Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

US: Family of Entrepreneurs Looks To Pioneer Vertical Farming In Utah

A Utah family of Korean immigrants is hoping to tap into the vertical farming market, an endeavor where values in the United States are projected to reach $3 billion by 2024 according to recent market research

August 4, 2019

MURRAY — A Utah family of Korean immigrants is hoping to tap into the vertical farming market, an endeavor where values in the United States are projected to reach $3 billion by 2024 according to recent market research.

Since moving to Utah in 1987 to pursue a master's in bioengineering at the University of Utah, Chihan Kim and his family have headed up a string of local business ventures, from a gas station to glove manufacturing and a coffee shop.

Scott G Winterton, Deseret News

James Loomis, Green Team Farm director for Wasatch Community Gardens in Salt Lake City, shows off vertical growing tomato plants on Monday, July 22, 2019.

In February, Kim said he found a "good deal" on a warehouse near 150 East and 4500 South and purchased it. "Plan A was renting the building to somebody," he said, but "I looked into several different businesses" in case "I cannot find a tenant."

One of the options he looked at was indoor farming. Kim said, "When I started (researching) indoor farming business, I liked it, you know, so I changed (my) mind to do a business in the building instead (of leasing)."

According to Jack Wilbur, spokesman for the Utah Department of Agriculture and Food, there are currently three commercial vertical garden operations in Utah that supply to restaurants and farmers markets in the state.

Wasatch Community Gardens also runs a vertical farm operation, although not for commercial purposes. The community garden's Green Team initiative provides a farm-based job training program for women who are experiencing homelessness.

At the time Kim submitted his application, Murray had no land use code for a vertical farming operation.

"Mr. Kim came in and said, 'I want to start indoor farming,'" said Murray City Community Development manager Jared Hall. He said city representatives told Kim, "We don't actually have something specifically for that, we don't have anything specifically prohibiting it either."

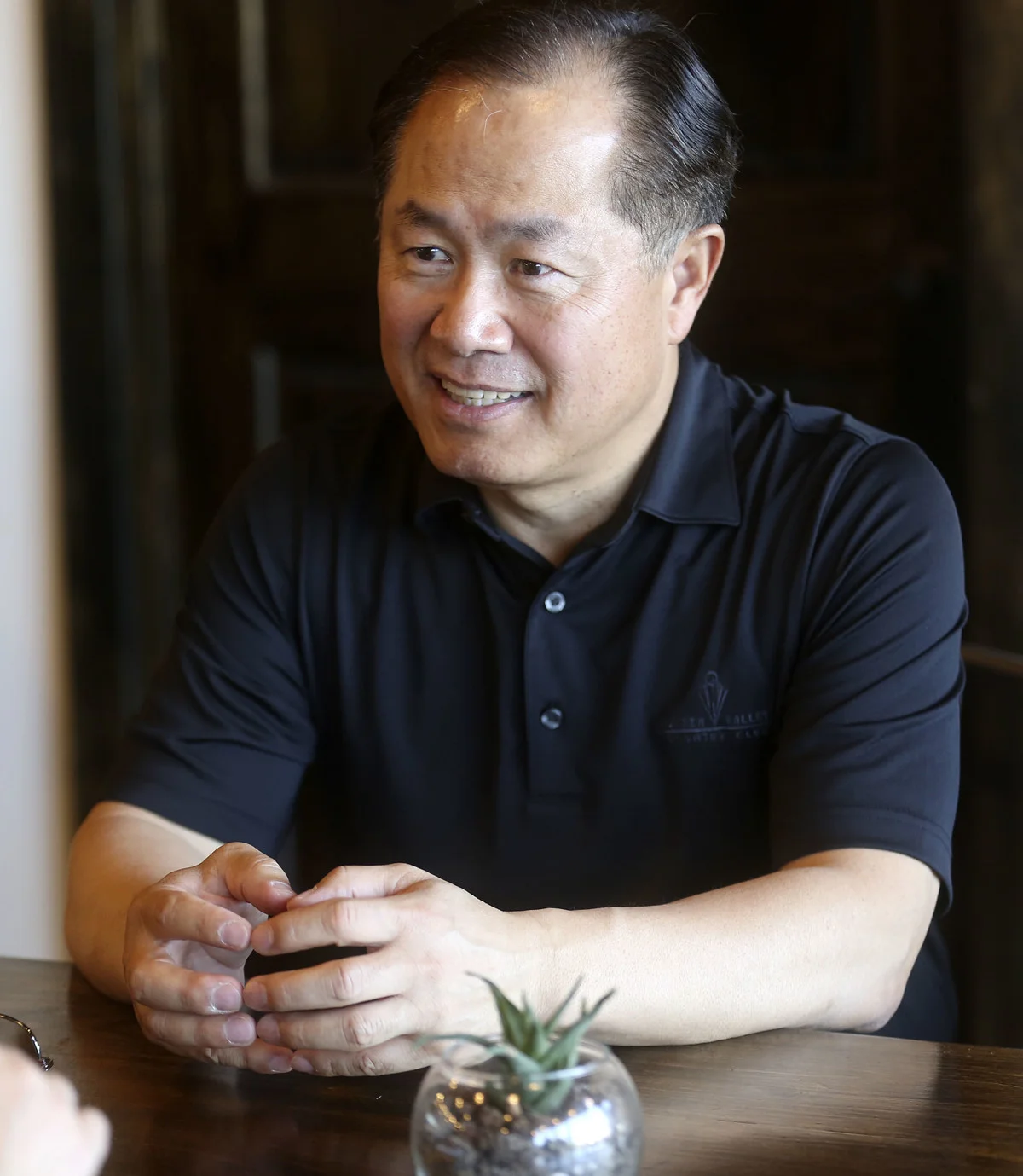

Eugene Kim and his father, Chihan Kim, pose for a portrait at their coffee shop, The Bean Yard, in Sandy on Thursday, July 18, 2019. Chihan Kim initiated an ordinance to allow vertical farming in Murray, which the City Council passed.

Hall said the city was supportive of the initiative, noting "the planning commission was very positive about it from the get go."

He said the idea of zoning for indoor farming appealed to the commission and the council so much they took the initiative one step further. "We took Mr. Kim's application and broadened it basically to include other zones," he said.

He noted that the building Kim hopes to farm in is located in the city's commercial development zone. However, the commission felt other zones would also be appropriate for future projects.

The ordinance, recommended to the City Council by the planning commission, was passed by the council unanimously on June 18.

The measure amended text in both the city's standard land use code and municipal code to allow for indoor farming in the city's mixed use, manufacturing general, commercial development, transit-oriented development and business park zones.

"In an area like Murray, where things are built out, we don't have large agricultural areas anymore. It's nice to put food production close by," Hall said, noting that the commission and council "saw a lot of pluses and not a lot of detriments" to the ordinance.

It was precisely this type of flexibility and room to grow that Kim said inspired him upon arrival in the United States to move away from academics and into business investments.

"In Korea, I have to go to school, good engineering school, then I can get a good job, then I can live comfortably. That's why I studied," he said.

After obtaining an engineering degree in Korea, Kim said he came to Utah to earn a master's degree, followed by a Ph.D. in mechanical engineering from the University of Utah.

"I planned to go back to Korea and work as a professor, you know, that was my original goal," he said.

However, Kim said, when he began exploring the U.S. he saw it as a "large open land" and realized "study is not everything."

"There's so many other things to do in the United States of America," he said, recalling that while his fellow students and colleagues at the university seemed to enjoy academics, he said he studied only "to survive."

His first business operation was a gas station, which he said he expanded to include a car wash and a site for safety and emissions inspection. In the mean time, Kim said, he started two other businesses, one selling eyewear and another exporting medical equipment to South Korea.

"I still have a lot of inventory," he said, indicating his personal glasses on the table beside him and noting that the frame was his own design.

According to Kim, his most successful business thus far has been Advanced Gloves, a venture which he happened upon after a friend from Korea asked for his help marketing a new glove model he'd produced.

"I did not really mean to be in that business," he said, adding that he had meant to simply "find (a) buyer (in the U.S.) and connect him." However, after bringing samples to various buyers, he said he found the product to be quite successful.

"I don't know if you see a FedEx Express driver come to your office. If you see them, they wear our gloves," he explained.

