as an environmentally friendly alternative to commercial farms, using less fuel for transportation and fewer chemicals. This could again render the greenhouse eligible to new sources of funding. AeroFarms in Newark, New Jersey, has adapted a combination of the previous two models. It uses environmentally friendly techniques and collaborate with Philip’s Academy Charter School (Boehm, 2016).

Greenhouses can additionally focus their business models on alleviating food insecurity by providing fresh produce to urban food deserts (US. New York State Energy Research and Development Authority, 2013). Unlike the previous cases, greenhouses that choose to focus on alleviating food insecurity would not be able to additionally use the method of targeting high-end markets, unless they make an effort to use the high-end markets to subsidize the cost of providing their produce to food deserts. An example of an urban farm targeting food insecurity is World Hunger Relief Inc. in Waco, Texas, which brings produce grown in its greenhouse to food deserts in the City of Waco at a market or discount cost. What these three options share is a business model that incorporates multiple bottom lines, which allows them access to new funding and volunteer labor to reduce costs.

As consumers increasingly look to eat locally produced food, for reasons such as to support the local economy, to protect the environment, to change food deserts and to understand better where food is coming from, urban agriculture is becoming a growing trend. Targeting high-value, niche markets or products, and adopting a social business model to provide agricultural jobs in urban areas, constitute some of the ways urban greenhouses to derive profit in a capital-intensive industry. By utilizing these techniques, individuals looking to start their own urban greenhouses can add value to their business and derive profit.

VIA 57 West

VIA 57 West, a decidedly fantastic architectural mash-up with resident connection to views and nature

Linda Velazquez on September 24, 2018 at 2:50

VIA 57 West

22,000 sf Courtyard Greenroof

New York, NY, USA

Greenroofs.com Featured Project September 24, 2018

With the launch of our website redesign today, what better way to follow up the awesome Venice-Mestre Hospital (Ospedale dell’Angelo Mestre – Angel Hospital) than with the over-the-top VIA 57 West, a decidedly fantastic architectural mash-up with resident connection to views and nature at the forefront of its design strategy?

And the fact that BIG is one of my personal favorite team of architects just sealed the deal.

We also chose VIA 57 West this week in honor of CitiesAlive 2018– Green Infrastructure: Designing the Future of Resilience held in NYC starting today, September 24 and running through Friday, September 28. Brought to you by Green Roofs for Healthy Cities, this year’s conference theme focuses on how green infrastructure builds resilience and equity in cities.

New York City has had quite a ride with an early array of beautiful and sensitive greenroof projects, and VIA 57 West adds a splash of the dramatic to its list of greened buildings.

Image courtesy of BIG, ©Iwan Bann

Mini Description & Details

Comprised of VIA, FRANK and Helena, the 57 WEST Superblock is an oasis in one of New York’s most vibrant neighborhoods. Designed by Bjarke Ingels Group (BIG), the multi-award winning 35-floor VIA 57 WEST is redefining green living with a vision of sustainability that both respects nature and promotes wellbeing.

And its gleaming tetrahedron shape is an immediately recognizable presence on Manhattan’s West Side. A hybrid between the European perimeter block and a traditional Manhattan high-rise, VIA 57 West combines the advantages of both typologies: the compactness and efficiency of a courtyard building with the airiness and the expansive views of a skyscraper.

Image courtesy of Starr Whitehouse

Image courtesy of BIG

By keeping three corners of the block low and lifting the north-east corner up towards its 450 ft peak, the courtyard opens views towards the Hudson River, bringing low western sun deep into the block and graciously preserving the adjacent Helena Tower’s views of the river.

The form of the 77,202 square meter building shifts depending on the viewer’s vantage point. While appearing like a pyramid from the West-Side-Highway, it turns into a dramatic glass spire from West 58th Street.

Image courtesy of BIG, ©Iwan Bann

Image courtesy of BIG, ©Iwan Bann

Designed by Starr Whitehouse, the design of the open-air landscaped courtyard shares the exact proportions as Olmsted’s Central Park, planted with 47 species of native plant material including over 80 trees and lawn.

Starting in a grove of fern and birch, the path meanders up one story into a plaza that recalls a forest glade. Crossing through a fog feature, the path climbs a flight of stairs to arrive on a platform overlooking the Hudson. At this rocky summit, visitors can barbecue, enjoy the view, or sunbathe on a grassy knoll beneath a honey locust, surrounded by sumac, pine, and meadow grasses.

Image courtesy of Starr Whitehouse

Image courtesy of Starr Whitehouse

The single-source greenroof system chosen for Via 57 West is the Garden Roof Assembly® with Waterproofing Monolithic Membrane 6125® from American Hydrotech.

Built with an array of sustainable features and materials – not to mention stunning, unsurpassed vistas across the Hudson River and Manhattan – the spacious alfresco courtyard sky garden beckons to become a part of the engaging VIA 57 West community.

Image courtesy of BIG, ©Iwan Bann

Image: VIA 57 West Facebook page.

Year: 2016

Owner: The Durst Organization

Location: New York, NY

Building Type: Multi Use, Multi-Family Residential

Greenroof Type: Intensive

System: Single-Source

Size: 22,000 sq.ft.

Slope: 5%

Access: Accessible, Private

Image courtesy of Starr Whitehouse

Credits:

ARCHITECT: BIG

PROJECT ARCHITECT: David Brown, BIG

EXECUTIVE ARCHITECT: SLCE Architects

LANDSCAPE ARCHITECT: Starr Whitehouse Landscape Architects and Planners

STRUCTURAL ENGINEER OF RECORD: Thornton Tomasetti

MEP ENGINEER OF RECORD: Dagher Engineering

CIVIL ENGINEER: Langan Engineering

MAIN CONTRACTOR: Hunter Roberts Construction Group

FAÇADE CONSULTANT: Enclos Corp., Vidaris, Inc.

