Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Risk of E. coli In Hydroponic And Aquaponic Systems May Be Greater Than Once Thought

A spate of foodborne illnesses in leafy greens and other produce in recent years has sickened consumers and disrupted growers and supply chains

Hye-Ji Kim (left), pictured with graduate student Seunghyun Choi, found the presence of E. coli bacteria in aquaponic and hydroponic growing systems, suggesting the bacteria could reach produce consumers. (Agricultural Communication photo/Tom Campbell)

WEST LAFAYETTE, Ind. – A spate of foodborne illnesses in leafy greens and other produce in recent years has sickened consumers and disrupted growers and supply chains. It’s been thought that hydroponic and aquaponic systems could reduce these issues since there is little opportunity for pathogens like E. coli to contaminate the edible parts of plants.

A Purdue University study, however, has found the presence of Shiga toxin-producing E. coli (STEC) – the same bacteria that have made consumers of several produce products ill – in hydroponic and aquaponic growing systems. Hye-Ji Kim, an assistant professor of horticulture and the study’s corresponding author, said the findings suggest growers using these systems should be careful in handling and harvesting to avoid contamination.

“Many people think that there is no chance that E. coli could be present in these systems and that risk of contamination is low,” said Kim, whose results were published in the journal Horticulturae. “Our findings suggest there is some potential for food safety concerns. We’re not saying that these foods are unsafe, but that it’s important to handle these plants properly and carefully.”

Aquaponic and hydroponic growing systems are thought to have little risk of containing bacteria that can sicken produce consumers. After finding E. coli in both types of systems, Hye-Ji Kim suggests growers to use caution to not introduce the bacteria to their operations. (Agricultural Communication photo/Tom Campbell)

The E. coli outbreaks that have occurred in recent years tend to happen in leafy greens and other vegetables grown in irrigated fields. Potential sources could be from E. coli in manure or groundwater that reaches the edible portions of plants, or from those contaminants getting to plants after root damage by wild animals.

Proponents of hydroponic and aquaponic systems suggest their growing methods would reduce or eliminate any risk of contamination. Both soilless systems, hydroponic plants are grown in water and chemical fertilizers or nutrient solutions, and aquaponic systems include the raising of fish, with fish wastewater utilized as water and nutrient source for the plants.

The fish used in aquaponic growing systems may introduce E. coli to water and potentially produce crops, and accidental contamination is possible in hydroponic systems. Hye-Ji Kim and Yi-Ju Wang (pictured) suggest growers take careful steps to ensure that these bacteria don’t reach plants that could sicken consumers. (Agricultural Communication photo/Tom Campbell)

Kim, Yi-Ju Wang, a graduate student in Kim’s lab, and Amanda Deering, a Purdue clinical assistant professor of food science, set up both hydroponic and aquaponic systems for growing lettuce, tomatoes, and basil for about two months. The scientists found E. coli in both systems at the time of harvest.

In the aquaponic system, the authors believe the E. coli was introduced by the fish. The bacteria was found in the water, on plant roots, and in fish feces.

“Our separate aquaculture system confirmed that fish feces were a major source of contamination with STEC in the aquaponic system,” the authors wrote. “These results indicate that introducing contaminated fish can be a source of foodborne pathogens in aquaponics.”

The presence of E. coli in the hydroponic system, in which fish were not used, suggests that the bacteria was introduced accidentally. Kim believes it could have splashed from a nearby aquaponic system or have been introduced by a visitor who brought it in from outside the greenhouse. Either way, the presence in the system suggests that accidental contamination is a real risk.

E. coli was also found on plant roots in both systems, but the bacteria did not internalize in the plants. In other words, even with the bacteria present in water and on the roots, the edible portions of the plants were still safe to consume.

The key, Kim says, is proper handling to ensure that E. coli or other pathogens don’t make it to the edible parts of plants. Damaged roots would allow bacteria into the plants, potentially making it to edible portions internally. And the splashing of water during growing or harvesting could introduce bacteria to the edible portions of the plants.

“The best way to manage these issues is to not touch roots or water throughout production cycles. If you do, you should thoroughly wash your hands before touching the edible parts of the plants,” Kim said. “Proper sanitization of equipment is also important. And acquiring fish that do not contain E. coli would also be beneficial.”

Kim’s lab is continuing to investigate food safety risks in hydroponic and aquaponic systems. Projects include damaging roots and simulating splashes to understand how much contamination can occur.

The Indiana State Department of Agriculture, the U.S. Department of Agriculture’s National Institute of Food and Agriculture, and the Purdue University College of Agriculture funded this research.

Writer: Brian Wallheimer, 765-532-0233, bwallhei@purdue.edu

Source: Hye-Ji Kim, 765-496-0122, hjikim@purdue.edu

Note to Journalists: A portrait of one scientist, a picture of another scientist in the lab and a picture of a growing system are available for journalists to use via Google Drive.

ABSTRACT

The Occurrence of Shiga Toxin-Producing E. coli in Aquaponic and Hydroponic Systems

Yi-Ju Wang1, Amanda J. Deering2, and Hye-Ji Kim1

Department of Horticulture and Landscape Architecture, Purdue University, West Lafayette, IN

Department of Food Science, Purdue University, West Lafayette, IN

Food safety concerns have been raised over vegetables and herbs grown in aquaponics and hydroponics due to the reuse of wastewater and spent nutrient solutions. This study was conducted to determine the occurrence of foodborne pathogens in greenhouse-based aquaponic and hydroponic systems. Fish feces, recirculating water, roots, and the edible portions of lettuce, basil, and tomato were collected at harvest, and microbiological analyses were conducted for the bacterial pathogens Shiga toxin-producing Escherichia coli (STEC), Listeria monocytogenes, and Salmonella spp. Enrichments and selective media were used for the isolation, and presumptive positive colonies were confirmed by PCR. STEC was found in fish feces, in the water of both systems, and on the surface of the roots of lettuce, basil, and tomato regardless of the system. However, contaminated water did not lead to the internalization of STEC into the roots, leaves, and/or fruit of the plants. Meanwhile, L. monocytogenes and Salmonella spp. were not present in any samples examined. Our results demonstrated that there are potential food safety hazards for fresh produce grown in aquaponic and hydroponic production systems.

Agricultural Communications: 765-494-8415;

Maureen Manier, Department Head, mmanier@purdue.edu

Nature Fresh Farms Sales Welcomes New Team Member To Sales Staff

Zanelle Hough began her career 14 years ago in Logistics working for a South African exporter

Leamington, ON (March 31, 2020)

Nature Fresh Farms Sales expands its team, welcoming Retail Sales Account Manager, Zanelle Hough to their sales department.

Zanelle Hough began her career 14 years ago in Logistics working for a South African exporter. Wanting to gain more experience in sales, she shifted to the Walmart Global Procurement team as a Logistics and Procurement specialist sourcing South African product for the various Walmart and Sam’s Club retail stores in the USA and Asia. Two years later Zanelle fully transitioned to a sales role working for a South African exporter called Freshworld, an organization that specializes in direct retail programs throughout the world. In addition to the retail accounts, she has managed the SunkistTM Global account for various customers throughout Asia and North America.

General Manager, Frank Neufeld shared his enthusiasm for the new extension to their team: “We are very pleased to welcome Zanelle to the Nature Fresh Farms Sales team. Having many years of experience in the produce industry, she will be a great asset in supporting our rapid growth and assisting our customers in the best possible way,” said Frank. “As business continues to expand it’s essential to find key individuals who will help bring Nature Fresh Farms to even greater heights.”

As Retail Sales Account Manager, Zanelle’s responsibilities will include generating sales from new and existing accounts, raising awareness of company offerings while increasing our market share, and building strong relationships with her retail partners. With Zanelle based in Leamington, ON, she will continue to help support the rest of the sales team with her invaluable experience.

“As our company continues to expand and gain market share, we are investing in the growth of our team. Adding Zanelle to the sales team provides us with a strong individual that can continue to help propel us forward,” shared Director of Sales, Matt Quiring. “Culturally, this is a great fit as well. You can see immediately when someone fits into your company’s culture and it excites me for what the future holds!”

With further developments on the horizon, Nature Fresh Farms is thrilled with the growth of the company and the new addition to the team. As business continues to expand, the company is excited to offer new opportunities for professional development.

