Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Nine Multi-Storey Carpark Rooftops in Singapore To Be Converted To Urban Farms

Mr Melvin Chow, senior director of SFA' s food supply resilience division, said that the launch of the tender for the nine sites comes in the wake of growing interest from the industry and the public towards urban farming in community spaces, following the launch of the agency's pilot multi-storey carpark rooftop farm in Ang Mo Kio last year.

SINGAPORE - The rooftops of a handful of multi-storey carparks in Singapore will be converted for use to farm vegetables and other food crops from the later part of this year.

The tender for nine such sites was launched on Tuesday (May 12) by the Singapore Food Agency (SFA).

They include five single sites in Ang Mo Kio, Tampines, Toa Payoh, Hougang, and Choa Chu Kang and two cluster sites - which comprises two sites each - in Sembawang and Jurong West. The size of the sites ranged from 1,808 sq m - or one-third of a football field - to 3,311 sq m - or three-fifths of a football field.

Each site is up for tender for a term of three years. For cluster sites, the successful tenderer will be awarded all sites within the cluster.

The launch is one of the strategies adopted by the SFA to increase local food production as part of Singapore's 30 by 30 goal - to produce 30 percent of the country's nutritional needs locally by 2030, said SFA and the Housing Board (HDB) in a joint statement.

Last month, SFA also launched the 30 x 30 Express grant to help local farms accelerate the production of fish, leafy vegetables and eggs over the next six to 24 months. Local farms produced about 14 percent of leafy vegetables, 26 percent of eggs and 10 percent of fish consumed in the country last year.

The ongoing battle against the Covid-19 outbreak and the resultant lockdowns imposed in many countries around the world have put the spotlight on Singapore's dependence on food imports and its vulnerability to global supply shocks. The Republic currently imports more than 90 percent of its food supply.

During the supplementary budget debate last month, Deputy Prime Minister Heng Swee Keat said that Covid-19 also underscored the importance of further strengthening Singapore's supply chain resilience and food security. He added that the Government will continue to ensure a stable supply of food and essential items by having a robust, multi-pronged strategy.

SFA said that it will continue to work with HDB to launch more multi-storey carpark rooftop sites for urban farming by public tender in the second half of this year, a move that is also in line with HDB's Green Towns Programme, which seeks to cool HDB towns through the use of greenery, such as on carpark rooftops.

Last month, the SFA said that it was also working to identify other spaces on the island - apart from multi-storey carparks - suitable for commercial farming, including industrial sites.

Mr Melvin Chow, senior director of SFA' s food supply resilience division, said that the launch of the tender for the nine sites comes in the wake of growing interest from the industry and the public towards urban farming in community spaces, following the launch of the agency's pilot multi-storey carpark rooftop farm in Ang Mo Kio last year.

"Residents in the area have been able to enjoy fresh produce from the farm at nearby supermarkets, and can witness first-hand the hard work involved in bringing our food from farm to fork," said Mr Chow.

Mr Teo Hwa Kok, founder of Citiponics, said that his company planned to take part in the latest tender and expand its production capacity beyond its Ang Mo Kio site, but that would be dependent on further on-site assessments.

He added that prior to the Covid-19 outbreak, various government organisations already had plans to open up such alternative spaces for food production but the decision to bring them forward in the light of the current situation showed "incredible support" in driving food resilience in Singapore.

Food security expert, Professor Paul Teng, said that the launch of the tender was a timely one as any additional space would mean more production in the short term.

"Initiatives like this are never too late as it is possible to convert unused space - such as rooftops - into productive vegetable gardens yielding produce for consumption or sale within as short a time as six months," he said.

The success of rooftop farms, however, will depend on many factors, including the choice of vegetables to grow and the growing method, Prof Teng added.

"While a dozen or so rooftop farms may not significantly affect the availability of vegetables as a whole in the country, any amount that is locally produced goes that extra step to reduce our dependency on imports.

"It also builds up the spirit of self-sufficiency and valuing fresher produce with low energy footprints."

More details on the tender are available on GeBiz and on SFA's website.

By Vanessa Liu | The Straits Times | May 12, 2020

Irish Vertical Farming Technology Startup Farmony Signs European Distribution Agreement With US LED Horticultural Lighting And Vertical Farming Equipment Provider Sananbio

Irish Agtech company Farmony has signed a European distribution deal with Sananbio for their vertical farming Radix systems. The Dublin based startup, established in 2018, will incorporate Sananbio’s technology into their controlled environment vertical farming solutions

Dublin, Ireland | May 19th, 2020

SANANBIO, a global leader provider in LED horticulture lighting and vertical farm technology, announces strategic distribution partnership with Dublin based startup for European markets. Farmony will build a network of interconnected, controlled environment vertical farms across Europe.

Irish Agtech company Farmony has signed a European distribution deal with Sananbio for their vertical farming Radix systems. The Dublin based startup, established in 2018, will incorporate Sananbio’s technology into their controlled environment vertical farming solutions.

“As our climate continues to change and populations across the globe expand, food production must evolve in order to keep pace with these unprecedented changes. We are delighted to announce our partnership with Sananbio; global leaders in cutting-edge vertical farming technology developed to empower the modern farmer and spur sustainable local food production. Sananbio is the ideal technology partner to complement our own customized, automated controlled environment software & hardware solution. ”- John Paul Prior, Strategy and Sales Director, Farmony

Farmony: Left to right: John Paul Prior (Strategy Director), Dan O’Brien (CEO), Rodrigo Andrade (Operations Director)

“Farmony provides Sananbio with the ideal partner to expand our industry leading technology into the European markets. With over one million square feet of commercial vertical farms currently using RADIX, farmers, and investors in more than 10 countries believe in our company's highly engineered grow technology. In Farmony we have a partner that adds significant value to our product offering through exceptional sales & marketing, IOT focus and new product development. " -Michael Yates, Vice President Sales, Sananbio

ABOUT Sananbio®

SANANBIO is a leading Ag-tech company backed by one of the world’s largest LED chip manufacturers. Supported by an elite R&D team comprised of plant scientists, researchers, and engineers; SANANBIO utilizes state-of-the-art technology that enables growers worldwide in the horticulture industry to increase the quality and quantity of their yields. Years of extensive research and real-world deployment and operations allow SANANBIO to offer its customers proven, scalable, efficient and cost-effective solutions in LED horticulture lighting and Controlled Environment Agriculture (CEA) vertical farming grow system; as well as turn-key vertical farm solutions including building, transfer, financing, and training of staff for both large and small-scale farming facilities. SANANBIO empowers growers with the technology and knowledge to achieve unprecedented results in farming operations.

Learn more: SANANBIO

Farmony build controlled environment Vertical Farming solutions: Left to right: Rodrigo Andrade, Dan O’Brien, John Paul Prior

John Paul Prior asks will vertical farming mean that Irish horticulture finally gets its 'day in the sun'?

ABOUT Farmony

With offices in Dublin & mainland Europe; Farmony provides an operating system for Controlled Environment Farms through a combination of software and hardware, customized specifically for vertical farming applications. The Farmony operating system provides producers with grow recipes, real time alerts, and feedback on the efficiencies of their farm, while also automating dosage, irrigation, and lighting.

Through the aggregation of the associated growing data from their network of producers, Farmony can then optimize yields and, through machine learning technology, ensure that the network is constantly improving it’s output for its network of users, establishing a growing efficiency algorithm.

Their partnership with Sananbio, facilitates all-year-round pesticide-free growth of leafy greens, microgreens, and herbs from a footprint of 55 Square Meters, producing the output equivalent of 5 acres of traditional farmland. Farmony has recently opened a facility in Poland to support their European expansion.

Learn More: www.farmony.ie www.farmony.pl

Media Contact: John Paul Prior +353 86 8116708

VIDEO: Guggenheim Tomatoes Are Monitored From The Netherlands

Although the Guggenheim’s “Countryside” show was shuttered by the pandemic, its crop of cherry tomatoes is still growing, and feeding New Yorkers. In a video Infinite Acres shows how they realised this project

and the tomato man takes care of them in empty city New York

Although the Guggenheim’s “Countryside” show was shuttered by the pandemic, its crop of cherry tomatoes is still growing and feeding New Yorkers. In a video, Infinite Acres shows how they realized this project.