TRAFFIC CONSULTANT: Philip Habib & Associates

VERTICAL TRANSPORTATION CONSULTANT: Van Deusen & Associates

ACOUSTICS CONSULTANT: Cerami & Associates

WIND CONSULTANT: CPP (Cermak Peterka Petersen)

ENVIRONMENTAL CONSULTANT: AKRF and ROUX Associates, Inc.

LIGHTING CONSULTANT: Brandston Partnership Inc.

GREENROOF SYSTEM: American Hydrotech Roof Garden Assembly®

Image courtesy of BIG, ©Iwan Bann

All the Info:

View the VIA 57 West project profile to see ALL of the Photos and Additional Information about this particular project in the Greenroofs.com Projects Database.

Image courtesy of BIG, ©Iwan Bann

Featured Project

Watch the VIA 57 West Featured Project Video above or see it on our GreenroofsTV channel on YouTube.

Greenroofs.com Featured Project 9/24/18 video photo credits: Courtesy of BIG, ©Iwan Bann and ©Nic Lehoux; Starr Whitehouse, ©Iwan Bann and others; and American Hydrotech, ©Kirsten Bucher.

Did we miss your contribution? Please let us know to add you to the VIA 57 West profile.

Would you like one of your projects to be featured on Greenroofs.com? We have to have a profile first! Submit Your Project Profile.

Love the Earth, Plant a Roof (or Wall)!

By Linda S. Velazquez, ASLA, LEED AP, GRP

Greenroofs.com Publisher & Greenroofs & Walls of the World™ Virtual Summits Host

Geothermal Energy May Make Indoor Farming Work in The Future

The farms of the future may be possible even in an urban setting with the right alternative energy.

September 27, 2018 By JULIE CAMPBELL

The farms of the future may be possible even in an urban setting with the right alternative energy.

Technology and geothermal energy advances are sending farming indoors on an increasing basis. This is the case both with urban greenhouses on a smaller scale or larger scale greenhouses.

The primary challenge with these types of greenhouse have to do with the energy they need.

Greenhouse operation is energy intensive, with high demands for electricity because of lighting, but, more importantly, heating. It is in the area of heating that geothermal energy presents a significant opportunity.

As populations rise and the demand for local food production increases, indoor farming may become much more important even in urban settings, according to a recent World Economic Forum article. That said, in order to make that financially feasible, producers need to look to affordable alternative energy options.

These urban operations rely on using every square inch to its greatest potential, as space is much more limited. Moreover, everything must operate on less water. That said, as these indoor farms – small or large in size – have the same heating and lighting requirements as a traditional farm. This requires affordable sources of energy.

Many in the industry believe geothermal energy will be among the leading solutions for indoor farming.

Among the reasons that many will look to geothermal energy is that there are already many success stories with this technology. It is not only receiving increasing attention from those in the industry, but it has also already proven itself in many examples.

For example, one of the largest flower producers in Kenya, called Oserien, uses geothermal power for heating as well as small-scale electricity production. In the Netherlands, energy is becoming increasingly expensive, so geothermal wells are being drilled for many greenhouse operators that need heat. Iceland has widespread geothermal energy heating in its greenhouses to make it possible to grow vegetables throughout the year.

Germany is home to several geothermal power projects being developed to use this resource for their greenhouse operator heating. A new effort has also been underway in Pagoda Springs, Colorado, where it is being used for vegetable production on top of broadening economic development.

Reusing Shipping Containers: Thinking Outside The Box

Let us introduce you to some of the creative-minded people who - literally - think outside the box!

By: AJOT | Oct 04 2018 | Intermodal News

Boots are made for walking and containers are made for shipping, right? Well, not if you ask everyone! Today, we see an exhilarating creativity in the reuse of shipping containers - living spaces, hotels, bars, pop-up stores, emergency shelters, bridges, art projects, and urban farming - the list goes on. Greencarrier Liner Agency loves the idea of recycling and innovation. Let us introduce you to some of the creative-minded people who - literally - think outside the box!

Urban farming – growing crops inside shipping containers

Freight Farms has found a way to grow crops inside shipping containers. Their hydroponic farming system called The Leafy Green Machine uses hi-tech growing technology to transform discarded shipping containers into mobile farm units. Each farm can produce as much food as a two-acre plot of land on a much smaller plot than is required by traditional crops.

As the outdoor climate has no impact on the conditions inside the container, food can be produced throughout the year and in any location. The project truly taps into the growing trend for urban farming and reduces the ecological footprint of food production.

Life uncontained – living inside Evergreen Line shipping containers

For the claustrophobic reader, it is now time to cover your eyes! After spending years not knowing what to do with their lives, this couple decided to chase what made them happy. Inspired by their past road trips, the hippies of the seventies, and Elon Musk, they chose to risk everything: They sold their traditional home, quit their jobs, and moved from Florida to Texas to build their dream debt-free net zero shipping container home using a couple of Evergreen Line Shipping containers. Are you intrigued? Follow their journey on YouTube!

A piece of container artwork you just can’t take your eyes off

As a part of his project “Women are Heroes,” the French artist JR turned shipping containers into a stunning piece of floating art. The picture assembled on the containers represents the eyes of a woman called Elisabeth who lives in the Kibera slums in Nairobi. When JR met and photographed her, she said “Make my story travel with you.” Using thousands of strips of paper placed by dock workers on the sides of the containers, JR created two eyes gazing at the world while travelling the oceans – two eyes belonging to women who will never travel across those oceans – made possible by art.

Container skyscrapers to replace slum housing

CRG Architects have come up with the concept for Container Skyscraper. The idea is to provide temporary accommodation to replace slum housing in developing countries. As many cities are facing unprecedented demographic, environmental, economic, social and spatial challenges, stacking recycled shipping containers to create cylindrical-looking towers can create high-density, cost-effective housing in urban areas. This is a truly innovative idea both in terms of CSR and the environment.