-30-

About Nature Fresh Farms -

Continuously expanding, Nature Fresh Farms has become one of the largest independent, vertically integrated greenhouse vegetable farms in North America. As a year-round grower with farms in Leamington, ON, Delta, OH, and Mexico, Nature Fresh Farms prides itself on consistently delivering exceptional flavor and quality to key retailers throughout North America, while continuing to innovate and introduce more viable and sustainable growing and packaging solutions.

SOURCE: Nature Fresh Farms | info@naturefresh.ca T: 519 326 1111 | www.naturefresh.ca

Here Are The ‘Dirty Dozen’ Fruit And Vegetables Laced With Legal Pesticides — Even Organics Have Traces

Nearly 70% of the fresh produce sold in the U.S. contains residues of legal though potentially harmful chemical pesticides even in small amounts, and a popular snack for children is another big offender

March 25, 2020

By Rachel Koning Beals

Raisins are surprise offenders this year with neurotoxic insecticide chlorpyrifos, which some research has shown can harm the nervous system in children

Nearly 70% of the fresh produce sold in the U.S. contains residues of legal though potentially harmful chemical pesticides even in small amounts, and a popular snack for children is another big offender.

Among the top choices to limit exposure to pesticides? Avocados, asparagus, and honeydew melon.

The analysis comes from the Environmental Working Group. Each year since 2004 it has ranked its Dirty Dozen and Clean Fifteen lists and combines them as a shopper’s guide for consumers. The “dirtiest” of all is not a fresh fruit or vegetable, but a dried one — raisins. Raisins weren’t ranked on the fresh lists but their surprising results caught the attention of EWG.

Toxicologists and other researchers at EWG compare the pesticide contamination of 47 popular conventional — meaning not farmed organically — fruits and vegetables. The review is based on the results of tests by the USDA and the Food and Drug Administration of more than 43,000 samples of produce.

Environmental Working Group

Most pesticide residues the agency finds fall within government-mandated restrictions, but advocacy groups such as EWG argue “legal does not mean safe.” Before conducting its tests, USDA washes, scrubs, and peels fruits and vegetables as consumers would.

Thomas Galligan, Ph.D., a toxicologist with EWG said researchers continue to study why raisins contained higher traces of pesticides than the grapes they’re dried from, though grapes ranked on the list this year. Read more of his analysis.

Children under the age of 15 eat a total of about 208 million pounds of raisins each year, or about half of the raisins consumed in the U.S., according to Zion Market Research. The average American consumed about 1.25 pounds of raisins in 2017, the latest year for which the USDA has information. Zion’s industry analysis shows that slightly less than two-thirds of raisins are consumed as ingredients in other foods, with the rest eaten as a stand-alone snack.

“Infants, babies and young children are exquisitely vulnerable to even low levels of pesticide exposure, so it’s important parents and caregivers take steps to safeguard children from these chemicals while also providing them diets rich in healthy fruits and vegetables,” said Dr. Philip Landrigan, a pediatrician and epidemiologist who’s director of the Program in Global Public Health and the Common Good in the Schiller Institute for Integrated Science and Society at Boston College.

“For many Americans, choosing an all-organic diet is not possible, so [pesticide guides] can help give consumers the tools to provide their families with a mix of both conventional and organic fruits and veggies without the pesticide punch,” he said.

Environmental Working Group

Producers generally use pesticides to improve crop yield, which can hold down retail prices, which is particularly important to low-income consumers. The findings also show that even produce labeled organic can show traces of pesticide.

The EWG group highlighted two chemicals in particular. One is neurotoxic insecticide chlorpyrifos, which some research has shown can harm the brain and nervous system in children at even low levels. The chemcial was detected on 5%, or 34 out of 670 samples, of conventional raisins, and 6%, or five out of 86, of organic raisin samples.

California, where the majority of the U.S. raisin supply is produced, recently banned all uses of chlorpyrifos because of the risks it poses to both children and farmworkers. That regulatory change was not carried through to the federal level, however.

The second chemical of note is neonicotinoids, which the USDA’s tests detected on almost one-fifth of fruits and vegetables. Neonics are the fastest-growing class of insecticides, “despite a decade of research making it clear that they are highly toxic to honeybees and other pollinator species,” EWG researchers said. Some studies on human health also suggest that exposure to neonics may be harmful to the developing fetus and children, they said.

Residues of at least one of three neonicotinoid pesticides banned in the European Union — imidacloprid, clothianidin, and thiamethoxam — were found on more than half the U.S. samples of potatoes, spinach and lettuce tested. At least one of these neonics was also found on more than one-fourth of the samples of U.S. cherries, watermelon, and strawberries.

The Alliance for Food and Farming, which represents both organic and conventional farmers of fruits and vegetables, argues that these annual lists overstate the amount of pesticide detection on food.

“To accurately assess consumer risks from pesticides, one needs to consider three major factors – 1) the amount of residue on the foods, 2) the amount of food consumed, and 3) the toxicity of the pesticides,” said Dr. Carl Winter, professor emeritus in toxicology at the University of California, Davis.

AFF points to an analysis and a calculator from toxicologists with the University of California’s Personal Chemical Exposure Program, which found a child could eat hundreds to thousands of servings of a fruit or vegetable in a day and still not have any health effects from residues.

Experts at EWG and the AFF stressed that maintaining fruits and vegetables in daily diets is the most important goal. Sometimes budget and availability limit shopping for organic produce.

“Although we believe consumers should be concerned about pesticide residues on the food they eat, the health benefits of a diet rich in fruits and vegetables outweigh the risks of pesticide exposure,” said Alexis Temkin, PhD, a toxicologist with EWG. “With the Shopper’s Guide, consumers don’t have to choose between pesticides and a healthy diet.”

EWG added specific guidance to its report as consumers respond to the coronavirus pandemic.

It is important to know that there is no evidence people can be exposed to the coronavirus through food, experts say. The spread pattern is quite different from foodborne pathogens like Salmonella and E.coli. That is why, even though the risks of COVID-19 are serious, consumers should continue eating plenty of healthy fruits and vegetables while in quarantine at home, the group said.

Lead photo:

Children under the age of 15 eat a total of about 208 million pounds of raisins each year or about half of the raisins consumed in the U.S. Getty Images

Professional Chefs Bring Out The Best of Madar Farms' Microgreens At Emirates Salon Culinaire

As part of the Expo Culinaire event, in collaboration with Emirates Culinary Guild, the chefs put their creative, gastronomic and artistic skills to the test in front of a judging panel

Abu Dhabi, 16 March 2020: Hundreds of professional chefs from the UAE and abroad prepared dishes using a variety of microgreens grown by Madar Farms at this year’s Emirates Salon Culinaire competition in Sharjah.

As part of the Expo Culinaire event, in collaboration with Emirates Culinary Guild, the chefs put their creative, gastronomic and artistic skills to the test in front of a judging panel.

Among the ingredients used were different ranges of microgreens that were grown in the UAE by AgTech company Madar Farms. Their local fresh produce included pea shoots, arugula, tendril peas, daikon radish, and amaranth.

Abdulaziz AlMulla, co-founder and CEO of Madar Farms, said: “As a partner, we are delighted to have been involved in this year’s Emirates Salon Culinaire. For any chef, fresh ingredients are key for preparing any type of dishes. With Madar Farms using cutting-edge farming techniques and advanced methods to grow quality produce every day, our supply of microgreens for the competition meant they were not only full of flavour but were grown here in the UAE.”

Chef Uwe Micheel, President of the Guild and Director of Kitchens Radisson Blu Hotel, Dubai Deira Creek, said: “We were privileged to have Madar Farms as one of our new partners for this year’s event. Madar Farms was our sole supplier for the microgreens and the freshness and quality of the products were very well received by the competing chefs.”

Major Food Shortages Possible In Asia Says "Food Industry Asia"

ASEAN Food and Beverage Alliance (AFBA), the regional associations representing Asia and ASEAN’s food and beverage (F&B) industries respectively, are jointly calling upon governments across the region to ensure the unhindered production and supply of food

30-Mar-2020 By

Jim Cornall

In light of the increasing number of nationwide lockdowns and border restrictions, Food Industry Asia (FIA) and the ASEAN Food and Beverage Alliance (AFBA), the regional associations representing Asia and ASEAN’s food and beverage (F&B) industries respectively, are jointly calling upon governments across the region to ensure the unhindered production and supply of food and beverages as each country tries to contain the outbreak of COVID-19.