As he spoke, Kim sat at a table in the Bean Yard, a coffee shop he owns and manages along with his wife, Haisoon Kim, and his son, Eugene Kim.

Kristin Murphy, Deseret News

Eugene Kim, co-owner of The Bean Yard, prepares a coffee at the Sandy shop on Thursday, July 18, 2019. Kim's father, Chihan Kim initiated an ordinance to allow vertical farming in Murray, which the City Council passed.

The coffee shop is located in Sandy, though Eugene Kim noted the family has plans to open another location in Salt Lake City this summer.

He said his father's latest business venture, indoor agriculture, was inspired by market research on the productivity of this type of agriculture.

"Growing outside is becoming more difficult, because seasons are changing, and people aren't able to predict the weather as well, as they had before," he said. "Hydroponic gardening in general is something that I think is good for people to start getting into now. And it's something that I think will ensure a more sustainable future."

Research for his venture in vertical farming has taken Chihan Kim as far as Korea and China to meet with suppliers for indoor agriculture equipment and research centers.

Eugene Kim noted that though his father had originally set his mind on lettuce, after some discussion and research the family had decided strawberries would be the best crop for their operation.

"The way that we see it is that lettuce, in general, does not make any money, and so (Chihan Kim) moved on to the next option of potentially doing strawberry farming", he said. Also, because strawberries tend to absorb a higher number of pesticides, he said, cultivating them indoors would be a good way of avoiding this.

Chihan Kim noted that his University of Utah studies will likely come in handy.

"Because I have an engineering background I can run this cultivation facility optimally," he said. His background and research will help him effectively test the efficiency of elements such as humidity levels, light and temperature.

To cover the start-up cost for the business, Kim plans to apply for federal agriculture loan programs, though he has also looked into and may apply for a state program that offers financing of up to $100,000 for high tunnel or indoor farming operations.

Wilbur said if Kim were to apply for and receive funding through the program, he'd be the first in the state to take advantage of it.

PHOTOS: Scott G Winterton, Deseret News

Join FarmBoxFood, Iot.Atl, Ponix, & New City Properties On The Eve of Smart City Expo Atlanta

FarmBoxFoods and Ponix Farms is developing end-to-end local food ecosystems focused on reclassifying food as a utility, much like water or electricity

Join FarmBoxFoods, IoT.ATL, Ponix, & New City Properties to help revolutionize the future of food with Vertical Hydroponic Farms in shipping containers| Tuesday, September 10th | 4 -7 pm | 725 Ponce De Leon, Atlanta, Georgia

FarmBoxFoods is proud to take the next step in building resilient communities by connecting people, companies and technology to forge a stronger path for the future.

On September 10th, partners from IoT.ATL, leaders in smart city technology, and community mavericks will converge at 725 Ponce in Atlanta to celebrate the innovation of FarmBoxFoods, Ponix Farms and the opening of the first IoT.ATL Living Lab!

FarmBoxFoods, a new and revolutionary manufacturer of Vertical Hydroponic Farms in shipping containers with Ponix Farms, a winner of the IoT.ATL AgTech Challenge, is identifying scalable AgTech solutions to address the need for resilient food systems and illuminate how technology can be used to solve the pressing social issues of our time. Through this lens, they will change the future of food and urban agriculture to benefit communities across the globe as the world urbanizes.

FarmBoxFoods and Ponix Farms is developing end-to-end local food ecosystems focused on reclassifying food as a utility, much like water or electricity.

Join us in celebrating this monumental product launch on the eve of Smart City Expo Atlanta at 725 Ponce, just steps off the Atlanta Beltline - across from Ponce City Market.

Thank you to our core partners; New City Properties, Georgia Power, Invest Atlanta, AGCO, Metro Atlanta Chamber, City of Atlanta, and the Atlanta Beltline for their tremendous support and sponsorship.

About IoT. ATL

The IoT.ATL Living Labs program is focused on testing and validating IoT and technology solutions to help ensure equity and inclusion in the wave of strong economic growth.

The future success of smart communities lies in the collaborative projects the region creates and the public-private partnerships like IoT.ATL that drive innovation forward.

The IoT.ATL Living Labs project was founded by Georgia Power, City of Atlanta, Invest Atlanta, the Atlanta BeltLine, the Metro Atlanta Chamber and AGCO to help address pressing challenges in the community and leverage technology for good. For more information, visit iot-atlanta.com.

Eindhoven: ‘We Are Ahead In The Field of Urban Greening’.

Eindhoven is one of the three demonstration cities participating in the European climate research project that will be experimenting for five years with projects which make the city climate-adaptive using nature-based solution

Uitzicht over de binnenstad van Eindhoven

Posted by Lucette Mascini | Aug 24, 2019 | Tags: Brabant, demonstration cities, Eindhoven, EU, TU/e

Eindhoven is one of the three demonstration cities participating in the European climate research project that will be experimenting for five years with projects which make the city climate-adaptive using nature-based solutions. The aim is for other cities to be able to apply any successful results in their own municipalities. We asked Luuk Postmes, project leader from the municipality of Eindhoven, which of these projects are being implemented.

You are leading the project on behalf of the municipality of Eindhoven. What does your job involve precisely?

“As a civil servant working on urban water matters for the municipality of Eindhoven, I am both a project leader and an advisor. That covers the sewage system, the underground water and the surface water. As a result of the changing climate, we have to deal with drought, torrential rain and extreme heat stress. The question is: how do you deal with all of this? Greenery is a solution for many climate problems. Greenery can be used to cool the city. In turn, greenery is also dependent on water. Since this project is about climate adaptation, I have become the leader of this European project for the municipality of Eindhoven. The De Dommel WaterBoard and the province are also indirectly involved. But they are not a partners in the project. Eindhoven University of Technology is however.”

Project leader Luuk Postmes from the Eindhoven council

In what way is TU Eindhoven involved?

This is due to the participation of Lighthouse [a division of TU Eindhoven that specializes in sharing smart urban solutions, ed.], which is led by Rianne Valkenburg and Elke den Ouden. They are responsible for drawing up roadmaps for the process that should make the city more climate-proof. They also work together with the Following Cities as part of the EU project and are developing a vision for the future in this area.

Why is Eindhoven a demonstration city and other cities are called ‘Following Cities’?

“We [the three demonstration cities of Eindhoven, Tampere and Genoa, ed.] had been working for some time on making the city climate more adaptive, among other things by making it greener. The Following Cities of the EU project – Stavanger, Cannes, Prague, Castellon, Başakşehir – are a bit further along in this trajectory. They are keeping an eye on things with us.”

Why is Eindhoven participating in this experiment?

“The subject resonates very well with what we are doing in Eindhoven. If such a European project is of interest to us, we will apply for it and make a proposal. Then it remains to be seen whether it will be selected.

Which projects is Eindhoven currently carrying out?

“Some projects have already been concluded. We are still working on others. We have arranged green spaces in several streets because these were completely paved. This is how we tackled the Wagenstraat and the Bilderdijkstraat. By using less pavement, less water is channeled into the sewerage system. For instance, we are working on greening the Vestdijk. This involves looking at different types of vegetation. We are working on the design of a greener Clausplein, which is currently completely paved over. The Victoria Park is already located at the back of a former Philips building nicknamed the Witte Dame on Clausplein. The Gender river will come through there the back of there as well. The area will have a park-like layout where residents will be able to enjoy the peace and quiet and the greenery around them. We are also experimenting with greenery that can be mowed and which has a positive effect on biodiversity. Another method for increasing biodiversity is to mow the grass only once a year. This way you get tall grass that attracts insects and the subsoil is better able to absorb water. What you see is that if you mow less often, there will also be more and more different types of flowers and shrubs. You can see this happening on Parklaan, for example.”

But is that innovative?

“This is something that we, as a city, are pioneering. Other cities are following us. You can see in some foreign cities that they are often paved over an incredible amount. Everything is sealed with stones, concrete or asphalt. You can even see that when there is a tree on the pavement, the ground around it is completely covered in asphalt all the way up to the trunk. In Eindhoven we are looking for the best ways to make the city greener. What kind of plants should you choose? Should you choose plants that are better able to withstand drought? Or should we water plants when there is a prolonged drought? Are there any possible changes that can be made in their management that will help them cope with climate change and which will increase biodiversity? We try to answer these kinds of questions. We are also investigating how we could create more green space in places where there is limited space. One example is Eindhoven city center. It will be redeveloped in the next few years with more green space. We are trying in particular to encourage private-sector initiatives.”