Container village startup hub for young companies

Dutch architect Julius Taminiau has created a temporary startup hub in Amsterdam using shipping containers. He has turned a derelict patch of land into a low budget, temporary space for young companies. In this dynamic village, the startups will inspire, collaborate across sectors, exchange knowledge and produce unexpected and paradigm-shifting creations. As the containers are placed upon concrete tiles, everything can be reused when the village is taken apart in the future and no trace will be left – an eco-friendly and innovative solution, which we are all about at Greencarrier Liner Agency!

3 reasons for reusing shipping containers.

As exemplified above – shipping containers can be so much more than just a box to ship commodity in. The reason for reusing shipping containers for other purposes than shipping is not only that they are extremely flexible, can solve a bunch of problems and be used in such innovative, unique, creative and cool ways – there is much more to it.

When containerisation conquered the global trade, shipping containers were standardised for intermodal freight transport. The standardisation made it possible to transport larger freight volumes and use different modes of transport without having to unload or reload the goods. Today, shipping containers still serve their purpose, but also provide great advantages when used as Intermodal Steel Building Units (ISBU).

1. Shipping containers are excellent construction material

From a structural point of view, containers are excellent construction material. As they spend the majority of their lifetime outdoors, the material is ideal for exposure to the elements of nature. The steel construction and design provide protection and strength as well as structural support and a long lifespan. The corner assemblies and locking mechanism also provide stability when multiple containers are being used in the construction of a building.

2. Buying empty shipping containers can be cost-efficient

Looking at costs, the reuse of shipping containers can be cost-efficient. A shipping container’s initial purpose is to carry cargo at sea, therefore it has to be cargo worthy throughout its lifespan. Most containers are finished as shipping containers after ten years in service and they are being replaced. Even though container stock is tight for most shipping lines, there is a big aftermarket for those replaced units retired from service at sea. To use those units as building material is inexpensive compared to traditional materials, such as wood, bricks or steel.”

3. Reusing shipping containers is sustainable construction practice

Recycling of any sort is eco-friendly. This is especially true when it comes to reusing shipping containers. It is, without doubt, sustainable construction practice; recycling unused containers for construction material puts an unused product to use while at the same time cleaning up spaces such as ports and shipyards. Shipping containers are also excellent for making use of solar power and can be insulated with eco-friendly materials.

CubicFarm Systems Readies For Expansion Into Cannabis Sector As Bevo Agro Prepares To Become Zenabis Global

Bevo introduces CubicFarm Systems Corp. (CubicFarms), an agriculture technology business that was developed by the Bevo management team.

On October 4, 2018, Bevo Agro announced that it had signed an Arrangement Agreement with Sun Pharm for a reverse take-over of Bevo, and announced its intent to change its name to Zenabis Global. Zenabis will have nearly 3.5 million square feet of available production space.

Now, Bevo introduces CubicFarm Systems Corp. (CubicFarms), an agriculture technology business that was developed by the Bevo management team. As part of the Arrangement Agreement cited above, Bevo's ~43% equity ownership in CubicFarms will be spun out to Bevo's existing shareholders, and CubicFarms intends to simultaneously list on the TSXV as a separate company. Zenabis (through Sun Pharm) also holds a stake in CubicFarms that it will retain post-amalgamation. This investment will be held by Zenabis Ventures, Zenabis' wholly-owned cannabis venture platform.

CubicFarms is the developer of patented technology that automates large-scale commercial farming operations in climate controlled growing chambers. By recycling water, each crop uses a fraction of the water required under traditional farming methods. Further, each machine is constructed inside an individually climate controlled growing chamber, allowing optimized climate, lighting, nutrients and other plant-specific needs, leading to faster growing cycles and year-round production. Utilizing CubicFarms' patented "undulating path" conveyor system, all plants are brought to those harvesting and planting, reducing labour significantly and increasing yield per cubic foot compared to other growing systems.

CubicFarms currently grows lettuce and leafy greens; microgreens; and basil and herbs. CubicFarms is also exploring cannabis cultivation applications in a joint venture with Zenabis named ZenCube. In addition, CubicFarms is further optimizing the technology for the nutraceutical and animal feed space.

CubicFarms has been building and selling systems since 2016, with its systems shipped from a state-of-the-art manufacturing facility. This facility is ramping up production to meet CubicFarms' growing global sales pipeline. CubicFarms operates its own commercial scale CubicFarm system, which it installed this summer in Pitt Meadows, British Columbia. This facility grows and sells a wide variety of leafy greens to the local retail and wholesale market, and also accommodates research and development.

"I am delighted that Zenabis sees the value in automating the growing process and reducing the space and labour requirements through utilizing CubicFarms technology to advance their growing capacity," said Dave Dineson, CEO of CubicFarm Systems Corp. "The joint venture between CubicFarms and Zenabis will make available cannabis-optimized growing machines for global customers who want to lower their growing costs, increase yields, reduce labour, water and energy usage, eliminate pesticides, and enjoy consistent quality growing."

"It's exciting that CubicFarms can expand on its patented technology to enter into a whole new vertical market," said Leo Benne, Chief Growing Officer of Bevo (Zenabis Global). "CubicFarms offers growers unparalleled accuracy and predictability, so that no crop ever goes to waste, while saving money and time by using a fraction of the resources."

"As a leading licensed producer of cannabis, we have long admired the pioneering technology introduced by CubicFarms," said Rick Brar of Sun Pharm Investments, the new CEO of Zenabis. "We look forward to working in partnership to help CubicFarms expand into worldwide markets as Zenabis continues to meet the growing global demand for cannabis."

For more information:

CubicFarms

cubicfarms.com

Publication date : 10/11/2018

Farming The Cities: An Excerpt From Nourished Planet

Worldwide, there are nearly a billion urban farmers, and many are having the greatest impact in communities where hunger and poverty are most acute.

The following is an excerpt from Nourished Planet: Sustainability in the Global Food System, published by Island Press in June of 2018. Nourished Planet was edited by Danielle Nierenberg, president of Food Tank, and produced with support from the Barilla Center for Food & Nutrition.