READ MORE

"With Our Concept, Everyone Can Be A City Farmer"

As Sweden is not on a lock-down yet, the virus is nevertheless having a great impact on jobs and the country’s economy

As Sweden is not on a lock-down yet, the virus is nevertheless having a great impact on jobs and the country’s economy. Crisis packages for jobs and transition are now being presented by the government. So far SweGreen has not noticed a great impact on business despite the COVID-19, rather the opposite. The absolute major part of SweGreen produce, based in Stockholm, is the distribution of their ‘Stadsbondens’ branded leafy greens and herbs to supermarkets. A particular increase in sales is visible, even though the company doesn’t do anything extra in-store to meet customers, besides deliveries.

Free greens

“We have some restaurants on our client list, and we see that they are suffering a lot now. We are actually delivering to them according to the agreement, but for free. We have chosen to not charge our restaurant partners anything during this crisis, just to show our compassion and goodwill,” Andreas Dahlin, CEO of SweGreen says.

The SweGreen salad mix

Stadsbondens

Stadsbondens, which means ‘The City Farmers’ in Swedish, is the leafy greens brand, that SweGreen uses for marketing their produce to supermarkets. As for now, the produce is sold at around ten supermarkets, located in Stockholm. SweGreen has recently set up service together with an online distributor which enables them to sell their fresh produce online and home-delivery of the greens. Dahlin notes: “It gives us the possibility to reach more people. Next to that customers don’t have to get out of the house, and our brand lovers can order the fresh produce no matter where they are located in Stockholm.”

Farming as a Service

SweGreen has developed its own farming service, which is a closed environment and automated in-store solution that gives customers within grocery and restaurants the possibility to be their own providers of fresh, nutritional, locally-produced greens harvested directly off the shelf.

A vertical basil wall

“Farming as a Service, as we like to call it, is the service we offer. We provide a whole system, containing both software and hardware, such as monitoring and steering. So basically with our concept, everyone can be a City Farmer as it automates the whole growing process”, Andreas Dahlin says. In Stockholm, the SweGreen city farm has been fully developed for automation. “We control everything that goes in and comes out. With a fully closed system, we also can digitally control every unit or crop that we provide to our client. One of the most important keys for Urban Farming is absolutely being able to get valid data from growing processes and having the ability to convert the data to value-shaping intelligence. We focus a lot on this now. In this way, we can improve the systems constantly together with our clients.”

A vertical fresh produce wall

Future aspect“

Our objective now is to further develop the Farming Service. Our customers really appreciate this service model and I think the circumstances right now prove the importance of factors such as sustainability, resilience and hyper-local production for the food industry."

Andreas Dahlin, CEO at SweGreen

"We have just closed our second seeding round with investors and we are planning on expanding internationally. Not only with the focus on supermarkets, because we also get a lot of interest from restaurants too. Restaurants and chefs are early adopters when it comes to the sustainable production of food”, Dahlin adds.

For more information:

SweGreenAndreas Dahlin, CEO, and partner

andreas.dahlin@swegreen.se

www.swegreen.com

Publication date: Fri 3 Apr 2020

Author: Rebekka Boekhout

© HortiDaily.com

A Journey Through The World Supply Chain With IFCO Systems

Founded in 1992, IFCO was the first pioneer to reintroduce a reusable packaging system for the entire fresh product supply chain, from producer to retailer

Founded in 1992, IFCO was the first pioneer to reintroduce a reusable packaging system for the entire fresh product supply chain, from producer to retailer. They are now the clear market leader in the world, with operations in more than 50 countries across five continents and subsidiaries in 30 countries. Their services are used by 320 of the world’s largest retail companies and over 14,000 growers and food producers. How did they grow from niche service providers to global supply chain leaders? I sat down with CEO Wolfgang Orgeldinger at FruitLogistica in Berlin to find out.

It starts with a pool of 314 million plastic containers

These containers account for 1.7 billion roundtrips per year, from one end of the supply chain to the other and back. The system is simple: first, a newly cleaned and sanitized container is sent to a grower or packer; the product is then packed and shipped to a distribution center, where it is distributed to retail outlets; the product is then sold and the container is returned to a service center where it is cleaned. Round trip complete.

The prime products are fresh fruit and vegetables, but IFCO also transports significant volumes of meat, eggs, seafood, and bread. Most containers stay in a regional pool: for example, containers will complete roundtrips for transporting cabbage in Germany, oranges in Spain, or leafed salad in Holland. But they are also used for southern hemisphere imports, bringing kiwis from New Zealand, grapes and apples from South America, and oranges from Argentina. If you ever wondered where your bananas came from, there is a good chance they came from Central America in an IFCO container.

Regional pools are flexible and scalable: you could have a specific pool for continents like North America and Europe, or scale down to a country level for Japan, Argentina, or Chile; or you could hyper-localize the pool down to a city level, for integration with vertical farms in an urban food system. To give an example, Mr. Orgeldinger cited the city of Sao Paolo, where 90% of fresh produce is grown within 100km of the city center. IFCO’s pool of containers in this region only moves within that circumference.

The operation of these pools is much more sustainable than transporting fresh products with single-use packaging.

To begin with, the containers are designed to be sturdy: each container is used for up to 120 round trips before it reaches the end of its life cycle. Small damage is repaired at servicing centers; if the container is beyond repair, the material is ground down and turned into new packaging. IFCO is the only company directly recycling its own crates to make new ones; this is possible because their crates are made out of one material and can be ground directly into the production process. This cradle to cradle system helps IFCO reduce CO2 emissions by 60%, consume 80% less energy and use up to 80% less water in its operations when compared to using single-use packaging.

But why use plastic at all? The answer is to reduce food waste. When you transport fresh products, you have to account for humidity and plastic is the best material to reduce this problem. With IFCO’s containers, the damage and spoil rates of fresh products is 90% less compared to a single-use container. A further innovation in the IFCO system is that it is totally modular: they design containers in two footprint specifications: 60X40 cm and 30X40 cm. Each footprint stacks perfectly to maximize space and reduce the likelihood of a fall. Finally, each container includes a ventilation system that extends the lifespan of the food in transit and on the shelf.

Given all the advantages of their product versus single-use packaging, it’s no wonder that customers are flocking to IFCO’s sustainable solution. ‘Customers come because the system reduces costs,’ says Mr. Orgeldinger. If you look at the cost-saving across the entire supply chain, from field to retail store, and account for all packaging related costs, all handling costs, and product damage, IFCO can save up to 27% of the total cost. Given the growing momentum of environmental concerns among consumers and suppliers, IFCO is well primed to lead the supply chain into the future. Let’s take a look at how else IFCO is innovating to help growers, producers and businesses save money and save the environment: it starts with technology.

Innovation in packaging: Apps, AI, and integration with vertical farms.

You might wonder how much technology can be packed into a plastic box. But it’s more about the technology that surrounds the box itself. Remember that pool of 314 million plastic containers? They are tagged and the new generation is readable by your smartphone. IFCO is developing a new app that enables smartphone users to identify and count all containers on a pallet. The new technology will first be rolled out in service centers and trialed in order to improve the AI algorithm. They will then provide this service to customers, enabling all participants in a given pool to act more efficiently.

Another new app enables customers to do all transactions with IFCO via their smartphone. This is an industry first, enabling growers who rely on mobile technology to participate in the supply chain more efficiently. Other technical innovations that were mentioned by Mr. Orgeldinger included integrating IFD and GPS-based systems and blockchain solutions into their producer to retailer model. But I was most interested to find out about how IFCO could integrate with innovations in other fields, like the transition of fresh food production to hyper-local vertical farms.

Vertical farms offer IFCO containers a shorter roundtrip journey

Mr. Orgeldinger told me that vertical farming is the most interesting solution for feeding the growing population who live in large urban areas. Modular, reusable plastic containers are perfect for transporting fresh produce across short distances and there is significant scope for integrating IFCO’s packaging with the shorter supply chains that are enabled by vertical farming. This is scaling down from continent to country to city, creating a whole new set of container pools for IFCO to fill. Both IFCO and the vertical farms they choose to work with will play a significant role in the sustainability of urban areas going forward. We will be watching this space closely.