What problems will these projects resolve?

“Initially, the disruption caused by heavy rain will be reduced. We will automatically be able to improve biodiversity by opting for a greener approach. That’ s a bonus for this project.”

How much money is the EU investing in it?

“The total budget is more than 10 million euros. Each of the three demonstration cities will receive approximately 1.7 million euros. The rest of the money will go to the other partners, including the Following Cities.”

The EU wants the results of the projects to be quantifiable. How are you going to measure them?

” It is still a struggle to figure it all out. But some results are fairly easy to measure. You are able to count how many species of bees and butterflies that have been added to a project site. Along with what the distance is between residents and green spaces and how many cool, green spaces have been added to the city. I have made a proposal to measure the heat stress sensitivity in the city using satellite images. In order to measure the effect on water management, we measure the soil infiltration capacity of areas with long grass. We compare the rates with those of areas where the grass is shorter. It turns out that the lawnmower compresses the subsoil. Consequently, water seeps into the ground less quickly if the grass is short, making it more difficult for it to soak into the soil.”

When will the project be finished?

“We have about three years for the implementation of the projects and two years for the monitoring. However, we won’t be able to achieve that for all of these projects. The main reason for this is that they conflict with the planning of other projects and processes. You can’t overhaul the entire city center all at once. The process may therefore take longer as a result.”

What are they doing in Tampere and Genua?

“In Tampere, Finland, they are focusing on two housing projects, one of which is on a former industrial estate. The most important focus point here is maintaining the water quality of the surrounding lakes. They have to take the shorter days and the lower temperatures in winter into account more. One experiment concerned the purification of water through the use of algae. The question was whether this would also work at those extremely low temperatures during winter. Which is what did transpire. The experiment was a success. In addition, they are also conducting experiments involving the construction of green roofs. In Genoa, Italy, they are converting an old barracks site into a park-like environment where you will be able to stay and enjoy leisure activities. In particular, they are looking at the use of greenery as a means of regulating water management.”

SUPPORT US!

Innovation Origins is an independent news platform, which has an unconventional revenue model. We are sponsored by companies that support our mission: spreading the story of innovation. Read more here.

On Innovation Origins you can always read articles for free. We want to keep it that way. Have you enjoyed this article so much that you want to contribute to independent journalism? Click here:

Share this article!

NEXTEDEN-ISS: Substantial vegetable harvest in Antarctica

ABOUT THE AUTHOR

Lucette Mascini

Is It Finally Time For Vertical Farming?

Vertical farming enterprises have faltered and a decade of low interest rates has caused many industries to express frustration. However, although progress has been rocky, the ecosystem is fueling what may become an urban-food-system transformation

October 23, 2017

These crops were grown in a Chicago urban farm.

(Credit for all images: Plant Chicago)

Vertical farming enterprises have faltered and a decade of low interest rates has caused many industries to express frustration. However, although progress has been rocky, the ecosystem is fueling what may become an urban-food-system transformation.

As more people move to cities, urban farms now produce a fifth of the globe’s food. In the United States, urban farms are blossoming in Cleveland, Chicago, and New York City. Currently, urban farms cannot meet local demand, so communities import from different industrial producers depending on the season.

Vertical farming is one example of agtech. According to CB Insights, agtech companies around the world will disrupt how United States citizens eat for the first time since World War II.

LED-powered vertical farms are expected to generate over $6 billion by 2023, according to Acumen Research. World Economic Forum has predicted they will become very influential in agriculture by 2025.

Promises of Vertical Farming

The United States is experiencing epidemic levels of obesity, diabetes, and heart disease. According to Harvard School of Public Health, this is due to nutrition-poor diets. One of the reasons for this is the relative difficulty of easy access to supermarkets. The American Nutrition Association has published data showing how widespread these “food deserts” are in the United States.

Reprinted with permission.

Vertical-farming technology will enable agriculture without soil or natural light and with much less water. Growing times and costs will fall and create opportunities for urban entrepreneurs to enable local, healthy food production year-round.

There are also huge conservation benefits: urban vertical farming takes the pressure off land cultivation and greatly reduces water consumption and contamination.

Depression-era food subsidies have fueled mass production of staple crops. The need for economic scale has promoted industrial-sized operations which over-develop marginal lands, wrecking ecological systems and increasing the need for toxic pesticides.

In addition to the runoff of toxins into our water supply, agricultural cultivation of our watersheds – such as reefs and marshes – degrades the natural infrastructure that purifies our drinking water and protects our homes against worsening floods.

At the same time, crops sometimes travel thousands of miles along a carbon-guzzling transport system that includes ground, air and sea. For example, imported garlic from China is estimated to cause 156 school absences a year due to pollution.

While the global trade of crops is a significant source of greenhouse-gas emissions, data published in Environmental Research Letters show that the environmental impact of producing food is highly dependent on its origin. Differences in farming practices, seasonal climate, and land and water availability mean that growing food locally is not always optimal.

Challenges of Vertical Farming

Vertical farming is not a new concept. As discussed during Aglanta, several promising companies - including Atlanta’s Podponics, Vancouver’s Local Garden, and Chicago’s FarmedHere - shuttered due to lack of economic viability.

Critics also question the societal value of vertical farming. Salon and Fast Company have argued vertical farms are expensive to start and use a lot of energy. By extension, only wealthy entrepreneurs can start up operations and only a limited range of produce can be profitably grown. Therefore, vertical farming is accused of focusing on elite urban markets rather than malnourished and underemployed communities outside major metros.

Promises of Agtech

Critics’ visions ignore the product life-cycle and creative destruction – the processes by which increased customer adaptation leads to lower prices. Investors, corporations, and governments across the world are investing hundreds of millions into developing efficient vertical farming technologies.

As vertical-farming firms continue to compete and the industry matures, the price of upfront capital investments will fall. Likewise, improved efficiencies in lighting and cooling shrink operating expenses towards profitability. For these reasons, Panasonic and Phillips are decreasing farming expenses by mass-producing professional-level LEDs.

Environmental stewardship goes hand in hand with sustainable investment – a growing space favored by millennials, according to Morgan Stanley. Businesses facilitating vertical farming will not only grow with the industry but also gain as responsible investors migrate to investments such as green bonds. According to Crunchbase, vertical farming start-ups AeroFarms, Bowery Farming, and Plenty have raised $35.3, $27.5, and $200 million respectively in 2017.

Firms are using advances in technologies - including machine learning - and their own systems to differentiate themselves from the competition.

Christina Ra, Plenty’s head of communications, said that “Plenty's vertical-plane growing technology provides a unique and patented difference that ultimately improves efficiency and plant health/quality. Plenty has developed its entire growing system - the vertical-plane towers, watering system, LED light systems, etc. - to grow well at scale.”

Ra also said technological improvements will enable vertical farming to grow a broader range of crops. “There has been no option other than to grow crops that can withstand travel, trucks, distribution centers, and the required days and weeks of that supply chain. Because we provide plants with the exact air quality, temperature, light, etc. that they want, everything is simply better.”

Deloitte has calculated that supplier vertical integration coupled with consumers’ expectations to consume products on demand will revolutionize the industry soon. By design, vertical farming relies less on established farming systems for inputs such as seed and pesticides.

However, Amazon’s acquisition of Whole Foods does present opportunities for more informed crop growth and distribution. One can imagine a situation where Plenty – with Bezos Expeditions, the Amazon CEO’s personal venture fund, already an investor – might play a role in supplying on-demand, locally produced crops for sale in stores at Whole Foods and digitally on Amazon.

Improvements to the Value Chain

The promise of urban farming is spurring proposed regulation around the country to create tax-advantaged agricultural zones in Illinois and elsewhere and bolster the United States Department of Agriculture’s involvement in the area.

It’s unclear how vertical farming will fare under new legislation, but water conservation, pesticide reduction, and year-round production offer society tangible advantages.