By 2050, 70 percent of the world’s people are expected to live in urban areas, and if we’re going to feed all those people, we’ll need to continue to make cities and towns into centers of food production as well as consumption. Worldwide, there are nearly a billion urban farmers, and many are having the greatest impact in communities where hunger and poverty are most acute. For example, the Kibera Slum in Nairobi, Kenya, is believed to be the largest slum in sub-Saharan Africa, with somewhere between 700,000 and a million people. In Kibera, urban farmers have developed what they call vertical gardens, growing vegetables, such as kale or spinach, in tall empty rice and maize sacks, growing different crops on different levels of the bags. At harvest time they sell part of their produce to their neighbors and keep the rest for themselves.

The value of these sacks shouldn’t be underestimated. During the riots that occurred in Nairobi in 2007 and 2008, when the normal flow of food into Kibera was interrupted, these urban “sack” farmers were credited with helping to keep thousands of women, men, and children from starving.

The role urban farmers played in saving lives in Kibera is probably only a precursor of things to come. In large parts of the less developed world, as much as 80 percent of a family’s income can be spent on food. In countries where wars and instability can disrupt the food system and where the cost of food can skyrocket overnight, urban agriculture can play a fundamental role in helping prevent food riots and large-scale hunger. In that respect, promoting urban agriculture isn’t only morally right or environmentally smart, it’s necessary for regional stability.

But urban agriculture isn’t important only in sub-Saharan Africa or other parts of the developing world. In the United States, AeroFarms runs the world’s largest indoor vertical farm in Newark, New Jersey, where it grows greens and herbs without sunlight, soil, or pesticides for local communities in the New York area that have limited access to greens and herbs. Another group, the Green Bronx Machine, which is based in New York City’s South Bronx neighborhood, is an after-school program that aims to build healthy, equitable, and resilient communities by engaging students in hands-on garden education.

Across the Atlantic, in Berlin, Germany, a group called Nomadic Green grows produce in burlap sacks and other portable, reusable containers. These containers can be set up in unused space anywhere, ready to move should the space be sold, rented, or become otherwise unavailable. In Tel Aviv, Israel, Green in the City is collaborating on a project with LivinGreen, a hydroponics and aquaponics company, and the Dizengoff Center, the first shopping mall built in Israel. This collaboration provides urban farmers with space on the top of the Dizengoff Center to grow vegetables in water, without pesticides or even soil. Green in the City also provides urban farming workshops and training in the use of individual hydroponic systems.

First Automated Indoor Farm In The U.S. Will Grow Greens For Whole Foods

America is about to get its first fully automated indoor farm.

BY KRISTIN HUNT

1 MONTH AGO

America is about to get its first fully automated indoor farm. This one-of-a-kind site will use robotics and artificial intelligence to grow fresh produce for supermarkets across the United States, including national chains like Whole Foods.

The farm is underway in Hamilton, Ohio — a city just 20 miles away from Cincinnati, where the company behind this innovative project is based. 80 Acre Farms has been on the vertical indoor farming scene since 2015, but this expansion will mark a dramatic increase in production.

The new farm will span over 150,000 square feet, or roughly 3.4 acres, and grow crops ranging from microgreens to kale. Once construction is complete, 80 Acres Farms will supply Whole Foods, Jungle Jims, U.S. Foods, Dorothy Lane Markets, and other food sellers and distributors with veggies year-round.

"We already have demonstrated that we can provide to our customers the freshest, best-tasting and nutritious locally-grown produce, while using renewable energy, very little water, and no pesticides," Mike Zelkind, co-founder and CEO of 80 Acres Farms, said in a press release.

"With the Hamilton facility we will achieve the next-generation of indoor vertical farming using best of breed technology. This project will deliver our proof of concept that indoor farming can be fully-automated, commercially scalable, higher-yielding, and profitable.

"It will serve as a prototype for our ambitious plans to co-locate similar facilities with commercial customers in other parts of the country."

80 Acres Farms uses a hydroponic system that nourishes plants with minimal resources. Hydroponic farming typically requires no soil, no pesticides, and much less water than traditional growing methods, making it the technique of choice among many sustainable food makers.

Indoor farms also allow for better temperature control. With four walls and a roof, growers can keep the environment as warm, cool, or mild as they like — meaning no crop is ever out of season.

They’re also not an energy drain. Thanks to efficient LED lights that nurture the plants’ growth, 80 Acres can manage its power needs. That efficiency extends to the day-to-day operations, which will be bolstered by artificial intelligence, data analysis, robotics, monitors, and control systems.

Despite the robot assistance, the farm will create 40 jobs with an average $40,000 to $50,000 salary — plus benefits.

"Hamilton thanks 80 Acres Farms for its investment in our city," Pat Moeller, the mayor of Hamilton, said in the release.

"80 Acres' high-tech indoor farm efficiently grows fresh produce that will continue to be sold locally. I have had the opportunity to purchase 80 Acres produce and really enjoyed the fresh, flavorful taste."

According to CNBC, the farm’s projected cost is somewhere between $10 and $15 million. Hamilton officials and 80 Acres Farms expect the first phase of the project to wrap by the end of this year, with three additional phases to follow after that.

It’s unclear when the new farm will be open and ready for business, but once it is, it could have a significant impact on the way the U.S. grows and sells food.

Indoor Farm Celebrates Groundbreaking in Welland

A new indoor farm is coming to Welland, phase 1 of the 20,000 sq. ft. industrial facility is about to get underway.

June 26, 2018 | Posted by: Erie Media

A new indoor farm is coming to Welland, phase 1 of the 20,000 sq. ft. industrial facility is about to get underway.

Niagara Holdings Canada announced Monday June 25/2018 that construction is about to get underway. They celebrated the start of this phase with a ground breaking ceremony at the Enterprise Industrial Subdivision at Hwy. 140 and Ridge Rd.