Find out more about IFCO at https://www.ifco.com/

KYLE BALDOCK

View All Posts

COVID-19 Roundtable: Indoor Ag Perspectives On Coronavirus

One of indoor ag’s greatest strengths is its diversity. Under one roof — hopefully, with a rooftop garden — it unites agriculture, tech, business, tradition, and innovation in a way few other industries can match

One of indoor ag’s greatest strengths is its diversity. Under one roof — hopefully, with a rooftop garden — it unites agriculture, tech, business, tradition, and innovation in a way few other industries can match. This diversity means that when it comes to confronting something like coronavirus, people may experience the crisis in different ways. And it means a world of different people bringing their unique experiences to the monumental task of keeping people fed while the rest of the world is shut down.

With that in mind, we reached out to our friends across the industry for a (socially-distanced, email) roundtable on what they’re seeing now, and what it means for the industry.

Supply and Demand Are Changing

As shelter in place orders go out across the country, shuttering bars and restaurants, Americans are returning to eating at home, and that’s changing how they buy.

“Supply chains are disrupted and most indicators say that it will take three to four weeks to adjust to the current coronavirus situation. There is a big shift away from restaurants and toward retail food purchases and direct to consumer options. Direct-to-consumer quickly went from something grocery stores and restaurants wanted to figure out to an urgent need given the number of people that cannot or do not want to venture out of their house.

“Local produce and products from vertical farms can fit nicely into this new model. They provide local and fresh options that can fill in current supply chain gaps. Consumers tend to increase purchases of local, organic, and natural products when there is a human health or food safety concern. This spike will likely happen here. The only factor pulling it down is that these products tend to be more expensive and many people are very worried about their jobs. Over 3 million people filed for unemployment this week and that number is expected to rise dramatically in the coming weeks.” — Michelle Klieger, Strategerm Consulting

Automation Is Imperative

Whether you harvest insects, like Ÿnsect, or make agtech solutions, like Autogrow, it’s clear that this moment underscores what we’ve known for a long time: automation is one of the keys to the next generation of indoor ag.

“We have a robotized manufacturing process, where we require very, very few workers. They are wearing a full suit, so they are secure, and have a mask, like a diver. The risks of contamination are very low.” — Alain Revah, Ÿnsect

“We recently launched our new environmental sensor network, Folium, and we’re super excited to present this state-of-the-art solution to commercial growers. Launching a new product just before a global pandemic hit, who could plan for that? We are responding to this by changing channels we utilize to connect with our customer base, including more marketing and video conferencing based meetings.”

“In the current climate it’s pretty evident that if you have advanced automation systems and new smart applications to run your farm, e.g. remotely accessible environmental and crop information along with farm management tools, it gives you the freedom to make sure you are aware of what’s happening with your crops and manage them, without having to always be physically on-site. And it minimizes commercial risk. You can’t do without a grower or manager (yet) but you can certainly use solutions that can help — especially during isolation situations, reducing risk to a minimum.” — Darryn Keiller, CEO, Autogrow

Protect Your People

Our product is great food, but great food comes from great, hard-working people, and their health is always key. That means shaking up business, and how we connect with each other on an emotional level, too.

“We restricted international travel earlier in March, we could see that coming. International travel and now domestic have effectively been suspended. Cancellation of trade shows has been the biggest impact, they are how the whole industry operates in terms of customer engagement.” — Keiller

“We are dealing with anxiety and the fear of the unknown with all of the employees. We are all human and struggle with not knowing details and being out of control. So lots of communication, discussions (which are slightly more awkward as we all practice social distancing). Trying to understand all of the new rules and options for employees as we continue to process the changes that are happening on a day to day basis.” — Paul Brentlinger, President, CropKing

A Silver Lining?

There is no doubt that coronavirus is awful in just about every way, but somewhere in there is small but powerful silver lining: it’s making people think seriously about where their food comes from, and what it takes to keep stores and markets full.

As Brentlinger puts, it, “I think it shows us how prepared we need to be for any situation, and how essential we are to the world.”

Amen to that!

Learn more about Contain and funding your indoor ag business at our website, and subscribe to Inside The Box, our weekly newsletter.

Agriculture Food Supply Chain Indoor Agriculture Vertical Farming

WRITTEN BY

Nicola Kerslake

We’re Contain Inc. We use data to improve access to capital for indoor growers, those farming in warehouses, containers & greenhouses. Contain.ag

The Climate Crisis May Have Helped Spawn Massive Locust Swarms in East Africa

East Africa is currently plagued with locust swarms of biblical proportions, but these swarms aren’t the act of an angry god. According to UN scientists, they may be a result of the human-caused climate crisis

East Africa is currently plagued with locust swarms of biblical proportions, but these swarms aren’t the act of an angry god. According to UN scientists, they may be a result of the human-caused climate crisis.

Hundreds of millions of these spooky creatures are flying across East Africa. The swarms are the worst to hit Ethiopia and Somalia in 25 years and the worst Kenya has seen in 70 years, the UN’s Food and Agriculture Organization (FAO) said in a statement. The insects are now plaguing Djibouti and Eritrea, too. By June, their numbers could grow by 500 times, and new swarms could form in Saudi Arabia, Sudan, and Yemen.

Locusts swarms aren’t by themselves unusual for the region, but last year, the East African region saw a lot of rain and eight devastating cyclones, which created the kinds of wet conditions that locusts need to breed in these numbers

.A Massive Locust Swarm Poses an 'Unprecedented Threat' to East Africa

A grim report from the United Nations warns that unusually large swarms of locusts will be…Read more

That rain came because of warming waters on the African side of the Indian Ocean; warmer waters mean more evaporation and precipitation. “That side of the ocean is much warmer than the other side, which meets with Australia and Indonesia,” Muhammad Azhar Ehsan, a research scientist at the International Research Institute for Climate and Society who studies the climate of the region, told Earther. “So the African side saw so much rain, but Australians got a drought.” That drought, of course, has furled the apocalyptic fires the Australian continent has been dealing with since last fall.

In 2018, East Africa saw drought peppered with cyclones. “Those cyclones were really unusual—they even created rainfall in the Empty Quarter,” said Ehsan, referring to the vast desert region in the southern Arabian Peninsula. “That’s a region known for high temperatures and [being] very dry. It never gets rain.” Those cyclones, too, created an extra-long breeding season for locusts, but they mostly lived in remote areas, so humans didn’t notice them at the time.“Nobody knew about it,” Keith Cressman, the FAO’s senior locust forecaster, told Buzzfeed News. “They were increasing about 8,000-fold for those nine months, with no disturbance and no control.”Swarms of desert locusts fly up into the air from crops in Katitika village, Kitui county, Kenya on Friday, Jan. 24, 2020.Photo: Ben Curtis (AP)The locusts aren’t just scary—they’re also threatening to exacerbate food insecurity. “A small swarm covering one square kilometer can eat the same amount of food in one day as 35,000 people,” the FAO said.

The creatures have already damaged pasture and croplands in Ethiopia, Kenya, and Somalia. “There are potentially severe consequences for the region where nearly 12 million people are coping with severe acute food insecurity and many rely on agriculture for their survival,” says the FAO. The recent floods and droughts had already put severe stress on agriculture, and the locusts storms are making that stress far worse.

The FAO has called for $70 million to help residents of Ethiopia, Kenya, and Somalia limit the spread of locusts and preserve people’s livelihoods. “Timing and location are crucial. I hope we can work hard day and night so people do not lose their crops,” FAO Director-General Qu Dongyu said in a briefing.

More money will likely be needed because the locust swarms are expected to grow. And if the Indian Ocean continues to warm, infestations like this could happen more frequently.

Dharna Noor. |. Staff writer, Earther

Lead photo: Ben Curtis (AP) | A girl tries to chase swarms of desert locusts away from her crops in Kitui county, Kenya on Friday, Jan. 24, 2020.

Unfazed By Covid-19, Infarm Arrives In Japan And In Canada

While centralized facilities have generally dominated the vertical farming venture capital domain, distributed and decentralized business models are gaining pace, according to AgFunder’s 2019 industry report. One in particular—Germany’s Infarm—nabbed $100 million last year to deploy its connected growing cabinets in supermarkets

March 26, 2020

Photo credit: Infarm

Strictly speaking, vertical farming has been with us since the dawn of agriculture; it would be interesting to see wheat growing any way other than vertically. But the term, despite its ambiguity, is now recognized shorthand for vertically stacked farming, where layers of crops are grown on top of each other, and where conditions like light, temperature, water or nutrients are artificially controlled indoors to allow for year-round growing.