The team with Infinite Acres tells how they realized the growing facility in New York and how they shipped several parts from the Priva company in De Lier, the Netherlands, to the US, combining it with local techniques to finish the growing facility.

Watch the video here.

Though the project has evolved quite unexpectedly due to the COVID outbreak, meaning that the halls of the Guggenheim Museum are pretty quiet these days, with mostly just its ghosts and some security guards as company for the art. Oh, and then there’s the guy who takes care of the tomatoes.

David Litvin, an indoor crop specialist at 80 Acres Farms, tends the plants in a temporarily shuttered exhibition, “Countryside, The Future.” 80 Acres Farms are the growers and operators of the module. He moved to New York from Tel Aviv in February, along with his wife, Stefanie, and their Dutch shepherd, Ester, with a plan to stay six months harvesting the Guggenheim tomatoes. He was going to see the city, too. “I went out once to a comedy bar, but that’s it,” he said to The New York Times. The museum has been closed since March 13, but Mr. Litvin still walks across Central Park every day around noon from his rental on the Upper West Side to tend to his flock. “When you grow tomatoes on Fifth Avenue, you want to have the perfect tomatoes, there’s no room to mess up,” he said. “If I have ugly plants, I’ll hear it from the neighbors.”

Read more at The New York Times.

Publication date: Tue 19 May 2020

PODCAST: Jim Pantaleo - Indoor Ag - The Future of Agriculture

Jim Pantaleo s a renowned expert and consultant for Indoor Vertical Farming and offers ag companies sound and technical advice on best practices

Jim Pantaleo is a renowned expert and consultant for Indoor Vertical Farming and offers ag companies sound and technical advice on best practices. Some of his services include performing market research and business development work. Other than companies, Jim also works with different universities such as the University of Arizona, UC Davis, and the University of Santa Barbara. He also enjoys writing about indoor vertical farming and regularly speaks at ag-related conventions.

Jim joins me today to describe how indoor vertical farming will change the way we look at sustainable food sources. He shares the current technology available for indoor vertical farming and what we can expect in the next few years. He discusses the myths about soil nutrition and crops regarding indoor environments. Jim also explains why the ag industry is experiencing its own version of the Dot Com era.

“There’s no degradation of nutrients when growing indoors because you’re controlling that environment.” – Jim Pantaleo

This Week on The Future of Agriculture Podcast:

The different kinds of skills modern agriculture needs.

Why fruiting plants are the goal of indoor agriculture.

The current challenges of indoor vertical farming.

The debate around nutrients, soil, and natural sunlight.

How they control the crops’ nutrient inputs.

What The AgTech scene in Los Angeles is like.

The major costs of having an indoor farm.

Startups that have made great strides in indoor farming.

Comparing the Dot Com era and the rise of indoor farming.

Resources Mentioned:

Why The World Wildlife Fund Is Trying To Spark An Indoor Farming Revolution

A network of caves in St. Louis, Missouri, was once used for brewing beer before the advent of refrigeration. Now, the conservation organization World Wildlife Fund is interested in helping the city repurpose some of that unused space for indoor farming—in a new pilot that can demonstrate how the indoor agriculture industry can become more sustainable and a viable way to make the food system more resilient

05-18-20

The conservation organization is known for work protecting endangered animals, but now it’s starting to help push for broad solutions—such as a major plan to expand vertical farms in St. Louis in an attempt to prove that local farming can cut emissions.

A network of caves in St. Louis, Missouri, was once used for brewing beer before the advent of refrigeration. Now, the conservation organization World Wildlife Fund is interested in helping the city repurpose some of that unused space for indoor farming—in a new pilot that can demonstrate how the indoor agriculture industry can become more sustainable and a viable way to make the food system more resilient.

The organization is best known for its work to save iconic species, such as protecting tiger habitat or reducing demand for elephant ivory. But within a section of the nonprofit called the Markets Institute, it also studies trends in agriculture and ways to help lower the massive environmental footprint of growing food, from the energy and water used on farms to the impact of clearing forests to make room for farmland.

The institute, launched in 2016, works with partners across the food industry on challenges such as how to prevent food waste or how to deal with impacts from climate change in the cocoa industry supply chain. The organization recognizes that the entire food system needs to change to protect nature, and it can play a role in catalyzing that change in the business world.

“We’re looking for new business models, new strategies and partnerships, and different ways of approaching things that are financially profitable as well as environmentally sustainable,” says Julia Kurnik, director of innovation startups at World Wildlife Fund. “Our goal as an institute is to find things that can happen quickly and at scale, so that’s why we’re interested in making sure they can really take off and live beyond our investment.”

Image: World Wildlife Fund]

It saw promise in the nascent indoor farming industry. Companies that grow produce in greenhouses, or stacked in vertical units inside warehouses, can grow more food on far less land than traditional farming, leaving room for forests to stay in place or be replanted. The methods they use to grow food without soil also use far less water. If indoor farms are distributed in cities, they can also help avoid the carbon footprint of trucking produce thousands of miles across the country. Because the spaces are sealed and insects can’t get in, they can also avoid pesticide use; the produce is also more uniformly perfect and gets to customers more quickly, so there’s less food waste; the farms also aren’t affected by extreme weather outside, so crops won’t be lost in storms or impacts from a changing climate.

Image: World Wildlife Fund

Still, indoor farms aren’t environmentally perfect. In a new report, World Wildlife Fund examined the total environmental footprint of growing lettuce on fields in California versus a hypothetical indoor farm in St. Louis. The organization chose St. Louis for its study and pilot after searching for cities that met a certain list of criteria—a climate that doesn’t allow for year-round growing, a large population, and stranded assets that could be used as infrastructure for growing food. Because of St. Louis’s unique industrial infrastructure, including the abandoned caves, it was chosen from a shortlist of 10 cities. (WWF is not investing in the projects itself, just helping set up the infrastructure for governments and companies to work together on the effort.)

In its study of the potential of indoor farming in St. Louis, the organization confirmed that soilless indoor growing can save land and water, but the researchers also identified challenges. The lights used to grow crops indoors use large amounts of energy, though the technology has become more efficient, and generate so much heat that greenhouses often have to use air-conditioning to maintain a steady temperature, even in the winter. If you grow lettuce in Monterey, California—in a region where much of the country’s lettuce is grown—and ship it to St. Louis, the carbon footprint is lower than growing in a standard indoor farm in St. Louis now. That’s because St. Louis still gets most of its energy from coal, and that outweighs the footprint of driving lettuce long distances in a refrigerated truck or the benefits from avoiding pesticides or food waste.

The report also examines ways that the industry could shrink that footprint, from fiber-optic tech that can bring sunlight into a room to options for renewable energy. If the farms can use less energy, there’s also an economic benefit—and that will begin to make it possible for companies in the industry to expand beyond growing leafy greens. Greens such as lettuce and spinach are common now in indoor farms because they grow more quickly than, say, strawberries or tomatoes, and they fit within the economics of current growing systems.

In St. Louis, the nonprofit is bringing together a group of stakeholders, including existing indoor farming companies, local plant science experts, community groups, the local power company, potential funders, and potential customers such as grocery stores, to test new alternatives. Several types of unused or underused infrastructure may work as farming space, such as cold storage in postal hubs, or space next to power plants that can take the excess heat from an indoor farm and convert that into energy.

The city’s caves are of interest because they’re naturally cool, helping offset the need for air-conditioning. By the end of the year, the aim is to have an agreement for a pilot design, either a single farm or a network of farms, that can be built in the city in 2021. “We won’t build the farm or own the farm,” says Kurnik. “Our model here is to bring all the players together.”

Once the pilot proves how well the new approaches work, that can be shared more broadly with the industry. The project may also be able to share some knowledge about technology such as automation, which can help bring down the cost of growing. (Labor is a major expense at indoor farms, and robots can help address that, while also spurring the creation of some more highly paid jobs in the industry than farm labor.) Right now, existing farms “are each investing in their own technology and R&D,” she says. “If there were standardizations across some of that, it might be able to boost the entire industry.”