” Well connected infrastructure, ready access to markets, business friendly incentive programs like the Gateway Community Improvement Plan and the proactive and dynamic attitude of officials from the City of Welland and Niagara Foreign Trade Zone, are the main reasons we chose Welland”, said Clarence D’Souza, President of Niagara Holdings in a press release.

Local and federal dignitaries attended the celebration.

Niagara Holdings held it’s groundbreaking ceremony Monday at the location of its new facility in Welland. Photo submitted

Niagara Centre M.P. Vance Badawey congratulated all those involved in bringing the project to Welland.

“Great work by all partners to bring this all together,” Badawey said.

”This project exhibits investor confidence in South Niagara,” he said. “This confidence is a reflection of our current designations as a Gateway Economic Centre and Foreign Trade Zone and our overall proximity to markets. Our ability to work together continues to strengthen our economic performance, globally.

The “purpose built” facility will be the housing for “sophisticated and automated indoor farms in the world,” the press release said.

It is the first on this scale in Canada.

The design is for high volume production of leafy green vegetables. Romaine, Arugula, Kale and Basil are the primary products to be produced at this facility.

The operators for the facility are going to be Intravision Greens (Canada).

“lntravision Greens (Canada), together with lntravision Group Norway (http:/ /www.intravisiongroup.com/), is a leading provider of technology featuring broad spectrum lighting and full system integration. Backed by technology perfected at the University of Guelph’s Controlled Environment Systems Research Facility, the company’s focus is on multi-band and spectrum variable LED lights, enabling biological control and optimization of plant responses to specific wavelengths between UV A and IR light,” the press release said.

“The location in Welland, with its ability to scale up rapidly, it’s green and clean environment and close proximity to several key markets, is of considerable strategic value”, said Amin Jadavji, President of lntravision Greens (Canada) in the release.

The building contract has been award to Timbro, “one of Welland’ s best known engineering firms, with over l 00 years of experience in Ontario,” the release said.

Operations are targeted to begin in the first quarter of 2019.

Moleaer Helps Big Tex Urban Farms Donate More to Local Community With Oxygen Nanobubbles

Big Tex Urban Farms wanted to incorporate an innovative solution that would help them grow more food per square foot to provide more produce to their local community.

By urbanagnews -

October 3, 2018

Moleaer, the leading manufacturer of industrial-scale nanobubble generators, announces that the Big Tex Urban Farms has installed its Boost nanobubble generator to increase crop production. Throughout the growing season, Big Tex Urban Farms donates all its produce to local Dallas area organizations.

Big Tex Urban Farms wanted to incorporate an innovative solution that would help them grow more food per square foot to provide more produce to their local community. After evaluating several options, they chose Moleaer’s nanobubble generator. The generator boosts the deep-water culture’s dissolved oxygen content through oxygen-enriched nanobubbles. When roots are exposed to oxygen- enriched nanobubbles combined with elevated dissolved oxygen content, they can absorb nutrients more effectively, translating into higher yields and ultimately, more food for the local community.

When Big Tex Urban Farms lost power, temperatures in the greenhouse soared above 110 degrees Fahrenheit. The nanobubble-infused water was able to mitigate the effects. Nanobubbles are unique because they are neutrally buoyant and remain suspended in water for long periods of time. In this capacity, they act like a battery, maintaining dissolved oxygen in the water beyond the point of aeration. When the farm lost power, the nanobubbles saved the crop by keeping the plants healthy until power was restored. The tank that did not incorporate a nanobubble generator experienced significant losses, demonstrating a unique benefit of nanobubbles in high-temperature applications.

Moleaer Inc., nanoBoost-enhanced roots on far left

“Big Tex Farms State Fair Project is all about growing, harvesting, and donating produce. We give everything that we grow away to the local community,” said Drew Demler, Director of Horticulture at the State Fair of Texas. “We are trying to feed people and we think that the Moleaer nanobubble system is going to be a big part of how we can get more fresh produce to South Dallas.”

About Moleaer

Moleaer (Latin for tiny air) is a Los Angeles based company that develops industrial scale nanobubble generators to enhance a wide range of processes. Nanobubbles do not float, have immense surface area and stay suspended in water for long periods of time resulting in an unprecedented high rate of gas transfer. These extraordinary properties are proven to help farmers grow more food, oil and mining companies recover more valuable resources and operators treat wastewater more cost effectively.

If Farms Are to Survive, We Need to Think About Them as Tech Companies

We’re not experiencing a food shortage—it’s a shortage of people to farm it.

By Brandon Alexander October 3, 2018

CEO of Iron Ox and former engineer at Google X's drone-delivery program, Project Wing

Growing up on my granddad’s farm—he grows cotton, peanuts, and potatoes in Texas—I often heard that technologies like genetically modified crops were required to scale food production. My granddad believed that organic practices do not scale and will not feed the world at an affordable price point. Given the state of technology then, I believe he was right.

But the industry has changed with much more than the seasons, and we need more than an iterative improvement on past technologies. We are reaching a plateau in food production. According to research published in Nature, about one third of the world’s agricultural lands have maxed out the amount of rice, wheat, and corn farmers can grow.

At the same time, the World Resources Institute suggests we will need to double our food production by 2050 to feed nearly 10 billion people. In order to boost yield, we need to systematically improve the entire grow process and maximize the potential of every plant. To enable this next age of agriculture, we will need to rely on two new advances: machine learning and robotics.

The amount of data available to farmers has skyrocketed. In addition to collecting data at a macro level from satellite or drone imagery, we can also capture data at the micro level, thanks to a combination of cheaper, lower-powered sensors. These sensors provide farmers with insights like hyperlocal measurements on soil conditions, for example.

AP PHOTO/RICH PEDRONCELLI

Farmers have already been using drones to spray crops for years—what tech will come next?

But a firehose of data does not equate to insights, and that’s where the newer methods of applied machine learning come in. Companies like Descartes Labs and Farm Logs are applying machine learning and computer vision to glean insights from these new data streams, providing farmers not just pretty graphs, but actionable information to increase yield.