There are two predominant visions of vertical farming: centralized and distributed. Proponents of centralized systems argue that large-scale production—and financial viability—depends on ever-bigger and higher farms. These farms, or plant factories as they are sometimes called, are proliferating, aided by huge sums of capital. Plenty scooped up a whopping $200 million in Series B funding back in 2017. US-based AeroFarms raised $100 million in late-stage funding in 2019, for example, while Fifth Season secured $50 million last year.

While centralized facilities have generally dominated the vertical farming venture capital domain, distributed and decentralized business models are gaining pace, according to AgFunder’s 2019 industry report. One in particular—Germany’s Infarm—nabbed $100 million last year to deploy its connected growing cabinets in supermarkets.

AFN has been keeping tabs on Infarm as a high-profile case study of the distributed vertical farming model. The company’s footprint already includes more than 600 cabinets in many European and US cities. During the first quarter of 2020, Infarm has been busy making progress on its global expansion strategy as well. In February, for instance, East Japan Railway Company (JR East) partnered with Infarm to deliver fresh produce grown and harvested in retail stores starting in summer 2020 (pending circumstances around the Covid-19 pandemic, of course). The partnership is Infarm’s first in Asia.

Infarm has also inked an agreement with national food distributor Muroo, which will support a phased roll-out of the Berlin-based company’s farms across Japan in 2021. Infarm has launched a new affiliate, Infarm Japan, to support its expansion in the country.

Similar plans are also afoot in Canada, where Infarm will soon launch its first fresh produce harvests at Safeway stores in Vancouver, with eventual expansion to Calgary, Edmonton, Halifax, Toronto, Victoria, and Winnipeg.

Roll-out timelines in both countries could yet be disrupted, as both Canada and Japan grapple with the Covid-19 outbreak. City lockdowns, movement restriction, and global logistics disruption may bolster the case for distributed urban growing models like Infarm’s, however.

“Urban farming by Infarm has the potential to drastically change the common practice of logistics,” Shunichiro Yamashita, the CEO of Muroo, wrote to AFN. “For produce to be consumed in large cities, such as Tokyo, we must rely on supplies from the suburbs and distant locations. By eliminating the distance between the customer and the place of origin, customers will be able to acquire fresher produce with peace of mind and safety.”

AFN caught up with Emmanuel Evita, global communications director at Infarm, (virtually, of course) to learn more about the company’s expansion strategy and the impact from Covid-19.

AFN: So how is Infarm progressing in light of the Covid-19 outbreak? How has that affected expansion, sales, and day to day operations?

Emmanuel Evita: We’re finding that the demand from many of our partners and consumers for fresh produce is increasing. In the past few weeks, for example, we were able to increase deliveries to stores with higher demand across our markets. With our hubs located in cities, as close as possible to many of the supermarkets and restaurants we serve, we’re able to keep growing and stay responsive to the needs of our partners throughout this period, whether we are growing fresh in-store or from our hub.

What did you have to adjust in your expansion strategy when thinking about Japan?

Overall, we are showing our capacity to build an operation quite quickly—from a single farming unit to hundreds of farms in supermarkets and distribution centers in cities around the world.

Japan is a nation of advanced robotics. Which synergies have you identified here with your own vertical farming offering?

There are a lot of synergies. IoT technology and Machine Learning are core to our farms, and it’s exciting to strengthen the relationship between technology and sustainable food in Japan.

In the popular imagination, Canada is a land of sweeping prairies, a place of vast outdoor agricultural production. Where would vertical farming be needed in this context?

We believe vertical farming is needed in diverse countries and cities all around the world. Modern agricultural production places an incredible burden on our environment. Not only are these processes responsible for 17% of total global CO2 emissions, but they sap plants of 45% of vital nutrients by the time they arrive in the supermarket. As climate change, soil degradation and the loss of natural ecosystems threaten to worsen these effects, we want to find another way.

Our mission is to help cities become self-sufficient in their food production while significantly improving the safety, quality, and environmental footprint of our food. We want to practice a form of agriculture that is resilient, sustainable and beneficial to our planet. And, we want to make fresh, pure, tasty and nutritious produce available to everyone.

By choosing Canada and Japan, you’re expanding simultaneously into two very different time zones, let alone cultures. How do you plan to handle and react to your growing data in real-time?

Japan and Canada mark our eighth and ninth countries, respectively, and we have more than 600 farms in stores and distribution centers around the world. Our machine learning and IoT technologies make it possible to collect huge amounts of data from our farms around the world in real-time.

With a decentralized strategy, keeping up unified growing conditions becomes difficult. How do you prevent infections at your vertical farms?

Infarm controls the farms remotely using sensors and a centralized, cloud-based platform that adjusts and improves itself continuously, so each plant grows better than the one before – providing plant seedlings with an ideal combination of light spectrums, temperature, pH, and nutrients for optimal growth. From the cloud at our Berlin headquarters, we’re able to gather up-to-the-minute information about how our plants are growing and how they respond to different growth environments on a minute scale. We can make many of the needed adjustments remotely. Our growers also offer support for the farms on-site as needed.

Infarm is the first hydroponic farming company to receive the Global G.A.P certification for the standard of quality and agricultural best practices and follow these best practices to maintain healthy plants for sale and consumption.

Is 2020 the year of hydroponics or aeroponics?

We specialize in hydroponic farms and that’s what we’re passionate about. But the Infarm approach is only one way to tackle the urgent agricultural and ecological challenges of our time.

What has been the biggest hurdle to driving down the price of indoor-grown fresh produce

Retailers set the price for the produce we provide in-store. The price does not tend to be significantly higher than their other produce offerings.

What is the ideal size of a vertical farm?

It depends on the environment. Our modular farms are easily scalable and rapidly deployable and can transform any space and fulfill any market demand, whether it’s a single unit in a restaurant or thousands of farming units chained together in a distribution center.

What can you grow? What’s been the hardest thing to grow? What’s been the craziest?

We have more than 65 herbs, micro-greens, and leafy greens as part of our catalog—from Italian Basil to Crystal Lettuce, to more special varieties like Peruvian Mint or Wasabi Rucola.

Are you collaborating with crop breeders to improve traits for indoor growing, boosting yields, taste and nutritional profiles? Can you mention any joint projects and what you have learned?

Yes, we are working with a range of responsible partners. However, we are more focused on optimized growing conditions and growing recipes than genetics at the moment as we see a huge untapped potential in improving yield, quality and consistency with that alone.

Where do you think AI will prove most useful in vertical farms by 2021?

AI can help collect and analyze data at a granularity that is remarkable for the agricultural industry. This data can be used to better plan and anticipate the growth patterns, yields and response of produce to different environmental circumstances in a way that allows farming to be implemented in a more strategic, efficient and ultimately sustainable way than ever before. Over the next several years, the marriage of real-time data capture and farming will truly revolutionize the agricultural industry.

Where will you expand to next?

We will continue to expand our operations in markets that will host the megacities of the future.