Communities outside St. Louis will also be able to learn from the pilot, both as a way to reduce the environmental footprint of their local food supply and a way to make the supply chain more likely to survive disruption from climate change. While interest in indoor agriculture is already growing in some areas—for instance, water-starved Abu Dhabi, which wants to create a more resilient food system that doesn’t rely as much on imports—it could eventually be much more widely used elsewhere if the energy and economic issues can be addressed. In California, increasing drought may eventually make traditional farming less and less feasible. Other impacts from climate change, including extreme heat and increasing storms and floods, are also beginning to make traditional farming more difficult. Indoor farming “has potential to be one tool in the toolbox for tackling those things,” says Kurnik.

ABOUT THE AUTHOR

Adele Peters is a staff writer at Fast Company who focuses on solutions to some of the world's largest problems, from climate change to homelessness. Previously, she worked with GOOD, BioLite, and the Sustainable Products and Solutions program at UC Berkeley, and contributed to the second edition of the bestselling book "Worldchanging: A User's Guide for the 21st Century."

Farming Fuels A Holistic Approach to End Homelessness at Lotus House

Growing fresh food helps Lotus House residents find their fresh start

Growing fresh food helps Lotus House residents find their fresh start

At Freight Farms we believe that everyone should be able to participate in the joy of eating fresh, healthy foods regardless of location, climate, or socioeconomic background. Our global Freight Farmer network makes this mission a reality–and none more so than the non-profit organizations that use hydroponic container farms to create meaningful and long-lasting change in their communities.

Today we’re highlighting just one organization: Lotus House in Miami, Florida. Lotus House is what many of us would call a “homeless shelter”, but the term fails to capture the sheer extent of their services. Lotus House refers to itself as a “holistic residential facility and resource center for women and children experiencing homelessness”. The difference is significant. Instead of focusing on providing bare minimum resources–a hot meal, a bed, a shower–Lotus House tries to address the initial cause of homelessness, with the intent of getting women and their families back on their feet. Their services provide up to 500 women and children residents with daycare, employment education, and arts programs, beauty salon, yoga and meditation, and much more.

Meet Farmer Jackie

To learn more about the incredible things happening at Lotus House, we connected with Jackie Roth. Jackie is the ideal person to talk to about the role of farming within the center’s greater holistic model:

“As Project Coordinator, I manage all aspects of the Farm in addition to other specialty health/research projects at the shelter. I lead sessions inside the Farm every day, as well as the cooking demonstrations and outdoor garden work, and oversee all Farm maintenance and volunteers. So I’m basically the resident farmer, and guests know me as such.”

Hear from Jackie and Constance (Lotus House Founder and Director) when you download webinar, recorded on April 30th 2020. Download here.

Good nutrition as a pathway to wellness

For Jackie, Lotus House’s farm is part of a much larger conversation about the essential role health and wellness play in building resiliency and ending the cycle of poverty:

“Our mission is to transform the trauma of homelessness into a window of opportunity, where guests can heal old wounds and build resilience for a brighter future. Rather than provide the temporary support of a bed and hot meal, we work to holistically end the cycle of poverty and abuse that too often leads women and families to our shelter. Health and wellness are essential to this healing, and food and nutrition are essential to that health and wellness. It truly takes a village and lots of moving parts to achieve this multidisciplinary vision, and the food and nutrition education component is no exception.”

The Lotus House farm works in tandem with the Culinary Center, where over 500 residents and staff members are served three free meals a day. The farm is mostly used to grow a variety of lettuces that go into the Center’s salad bar, along with other specialty greens, root vegetables, and edible flowers. For Lotus House, the Greenery is the perfect intersection of food, nutrition, and education, and it has been deployed accordingly.

“We aim to serve largely plant-based foods and healthful meals that nourish the healing and developing minds and bodies of those who live here. The Culinary Center is home to one of our paid internship programs for guests where they earn their Food Handler’s certification, participate in the inner workings of a commercial kitchen, and hopefully create new career opportunities for themselves in a city with such a prominent hospitality and entertainment industry.”

Furthermore, the farm and the center have a symbiotic relationship. Jackie explains the benefit of the farm for Lotus House, and the greater community:

“Our Farm saves us thousands of dollars a year on produce costs; in addition, we work closely with local nonprofits and businesses who donate reclaimed food that would otherwise be thrown away. And when we have more food than we need for ourselves, we give it back as groceries for people in the neighborhood - because the community’s health is so tightly linked to our own. So there’s lots of internal and external coordination involved in sustaining our own food source, reducing food waste, and bringing real nutrition to the people who need it most.”

Achieving good nutrition through education

Beyond the dining program, the farm serves an important role in educating and engaging many of the organization’s youngest residents (ages 3-12) on weekdays after school. Jackie, who oversees all the in-farm programming overviews the day-to-day:

“The Farm is the home for an innovative after-school program where children witness the seed-to-harvest life cycle and farm-to-table growing. We also do cooking demonstrations where kids can see different hands-on ways to use their vegetables and learn basic kitchen skills like chopping, mixing, blending, etc.”

Lotus House’s education farming program doubles as a mini-workforce. During their afternoon sessions, younger kids help Jackie plant seeds and harvest mature plants for delivery to the Culinary Center, where they will be served the very next day. Beyond that, older kids interested in the farm help Jackie with the more detail-oriented tasks, like transplanting and maintenance.

But the farming program doesn’t end there! As with everything Lotus House does, the farming program has a holistic and multidisciplinary approach. In addition to the Greenery, the center has built out a general nutrition and gardening presence at the shelter. The building features an outdoor rooftop garden where the children grow basil, cilantro, beets, mint, broccoli and strawberry sprouts–started in the Greenery–in the soil and learn how to compost waste from the Greenery operations (grow plus, leaves, etc.).

The center runs also smaller events and initiatives about nutrition, such as the ‘Farm Stand’ where the Lotus House staff highlight a Farmer of the Week, share what’s growing, provide samples, and give out nutrition-themed activity sheets.

Changing habits to change lives

Ultimately, the goal of the Lotus House Farm program is to encourage residents to eat more fruits and vegetables by connecting them to their food source.

“With the Farm, we have a really unique opportunity to give guests a transparent lens into how food grows, from seed to plate, and get them excited about eating something cultivated in this high-tech environment. The approach is not to lecture people on what’s good for you or what’s bad for you, but to show them how cool plants are and all the different ways you can enjoy them.”

The opportunity to work with kids from a young age is particularly important in this goal. “It’s best to intervene young so they can build healthy habits early on, and hopefully share what they learned with mom to influence her attitudes and habits...If we can play even a small part in ...getting children excited about eating fruits and vegetables, exposing them to something they’ve never eaten before, or bringing moms and kids together to watch their plants grow and prepare a healthy snack, then it’s a worthy battle.”

Inspiring future farmers

With robust educational programs established and successful, Jackie turned her focus for 2020 on two new initiatives: creating a wider volunteer program and rolling out a hydroponic farming job training program for teens and adults.

The volunteer program sought to engage people all over Miami with the center and the farm, based on their availability: “The volunteers are integral to maintaining a beneficial student-teacher ratio, implementing therapeutic teaching techniques, and ensuring all necessary maintenance work is completed and our Farm stays hyper-clean.”

The job training program would teach residents basic farming skills before they started paid jobs with local container farming community partners, like fellow Freight Farmers at Hammock Greens: “We want every abled person in our shelter to come out with a good paying job, and even with the kids and volunteers there was often lingering Farm work, and we had lots of adults who expressed interest in learning more about gardening.”

Unfortunately, COVID-19 brought both programs to a screeching halt just as they were gaining momentum: volunteers stopped coming in and partnering businesses closed their doors. Jackie remains hopeful, however, making sure that post-COVID, the programs are still viable.

These new programs are not the only ones that had to be re-thought in today’s coronavirus reality. As Lotus House works to protect its residents, Jackie is aware of how the farm is at the center of two competing forces:

“On the one hand, we want to exercise the utmost caution in every regard due to the compact interior of the Farm and the nature of growing fresh, uncooked food for hundreds of people when there are still so many unknowns about this virus and its transmission. But on the other hand, supply chains are so uncertain right now and we are acutely reminded of the value of being able to produce our own food. And, all the kids are off school with extra time on their hands and a deep desire for some semblance of fun and normalcy.”