Machine learning and computer vision enables us to scan each plant in acres of land, detecting plant diseases before they spread and significantly minimizing yield loss and the need for pesticides. For example, traditionally a farmer would inspect parts of a plot of land for plant diseases like powdery mildew or signs of pest pressure like aphids. Because it was physically impossible for them to inspect each plant on acres of land, they would have to extrapolate their findings across the entire plot. Now, modern computer-vision techniques can take multiple images of every plant and stitch them together for a full 3D reconstructed model of the produce.

Data may give us the information we need to improve yield, but something still needs to perform the action. And it’s increasingly not humans.

We are experiencing a growing labor-shortage epidemic. According to the US Census, the average farmer is 58.3 years old, and new generations are not inspired to take on the laborious task that their elders did—even those who have generations of farmers in their family, like myself. This issue isn’t a shortage of food: It’s of people. Crops are rotting on bushes and vines because there aren’t enough staff to maintain and pick them. Considering that one in nine people onEarth aren’t getting adequate nutrition every day, it’s devastating.

This means that though there are more mouths to feed than ever, there will be less land to provide them food, and less calloused hands to tend to the crops that will feed them. So what do you do when you have little land to work with and fewer hands to help? You turn to technology.

Automation allows for a more accurate work environment with little human oversight. It will involve hardware that is more agile than the human eye or hand, and it will be able to give each and every plant the unique attention it needs.

Recent advancements in computing power, dexterity, motion planning, and computer vision are enabling a new generation of robotic applications. Robotics excel at rapidly performing repetitive tasks, but combined with computer vision, robots can start making real-time decisions on a per plant basis, from adjusting the nutrients to pruning. Companies like Blue River have successfully automated tasks like weeding (a manual process for non-GMO crops) to great effect, which is why John Deere bought the company for over $300 million last year.

DAVE GERSHGORN/QUARTZ

A sample of Iron Ox’s automated grow operation.

At Iron Ox, we’ve designed the entire grow process with a robotics-first approach. That means not just adding a robot to an existing process, but designing everything, including our own hydroponic grow system, around the robotics. In an indoor farm, tasks like seeding or harvesting are happening thousands of a times a day. These labor intensive, repetitive tasks are perfect for robotics. And by integrating machine learning and computer vision, we’re able to have the robots respond to an individual plant’s needs. For example, our robot can quarantine a plant if it shows early signs of pest pressure before it contaminates others nearby or change the nutrition recipe for a plant based on phenotyping.

And we don’t even need arable land: By creating indoor farmhouses with these technologies, we can open farmhouses in any location. This means we will be able to control the weather and take chance out of the growing process; currently, we’re losing more and more crops every year to drought, extreme heat and cold, and spontaneous weather incidents. We will also be able to grow crops closer to the communities that need them, reducing the amount of miles travelled to consumers’ kitchens and the industry’s carbon footprint writ large—and for much cheaper.

If farms are to survive, we need to think about them as tech companies. And that means they should be taking advantage of what many other industries are already harnessing: automation.

This story is part of What Happens Next, our complete guide to understanding the future. Read more predictions about the Future of Food.

Get The Free Report On The Investment Potential Of Greenhouse Business In Russia 2018

Last year was one of the most successful years for Russia’s greenhouse industry. Over 250 ha new commercial greenhouses were commissioned, the number of 5-gen greenhouses increased. Further expansion of greenhouse area is expected – new projects are set to be launched in different regions across the country.

Last year was one of the most successful years for Russia’s greenhouse industry. Over 250 ha new commercial greenhouses were commissioned, the number of 5-gen greenhouses increased. Further expansion of greenhouse area is expected – new projects are set to be launched in different regions across the country.

Prior to the International Investment Forum and Exhibition “Greenhouse Complexes Russia 2018”, Vostock Capital team of analysts has conducted a research on the investment potential of Russian greenhouse industry, which covers:

the information about the prospects for the development of Russian greenhouse industry

new investment greenhouse projects (construction and modernisation)

criteria for the selection of technology and equipment by the decision-makers of greenhouse companies and agriholdings and many other important results.

Request the report:

The research involved over 250 respondents, including the C-suite of agroindustrial holdings and greenhouse complexes, suppliers of latest technologies and equipment, regulators, project operators, representatives of financial institutions and investors, independent market experts.

The international Forum and Exhibition “Greenhouse Complexes Russia 2018” is the high-class professional platform to unlock investment in Russian greenhouse industry, discuss industry development strategy, share experiences between key market players and conclude new lucrative contracts.

The Event spans investors from the CIS, Europe, and Asia, initiators of investment projects from across Russia, decision-makers of federal and regional agriholdings, dedicated ministries and agencies, heads of regions, retail chain executives, service providers, presidents of national unions and associations.

Contact: Elvira Sakhabutdinova, Project Director

ESakhabutdinova@vostockcapital.com Tel. +7 499 505 1 505

Website: http://www.greenhousesforum.com/en/

Farm Family: Ernessi Farms

(Midwest Farm Weekly/WFRV)

Harvest season will come to a close in a matter of weeks, but not for one Ripon, WI farm. They do not rely on mother nature to dictate seasons. In fact, it is always spring at Ernessi Farms.

The weather is always perfect at Ernessi Farms to grow everything year round because they are able to control the entire growing environment from the lighting, to the temperature, and even the nutrients. Ernessi does all of this the basement of a Watson Street business and they do it hydroponically.

Bryan Ernst, owner of Ernessi Farms says that “because we're able to control everything down to the wavelength of the light of the plants receive we can fine-tune every single plant so that way they grow their optimum size.

Visit ErnessiFarms.com to learn more about the products they offer!

What's The Future of Food?

Scientists And Entrepreneurs Have Been Cooking Up Innovative Ways To Put Food On Our Tables.

What Are They Serving Up Next?