Moreover, advances in financial technologies will decrease the cost of working capital. Blockchain is especially well posed to enable urban farming growth. Blockchain’s near-instantaneous post-trade settlement removes the uncertainty of lags between trades and settlements that could take weeks. With this technology, farmers can analyze their commitments and make better-informed strategic decisions about growing and selling.

Likewise, higher trading transparency can lead to better financing terms from insurers, banks and investors.

Finally, real-time supply-chain management decreases expenses associated with monitoring crop history – including organic status, environmental pollution, and working conditions. Knowing these variables allows consumers to make informed decisions and leads to pricing premiums for locally-sourced food.

Whereas scale is required now to satisfy buyers’ needs, local agricultural futures exchanges would allow for a pool of diversified urban farms to independently sell to institutional buyers. With buying-commitments from grocers, schools, or hospitals, farmers can efficiently forecast profit margins. Instead of searching for working capital and marketing crops, they can spend their time maximizing crop yields.

To comment on this article, please post in our LinkedIn group, contact us on Twitter, or email the author via our contact form.

Tagged with: agricultural programs

Looking For Urban Farming 'Silver Bullet' In China

After a successful first edition, the Urban Greenhouse Challenge is back.

After a successful first edition, the Urban Greenhouse Challenge is back. This time, student teams are developing an urban greenhouse in Dongguan, China. Fortunately, they're not left alone - partner companies, including main partners Rabobank and Country Garden Agriculture, are ready to help, and five top universities are involved: China Agricultural University, the University of São Paulo, Cornell, UC Davis, and of course Wageningen University & Research. We asked Marta Eggers, Project Officer WUR Student Challenges, to tell us a bit more about the upcoming challenge.

"Urban farming exists for a very long time already. Now there's a sort of revival of urban farming, and a lot of people are very excited about it. But we have a feeling that there's not a good model for how to do it. There's a lot of searching going on, but there's not a silver bullet solution yet."

The challenge is a way to come up with solutions that can inspire progress and boost innovation. "We want to make people enthusiastic about urban farming. We hope we can bring it to the next level", Marta says, referring to the challenge's slogan: 'Will you bring urban farming to the next level?'

Image: Spark Architects

Dongguan: Economic hub for China and the world

While the first Urban Greenhouse Challenge took place in the Netherlands, this edition is looking a bit further east. The choice for China seemed logical, given the relationship Wageningen University has with the country. "We have ongoing collaboration and very close links with China", Marta says, "and we also have a China office, so with this challenge, we're building on this collaboration."

The site itself is "one of the most fascinating areas in the world", she argues: the agropark of Dongguan is located in the Pearl River Delta Economic Zone. "It's like a special zone in China, a place where a lot of experiments take place. It's all very high tech and innovative. For instance, when paying, you don't use a credit card, but you pay with your face. It's an economic hub for China, but also for the world; it's a very fascinating place."

Part of that 'fascinating place' will be the Dongguan agropark. "It's going to be a very big project," Marta says, "with a mission to create a sort of clean island in a very urbanized area, and our project will be a part of it."

A rendering of the Dongguan agropark, with the challenge site in the foreground

Catalyst for change

Going beyond this particular project, the second Urban Greenhouse Challenge is really looking for a 'catalyst for change', Marta explains. "We really want to provide experiments for more innovation." Last year's challenge is evidence that this is indeed how it works - many of the participants have followed up, going further into the field of urban farming.

Another way in which the challenge seeks to be a source of inspiration is by bringing together disciplines that often don't work together, like architecture and agriculture. "Those are the groups that also don't really know each other. This will also spark new ideas and add value."

The winning design in the first Urban Greenhouse Challenge

Lessons learned

The UGC team's experience from the first edition of the challenge has geared them up for the second. "The first Urban Greenhouse Challenge was a big experiment. The idea of Wageningen organizing such a challenge came up in January 2017, and in June it was decided that the challenge would go through. So we didn't really have much time to prepare", Marta says, laughing. "When it started, we were still working out the details and running the challenge. It was crazy and very intensive, but we also learned a lot."

They used that experience for the second challenge. "We very much revised the format." The idea is the same: student teams developing a greenhouse in an urban environment and involving the local population, but a few things have been tweaked. "For instance, we have included milestones this time, we have very clear instructions for all the participating teams. We have also developed an online platform. We now have a website with a lot of functionalities to facilitate communication with teams."

Team GreenWURks, winners of the first UGC

Connecting student with companies

With the online platform that's been developed, participating students are able to get in touch with experts who can offer them advice. "We really hope that some interesting innovations will come out of this", Marta shares. "All our partners get access to the online platform, and the online platform is a meeting place. Via the online platform, you can initiate chat, which can be followed up by Skype calls or face-to-face meetings."

Getting in touch with companies isn't just beneficial for the students - there are mutual benefits. "We think this is a great HR opportunity for the companies. The people who join the challenge are really very eager students. They'd be the perfect employees because they are very ambitious, curious about the topic and very innovative."

If your company is looking to get in touch with those talented students, be sure to get in touch with the Urban Greenhouse Challenge team - they're still looking for expert partners.

For more information:

WUR Urban Greenhouse Challenge

studentchallenges@wur.nl

urbangreenhousechallenge.nl

Publication date: 8/29/2019

Author: Jan Jacob Mekes

© HortiDaily.com

AgTech Insight, Agritecture Announce Strategic Partnership

AgTech Insight will advise and provide services to Agritecture clients in the large scale outdoor agriculture industry while Agritecture will advise and provide services to AgTech Insight clients in the urban agriculture space

September 6, 2019

The Deal Will Allow Both Companies To Offer

Clients A Broader Collection of Services

AgTech Insight, based in Salinas, California, and Agritecture, based in Brooklyn, New York, have announced the formation of a strategic alliance between the two firms. AgTech Insight will advise and provide services to Agritecture clients in the large scale outdoor agriculture industry while Agritecture will advise and provide services to AgTech Insight clients in the urban agriculture space. The focus of the mutually beneficial effort is aimed at improving both firms capabilities across a broader array of services for clients in the ag sector globally.

"The urban and indoor agriculture space is rapidly growing around the world and collaborating with Agritecture, given their leadership in their industry sector and global vision using innovation and best practices to help a growing population is a natural fit," Aaron Magenheim, founder of AgTech Insight, said, per a press release. “Over the past year, it has been great to work with David Ceaser and the Agritecture team sharing our expertise and working on projects together. There is a unique resource we have been developing together which we will be sharing with the world soon and are excited to be working together to bridge the urban and large scale agriculture sectors.”

"Agritecture is very excited about our collaboration with AgTech Insight," David Ceaser, Agritecture's horticultural specialist said, per the release. “ Urban and peri-urban farming is generally smaller scale agriculture and focuses on smaller more niche consumer markets. But, as far as the farming goes, there is no reason to re-invent the wheel. There is a ton that we can learn from large scale outdoor ag. The vast amount of experience and knowledge that Aaron and his team bring to the table is invaluable for us.”

Crop One Holdings Appoints Dr. Jenna Bell As Vice President of Nutritional Science

As pioneers in agriculture, Crop One grows local, fresh produce through advanced hydroponic, indoor farming practices. The company is dedicated to being environmentally sustainable, scalable, productive, and now, better for human health and nutrition

OAKLAND, Calif.--(BUSINESS WIRE)--Sep 5, 2019--

Crop One Holdings (Crop One), a leading global vertical farm operator, announced the appointment of Dr. Jenna Bell to the position of Vice President of Nutritional Science, effective immediately.

As pioneers in agriculture, Crop One grows local, fresh produce through advanced hydroponic, indoor farming practices. The company is dedicated to being environmentally sustainable, scalable, productive, and now, better for human health and nutrition.

“Crop One is committed to being part of the solution for some of the world’s most challenging issues in farming and food production – from land and water usage, to safe and clean growing practices," explained Sonia Lo, Crop One’s Chief Executive Officer. “As part of that commitment, we recognize that the nutritional value of the food we grow and our impact on wellness is integral not only to our success, but to improving human health around the world.”

As a registered dietitian and former academician, Dr. Bell will bridge the gap between plant science and human health alongside Crop One’s team of top plant scientists and systems engineers. She has over 20 years of industry experience, most recently from Pollock Communications, a food, nutrition and wellness-focused public relations agency, where she served as Senior Vice President. She worked with some of the top food and beverage companies in the world, including Unilever, PepsiCo and Danone North America, as well as commodity foods like cranberries, beans/legumes/peas and rice.