Luckily, Jackie and her helpers were well-prepared to address public health and safety in the farm. Well before the coronavirus reared its ugly head, Jackie implemented rigorous cleanliness practices to avoid contamination like wearing gloves, sanitizing multiple times daily, “dabbing” when sneezing or coughing, and routine deep cleaning of the farm. Since the pandemic reached Miami, they’ve expanded the precautions:

“Most drastically we’re restricting our attendance to no more than two kids at a time in accordance with social distancing. And because of limited attendance, we have fewer hands to help and are therefore at a reduced capacity. Despite all of this, we’re still going. There’s still interest and definitely still a need. Even if we get to a complete quarantine, our guests still have to eat and we will still strive to serve them nutritious options.”

In spite of the increased work and stress of running a farm in the center’s close quarters, Jackie feels that the pandemic situation has reinforced the importance of her work: “The good fight to end homelessness never stops–shelters keep running through even the most unprecedented emergencies, and we are charged with protecting some of society’s most vulnerable people. It’s actually been quite a blessing to grow closer as a team, adapt together, and try to preserve this homey space of healing and sanctuary despite all the madness outside.”

Supporting Lotus House during COVID-19 and beyond

In light of the unprecedented circumstances surrounding the COVID-19 pandemic, we asked Jackie how the greater Freight Farms community can help Lotus House.

“Because of the pandemic, we truly need help now more than ever. If you head to our website, you’ll see a donation link on the homepage. Anything helps. Your support is critical and immensely appreciated! We are taking so many extra measures and expenditures to supply PPE to our staff and guests, to hire additional persons for added sanitation, to ensure our supply stocks are sufficient, to do whatever we can to protect everyone living and working with us. And to prepare for the inevitable spike in homelessness that will result from this economic collapse.”

Looking beyond COVID-19, Jackie also outlined how community support will help support the Lotus House farm in the future: “Our Farm was purchased and funded the first year through some local community grants, but those grant periods ended last month. We are now exploring new funding streams to advance the program. We accept donations, specifically made out to “The Farm” if possible. We also designed our own educational curriculum for the program, and are happy to share this along with technical training if you would like to replicate what we’re doing. And anyone interested in volunteering can reach out to me at jackie1@lotushouse.org!”

Variety of Healthy Foods From Vertical Farming Platform

When talking about technology, it's easy to focus on things like computers, smartphones, apps and the growing number of smart gadgets around the house. But technology is far-reaching and can influence and change traditional sectors quickly, one of them being the agricultural sector.

When talking about technology, it's easy to focus on things like computers, smartphones, apps and the growing number of smart gadgets around the house. But technology is far-reaching and can influence and change traditional sectors quickly, one of them being the agricultural sector.

One company that is looking to take on the commercial agricultural industry is Eden Green Technology, just out of Texas. This company focuses on sustainability in the food industry. Eddy Badrina, CEO of the company tells about what they do, how they use technology, and how they envision the future of the agricultural industry.

Efficient use of space

"Eden Green Technology is a vertical farming platform that grows large quantities of local produce safely, sustainably, and efficiently. We use less land, energy, and water than both traditional farming and other indoor solutions. Our greenhouses are constructed on small footprints, in urban or suburban areas, to provide stable jobs and produce non-GMO, pesticide-free produce, which goes from farm to table in as little as 48 hours, compared to the 14 days it usually takes under the traditional model," Eddy says.

The founders of Eden Green are brothers Jacques and Eugene van Buuren. They came to the US to secure investment, source talent, and experiment with their technological solutions in diverse climates. They started in Texas, with its own extreme range of environmental considerations, agricultural know-how, and business opportunities, and built from there.

Technology company

"Our technical secret sauce consists of a few ingredients, including our patented vertical “vines,” where our produce grows, and the way we create microclimates for each individual plant with temperature-controlled air and nutrient-enriched water. We also designed and built a proprietary mechanical, electrical, and plumbing solution specifically to automate and remotely monitor all our greenhouses. Because of that hardware and software combination, we like to think of ourselves as a technology company that happens to grow produce."

Read more at Vator.

By Horti Daily | May 4, 2020

Vertical Gardens Take The Hudson Valley’s Farm-to-Table Scene to New Heights

“Vertical Field offers a revolutionary way to eat the freshest greens and herbs by producing soil-based indoor vertical farms grown at the very location where food is consumed,” explains Vertical Field’s Chief Executive Officer Guy Elitzur

Sabrina Sucato

Photos by Vertical Field

Vertical Field Makes its Local Debut At a Leading Poughkeepsie Restaurant, With a Monsey Grocery Store Soon To Follow

In the Hudson Valley, farm-to-table is less of a foodie trend and more of a way of life. As an ideal, it’s woven into the threads of the community, crisscrossing its way between farms, artisans, restaurants, and the locals who support them all.

Even during the COVID-19 crisis, when so many in the region struggle to find their footing, the movement lives on through support for farm markets and restaurants, many of which are in new territory when it comes to delivery and takeout.

Yet it’s never gone quite this far. Or, ahem, this high.

Photo by Vertical Field

In a first for the Hudson Valley, farm-to-table takes a vertical turn. It’s all thanks to Vertical Field, an Israel-based agro-tech startup that crafts vertical agricultural solutions that make access to food easier and faster while reducing waste and cutting down on human handling – a major boon during a time of social distancing.

“Vertical Field offers a revolutionary way to eat the freshest greens and herbs by producing soil-based indoor vertical farms grown at the very location where food is consumed,” explains Vertical Field’s Chief Executive Officer Guy Elitzur. “Our urban farms give new meaning to the term ‘farm-to-table’ because one can virtually pick their own greens and herbs at supermarkets, restaurants, or other retail sites.”

While Vertical Field has installed gardens across the Middle East and Europe, it’s recently found a home at Poughkeepsie’s Farmers & Chefs, where chef and owner John Lekic uses it to take the hyperlocal experience at his restaurant even further.

“It’s making a full circle for a chef and restaurateur,” he says. “You get to serve the food you not only prepared or cooked, but you also grew from seed to plate.”

When Lekic first came across Vertical Field during an exhibition at the Culinary Institute of America in late 2019, he was hooked from the start. Knowing that the system would be a perfect fit for his concept, he ordered one for his Hudson River food truck-turned-eatery.

Lekic’s vertical garden arrived two days after Governor Cuomo mandated the closure of on-premise restaurant operations in New York State.

“It was a lot of anxiety and uncertainty,” Lekic recalls. For the safety of his staff, he called for a break in operations to ensure no one was sick. During that time, he dedicated himself to setting up his vertical field. “It kept us busy. We installed our farm and planted about 10 days after. We already had our first crop.”

A rapid turnaround time is one of the pros of Vertical Field gardens, which take about three to four weeks per harvest. According to Lekic, he anticipates he’ll be able to grow about 400 pounds of produce per month. Much of it will be salad greens such as buttercrunch lettuce, kale, and arugula, although he also planted herbs like rosemary, sage, and basil.

While Lekic appreciates the convenience of the garden, which resides onsite at the restaurant for customers to see, he also loves that it’s a bug-free, pesticide-free operation with less need for human contact. With fewer intermediary steps (no transportation from producer to restaurant, for example) and up to 90 percent, less water required than in a traditional garden, Vertical Field urban landscapes are just about as eco-friendly as it gets.

“You can definitely taste that,” Lekic enthuses. “There are no chemicals. That’s a great experience.”

Just as Lekic values the freshness, so too do his customers. Farmers & Chefs is open for delivery and pickup during quarantine, so consumers are able to taste the metaphoric fruits of the garden’s labor for themselves. In fact, the garden has been such a hit that Lekic is brainstorming ways to incorporate the produce into more unique offerings.

“We make housemade ice cream with brown fennel and pistachio,” he says. “We’re playing around with some product that we aspire to take to market.”

Lekic may be the first to install a Vertical Field in the Hudson Valley, but he’s already paved the way for others. In Monsey, Evergreen Supermarket will soon have a sky-high garden of its own.

“I heard about [Vertical Field] through some people from Israel who showed me how some vertical farms are being set up in supermarkets,” explains supermarket representative Menachem Lubinsky. If not for the COVID-19 outbreak, he adds, Evergreen’s vertical garden would already be in place. As it stands now, the market expects the container will be delivered soon.