CALEB HARPER This computer will grow your food in the future

What if we could grow delicious, nutrient-dense food, indoors anywhere in the world? Caleb Harper, director of the Open Agriculture Initiative at the MIT Media Lab, wants to change the food system by connecting growers with technology. Get to know Harper's "food computers" and catch a glimpse of what the future of farming might look like.

SARA MENKERA global food crisis may be less than a decade away

Sara Menker quit a career in commodities trading to figure out how the global value chain of agriculture works. Her discoveries have led to some startling predictions: "We could have a tipping point in global food and agriculture if surging demand surpasses the agricultural system's structural capacity to produce food," she says. "People could starve and governments may fall." Menker's models predict that this scenario could happen in a decade — that the world could be short 214 trillion calories per year by 2027. She offers a vision of this impossible world as well as some steps we can take today to avoid it.

MATILDA HO The future of good food in China

Fresh food free of chemicals and pesticides is hard to come by in China: in 2016, the Chinese government revealed half a million food safety violations in just nine months. In the absence of safe, sustainable food sources, TED Fellow Matilda Ho launched China's first online farmers market, instituting a zero-tolerance test towards pesticides, antibiotics and hormones in food. She shares how she's growing her platform from the ground up and bringing local, organically grown food to the families that need it.

PIERRE THIAM A forgotten ancient grain that could help Africa prosper

Forget quinoa. Meet fonio, an ancient "miracle grain" native to Senegal that's versatile, nutritious and gluten-free. In this passionate talk, chef Pierre Thiam shares his obsession with the hardy crop and explains why he believes that its industrial-scale cultivation could transform societies in Africa.

PAMELA RONALD The case for engineering our food

Pamela Ronald studies the genes that make plants more resistant to disease and stress. In an eye-opening talk, she describes her decade-long quest to isolate a gene that allows rice to survive prolonged flooding. She shows how the genetic improvement of seeds saved the Hawaiian papaya crop in the 1990s — and makes the case that modern genetics is sometimes the most effective method to advance sustainable agriculture and enhance food security for our planet’s growing population.

Prestigious Professional Platform For Decision-Makers of CIS And Russian Greenhouse Industry

We are very pleased to announce that the “Greenhouse Complexes of Russia” has already attracted confirmed attendance from over 700 leaders of the greenhouse industry. But, as the number of places in Moscow’s Baltchug Kempinsky hotel is limited, registration for participation will now close before the previously established date. If you still hope to join us – to present your products, technologies, or services, we ask that you let us know now. Two remaining booth spaces will be made available to the participants who respond first.

Gold Sponsor: Grodan. Silver Sponsor: Signify, Svetogor, Green Automation Group. Bronze Sponsors: Royal Brinkman, Rijk Zwaan, Mir Stekla, AWETA, Lider-Pak. Video Promotion Sponsors: Uralchem, RICHEL Group, AHPS.

Request a Call

Among the honoured guests and presenters of 2018:

Aleksandr Rudakov, President, APH ECO-Culture

Sergey Rukin, President, Greenhouse Growth Technologies

Dmitry Lashin, Chairman of the Council of Directors, TK Lipetskagro

Nurbek Adaev, Director, TK YugAgroHolding

David Bondarenko, Director, CHINAR

Viktor Ovchinnikov, Executive Director, Greenhouse Complex Podosinki

Sergei Kirillov, General Director, Greenhouse Plant Tatarinovo (STK) and many others.

Register Now

I will be very pleased to respond to all possible questions and receive your comments.

Elvira Sakhabutdinova

Project Director

Tel: +44 207 394 3 090

Fax: +44 207 231 1600

Email: ESakhabutdinova@vostockcapital.com

Web: http://www.greenhousesforum.com/en/

Investment Projects For The Construction and Modernization of Greenhouse Complexes Will Be Presented at the 3rd Annual Forum and Exhibition

“Greenhouse Complexes Russia 2018”

Date: 5-6 December 2018

Venue: Moscow, Baltschug Kempinski Hotel

Organiser: Vostock Capital

Website: https://www.greenhousesforum.com/

The 3rd annual international Forum and Exhibition “Greenhouse Complexes Russia 2018” is the high-level professional platform to unlock investment in Russian greenhouse industry, discuss development strategies, share experiences, and conclude new lucrative contracts.

The Forum gathers investors from the CIS, Europe, and Asia, initiators of greenhouse investment projects from all Russian regions, decision-makers of federal and regional agro holdings, dedicated ministries and agencies, heads of regions, retail chain executives, service providers, presidents of national unions and associations.

Among Forum attendees 2017:

Alexander Tkachev, Ministry of Agriculture of the Russian Federation

Jambulat Khatuov, First Deputy Minister of Agriculture of the Russian Federation

Sergey Dankvert, Head of the Federal Service for Veterinary and Phytosanitary Control

Vladimir Vladimirov, Governor of the Stavropol Territory

Sergey Korolev, President, National Union of Fruit and Vegetable Producers

Sergey Rukin, General Director, Greenhouse Growth Technology

Viktor Semenov, Chairman of the Supervisory Board, Belaya Dacha

Alexander Rudakov, Chairman of the Board of Directors, APH Eco-culture

Alexander Zaklyepkin, General Director, Vyborgec Agrofirm

Irina Meshkova, General Director, Agro-Inwest

Nurlan Adilkhan, Director, BRB APK

Anatoly Tarasov, General Director, Teplitsy Belogoria

Andrey Volkov, General Director, Udmurt Flowers and many others.

Greenhouse Complexes Russia 2017 in facts and figures:

500+ participants representing flagship greenhouse complexes and agro holdings from Russia and the CIS – Greenhouse Growth Technology, Udmurt Flowers, YugAgroholding, TK Rodina, Ivanisovo Agrocomplex, Teplitsy Belogoria, Yuzhny Agrokombinat, BRB APK, Agrokultura Group, Teplichny Agrokombinat, Volzhsky Agrocomplex, Grodnenskaya Ovoschnaya Fabrika, Kaskad Mushroom Complex, Iftikhari, ECOS, RoseHill, Chekhov Garden, EcoProduct and many others.