An accomplished leader in her field, Dr. Bell is also a frequent resource for the media. She is a well-published consumer and technical writer who has co-authored two books on nutrition and dietetics, and serves as editorial advisor for Today’s Dietitian magazine. Dr. Bell is an active member of the Academy of Nutrition and Dietetics. Dr. Bell holds a Bachelor’s and Master’s in Nutritional Science and a PhD in Exercise Physiology, with extensive experience in dietetics.

“We are delighted to welcome Jenna as a member of Crop One. She is a proven thought leader with a wealth of experience in helping brands connect with consumers, providing expert nutritional insights and guidance,” continued Ms. Lo. “Jenna will work alongside our plant science team and will be instrumental in helping to shape product development and presenting our extraordinary nutritional capabilities to consumers around the world.”

California-based Crop One Holdings is a vertical farming technology company that enables fresh produce growing in a sustainable manner for its customers. It operates two subsidiaries: FreshBox Farms in Millis, Mass., and a joint venture with Emirates Flight Catering in Dubai South, United Arab Emirates. Crop One has been in continuous commercial production longer than any other vertical farmer in North America. The company’s proprietary technology and plant science put it ahead of its competitors, producing crop yields among the highest of the industry, but at 25% to 50% of the capital cost of other vertical farming companies. To learn more, visit https://cropone.ag/.

VIDEO: Plants Ready To Go In At New Russian Indoor Farm

iFarm is a Russian vertical farming company that both operates farms and supplies the techniques to do so, as well as conducting a lot of research to get the best out of leafy greens, vegetables, berries and flowers

Plants can go in any day now at the newly installed vertical farm by the Russian company iFarm. The project, which is located in the city of Novosibirsk, is eight layers high and is the first project of this size conducted by the iFarm team.

“Our technologies for vertical farming have passed another test", co-founder Konstantin Ulyanov shares proudly. "Earlier we projected and built small farms which we tested the automation on, sampled the taste quality and contents of the lettuce and herbs. We learned to scale the technology (three times for this particular project), and increased the amount of varieties that could be grown in our farm."

iFarm is a Russian vertical farming company that both operates farms and supplies the techniques to do so, as well as conducting a lot of research to get the best out of leafy greens, vegetables, berries and flowers. Earlier this year they opened a laboratory for edible flowers. Currently they are also realizing projects near Moscow. Construction of three farms will start this month. "The next step is to launch such farms via distributors, like we already do abroad", Konstantin adds. For example, an iFarm showroom is being realized in Helsinki.

Some serious numbers

The new farm is located in the building of a former car dealer. To get this one ready for indoor growing, 20 tons of construction materials have been brought to the site, of which 90 stacks with 8 layers each have been installed. In it also 3 kilometers of wiring, 20 square meters of partitions and 1000 meters of pipeline. It took 10 people working in two shifts to assemble the racks in 30 days - working without a day off. They drilled 3333 holes and connected 60,0000 parts to assemble the 90 racks.

The first seeds will be planted at the end of August. Six types of leafy greens will be grown on 749 shelves: romaine lettuce, kale, chards, leaf lettuce, basil and bok choy. The overall growing area will comprise 1000 square meters, and planned production capacity is 42 thousand pots a month.

Pesto

The new production site will be equipped with a processing center to create pesto from the rucola and basil, as well as healthy chips, oils and fresh juices. Another part of the farm will be turned into a showroom: the visitors will be able to see the greenery growing process through glass partitions.

The vertical farm has been constructed with the help of attracted private investments. The projected payback period for a vertical farm of this size should be reached within 5 years. The farm will be producing 25 to 30 tons of greenery a year, the production margin being 27%. The first crops should be collected in October 2019.

Company Vega-Absolut acts as a strategic and technological partner of iFarm. The first vertical iFarm with a showroom of 300 square meters growing area is currently operational at the Novosibirsk science campus.

AUDIO: Why A New Rooftop Farm In Paris Is A Glimpse Into The Future

The city of light may become the city of fruits and vegetables soon. French company Agripolis is slated to open a 150,000-square-foot rooftop farm in 2020, hosting 2,000 pounds of crop each day

By Tyler Kern

August 28, 2019

The City of Light May Become The City of Fruits And Vegetables Soon

French company Agripolis is slated to open a 150,000-square-foot rooftop farm in 2020, hosting 2,000 pounds of crop each day.

Urban farming and aeroponics have spread to America but this project is the most ambitious yet.

“In Europe they’ve really gone to another level with it,” Dave Schupmann, Senior Vice President of Sales and Marketing at Fortis Warranty, a roofing warranty provider, said.

Concerns about weeds and heaviness from rain and snow have traditionally been problems for rooftop farms, but advancements have made projects like this one more viable.

“Sustainability is great. The products that we’re using today, much more than ever are lasting longer. So, you’re able to put these giant farms on top of these systems without them breaking down every 10-15 years,” Schupmann said.

While green roofs are still relatively uncommon in the United States, the ability to turn a profit from them may spur more investment in the model, according to Schupmann.

“I think it’s fantastic what they’re able to do with the vegetative roofing, really making it more than just something nice to look at but making effective use of the land for the tenants around it,” he noted.

According to Curbed.com, the farm will host more than 30 different plant species. Parisians will also be able to occupy their own plots of land on the roof, creating a communal space for residents.

Tune in to Business Casual, MarketScale’s live radio broadcast, every Wednesday and Friday at 8 a.m. CST.

UK ‘Closing In’ On Large-Scale Vertical Lettuce Production

As investment increases and the cost of production comes down, vertical farming has the potential to replace imports in leafy salads

29th August 2019 London

BY FRED SEARLE

Vertical farm director says indoor production of salad heads in Britain has potential to replace imports from Spain as sector gathers steam

As investment increases and the cost of production comes down, vertical farming has the potential to replace imports in leafy salads.

This is the view of Vernon Mascarenhas, a director at the London-based vertical farming company GrowUp Farms, which has specialised in growing microgreens, salads and herbs for the restaurant sector and is now focused on applying its know-how to industrial-scale salad production.

Several companies in the UK and abroad are making good progress on the challenges of making vertical farming work at scale, said Mascarenhas, who believes we are no more than a few years away from produce grown in industrial-scale vertical farms becoming an established part of the UK supply chain.

Also a commercial director at New Covent Garden catering supplier Nature’s Choice, he stressed that if UK growers can start growing salad heads year-round in Britain, the implications of not having to import large volumes from Spain in the winter will be huge.

“If companies like G’s don’t invest multi millions, they will have a real problem,” he said. “As soon as we get up and running and can produce gem and cos in the UK in the winter, it’s going to replace supply from Murcia, and this will increase suppliers’ margins.

“The price of a two-pack of gem in a supermarket is around 75p, and to bring it over from Murcia costs around 28p. Instead of wasting this 28p per pack on long-distance haulage, we can use it to pay off the capital investment required to build vertical farms where we will soon be able to produce gems for around 12p.”

Mascarenhas also said UK supermarkets are on the verge of having vertical farms in store, on their rooftops or in their car parks that not only showcase food production, but also provide significant supply – in wholehead salads as well as herbs.

In Britain he thinks Ocado, Amazon or possibly Asda could be the first to invest in vertical production, predicting that Asda’s owner Walmart could soon be taken over by Amazon – “Amazon will invest whatever they need to in this kind of thing,” he said.

Indeed it has already been announced that Berlin-based start-up Infarm is set to launch its in-store vertical farms withsome of the UK’s largest online and brick-and-mortar supermarkets in September, adding to its network of over 200 in-store farms across Germany, Switzerland and France.

Although many are sceptical about the financial viability of growing vertically, Mascarenhas is confident the cost of production will come down quickly in the next few years as technology advances, operational knowhow improves, and large investments are made in the sector. For example, in June Ocado invested £17 million in two vertical farming businesses, with plans to grow herbs and leafy greens next to its distribution centres.