“I’m very excited about it,” says Lubinsky. “The technology allows it to have constantly changing light and heat. It eliminates the transfer from farm to supermarket and guarantees supplies.”

Lubinsky expects that Evergreen’s clientele, many of whom are already interested in more natural, organic products, will take to the Vertical Field produce immediately. Since Evergreen will set the container up in its parking lot, customers will be able to watch the garden grow during every shopping trip. If all goes well, the store may even purchase a second Vertical Field for its store in Lakewood, NJ.

“Almost everything you want to grow can grow,” Lubinsky enthuses. Fingers crossed, he hopes strawberries will soon be available for Vertical Field gardens, too.

Bowery Farming Hires Rachel Alkon As First Head of Comms

The indoor farm startup says it is seeing a surge in demand amid COVID-19

May 12, 2020, by Diana Bradley

NEW YORK

Whole Foods Market alum Rachel Alkon has joined indoor farming startup Bowery Farming as its first head of communications.

Alkon started at Bowery last week, reporting to CMO Katie Seawell.

The technology-focused company operates indoor farms in New Jersey and Baltimore. Alkon is responsible for building the brand narrative, external storytelling, media relations, community impact and public affairs.

“The company is now at a point where we want to define the narrative and do some more external storytelling,” said Alkon. “The time was right to bring on a comms head.”

Bowery Farming has received communications support from AOR Derris and Gillian Small PR. It is planning to continue to work with both agencies.

Bowery uses zero pesticides, 95% less water, and its farms are 100 times more productive “on the same footprint of land than traditional agriculture,” according to Alkon. Its produce is available at select Whole Foods and Foragers stores and is featured on the menus of Tom Colicchio’s New York restaurants, Craft and Temple Court. Based in New York City, the company has raised more than $170 million from investors including GV, General Catalyst, GGV Capital, First Round Capital, Temasek, and Almanac.

Bowery Farming’s business has more than doubled with some online distributors, and is up between 25% and 50% in stores, Axios reported last month. Indoor farms, which grow produce in warehouses with tightly controlled climate and light conditions, are seeing a surge in demand amid COVID-19 because “people are more concerned about who is handling their food, where it's coming from, how many stops did it have before hitting the shelves," Irving Fain, co-founder, and CEO of Bowery Farming, told Axios.

Alkon worked at Whole Foods Market for two years before she left the role of principal of global policy and public affairs in April. Alkon was also the director of corporate communications at Brunswick.

By Diana Bradley | PR Week | May 12, 2020

Indoor Composters For A More Sustainable Life

If you’re new to the compost game, getting a bin is the perfect first step. Here are some of our favorite indoor composters available today

Curb Your Carbon Footprint Conveniently

Composting is an easy way to reduce the amount of waste produced by your household, sending organic matter like food scraps back into the soil. While many people compost outside in compost piles, it is possible to compost even if your home doesn’t have a garden or outdoor area. Indoor composters are compact and low-odor containers for food scraps. Having one in the house is important for people that have weekly compost pickups or drop offs. Indoor composters also make life easier for people with outdoor compost piles, decreasing the frequency with which they have to step outside to dump food scraps. If you’re new to the compost game, getting a bin is the perfect first step. Here are some of our favorite indoor composters available today.

This five-gallon compost bin can live on a countertop and comes with liquid Bokashi, which can ferment and break down your food waste into soil and compost tea. Compost tea is a liquid that fertilizes plants and can be dispensed from the nozzle at the bottom of this SCD bin. Bokashi composting is especially great for the indoors, because it minimizes odor. With a tight lid and carrying handle, you can easily transport this bin to your outdoor compost pile or compost drop-off site.

This is an awesome choice for plant-lovers and gardeners, as it can turn your compost into soil amendment in just three hours. It is also space-efficient and can reduce the volume of your food waste by 90 percent. It is a tightly-sealed and odor-free container, using heat and carbon filtration to break down food, including bones, pits and shells. The machine will let you know when the filter needs to be replaced.

This 2.4 gallon polyethylene compost bin is a convenient size for any kitchen. It comes with a year’s worth of carbon filters, which help combat odor. You can safely put this in the dishwasher after it is emptied.

If you aren’t producing large amounts of food waste, something smaller and more aesthetic-forward could be the ticket. This 1-gallon compost bin is a small pail that will look stylish in an urban kitchen and get the job done. You can remove the plastic container from the pail to dump your compost and throw in the dishwasher. Its lid is ventilated for moisture and temperature control, but the activated charcoal filters help prevent odor from escaping and stinking up your kitchen.

By PopSci Commerc Team | Popular Science | May 4, 2020

Building Resilience Into The Vegetable Supply Chain Using Container Farming

Canada’s food supply chain is robust and reliable - even in times of the COVID-19 crisis - but there is an opportunity to become more self-sufficient. Container farming can provide your food supply with some autonomy and reduced reliance on external food supply chains

Canada’s food supply chain is robust and reliable - even in times of the COVID-19 crisis - but there is an opportunity to become more self-sufficient. Container farming can provide your food supply with some autonomy and reduced reliance on external food supply chains.

THE SUPPLY CHAIN DURING COVID-19

Empty shelves at the outbreak of the pandemic were a shock to many as grocery store retailers have experienced shortages, or delays, in their supply chain during this adjustment period.

The Food and Agriculture Organization of the United Nations (FAO) wrote in a special COVID-19 report that “supermarket shelves remain stocked for now [...] but a protracted pandemic crisis could quickly put a strain on the food supply chains, a complex web of interactions involving farmers, agricultural inputs, processing plants, shipping, retailers and more.” The FAO emphasizes that there is enough supply, but transportation is lacking to help get the crops where they are needed most.

FOOD PRICES ARE RISING

Even before COVID-19 struck, food prices in Canada were predicted to rise between 2 and 4 percent, especially vegetables and bakery items. Now, according to a new forecast by the University of Guelph and Dalhousie University, researchers say the factors contributing to the rise have changed but they still expect prices to rise nonetheless. Plus, grocery stores are now spending more to ensure the proper protection protocols are in place on top of paying their essential workers more. These costs won’t be changing soon, so what ways can more resilience be built into the grocery store model?

Students in Kugluktuk, Nunavut help run their Growcer system which provides produce to the school and community.

EVERYONE IS IMPACTED DIFFERENTLY

It is important to note that not every community’s food supply is going to be impacted the same way. In a Food Secure Canada webinar about Food Policy and COVID-19, the speakers spoke to how rural and Indigenous communities will be impacted differently than cities. One of the speakers, Jessica McLaughlin with the Indigenous Food Circle, said, “What has become very evident to us is the vulnerability of communities on that big industrial food supply chain and the lack of autonomy to self-determine their own food systems.” However, Mclaughlin added that despite this, communities are working together. “In this crisis, communities have been really resilient . . . you really see how communities pull together and they are taking this into their own hands,” McLaughlin said.

WHAT COULD A SOLUTION LOOK LIKE?

Each community has different needs, but one possible solution is container farming. With container farms, communities and grocery stores can grow a variety of produce year-round, no matter the weather, and even customize what’s being grown to match the demand of the community. You’re also not stuck to growing one crop. A grower can grow multiple types of produce at a time and switch out what’s being grown regularly. Having a local, year-round, consistent supply of produce allows the community not to rely solely on external sources and can provide a buffer when the supply chain experiences delays.

The Yellowknife Co-op's Growcer unit is operated by its existing employees who see it as an opportunity to serve their community.

Now, hydroponic growing might sound technical but operating one of Growcer’s systems is extremely simple. It only takes one week of on-site training to have employees comfortable with the system. Justin Nelson, general manager for The Yellowknife Co-op, shared that their employees love working in the Grower unit. “On a cold dark day in Yellowknife there’s no better place to be than inside the Growcer unit,” Nelson said. “When you’re actually harvesting the product that you’re selling it’s a great feeling.” You can read more about The Yellowknife Co-op’s story to see how they integrated a container farm with their store.

Food sovereignty and the ability for communities to decide how their food systems run has been brought to the forefront during COVID-19. It’s impossible to predict what lays ahead, but we do know that this could be a time for a reset for some of us.