60+ major investment projects – Alania Greenhouses, Avasyuninsky, Prompark, Master-R, Agrocluster, and a lot more

20+ presentations with key information delivered by the heads of such companies as Vyborgec Agrofirm, APH Eco-culture, Dolina Solntsa, Demetra Technology, NPO BioGreen, LipetskAgro, Agro-Inwest and others

Delegations of the government and development corporations – Stavropol territory, Ulyanovsk region, Irkutsk region, Tyumen region, Kaliningrad region, Voronezh region, Oryol region, Moscow region, Bashkortostan Republic, Karachay-Cherkessia Republic, Tambov region and other regions across Russia

Forum Highlights 2018:

500+ decision-makers of flagship greenhouse complexes and agro holdings from Russia and the CIS – Kazakhstan, Uzbekistan, Belarus, Armenia, Azerbaijan, as well as investors, government officials, chief agronomists, retail chain executives, service providers

Presentation of 30+ greenhouse investment projects to be executed within 2019-2025 from across Russia and CIS countries

Leaders debate: Ministry of Agriculture of the Russian Federation, investors, initiators, agri holdings. How will the Russian greenhouse industry evolve beyond 2020?

NEW! AGRONOMY DAY – specialized workshops on growing tomatoes, cucumbers, lettuce. Modern techniques of working with hybrids, effective use of LED-lighting and hydroponics

STRATEGIC FOCUS: ASSORTMENT POLICY – diversification and new business areas. What niches are the most promising in the greenhouse industry?

Dedicated exhibition of modern equipment and technologies delivered by the lead companies from Holland, Israel, Germany, Italy, Spain, and other countries

IMPORTANT: FINANCING. Cooperation with investors and banks, project financing. How to get best credit conditions?

ROUNDTABLE ON MUSHROOM FARMING AND FLORICULTURE – explore peers’ practices and learn about industry development prospects

FOCUS-SESSION: ENERGY-SAVING – connection to the electricity network, on-site generation, distributed power. What tariffs are to be expected in 2019?

Fast and effcient! Roadshow of innovative technologies and equipment from the global leaders

SPECIAL SESSION: THE TALENTS MAKE ALL THE DIFFERENCE! How to find a prospective hire?

Contact: Elvira Sakhabutdinova, Project Director

ESakhabutdinova@vostockcapital.com Tel. +7 499 505 1 505

Website: http://www.greenhousesforum.com/

UPDATE:

440+ decision-makers of major greenhouse complexes, agriholdings, investment projects, regulators, and lead service and equipment providers have already confirmed their participation and will present their projects at the 3rd International Investment Forum “Greenhouse Complexes Russia 2018” (5-6 December, Moscow).

Gold sponsor: Grodan. Silver sponsors: Signify, Svetogor, GREEN AUTOMATION EXPORT. Bronze sponsors: Royal Brinkman, Rijk Zwaan, AWETA, Lider-Pak. Sponsor of video-promotion: Uralchem.

Request the full list of confirmed participants

Speakers and VIP-guests 2018 include:

Alexander Rudakov, President, APH Eco-culture

Irina Meshkova, General Director, TK AgroInwest

Gury Shilov, General Director, Greenhouse

Nurlan Adilkhan, General Director, BRB APK (Kazakhstan)

Yanis Galanidi, General Director, Dolina Solntsa

David Bondarenko, Director, CHINAR

Valery Astapchik, Director, Grodno Vegetable Factory (Belarus)

Alexey Soshnikov, General Director, Ecoresurs

Jamal Majidov, Greenhouse Director, Grow Group Azerbaijan (Azerbaijan) and many other leaders of greenhouse industry in Russia and the CIS.

Northeast Greenhouse Conference

November 7 & 8, 2018

Boxborough, MA

For more information go to negreenhouse.org

The NEGC will have more than 40 sessions delivered by nationwide experts.

Topics include disease management, IPM, water and nutrient management, greenhouse technologies, basic production techniques, buisiness and marketing.

Special sessions include greenhouse vegetables and perennials, and practical training for the Spanish-speaking workforce, and hands-on training sessions.

Pesticide Recertification Credits: A total of 12 hours of presentations (credits will vary by state) will be offered for the six New England states plus New York and Pennsylvania.

The updated New England Floriculture Guide will be available at a reduced price in the conference.

For more information about the program, go to:

https://www.negreenhouse.org/schedule.html

Register today at: https://www.negreenhouse.org/registration.html

Chapter 11: Urban Farming In Tokyo

Toward an urban-rural hybrid city.

Linked by Michael Levenston

By Toru Terada, Makoto Yokohari, and Mamoru Amemiya

From Green Asia: Ecocultures, Sustainable Lifestyles, and Ethical Consumption

Edited by Tania Lewis Routledge, NewYork

Excerpt:

Cities are places of both consumption and production. There is actually a city that had already realized this future vision of Japan in which agro- activities are incorporated into society. It is Tokyo’s predecessor, Edo. Edo, one of a handful of the world’s megacities that had a population of more than 1 million at the beginning of the eighteenth century, was a garden city with numerous farms integrated into the city. Fujii, Yokohari, and Watanabe (2002) reconstructed the land use in Edo in the mid-nineteenth century based on historical documents and maps.

They found that, at the time, a little more than 40 per cent of land in Edo was used for agriculture and that numerous farms were interspersed in the urban area radiating outward for a distance of 4 and 6 km from the Edo Castle. Local production and local consumption were thoroughly enforced, with vegetables produced on farms within the city being consumed within the city. Meanwhile, Edo maintained an outstanding sanitary environment that was unmatched by any other megacity in the world at the time, whereby human waste generated in the city was returned to the farms. Describing it in modern terms, Edo was a smart city with relatively little environmental burden and high-quality amenities. The coexistence of city and farms was a manifestation of Edo’s advanced environment.