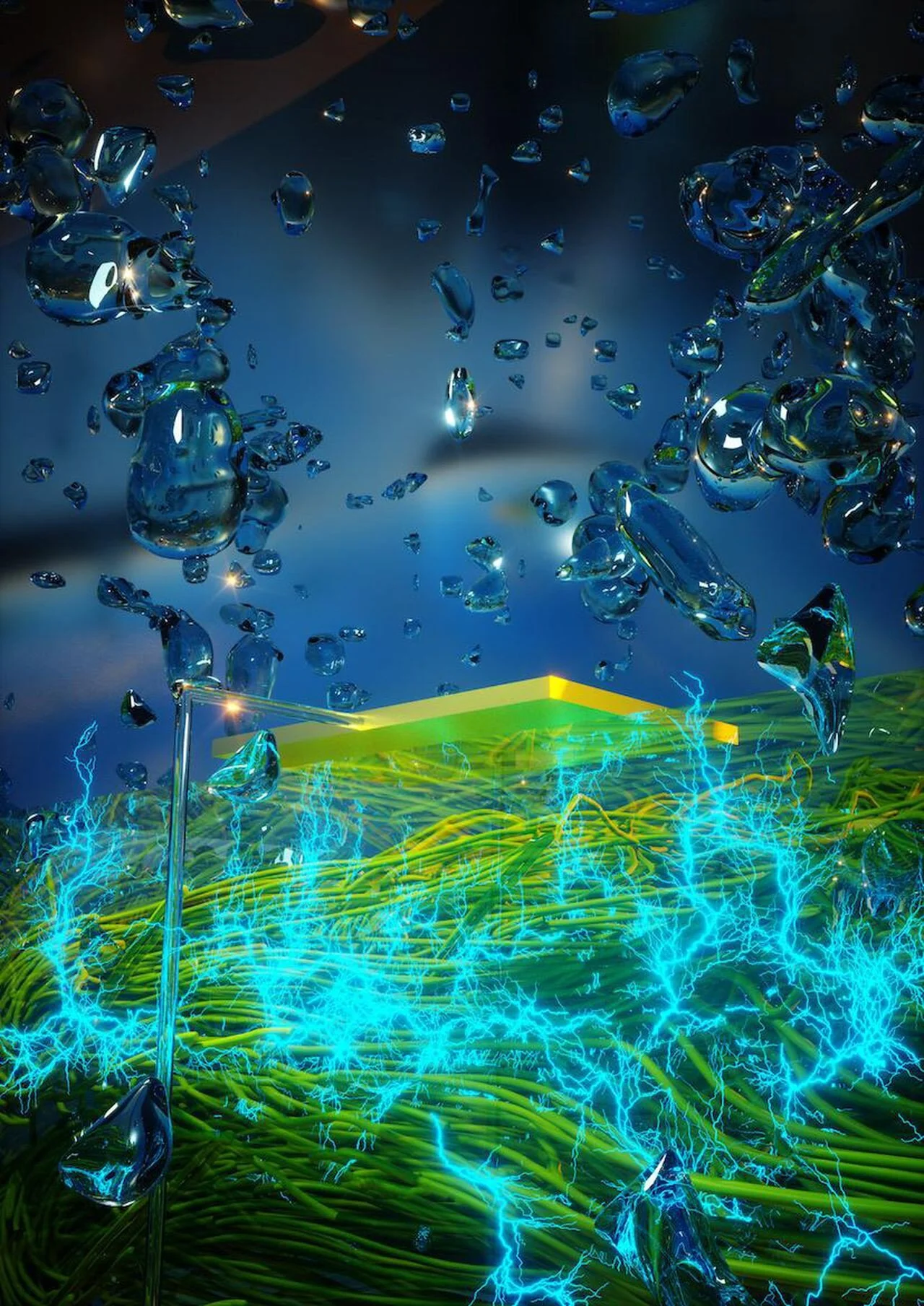

Engineers Found A Way to Generate Electricity From Thin Air

If it can be scaled up, Air-gen technology could power everything from iPhones to car charging stations

Green energy, as far as we’ve implemented it, is at best a shade of greenish-brown — army, perhaps, or olive. Solar farms harness the sun’s renewable energy but require large swaths of land and rare Earth metals. Wind power has a minimal carbon footprint, but, like solar, gets stored in batteries made from lead and lithium. Nuclear power is appealingly low carbon, but the risk of another Chernobyl is hard to stomach. All of these options are a huge improvement over coal power, but there’s real pressure to find an energy source that’s truly scalable, cheap, and 100% green.

Last week, scientists from the University of Massachusetts Amherst rose to the challenge, presenting a low-cost device they call the Air-gen, which generates electricity from thin air — enough to theoretically power devices like cellphones and electric cars. And since it doesn’t require harsh chemicals to produce, “the whole process,” corresponding author and assistant electrical engineer professor Jun Yao tells OneZero via email, is “green.”

Improbable as it sounds, the device’s technology is based on a natural phenomena: electricity-generating threads of proteins, called nanowires, that emanate out of a tiny bacteria called Geobacter sulfurreducens (a plush toy version of the bacteria looks like a Cheeto with tentacles). In the paper they published in the journal Nature last week, Yao and his co-authors describe their key discovery: Moisture suspended naturally in the air is the “driving force” behind the electricity-generating ability of the nanowires.

Think back to high school physics. Electricity is basically the flow of electrons, the negatively charged particles that circle atoms, from an area of high charge to an area of low charge. Water can be a good source of these charged electrons if it can be broken up into its building blocks, hydrogen, and oxygen.

The team theorizes that when a tangle of the nanowires is pressed into a mesh-like film, water from the air collects only at the top of it and breaks up into two Hs and an O, freeing up the water’s electrons. This gives the top of the film a greater charge than the bottom, setting up the perfect conditions for electrons to flow. When the researchers sandwiched one of these films between two gold electrodes to create a circuit, the tiny device produced a voltage of 0.5 volts across a film just seven micrometers thick. (A charged car battery, for comparison, measures at about 12.6 volts.)

“The whole process is green.”

Essentially, the Air-gen can generate a flow of electrons without much input, thanks to the impressive biology of Geobacter’s nanowires. Co-author and distinguished microbiology professor Derek Lovely, who has dedicated more than 30 years of study to the electric microbe, compares the wires to individual human hairs — a thread made up of different proteins, only 20,000 times thinner than what you’d pluck out of your scalp.

Before we can slap patches of these nanowire films onto an iPhone or Fitbit, their production will need to be scaled up so that multiple patches can work in tandem to generate enough electricity to power modern devices. Figuring out how to mass-produce the nanowires, plus devising a “clever engineering strategy” to put them together in a compact way, says Yao, will be key.

They’ve already started tackling the former problem by attempting to cut Geobacter bacteria itself out of the picture. “It is not easy to make large quantities of wires with Geobacter,” explains Lovley. Some bacteria are easier to grow en masse than others. Because it grows so quickly, E. coli has become scientists’ go-to for genetic engineering. Lovley’s team engineered a strain of E. coli that produces Geobacter’s nanowires, so now they have a ready supply.

“Now that we have solved the microbiological bottleneck, the engineers can begin designing larger Air-gen devices,” he says.

There’s still the question of whether the technology is as miraculously green as it seems to be. Yao maintains that production of the nanowires is completely harmless to the environment — and cheap to boot — because “we simply feed renewable feedstocks into the bacteria without harsh/toxic chemical involved.” The cost, according to an estimate from Lovley, would be 100-fold lower than that needed to make semiconductor-grade silicon, which is used for solar cells.

From the nanowires to the way they’re produced to the energy generated, says Yao, “All are green.” When the green label is placed on technology, he points out, it often “only means that the energy production part is green, and can still generate e-waste.”

Lovley says that there isn’t any existing technology that resembles Air-gen, as far as he’s aware. There doesn’t appear to be a patent on the Air-gen at the time of this article’s publication, but the research was funded by a seed fund through UMass-Amherst’s Office of Technology Commercialization and Ventures. The team appears set to scale up quickly.

The way Yao sees it, powering a large device with the Air-gen is only a matter of adding up many tiny generators. It’s analogous to using “thousands of battery cells” to “drive a Tesla car,” even though each individual battery cell only has limited energy. They can potentially power small-scale wearables, medium-scale electric tools, or even a remote station, as long as they can scale quickly. And they seem confident that they can.

In a cheeky tweet last week, he sent a “final response” to reviewers of their Nature paper: a gif of Gene Wilder in Young Frankenstein, mouthing his iconic line “It could work!”

“Now that we can make more wires, addressing this question should be relatively straight forward,” Lovley says.

OneZero

The undercurrents of the future. A Medium publication about tech and science.

Engineering Electricity Energy Science And Medicine Power

Lead Image: UMass Amherst/Yao and Lovley Labs

WRITTEN BY

Yasmin Tayag

Senior editor at OneZero at Medium. Previously at Inverse. Covering all science that’s shaping the future.

OneZero

The undercurrents of the future. A Medium publication about tech and science.

SoftBank-Backed Farming Startup Plenty Is In Talks to Raise Cash

Indoor farming startup Plenty Inc. is in talks to raise $100 million or more in a fresh round of funding, according to people familiar with the matter

(Bloomberg) -- Indoor farming startup Plenty Inc. is in talks to raise $100 million or more in a fresh round of funding, according to people familiar with the matter.

SoftBank’s Vision Fund is in discussions to lead a new fundraising round for Plenty at or below the $1 billion valuation that was ascribed to it in its most recent round, said the people, who requested anonymity because the matter is private. They cautioned that no agreement has been reached, and that one may not be finalized.

“Plenty does not comment on financing proposals and has not committed to any new financing rounds,” a spokeswoman for the South San Francisco-based company said in an emailed statement. “We are not in need of new equity financing, and evaluate any proposals opportunistically,” she added.

A representative for the Vision Fund didn’t immediately respond to a request for comment.