Up until now, only micro greens and herbs have proven financially viable for vertical production in the UK, but such developments will allow mainstream salad produce to be grown domestically for the retail sector – both in store and, more importantly, in big warehouses – starting with baby leaf and moving into gem and cos lettuce, lollo rossa, oakleaf and other salad leaves.

“These vertical farms will be completely automated," he said. "The salad seeds will be sown, grown, watered, harvested and packaged without a human hand and the products will be grown in controlled conditions, with no pests or chemicals.

“We have all that technology already and established horticultural companies are heavily involved in making this happen.”

Produced vertically, a gem lettuce will only take 28 days to grow from sowing to harvesting, according to Mascarenhas, and once this has been achieved, producers can move on to rocket and spinach, which he says will be possible to produce in just 18 days.

He added that as well as allowing for more consistent year-round production, vertical farming can deliver higher quality and safer products than are currently available since they are grown in a controlled environment.

“Leafy products are just the tip of the iceberg,” he said. “Trials are currently happening around Europe on fruiting crops such as strawberries, raspberries, tomatoes and cucumbers, although these are still very early stage and it will be a while before the know-how and technology gets to a place where it makes commercial sense to grow them in a vertical farm.

“Basically, anything that grows as a root crop doesn’t work, but anything that grow upwards might. There’s a possibility that products like courgettes, beans and peas could be grown vertically but we have no idea yet what the economics of that would look like.”

Worker-Owned Greenhouse Grows Its Business In First Year

The largest urban commercial greenhouse in Massachusetts is marking its first year of production

he Wellspring Harvest greenhouse built on a "brownfields" site in Springfield, Massachusetts using hydroponic farming technology. At peak production it can put out 10,000 heads of lettuce a month.

CREDIT WAMC

Listen

The largest urban commercial greenhouse in Massachusetts is marking its first year of production.

Wellspring Harvest, a hydroponic greenhouse built on the once-badly contaminated former Chapman Valve property in Springfield’s Indian Orchard neighborhood, made its first delivery of lettuce to four Big Y supermarkets just about one year ago.

Like many new businesses, the first year has been a learning experience, according to Fred Rose, co-director of Wellspring Cooperative Corporation.

"We have learned an enormous amount about growing, about selling to different markets, about building our work team," said Rose.

The greenhouse now sells to over 25 stores including Whole Foods and seven institutional customers that include area colleges and two hospitals.

"That has been the real success, to get in the door in lots of important places," said Rose.

Wellspring, a non-profit that develops worker-owned cooperative businesses in low-income neighborhoods, initially spent over $1.2 million to purchase the 1- acre site and construct the greenhouse. An additional $250,000 had to be raised to subsidize operations as production ramped up during the first year.

" I think this fall we will get to full production and sales and break even by early spring. That is the idea," said Rose.

One of the greenhouse’s biggest customers is River Valley Co-op market in Northampton. General Manager Rochelle Prunty said there is a growing brand recognition for the lettuce with the Wellspring Harvest label.

" Produce is one of our biggest categories and we specialize in local produce. This lettuce to have it year-round is really special," said Prunty.

Mercy Medical Center in Springfield was an early investor in the greenhouse project. Now, Doreen Fadus, regional executive director of Trinity Health New England, said she’s trying to convince more of the organization’s hospitals to buy the lettuce.

" It is great lettuce," said Fadus. " No one is doing anybody a favor by buying it. It is a great product."

Eight people work at the greenhouse. Alicia Brown, who lives right across the street, was one of the first people hired. Now, after a year of learning the business she has become a worker-owner.

"It feels good to say I'm a part-owner," said Brown.

Wellspring has two other worker-owned cooperatives in Springfield: a furniture repair and re-upholstery business and a window restoration shop.

TAGS: WELLSPRING HARVEST WELLSPRING COOPERATIVE CORPORATION HYDROPONICS

US (NY): Farm Tours, Panels, Workshops And Networking Events During AgTech Week

The NYC Ag Collective - a consortium of 15+ commercial urban farms, tech companies, and non-profits - announces the 4th annual NYC AgTech Week, the only AgTech conference on the East Coast run by the leaders of the industry themselves

September 21-26, New York City

The NYC Ag Collective - a consortium of 15+ commercial urban farms, tech companies, and non-profits - announces the 4th annual NYC AgTech Week, the only AgTech conference on the East Coast run by the leaders of the industry themselves. This six-day conference features exclusive farm tours, panels, workshops, and networking events all focused on the innovative AgTech sector, promising unprecedented access to industry founders, investors, startups, and thought leaders.

Other events that are being held in conjunction with AgTech Week, such as the “Vineyard in the City Networking Finale”, “Chef x Farmer Mixer + Grazing Table”, as well as the “AgTech x UrbanTech Mixer”, will also provide a chance to network and mingle with these industry leaders.

Publication date: 8/26/2019

New Ways To Make Vertical Farming Stack Up

From the outside it looks like a tall, metal-clad barn. But step in, through a large airlock designed to keep out the bugs, and a kaleidoscopic scene emerges

Cultivating Fresh Produce In An Artificial Environment

Is Getting Cheaper

August 31, 2019 | INVERGOWRIE

From the outside it looks like a tall, metal-clad barn. But step in, through a large airlock designed to keep out the bugs, and a kaleidoscopic scene emerges. A central aisle is flanked by two pairs of towers. Each tower is stacked with a dozen or so trays on which are growing strawberries, kale, red lettuce and coriander. And each tray is bathed in vibrant light of different colours, mostly hues of blue and magenta. Douglas Elder, who is in charge of this artificial Eden, taps some instructions into an app on his mobile phone and, with a short whirr of machinery, a tray of lush, green basil slides out for his inspection.

Mr Elder is product manager for Intelligent Growth Solutions (igs), a “vertical farming” company based at Invergowrie, near Dundee, in Scotland. Each of the nine-metre-high towers in the demonstration unit that he runs occupies barely 40 square metres. But by stacking the trays one on top of another an individual tower provides up to 350 square metres of growing area. Using his phone again, Mr Elder changes the colours and brightness of the 1,000 light-emitting diodes (leds) strung out above each tray. The app can also control the temperature, humidity and ventilation, and the hydroponic system that supplies the plants, growing on various non-soil substrates, with water and nutrients. Armed with his trusty phone, Mr Elder says he can run the farm almost single-handedly.

Plant power

Vertical farming of this sort is not, of itself, a new idea. The term goes back to 1915, though it took a century for the first commercial vertical farms to be built. But the business is now taking off. SoftBank, a Japanese firm, Google’s former boss Eric Schmidt and Amazon’s founder Jeff Bezos have between them ploughed more than $200m into Plenty, a vertical-farming company based in San Francisco. And in June Ocado, a British online grocery, splashed out £17m ($21.3m) on vertical-farming businesses to grow fresh produce within its automated distribution depots.

The interest of investors is growing just as technology promises to turn vertical-farming operations into efficient “plant factories”. The high-tech leds in igs’s demonstration unit are optimised so that nary a photon is wasted. The hydroponics, and the recycling that supports them, mean the only water lost from the system is that which ends up as part of one of the plants themselves. And towers mean the system is modular, and so can be scaled up. Most of the systems which igs hopes to start delivering to customers early next year will consist of ten or more towers.

Some people, however, remain sceptical about how much vertical farms have to offer that good-old-fashioned greenhouses do not. Vertical farms are certainly more compact—a bonus in places like cities where land is expensive. Since sales of fresh produce to the urban masses are often touted as one of vertical farming’s biggest opportunities, that is important. But a greenhouse gets its light, and much of its heat, free, courtesy of the sun. And modern greenhouses can also use solar-powered supplementary led lighting to extend their growing seasons and hydroponic systems to save water, says Viraji Puri, co-founder of Gotham Greens, an urban-farming company that operates greenhouses on the roofs of buildings in New York and Chicago. As for food miles, they could not get any shorter for Gotham Greens’s rooftop greenhouse in Brooklyn, which supplies the Whole Foods Market located downstairs.

The biggest drawback of vertical farming is the high cost of the electricity required to run the large number of leds. This has meant that production has been commercially viable for high-value, perishable produce only, such as salad leaves and herbs. That, nevertheless, is a market not to be sniffed at. But for a broader range of produce, it can prove too expensive. In 2014 Louis Albright, an emeritus professor of biological and environmental engineering at Cornell University in America, calculated that a loaf of bread made from wheat grown in a vertical farm would be priced at about $23.