April 27, 2020

VIDEO: Babylon Harvested Here - Remotely Managed Micro-Farm

Babylon is often asked how our remotely managed, but locally supported micro-farms work

International Manufacturing and Distribution,

Sales and Marketing Management, Connector.

Babylon is often asked how our remotely managed,

but locally supported micro-farms work

The new video below should answer some of your questions but please contact us for any additional information. (www.babylonmicrofarms.com)

Justice Department Responds on Behalf of USDA Against Lawsuit to Restrict Supplies of Organic Foods

As USDA acknowledges in its response to the complaint, “certifiers have certified organic hydroponics operations since the beginning of the program and continue to certify organic hydroponics operations.”

SAN DIEGO, CALIFORNIA

May 19, 2020

The Coalition for Sustainable Organics (CSO) is heartened by the initial response of the Department of Justice to defend organic growers’ rights to incorporate appropriate and legitimate growing techniques in their organic operations. The CSO opposes the efforts of the Center for Food Safety and a handful of growers to limit the availability of fresh organic fruits, vegetables, herbs, and mushrooms.

Lee Frankel, executive director of the CSO, stated, “The lawsuit takes aim at all container systems. The requested decertification of organic growers would include everything from microgreens grown in a tray using soil to tomatoes grown with plastic lining under the planting bed to berries grown in a pot to leafy greens grown in a circulating water system.”

“Demand for organic produce has grown even stronger in recent weeks as consumers are looking for ways to strengthen their immune systems by avoiding unwanted chemicals, hormones, and antibiotics in their diet,” Frankel continued. “We oppose this lawsuit and support the most recent vote of the National Organic Standards Board to not make containers and hydroponic production methods prohibited practices.

As USDA acknowledges in its response to the complaint, “certifiers have certified organic hydroponics operations since the beginning of the program and continue to certify organic hydroponics operations.”

Frankel continued, “If producers, marketers, and retailers truly support bringing healthy food to more consumers, especially in light of the pressures many households are facing as a result of the recent economic contraction, they must speak out against these efforts to restrict supplies.”

FOR MORE INFORMATION:

Lee Frankel, Executive Director

info@coalitionforsustainableorganics.org

619-587-4341

What The Heck Is Farm Management Software?!

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag.

By Aaron Magenheim, CEO & Co-Founder of AgTech Insight & Growers Insight

May 2020

Technology specifically built for Agriculture, (commonly known as AgTech or Precision Ag), has become an exciting space with Farm Management solutions leading digitalization. “Farm Management” has also turned into a buzzword many people use broadly and don’t really understand the importance of and details around – especially in our rapidly changing world.

As CEO and co-founder of AgTech Insight, a global advisory and implementation firm specializing in AgTech, I have been monitoring the evolution of this industry for several years, evaluating both existing and new solutions and companies. In 2015 we launched our first AgTech Market Map leveraging our internal solutions database by providing a free, valuable resource for those wanting a better understanding of which companies are leading the market organized by category.

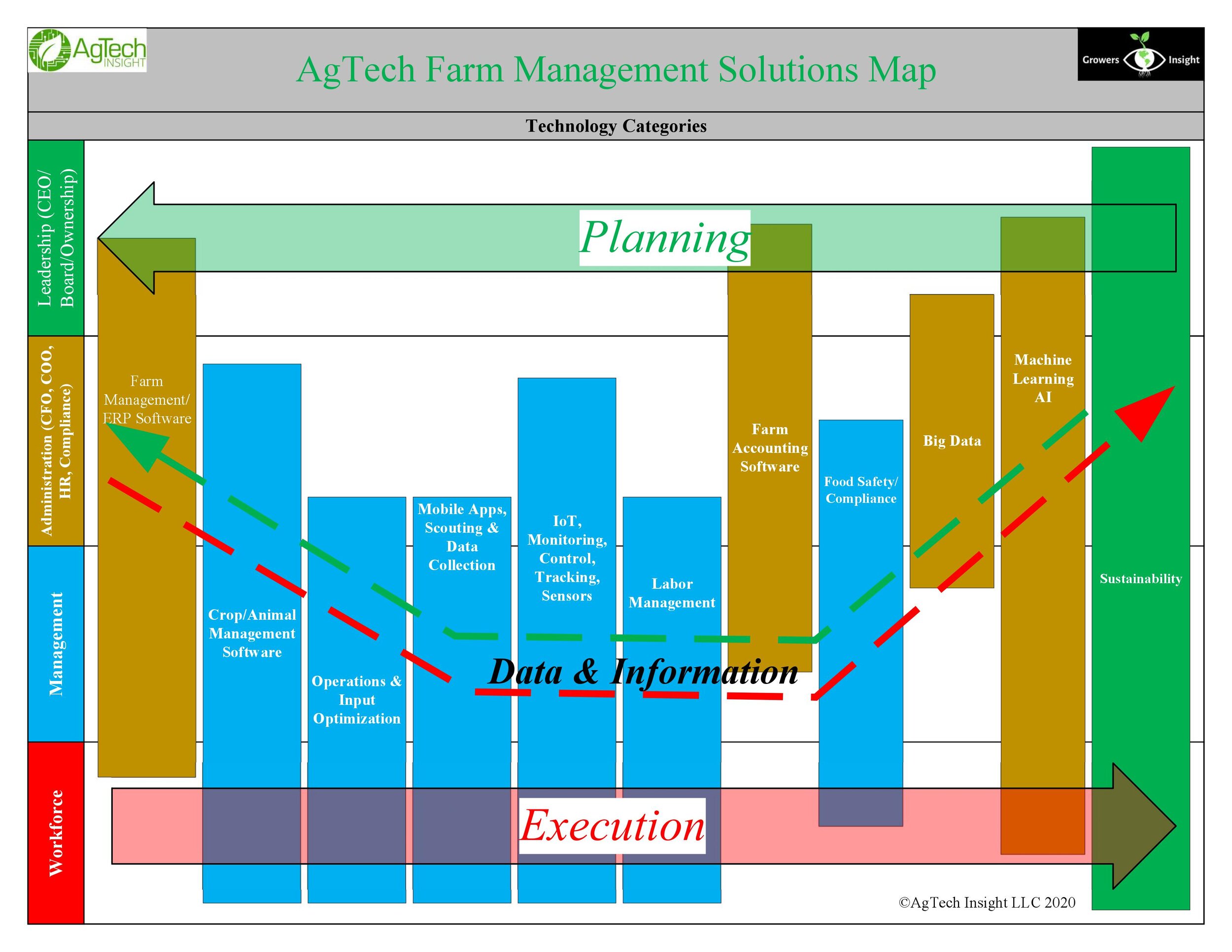

Over the past couple of years, our database of digital AgTech solution providers has grown to over 3,000 companies. Farm Management Software (FMS) has become the largest category, with over 500 listings. As we once again reviewed the details of each company to choose those we feel are leading their sector, it became clear we needed to further break down the FMS category based on core competency. This article explains the industry’s current state and how, as these AgTech solutions work in combination, they become extremely valuable for AgriFood businesses. We’ve also included an infographic illustrating how these technologies work together, who uses them, dataflow processes, and the value they bring throughout the organization.

Five years ago, lots of companies wanted to be the leading “FMS” platform. Today there is still no clear winner, so I think we can all agree it’s too big of a task with too many variables for one technology company. We must focus on user success, adoption, and RoI, therefore, our approach is to piece together many best-in-class solutions and then aggregate them — like they do in almost every other industry — to meet the needs of customers.

As the AgTech industry matures, there are companies who get really good at solving one specific problem becoming their “core technology.” This helps everyone understand where each company can provide the most value, as well as identifying the solution as complementary rather than competitive.

While the industry becomes more collaborative and standardized, each solution will continue to be a very important tool used day-to-day by some people on the farm while also feeding that data into larger farm management systems and platforms. These larger platforms are aggregating a variety of point source data being collected and provide a wider view of what’s happening on the farm for mid-level management. This data will be further shared to a business intelligence platform, which helps leadership make financial and business decisions but will not typically be used by a farm supervisor managing daily activities and production.

Leadership Level Solutions

Farm Management/ERP Software Platforms

You can think of these platforms as “enterprise solutions” from Microsoft, IBM, Oracle, and SAP’s of the world...but for Ag. They work with a variety of integrated software applications and systems to bring these dispersed datasets together and provide a variety of often custom analytic insights to company leadership. These platforms require an administrator and are primarily used to make financial and large business decisions rather than improving the day-to-day production of a specific crop.