Plenty has raised about $400 million in capital over the past four years, according to PitchBook. In addition to the $100 billion Vision Fund, other backers include Data Collective, DCM, and funds that invest on behalf of Amazon Chief Executive Officer Jeff Bezos and former Google CEO Eric Schmidt.

The startup aims to be more efficient than traditional farms, yielding more produce in a given space, while requiring less water.

Last fall, Plenty said it intended to expand beyond the Bay Area and had identified Compton, Los Angeles, as the location for its next farm, with building slated to begin in late 2020.

SoftBank is seeking $10 billion so its Vision Fund portfolio companies can support portfolio companies battered by the coronavirus pandemic, Bloomberg News reported earlier this month.

Some of the Vision Fund’s companies have laid off employees this month including co-working giant WeWork and residential real estate brokerage Compass.

For more articles like this, please visit us at bloomberg.com

Subscribe now to stay ahead with the most trusted business news source.

©2020 Bloomberg L.P.

Corona-Update: 'US & Europe Already In Recession'

In the US, potatoes are a hot item across the nation. Unfortunately, in other news, the US & Europe already seem to be in recession

In the US, potatoes are a hot item across the nation. Unfortunately, in other news, the US & Europe already seem to be in recession. On a lighter note, UK farming leaders have stated that surplus food supplies caused by the closure of major restaurant chains like McDonald’s will now be redirected the consumers. There is also a general directive about what New Zealand growers need to know in the current environment, as well as news on markets and initiatives in India.

Potatoes flying off US retail shelves

All over the US, potatoes are suddenly a hot item across the nation and there are reports of goods flying off grocery store shelves. “It’s been really remarkable how fast … potatoes have been flying off the shelves,” said Blair Richardson, president, and CEO of Potatoes USA, the nation’s potato marketing organization. “Potatoes are being purchased as soon as they come into stores in many areas.”

“You can hardly find retailers with potatoes on the shelves” in some places, Idaho Potato Commission CEO Frank Muir told postregister.com.

The sale of potatoes through foodservice channels has dropped significantly as many restaurants and schools have shut down because of the coronavirus outbreak, Muir said.

But retail sales have jumped significantly and the IPC has sent out a communication to retailers, foodservice customers and shippers trying to facilitate a quick shift of spuds from foodservice to retail channels.

A farmer from Hammett said he’s heard that “retail can’t keep up with the demand for potatoes right now.” He said the industry, with the help of the commission, is undertaking a major effort to move potato cartons from food service to retail.

Even though spuds are a hot item right now, industry leaders said there is no shortage of potatoes in this country, nor will there be next year.

US & Europe already in recession

The closure of retail chains, offices, and workplaces is freezing economic activity, tipping the US into recession. The US and global economies are already falling into recession, with forecasts being revised on the fly as the coronavirus disease 2019 (COVID-19) spreads around the world, putting an end to a 10-year US economic expansion, according to IHS Markit Chief Economist Nariman Behravesh.

“There’s no question we’re in a recession,” Behravesh said Thursday during the JOC webcast, TPM20: What We Missed — The Economic, Trade, and Container Shipping Outlook. “The only question is how deep.” As of Thursday, IHS Markit, parent company of JOC.com, forecast the US economy would contract 0.2 percent in 2020, “but that will very soon get revised down to at least -1 percent,” perhaps by the end of the week, Behravash told the more than 1,100 logistics executives who attended the webcast.

The direct cause of the recession is the spreading coronavirus, or more precisely the precautions taken against the coronavirus, he said. “So far, it looks like the only way to stop it (COVID-19) is by freezing economic activity, and that plunges the economy into recession,” Behravesh said. “The virus itself isn’t killing the economy, but the response to it is sending us into recession.”

UK farm supplies diverted to retailers after McDonald’s closes

Farming leaders said the “huge surplus” of food supplies caused by the closure of major restaurant chains like McDonald’s will now be redirected to shops where consumers can buy it.

Concerns over the spread of coronavirus have forced the fast-food giant to temporarily close all of its 1,270 restaurants – which source £600m of ingredients each year from 23,000 British and Irish farmers, including many in East Anglia.

But the region’s agricultural leaders are confident that supplies of beef, potatoes, and pork – originally destined to become takeaway fries and burgers – will be quickly diverted to retailers via their “incredibly flexible and nimble” supply chains.

Andrew Blenkiron, estate director of the Euston Estate near Thetford, is also vice-chairman of the Red Tractor assurance scheme and vice chairman of the Suffolk branch of the National Farmers’ Union (NFU). “Everyone is so integrated in this supply chain that they have the ability to easily redirect product from one customer to another,” he said. “The people who process and pack for McDonald’s will also process and pack for supermarkets as well. So instead of minced beef for fast food burgers, it could be prime cuts for the supermarkets.”

Neil Shand, a director at the National Beef Association (NBA), said: “From the NBA’s perspective, we are living in a country that is now on lockdown. We are less than 70pc self-sufficient in beef and we have surplus created by some organizations, such as McDonald’s, not operating in their normal way.

“Any meat produced by farmers that is not going to be used for trade-in McDonald’s will be redirected in the food chain to make sure everybody is catered for and used to keep the country fed.”

South Africa reserves R1.2 billion aid package On March 24th, Ms. Thoko Didiza, South Africa’s Minister of Agriculture, Land Reform and Rural Development sent out a message to the Agriculture and Food Sector of South Africa. Full statement here.

“As you may be aware, that last night the President announced measures to deal with the COVID-19 pandemic, which include a 21-day lockdown. Several businesses will be affected, but the agriculture and food supply sector is one of the essential systems for livelihood and therefore will remain operational.

Our food supply system will remain functional during this period. Agricultural production in all its forms will remain uncompromised. This includes all services including provision of veterinary and advisory services. Live auctions of livestock and sale of other agricultural commodities will continue but under the strict conditions, a prescribed by the President. Exports and imports of critical agriculture commodities and the logistical measures will continue during this lockdown period to ensure global and national food security."

“The Department has set aside a package of R1.2 billion to address effects of the corona virus and ensure sustainable food production post the pandemic. The Department soon will make the details of this package together with the application channels available. The Department has also presented R100 million to the Land Bank to assist farmers under distress. Together with the industry, we are working on a sector operational procedures that would ensure adherence to the measures announced by the President this includes the provision of sanitation to employees within the sector especially farmworkers.”

“To wholesalers and retailers, we urge you not to engage in price gouging, at such a crucial time for the country. You have an important role to play in the supply of food, and the fight against COVID-19. We ask that you continue to serve the nation and help ensure food security at this critical juncture.“

California Citrus Mutual wants letters for essential workers

As part of the state effort to control the Covid-19 (coronavirus) pandemic, California Governor Gavin Newsom announced a state-wide stay-at-home order that went into effect last Friday, March 20. The order does not apply to workers in essential businesses, which includes agriculture.

In some parts of the state, the order is being aggressively enforced by local law enforcement. Reports are circulating that some employees have been stopped on their way to and from work and asked to return home.

California Citrus Mutual (CCM) recommends all members provide their employees with a letter stating that they are an employee of an essential business. All employees should keep the letter with them while traveling to and from work.

The letter should be on company letterhead and signed by a company manager. CCM recommends the following wording: “According to the Department of Homeland Security’s Guidance On The Essential Critical Infrastructure Workforce, dated March 19, 2020, food and agriculture are deemed a critical infrastructure that must be maintained during the COVID-19 crisis. (Company Name) is an agricultural business that is critical to the food supply chain, and (Employee Name) is an essential employee of the business.”

COVID-19 shuts down Miami farmers markets

At this point in time, keeping fresh produce in the house is tough when online delivery is limited and Miami’s farmer’s markets are mostly shut down. But the Urban Oasis Project has found a way to keep bringing veggies to the people during the coronavirus pandemic.

The non-profit, which operates several of Miami’s farmer’s markets including the ones at Legion Park, Tropical Park, and Surfside Market, is upping its game with delivery service and pop-up pick-up sites around town. In states like California and New York, farmers’ markets have so far been deemed “essential businesses” and allowed to stay open in the wake of coronavirus measures. That’s simply not the case in Miami, where the cancellation of temporary event permits has shut down the markets.

Coronavirus: What New Zealand growers need to know

More information has been provided on how those working in the agriculture sector will operate during the COVID-19 lockdown restrictions. Primary industries and those who supply them have been deemed an essential service, however, will need to follow strict rules to stop the spread of the virus.