Blue is the colour

One way of saving electricity is to use leds that generate only the colours that plants require, instead of the full spectrum of plain white light. Plants are green because their leaves contain chlorophyll, a pigment that reflects the green light in the middle of the spectrum while absorbing and using for photosynthesis the blue and red wavelengths at either end of it.

The vertical farm at Invergowrie takes this idea further. It uses leds that are highly tuneable. Although the lights produce mostly blue and red wavelengths, researchers now know that other colours play an important role at various stages of a plant’s development, says David Farquhar, igs’s chief executive. A dose of green at an appropriate moment produces a higher yield. A timely spot of infrared can improve the quality of foliage. The lights can also produce various blue/red mixes.

To operate these leds efficiently, the company has developed a low-voltage power-distribution system. This, says Mr Farquhar, can cut energy costs to about half of those incurred by existing vertical farms. As a result, all four towers can produce 15-25 tonnes a year of herbs, salad leaves, fruit and vegetables. This, the company claims, is between two and three times more than a conventional greenhouse with an equivalent but horizontal growing area, and equipped with supplementary lighting and heating, could manage. And the system can grow all this produce at a similar cost-per-kilogram.

One of the jobs of the Invergowrie unit is to develop lighting regimes tailored to individual crops. Another is to develop algorithms to control, in an equally bespoke way, the climatic conditions preferred by different crops. The idea is to design crop-specific weather “recipes” in order to boost the yield and quality of whatever varieties are grown in the vertical farm. All the processes involved are engineered to be efficient. Irrigation, for instance, relies on captured rainwater. This is cleaned and recycled, but only 5% gets used up by each harvest—and most of that as the water-content in the plants themselves. Ventilation is also a closed loop, harvesting surplus heat from the leds while managing humidity and oxygen levels.

By reducing running costs, the system should make it profitable to grow a wider variety of produce vertically. The firm has already succeeded with some root vegetables, such as radishes and baby turnips. Bulk field crops, such as wheat and rice, may never make sense for a vertical farm, and larger, heavier vegetables would be tricky to raise. This means full-grown potatoes are probably off the menu, at least with existing technology.

Seed potatoes, though, are a good candidate, says Colin Campbell, head of the James Hutton Institute, a plant-science research centre backed by the Scottish government. It is based next door to igs and works with the company. Many fields around the world, Dr Campbell observes, are suffering a growing burden of pests and disease, such as potato-cyst nematode. In the controlled environment of a vertical farm, from which both pests and diseases can be excluded, seed potatoes could be propagated more efficiently than in the big, bad outdoor world. This would give them a head start when they were planted out in fields.

The institute’s researchers are also looking at plant varieties that might do particularly well indoors, including old varieties passed over in the search for crops which can withstand the rigours of intensive farming systems. By dipping into the institute’s gene banks, Dr Campbell thinks it may find some long-forgotten fruits and vegetables that would thrive in the security of a vertical farm.

All this could go down well with foodies, and unlock new and forgotten flavours. Shoppers might even find some exotic varieties growing in supermarket aisles. In Berlin a company called Infarm provides remotely controlled shelved growing cabinets for shops, warehouses and restaurants. Herbs and salad leaves, including exotics such as Genovese basil and Peruvian mint, are resupplied with seedlings from the company’s nursery as the mature plants are picked.

Vertical farming then will not feed the world, but it will help provide more fresh produce to more people. It may even be that, as vertical-farming systems improve further, miniature versions will be designed for people to put in their kitchens—thus proving that there is nothing new under either the sun or the led. Such things used once to be called window boxes.■

This article appeared in the Science and technology section of the print edition under the headline"Growing brighter"

DASCOM Americas Announces Contained Environment Horticulture Systems To Be Globally Marketed And Jointly-Branded As HYVETM and EPONICTM

According to Ken Bryant, Marketing Director for DASCOM Americas: “The joint-branding effort will provide consistency and logistical advantages for our clients and prospects worldwide

August 22, 2019, Verona, Virginia – DASCOM Americas, a worldwide diversified technology leader today announced a joint branding initiative for its complete indoor hydroponic farming systems. Going forward the systems will be developed, marketed, and sold as either HYVETM (www.growhyve.com) or EPONICTM (www.eponicagriculture.com) depending on the geographic region of the globe.

HYVETM is led by Ron Acorn, President of DASCOM Americas and has its offices and grow lab facilities approximately 2 1⁄2 hours southwest of Washington, D.C.

EPONICTM is a brand of Eponic Agriculture Company, Ltd. Based in Zhuhai, Guangdong, China. Eponic Agriculture is led by Liu Guowei, a noted developer, engineer, entrepreneur, and horticulture system specialist. The company has enjoyed success throughout Asia and Europe with its innovative hydroponic growing systems and has developed a branded following with the EPONICTM name.

The respective farming systems consist of scalable product offerings including a comprehensive solution for commercial growing which includes vertical racking, irrigation, fertigation, LED grow lighting, robotics, programmable logic control, and other ancillary system components that provide industrial growers with a “complete solution” from one source.

Acorn says of the commercial vertical system: “Our complete solution is different than any system in the market because we combine all elements of contained environment horticulture into one product system offering. Our vertical racking offering is designed to provide growers with a great return on investment and consumers with a choice for the healthiest and freshest plants in the market. Indoor farming cuts down on transportation and spoilage costs, limits the exposure to diseased plants, and is safer largely because of no need for herbicides or pesticides.”

The brands are also offering a smaller home hydroponic unit that is a solid offering for education, residential, or small business use. The “LF-ONE” allows users to grow up to 54 mature plants per grow cycle and is programmable and automated much like the larger system. It is easy to assemble and use and provides fresh produce and the opportunity to grow 365 days a year.

Going forward HYVETM will direct its primary focus and brand in the North America and LAT regions of the globe. EPONICTM will be the brand name for systems marketed in EMEA and most of China and select other Asia-Pacific Regions. The exception in the China market will be that XiaMen New Green Ecological Technology Company LTD will utilize the HYVETM brand name as part of an exclusive distributorship agreement.

According to Ken Bryant, Marketing Director for DASCOM Americas: “The joint-branding effort will provide consistency and logistical advantages for our clients and prospects worldwide. EPONIC Agriculture is an expert company in development of products for contained horticulture systems. Our collaboration from day one has been extremely strong. Together this will allow us to capitalize on the strong EPONICTM brand in select markets while we build the HYVETM brand in our region of the world, while assuring our combined customers and prospects will experience consistency in equipment advances, customer service, and pricing.”

####

What Is The State of Indoor Farming? Your Help Is Needed

The survey is open to all specialty crop growers and operators of enterprise farms, including operators of greenhouses, high tunnel farms, indoor facilities, and field growers, and will close for responses on Oct. 15, 2019

Posted by Brian Sparks

August 24, 2019

Artemis, an enterprise Cultivation Management Platform (CMP), has launched its first Global Ag Report survey, which is designed to capture the latest trends, challenges, and opportunities for growers producing fruits, vegetables, ornamentals, cannabis, hemp, and other specialty crops. The survey will inform the newest iteration of the State of Indoor Farming Report, released in previous years by Artemis under the company’s former name, Agrilyst.

The survey is open to all specialty crop growers and operators of enterprise farms, including operators of greenhouses, high tunnel farms, indoor facilities, and field growers, and will close for responses on Oct. 15, 2019.

The purpose of the new and improved survey is to give specialty crop farmers an industry voice around the most significant issues they are facing today. Artemis plans to use the survey responses to inform its first Global Ag Report. The report will provide an overview of the global specialty crop industry, as well as a deep dive into key topics such as production and operations, technology, and market outlook.

“Today we work with large international specialty crop farms that face a different set of challenges and opportunities than smaller, local operations,” said Allison Kopf, CEO of Artemis. “This report will dig into their pain points and market potential, to produce a comprehensive look into the global specialty crop industry. That is our priority in constructing our new survey for the Artemis Global Ag Report.”

Data from the survey will be supplemented with additional research from Artemis, and growers can use these shared insights as a resource for industry awareness, strategic planning and implementation of best practices in the coming years.