Sustainability

Sustainability is an important topic across any organization and (along with agility) drives its future. Most companies and governments are integrating sustainability efforts across their business from soil and animal health through carbon farming and logistics. To meet the United Nation’s Sustainable Development Goals (SDG’s) by 2030, a huge effort needs to be put forth by every person, so this category spans the entire organization.

The following diagram shows the flow of decisions and data including each user group by category:

Upper-Level Management/Administration Solutions Farm Accounting Software

Tracking an Ag company’s financials is more important today than ever, thus feeding granular data from both revenue as well as ops/expenses to count pennies is of utmost importance – not only to keep the company in business, but to be able to calculate real RoI (Return on Investment) for innovation efforts and other expenditures. Many of the other systems being used across the operation will feed financial data into this system.

Big Data Providers

There is a plethora of data being collected from millions of sources, and while it may not always be extremely specific to your exact case/location (as in weather), leveraging Big Data across market pricing, asset values, consumer trends, and even imaging can be used to further support a farmer’s decision- making by finding anomalies, providing a larger data set, and more.

Machine Learning and Artificial Intelligence (AI) Tools

As Ag-focused tools to fill the needs of the sector have not yet emerged, great platforms and developer’s tools prominent in other industries are the solutions we can leverage in the near future. These tools can be used as a front end user interface like Power BI or Tableau, allowing the user to run data into the platform to analyze, build projections, prescriptions, and automate processes. They can also be used in the back end of other solutions, doing the heavy lifting and data crunching before sending the prescriptions and actions back to a software’s user interface or to be carried out autonomously.

Mid-Level Management and Workforce Solutions

Crop/Animal Management Software

This is still the largest bucket in the Ag software world, but we have narrowed it down significantly. These FMS are focused more on the operations side, helping to grow a better crop while reducing inputs. They are typically pureplay software and use API’s (Application Programming Interfaces) to collect and share data from a variety of applicable sources. These solutions are most often used by Ag operations directors through ranch managers to get a high-level view of what’s happening across their operations and highlight potential issues and opportunities for improvement. The workforce also uses these solutions by tracking their activities and receiving recommendations. It can also be a catch-all place to aggregate data and display important KPI’s (Key Performance Indicators) on a dashboard for easy and quick access to what is most important while allowing a deeper dive to further inspect as needed.

Mobile Apps, Scouting and Manual Data Collection

These important tools are typically used by advisors, agronomists, PCA’s (Pest Control Advisors), foremen, laborers, etc. to collect data and verify as tasks are being done. They also create an historic record that can be used in the future to compare and analyze events like pest infestations, animal health, or water usage.

IoT, Monitoring, Control, and Animal Tracking

There are a number of IoT platforms which focus on fixing a certain problem such as collecting soil moisture, irrigation data, and weather, or tracking a cow to alert when it’s becoming sick or ready to be bred. Their intention is to improve profitability and sustainability while also growing a better product. These hardware-centric approaches use real-time sensors (often from 3rd parties) to collect a variety of data on crops, animals, weather, equipment, people, and more before sending it to a database in the cloud. They produce real records and ground-truthing which can be used to trigger alerts, for analytics, modeling, to calibrate machine learning or AI models and more.

IoT Plus Analytics User Interface Similar to the above category, this is a large sector which also focuses on a specific problem. However, these companies have not only built the hardware portion, but they have also built a software user interface including more advanced analytics or modeling to provide actions around the conditions they are reporting. They typically will also pull in data from other sources to support the decision-making for the specific problem they are solving.

Input and Farm Operations Efficiency and Optimization

These solutions concentrate on helping improve the efficiencies around spray, variable rate applications, or energy/water usage. They can also help with logistics and optimization across a farm by having the right people, equipment and other resources at the right place, at the right time. This can reduce harvest costs by not having trucks and trailers waiting around and streamlining trucks arriving at a processing facility.

Labor Management

Ensuring you have the required workforce and staying connected with them has become a constant battle, as has ensuring they are performing the tasks planned at an acceptable level. These solutions can help mitigate labor shortages while collecting valuable insights to be fed into a FMS and enterprise solutions.

Food Safety/Compliance

This sector of solutions have mostly been built to mitigate risk but have a much larger role to play as they are integrated into larger platforms. Many will start using a backbone blockchain technology, allowing for easier data segregation and to provide invaluable insights into both cost and risk evaluation.

Summary

With so many great technology solutions available today, deciding where to start and who to work with is important. The key to success comes through creating a cultural shift into modernization throughout a business organization. Our companies specialize in designing and implementing successful innovation plans for our clients.

Please Click Here to View: Growers Insight - Grower Overview Slides 3.0

For support through your AgTech journey, please contact:

Aaron Magenheim, CEO & Founder AgTech Insight & Growers Insight

AaronM@AgTechInsight.com

+1-831-595-6064 Mobile

+1-855-410-2030 Office

© AgTech Insight LLC 2020

You Must Be Able To Sell Vertically-Farmed Goods At Competitive Prices

Urban Harvest’s owners do see a future in vertical farming but do not believe it will replace ‘normal’ greenhouse cultivation. “It is better to consider vertical farming as a supplement to a greenhouse and full soil farming.

Two years ago, business partners, Alexandre Van Deun and Olivier Paulus, opened one of the very first vertical farms for herbs in Brussels, Belgium. Now, the complete classic herb assortment is grown. Not only for local retailers like Delhaize and Aveve, but also for catering companies and restaurants. The farm's current 1,400m2 has become too small. This duo's next step is, therefore, a new 2,5-hectare farm with 15 cultivation layers.

Urban Harvest is currently located in an old meat market in the heart of Brussels. “The building was standing empty, and we wanted to grow our products locally, close to the consumer,” says Urban Harvest’s Alexandre. “At the moment, we cultivate on five or six layers in a 1,400m2 farm. We have all the traditional pot herbs in our range and also grow special herbs per client orders. Our clients are always interested in novelties. So we are always busy testing new products and growing techniques to respond to their demands.”

Herbz“The two largest retailers that buy our herbs are Delhaize and Aveve. Delhaize sells the herbs under their private label, and at Aveve, from May, they will be sold under their house brand, Herbz. The packaging is completely plastic-free, and on it, you can see that the herbs are grown, sustainably, in a vertical farm."

"In stores, there is no surcharge for vertically-farmed herbs. Sustainability is important to consumers, but they will not pay more for a different cultivation method. We deliberately built our system in such a way that we can supply our products at competitive prices,” continues Van Deun.

Flavor and shelf lifeUrban Harvest cultivates its herbs on a substrate and, according to Van Deun, this contributes to the herbs’ good flavor and the plant’s resilience. “There are crucial aspects. The flavor must win over consumers, but the herb must also store well. Our herbs can easily last a week in someone’s kitchen,” explains Alexandre. “One of the most difficult herbs to grow is mint. We grow our plants from seeds, but it is almost impossible to find mint seeds. In the business, we mainly work with cuttings, making it hard to find good mint seeds. That is a puzzle we have not yet cracked.”

“Automation equals costs”Alexandre and Olivier developed the entire vertical farm themselves. “We were busy building the farm for 16 hours a day, seven days a week. We are very proud of that. Once we got four investors, we were ready for the next step,” continues Van Deun. “Our current and new farms are not completely automated. There are plenty of textbook examples of vertical farms that are not fully automated. There are costs involved with automation that people are not prepared to pay."

"That is why we decided to only focus on processes that make sense to automate. We, therefore, retain a measure of human interaction. Harvesting is still done by hand, and being able to control the quality is a considerable advantage of this. A harvesting robot would not be able to do so. In contrast, planting is automated. There are machines that do this perfectly, so why do it manually?”

Fifteen cultivation layers“We have since burst out of our seams and so, had to go in search of a new location. We will remain in Brussels, with a site that lies adjacent to the channel. We soon want to use the channel to transport raw materials, rather than using road transportation. We are already busy building the new vertical farm at this new location. It will be 2.5 hectares in size, and ten meters tall, so we can grow on 15 layers,” says Alexandre. If all goes to plan, the new farm will be operational in 2021.