Agriculture Minister Damien O'Connor says the Ministry for Primary Industries (MPI) has been working closely with food producers and other government agencies to ensure safe operations.

"The primary sector from the biggest companies, co-operatives, large orchards, right down to the smallest farms must keep high standards in workplaces for their own safety and others' wellbeing," he says.

MPI has set up a registration system for those businesses which intend to continue to operate during the lockdown.

Nagpur markets deserted, prices of fruit & vegetables rising

With the entire state concerned by the recent curfew, most of the markets in the city had a deserted look on Tuesday. "The markets are not the same anymore in the light of social distancing advisory to prevent the spread of the coronavirus. Sales have drastically dropped due to virtually no footfall," said one retailer.

The sale of fruits and vegetables has drastically dropped even in local vegetable markets like Khamla, Gokulpeth, and Itwari as a result of the low footfall. Many shopkeepers sold vegetables at discounted rates fearing that these would rot and turn into waste. To maintain social distancing at local markets, the Nagpur Municipal Corporation has used chalks and demarcated lines outside every unit in almost all markets.

Even orders at food chains, especially kitchen restaurants, have dropped drastically. The owner of a kitchen restaurant from Sadar, requesting anonymity, said that online food orders have dropped since Monday. Prashant Sahare, a professional and a bachelor staying in an apartment in KT Nagar, said that he continues to get food online since his firm has asked him to work from home.

India: AMC will sell vegetables door-to-door

Beginning tomorrow, the Ahmedabad Municipal Corporation is sending e-rickshaws full of fresh goods to people’s doorsteps. The AMC wants to do away with hordes gathering at vegetable markets and ensure maximum compliance to the government's lockdown orders.

The Smart City and Urban Community Development departments will work together to implement the same. Deputy Municipal Commissioner Nitin Sanghwan said, "We are yet to fix the timings. We are in the process of preparing a road map and decide on which areas to cover first and how to go about it."

In all, there will be 10 e-rickshaws that will cover all the areas under seven zones."Women's self-help groups will be in charge of providing a steady supply of vegetables. The purpose is to avoid large congregations and keep people safe in their homes. There won't be issues pertaining to hygiene; said Mukesh Gadhvi, Deputy Municipal Commissioner. In keeping with the lockdown orders, only a few vegetable shops in the city are open and that too only for limited duration. Besides, citizens have been complaining about hikes in retail prices of potato, lemon, carrot, and cabbages. However, the prices have not been affected, largely.

Indian Supreme Court receives appeal to three-month export ban

The Supreme Court was requested to redirect the ban on export of vegetable and fruits for three months, so that the people could get fruits and vegetables at affordable prices. Advocate Zulfiqar Ahmed Bhutta filed a petition in the Supreme Court under Article 184(3) of the Constitution making federation through secretary Establishment Division as respondent.

He called on the court to direct the federal and the provincial governments to formulate export policy by which hike in prices of food and vegetable be stopped. The petitioner submitted that due to the rapid spread of coronavirus across the globe, everyone was terrified about his/her survival and several countries had imposed mandatory lockdown recommending around 1.7 billion people to stay at home.

Philippines: Vegetable deliveries hampered at checkpoints

Despite the Department of Agriculture’s (DA) assurance that Metro Manila will continue to have a stable food supply despite the crisis, the price of goods —particularly of vegetables— have continued to surge during the past days.

Since September 2019, The Murang Gulay Shop has been sourcing vegetables from farmers primarily from the provinces of Benguet and Pangasinan. However, the declaration of the Luzon-wide enhanced community quarantine as a result of the COVID-19 pandemic has disrupted the transport of produce to Metro Manila, giving other traders an opportunity to jack up their prices.

Cargo trucks from Benguet are held up at several checkpoints and reach Metro Manila only days later. Meanwhile, vegetable farmers from Pangasinan and neighboring areas are not able to transport their harvest because tricycles have been banned from traveling in some areas, even if they’re ferrying foodstuff.

Turkey: Fines to be imposed on those with exorbitant prices

Turkey’s Competition Authority has stated that “Nowadays, the global COVID-19 epidemic is experienced in the food market of our country, especially in the fresh fruit and vegetable market. It is observed that exorbitant price increases were made with an opportunistic approach.”

The Competition Authority, which is empowered to protect consumer welfare and prevent actions and transactions that disrupt effective competition conditions, closely monitors the price increases and all actors contributing to this increase.

In this context, the heaviest administrative fines determined by the Competition Law will be imposed on individuals and institutions (all kinds of actors such as producers, intermediaries, carriers, end sellers) engaged in anti-competitive actions in the food market, especially fresh fruits and vegetables.

Vietnamese agro exports to US & EU badly affected

With Vietnam’s main agro-forestry-fishery export markets after China such as the US and Europe being hit by the new coronavirus, Vietnamese exporters are suffering.

Nguyen Dinh Tung, Chairman, and CEO of Vina T&T Group, which exports fresh fruits to several demanding markets, said fruit exports by air to the US and EU were down 70-80 percent since many airlines had stopped flights. "Shipments by sea are relatively stable but customs clearance in importing countries is expected to be prolonged because workers and officials are absent from work due to the pandemic, which could affect the quality of the goods. Therefore, at least in the next one month, vegetable and fruit exports to these markets will drop sharply."

After that, the export situation would depend entirely on how the countries control the pandemic, he said. His company now exports only three items, coconut, longan, and durian, because they last long, and temporary stops exporting other fruits.

Kazakhstan restricts agricultural goods export Kazakhstan has introduced restrictions on export of agricultural goods for the period of emergency state in the country, Trend reports with reference to Kazakhstan’s Ministry of Healthcare.

The list of products that were prohibited from export includes buckwheat, sugar, potatoes, carrots, onions and white cabbage. The corresponding decree of Kazakhstan’s Agriculture Ministry said that the prohibition on the export of these goods from Kazakhstan to third countries is valid from March 20 till April 15, 2020

On March 15, 2020, Kazakhstan’s President Kassym Jomart Tokayev signed a decree introducing an emergency state in Kazakhstan due to coronavirus outbreak, which will last till April 15, 2020.

The first two cases of coronavirus infection were detected in Kazakhstan among those who arrived in Almaty city from Germany on March 13, 2020. The latest data said that the overall number of coronavirus cases in Kazakhstan is 68 people.

Russia bans potatoes from Kazakhstan

The order to ban the export of certain goods from the territory of Kazakhstan was enacted in accordance with the presidential decree "On Further Measures to Stabilize the Economy." The Ministry of Agriculture of the country called food products that are forbidden to be exported to third countries until April 15, Tengrinews.kz reports.

The list includes buckwheat, white sugar, potatoes, carrots, onions, and white cabbage.

Publication date: Wed 25 Mar 2020

Coronavirus And The Water Cycle — Here Is What Treatment Professionals Need To Know

As the global health community tracks the spread of this virus, it’s important for water and wastewater professionals to keep updated on potential impacts

Guest Column | March 5, 2020

By Nicole McLellan, David Pernitsky, and Arthur Umble

As the global health community tracks the spread of this virus, it’s important for water and wastewater professionals to keep updated on potential impacts.

It's hard to miss the headlines. The recent outbreak of novel coronavirus (2019-nCoV or COVID-19) has dominated news cycles in recent weeks. The World Health Organization (WHO) is calling it “public enemy number one.” But what information do we have that is related to coronaviruses in water and wastewater systems? And what can water- and wastewater-system operators do to protect public health?

Modern water and wastewater treatment systems play an important role in public health protection. With the potential for environmental transmission, water and wastewater operators need to know the potential for survival of this type of virus in water and wastewater treatment systems.

Coronaviruses, named for the crown-like spikes on their surface, were first identified in the mid-1960s. Currently, seven coronaviruses are known to infect people and make them ill. Three of these — MERS-CoV, SARS-CoV, and COVID-19 — emerged in the last 20 years and are examples of how some coronaviruses that infect animals can evolve to infect humans. COVID-19 is a new variety of coronavirus and is an enveloped, single-stranded (positive-sense) RNA virus.

So, what is the fate of coronavirus in sewage and wastewater treatment plants? Or in the aquatic environment? And should we be worried about the efficacy of water treatment filtration and disinfection processes for coronavirus removal and inactivation?

The short answer: No — if we take proper precautions and risk considerations.

The long answer: This is a new virus without an extensive body of literature on the effectiveness of water and wastewater treatment processes. And real-life experiences will vary due to water quality and treatment plant details.