Artemis is a partner to some of the world’s largest farming companies. Since launching in 2015, it has seen strong customer growth with companies worth a collective $5 billion using the platform daily. Artemis has attracted a wide range of users that are foremost interested in the security, compliance, profitability, and potential to expand their operations.

Global Ag Report Survey

Brian Sparks is a senior editor of Greenhouse Grower and editor of Greenhouse Grower Technology.

Germany Presents The First Space Greenhouse Model

Scientists from the German Aerospace Center (DLR) have presented in Bremen a model of a space greenhouse that could supply astronauts participating in space missions with fresh food

Scientists from the German Aerospace Center (DLR) have presented in Bremen a model of a space greenhouse that could supply astronauts participating in space missions with fresh food.

The model was based on the results of the Eden-ISS project, through which vegetables were grown in Antarctica.

The design is based on a module that can be transported by a Falcon 9 rocket and that can be deployed on the surface of the Moon or Mars, covering an area of 13 m2, stated Daniel Schubert, the director of the Eden-ISS project. Schubert added that the DLR will be able to present the first prototype within five years.

The Eden-ISS project supplied researchers from the German base Neumayer III, in Antarctica, with fresh food during the polar winter. The food was grown in an insulated container with a cultivation area of 13 m2, where the plants grew at outdoor temperatures of up to 42 degrees Celsius below zero without soil, daylight, or pesticides. The necessary energy came from the Neumayer III station, located 400 meters away.

The experiment produced over 270 kilograms of vegetables under extreme conditions, including 67 kilograms of cucumbers and 46 kilograms of tomatoes.

VIDEO: Can Vertical Farming Solve Asia’s Food Crisis?

The government is looking to curb this dependence on outside food sources under a programme titled ‘30 by 30,’ which aims to allow Singapore to grow 30% of its produce by the year 2030

Singapore Has Only 1% of Its Land Available For Agriculture, So It

imports 90% of Its Food Requirements.

The government is looking to curb this dependence on outside food sources under a programme titled ‘30 by 30,’ which aims to allow Singapore to grow 30% of its produce by the year 2030.

Local vertical farms like Sustenir are at the forefront of bringing about this change.

VICE visits the sustainable start-up to understand the future of food.

CEA Advisors & Farminova Plant Factory Join Forces For Global Cooperation

For future projects developed jointly, CEA will provide consulting, marketing, project development and operations expertise, contributing its best-in-class vertical farming experience and Farminova will provide R & D support, HVAC systems, Control systems and its proprietary modular growing systems including its scalable next-generation, fully automated Plant Factory system

CEA ADVISORS LLC (CEA), a leading global vertical farming consultant, manufacturer and developer and Farminova Plant Factory (Farminova), a one-stop vertical farm technology provider have formed a strategic partnership to jointly develop future vertical farm projects for supermarkets and other commercial and industrial end users worldwide.

For future projects developed jointly, CEA will provide consulting, marketing, project development and operations expertise, contributing its best-in-class vertical farming experience and Farminova will provide R & D support, HVAC systems, Control systems and its proprietary modular growing systems including its scalable next-generation, fully automated Plant Factory system.

Glenn Behrman, CEA Founder and President, commented, “We are thrilled to collaborate with Farminova in developing our combined pipeline of vertical farming projects. This partnership recognizes the value of our company and strategy, and significantly expands both CEA’s and Farminova’s reach in the vertical farming sector while leveraging our respective strengths. We are extremely impressed with Can Hakan Karaca, Chairman of Parent Company, Cantek Group and the Farminova management team and believe its growing suite of best-in-class Plant Factory solutions is the perfect complement to our mission. Importantly, we share the same approach to pursuing a model in building vertical farms that are focused on water conservation, energy efficiency, labor savings, automation, optimization and are scalable while always focused on economics.

Can Hakan Karaca, Cantek Chairman stated, “We believe that the CEA and Farminova alliance in vertical farms is an important step forward for the industry, with the potential to serve a full range of commercial clients, including grocery retailers worldwide with automated farms capable of producing substantial quantities of both food and non-food products. As a proven leader in the vertical farming sector, CEA is the ideal partner for us. They have a demonstrated track record of success in developing vertical farms and many years of industry experience”.

“The Farminova growing systems are backed by many years of manufacturing expertise including HVAC & Environmental systems, Control systems, automation and supported by a team of professionals with deep expertise in Horticulture, R & D, quality control, and sales and marketing. In combination, CEA and Farminova will be able to provide a complete range of solutions, from growing systems and technologies for both food and non-food production, which we believe is a significant competitive advantage. We are very excited about this strategic partnership with CEA and look forward to working with them on providing customized Controlled Environment Plant Factory solutions for industry.”

Contact Information:

Mr. Erdem Aksan

erdem.aksan@farminova.com

Farminova Plant Factory

Organize Sanayi Bolgesi 3, Kisim 25. Cad. No:14 Antalya, Turkey

www.farminova.com/En

Sustainability In Agriculture’s Pioneering Forum

International Professionals Leading The Agtech Supply Chain Come

Together To Share Initiatives And Spur Innovation

September 3, 2019

(Miami, Fl., October) - The 2019 Sustainability & Digitalization Leaders forum is fast becoming the exclusive conversation series every thought leader in agtech should be a part of. Announcing the next cohort of speakers to present this October 22-24, the agenda demonstrates an awareness of the most relevant sustainability issues across the current landscape, from land degradation to carbon sequestering; cell cultured meats to regenerative urban food systems.

Featured presentations from global innovators include: impact and long term predictability of extreme weather patterns; regenerative practice of soil and land masses; the role and security of ground level farmers in a fast moving agricultural landscape. As companies continue to develop at the intersection of agriculture and emerging innovation, harnessing and deploying new technologies sustainably remains a roadblock.

Alongside SDL speakers including Mars, Rabobank, AeroFarms and Microsoft, the next round of international thought leaders have been confirmed:

Adam Bergman - SVP, Head of AgTech Practice, Wells Fargo Jasmine Crowe - CEO, G oodr

Ed Smith - Head of Indigo Carbon, Indigo

Lloyd Day - Deputy Director General, IICA

Kraig Westerbeek - Senior Director, S mithfield Renewables

Ingrid Fung - Investment Associate, Finistere Ventures

Kevin Krueger - Procurement & Sustainability, St Jude Children’s Research Hospital Michelle Adelman - CEO, Infinite Foods

For a full list of speakers visit: https://www.sdleaders.com/speakers

Occupancy for the event is limited and organizers urge attendees to secure their registration.

For more information on SDL or to purchase tickets visit: https://www.sdleaders.com/

About Sustainability & Digitalization Leaders

SDL is a program of events that address our planet’s most pressing issues, bringing together the decision makers who directly impact global change and can implement the necessary strategies to move the conversation forward.

A core advisory board oversees and advises on partnerships. For enquiries please email lyndsey@sdleaders.com.

About Keynote

Hosting international events since 2012 across Europe, North America and the Middle East, Keynote has curated forums for emerging technology industries, launching high profile fintech projects and acting as a platform to raise significant funds, connecting and enabling companies to reach their potential.

For more information about Keynote’s upcoming conferences visit

www.keynote.ae

For media partnership enquiries: moe@sdleaders.com

For partner and sponsorship enquiries: amy@sdleaders.com

How To Determine If LED Grow Lights Are A Good Investment

As LED grow lights continue to become more affordable, an increasing number of greenhouse growers and vertical farmers are considering whether the lights would benefit their production systems

Based on the benefits controlled environment growers are experiencing with LED grow lights, a return on investment (ROI) analysis could help you decide how quickly the payback would be for your operation.

As LED grow lights continue to become more affordable, an increasing number of greenhouse growers and vertical farmers are considering whether the lights would benefit their production systems. Add to this the testimonials of growers who have installed LEDs and the positive results they’ve gotten with commercial horticultural crops has caused more growers to look at the efficiencies these lights have to offer.

Comparing investment options

“The information on return on investment (ROI) for LED grow lights would have application to any type of equipment growers would be looking to purchase,” said Nathan Farner, president and CEO at North Ridge Solutions Inc. in Dallas, Texas, who is an adviser to Hort Americas. “Growers would be using a business case modeling approach to determine full project costs of various solutions and to understand what it takes to implement those solutions.