Urban Harvest’s owners do see a future in vertical farming but do not believe it will replace ‘normal’ greenhouse cultivation. “It is better to consider vertical farming as a supplement to greenhouse and full soil farming. That is why, nine times out of ten, an idea like a roof greenhouse fails. Why build a conservatory in the middle of a city, on an expensive site? This can easily be done at the edge of town or in the countryside. If something’s production price is too high, there is no sense in investing in it,” concludes Alexandre.

More info

Alexandre Van Deun

alexandre@urbanharvest.eu

Urban Harvest www.urbanharvest.eu

By Sharon De Ridder | FreshPlaza.com | May 7, 2020

Elevate Farms Executes Agreement to Bring Food Security to The Yukon and Other Isolated Northern Territories of Canada

Elevate and North Star have agreed to develop and construct a series of automated large-scale facilities (“CEF Facilities”) dedicated to the mass production of leafy green plants implementing, among other techniques, the use of patented LED lighting, moving grow boxes and controlled growth environments (“CEF Technologies”)

TORONTO, May 12, 2020

(GLOBE NEWSWIRE)

Elevate Farms Inc. (“Elevate” or “Elevate Farms”) is pleased to announce it has entered into an agreement (“Agreement”) for an initial build-out commitment of US $10,000,000 with North Star Agriculture Corp. (“North Star” or “North Star Agriculture”) to bring Elevate’s proprietary vertical farming, and cost-effective production of leafy green vegetables, to the Yukon and other isolated northern territories of Canada. Elevate and North Star have agreed to develop and construct a series of automated large-scale facilities (“CEF Facilities”) dedicated to the mass production of leafy green plants implementing, among other techniques, the use of patented LED lighting, moving to grow boxes and controlled growth environments (“CEF Technologies”).

The Agreement contemplates the development of CEF Facilities for the production and supply of leafy green plants employing financing, as well as operations and retail expertise, from North Star and industrial and technical support of the CEF Technologies from Elevate. Each element of the process of development of the CEF Facilities are conditional upon the completion of supporting documentation including the settlement of definitive agreements including, but not limited to, shareholders’ agreement, reverse vesting agreement, licensing agreement, and supply agreement. Each CEF Facility, once complete and operational, is expected to produce an estimated 10-tons (9,100 kilograms) of leafy green vegetables per week, which is the equivalent to in excess of 1,000,000 pounds (473,200 kilograms) of leafy green vegetables per year.

Amin Jadavji, Elevate Farm’s Founder and CEO, stated “We are extremely excited to partner with North Star to bring food security and nutrition to a particularly isolated and vulnerable region of Canada. This is Elevate Farms’ second Canadian million-pound facility for which Elevate has secured financing commitments - with significantly larger faculties already financed in New Jersey, USA and in Hamilton, New Zealand. Elevate is making excellent progress in executing our plan on creating a global brand in the area of food security and local sustainability.”

Sonny Gray, CEO of North Star, stated: “North Star Agriculture is committed to #FeedtheNorth by developing a variety of food security based projects and initiatives. Our partnership with Elevate perfectly unites with our goal of developing agriculture ‘north of 60’ with the aid of modern technology and sustainable farming practices.”

Travis Kanellos, Elevate Farm’s Chief Strategy Officer stated: “Food security, as defined by the United Nations' Committee on World Food Security, means that all people, at all times, have physical, social, and economic access to sufficient, safe, and nutritious food that meets their food preferences and dietary needs for an active and healthy life. As we have become aware, broken links in supply chains, at home and abroad, have become all-too-real as communities implement travel and supply restrictions to combat COVID-19. The underlying causes of food insecurity are not only drought and conflict in faraway lands but also distribution and access concerns in the end user’s locality.”

Amin continued, “Our vertical farming solution provides fresh and healthy leafy green vegetables - the only vegetables that cannot be frozen for later consumption - by securing availability, access, use, and utilization, as well as increased general stability with the potential for years-long self-sufficiency during uncertain times which may include events such as government-mandated quarantine and self-isolation. Elevate’s patented food production solution goes a long way to solve the issues facing the North, and other dependant environments affected as they may be difficult to reach regions or fragile ecosystems. ”

ABOUT ELEVATE FARMS

Elevate Farms Inc., previously operating corporately as Intravision Greens Inc., is a technology-driven vertically-stacked indoor farming enterprise focused on a mass scale and cost-effective operations with patent secured and patent-pending technology as well as over a decade of advanced photobiology research deployed.

Amin Jadavji

ajadavji@elevate.farm

Interview With Eddy Badrina, CEO of Eden Green Technology

One company that is looking to take on the commercial agricultural industry is Eden Green Technology, a company based out of Texas that focuses on sustainability in the food industry

Josiah Motley · April 27, 2020 · Short URL: https://vator.tv/n/5018

A look at the vertical farming platform that uses tech to grow a variety of healthy foods

When we talk about technology, it's easy to focus on things like computers, smartphones, apps, and the growing number of smart gadgets found in our homes.

But technology is far-reaching and can influence and change traditional sectors quickly. One sector that may seem immune to the growing use of technology is the farming industry, but a quick look at what farm equipment is becoming can prove that wrong quickly (even if the transition is proving difficult for some).

One company that is looking to take on the commercial agricultural industry is Eden Green Technology, a company based out of Texas that focuses on sustainability in the food industry.

I had the chance to interview Eddy Badrina, CEO of the company, to learn a bit more about what they are doing, how they use technology, and how they envision the future of the agricultural industry.

Check it out below.

Care to introduce yourself and your role with Eden Green?

Sure. I'm Eddy Badrina, and I’m the CEO of Eden Green Technology.

In just a few sentences, what is Eden Green?

Eden Green Technology is a vertical farming platform that grows large quantities of local produce safely, sustainably, and efficiently. We use less land, energy, and water than both traditional farming and other indoor solutions.

Our greenhouses are constructed on small footprints, in urban or suburban areas, to provide stable jobs and produce non-GMO, pesticide-free produce, which goes from farm to table in as little as 48 hours, compared to the 14 days it usually takes under the traditional model.

What inspired the creation of the company?

The founders of Eden Green are brothers Jacques and Eugene van Buuren. They witnessed firsthand the effects of hunger in their native South Africa and thereafter dedicated themselves to helping feed the world.

They came to the US to secure investment, source talent, and experiment with their technological solutions in our diverse climates. They started in Texas, with its own extreme range of environmental considerations, agricultural know-how, and business opportunities, and built from there.

What types of produce can your vertical farms grow?

Our greenhouses can grow 50+ varieties of produce, including herbs, leafy greens like spinach, kale, and arugula, and a sizable array of vegetables, plus other non-produce plants like hemp and research crops.

You call yourself a tech company, can you go into more detail on that?

Absolutely. So, our technical secret sauce consists of a few ingredients, including our patented vertical “vines,” where our produce grows, and the way we create microclimates for each individual plant with temperature-controlled air and nutrient-enriched water.

We also designed and built a proprietary mechanical, electrical, and plumbing solution specifically to automate and remotely monitor all our greenhouses. Because of that hardware and software combination, we like to think of ourselves as a technology company that happens to grow produce.

Eden Green seems extremely relevant right now with coronavirus, are you doing anything to help people and businesses affected by the virus?

We directed our R&D facility to start a unique partnership with a local business that had to pivot from supplying high-end restaurants to starting home deliveries of high-quality poultry, eggs, beef, and produce.

For every pound of our produce they deliver, we are giving one pound away to local food banks, homeless shelters, and other nonprofits. The creative problem-solving of combining how to sell our produce, help another small business grow, and feed the local underserved population all at the same time, was a really valuable experience.

More generally, the coronavirus crisis brings into focus the kinds of problems with traditional farming methods that we help directly address - easy access to local food sources, sustainability, and resiliency.

A more-widespread application of greenhouses like ours would also help defray the market effects of workforce shortages due to sickness, the personal effects of crowded, unsanitary, and otherwise-unsafe work environments, and the problems that come with relying on low-paid seasonal work.

What locations are you currently available in and do you plan on expanding?

We currently have our R&D facility in Texas and are prepping for facilities to be built in two other countries and a number of states.