Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

US: Chicago - Vertical Farming Brings High-Tech Approach To Metropolitan Agriculture

"We're doing for farming what Henry Ford did for the automobile," said entrepreneur Jake Counne

A Local Entrepreneur Has A High-Tech Take

On Agriculture That Could Change What Ends Up On Our Plates

By Meghan Kluth

Thursday, August 15, 2019 CHICAGO (WLS)

You could call it farming for the future.

A local entrepreneur has a high-tech take on agriculture that could change what ends up on our plates.

"We're doing for farming what Henry Ford did for the automobile," said entrepreneur Jake Counne.

Counne has found a way to grow produce locally, even when it's below 50 outside. He said the answer is using cameras, software and a conveyor belt in what's called a vertical farm.

"I came across vertical farming and I was just enamored with the ability to exponentially out produce the natural ability of that land," said Counne, who is the founder and CEO of Backyard Fresh Farms.

Six types of lettuce are stacked on a four level tower under the glow of purple LED lights in his Back of the Yards facility.

The farm produces three tons of greens in one year's time, which is what a farmer could do with Soldier Field but in just four parking spaces.

Counne's vertical farm reduces costs of energy, labor, and his produce has proven to last weeks.

"We've already beat the cost of a field farmed equivalent products," Counne said.

An automatic lift collects trays of ready plants and brings them to an assembly line of workers for harvest. It has reduced labor by 80% compared to the first vertical farms of its kind.

"We are quite literally building an assembly line of greens," Counne said.

Counne has nine patents pending that are helping him create the perfect environment for a plant every day of its life.

"The software here is looking to try to figure out what the optimal amount of light. It's also looking for early signs of stress in the new growth," said Counne.

Some of the cities high end restaurants are already using Counne's produce and when put to the taste test, it's clear this is not your average lettuce.

Counne's plan is to expand and open 100,000 square foot facilities near every major metropolitan area around the country

Could Vertical Farming Meet The Food Needs of Tomorrow's Cities?

The majority of today’s global population lives in cities and by 2050, our population will have reached 9 billion people with 70% - 80% living in cities and urban areas

Five Takeaways

The majority of today’s global population lives in cities and by 2050, our population will have reached 9 billion people with 70% - 80% living in cities and urban areas.

Apart from large scale food security concerns, the world is also facing the loss of arable land and decreased access to fresh water fueled by global warming.

Vertical farming creates the future blueprint for securing the world’s food supply. It refers to growing crops in multiple vertical layers indoors, in controlled-environments, repurposed warehouses, growth chambers and even shipping containers.

Here are Heliospectra's five takeaways:

LED Grow Lights Make Vertical Farming Viable

LED grow lights have been the catalyst for growers looking to grow vertically. With recent developments in technology, growers can now maximize crop yields and standardize production 365 days a year.

The ability to alter light spectra and the quality of light that the crops are exposed to has huge implications on every aspect of production. Growers gain more control than ever by knowing that correct light can influence each variable—from how crops develop, when they bloom, how they taste, and even their chemical compositions.

Vertical Farms Use Less Water for Food Cultivation

Agriculture currently accounts for roughly 70% of our water usage and is also responsible for the vast majority of water runoff and contamination issues that are present today.

In contrast, vertical farming utilizes 70% - 95% less water compared to traditional farming. Some of the largest and most successful vertical farms also incorporate closed-loop water circulation systems to recirculate water to their crops, leading to an even greater reduction in water usage.

Vertical Farming is Less Labour Intensive

Vertical farming enables smart farming with precision technologies and controls to greatly reducing the crop input costs and intense labour of field farming.

The increasing development of Al, automation and robotics will also continue to increase revenue for growers and support even greater resource savings and operational efficiencies.

Vertical Farming Has the Ability to Conserve Land

Simply put, vertical farming produces more food per square meter, using up to 90% less land. This can help promote biodiversity as farmers drastically reduce their environmental footprint by growing more food on less land, encouraging an increase in livestock populations and natural enrichment of arable farmlands.

Arable land is also a valuable resource and as soil health decreases with use, so does the nutritional value of our food. The more we continue to farm through traditional methods, the more we reduce the bare mineral components and quality of soils. Vertical farming changes this by instead using aquaponic, hydroponic and aeroponic growing mediums instead of soil. By using these controlled media, vertical farming has also helped farmers move away from using pesticides in their production.

Vertical Farms Bring Local Food to Consumers and Neighbourhoods

Reducing emissions from transport is one of the most important measures to combat global warming from cars, trucks, aircraft and boats creating almost 20% of manmade carbon dioxide worldwide. Vertical farming addresses these issues by creating a sustainable model for locally grown produce. By growing local, food has to travel less distance and requires less artificial protection (i.e. refrigeration), resulting in produce that is not only fresher, but has a smaller environmental impact across the entire production chain.

All Pictures are Heliospectra’s SIERA Light Bar in different Vertical Farming environments.

For more information:

Heliospectra

info@heliospectra.com

www.heliospectra.com

Publication date: 8/19/2019

National Geographic Features UVI Aquaponics Program

The University of the Virgin Islands Agriculture Experiment Station is featured in the August issue of National Geographic, one of the leading magazines on science, geography, history, and world culture

By Source staff | . August 18, 2019

A raft of lettuce grows in a pond, with the shaded tilapia tanks in the background. (UVI photo)

Aquaponically grown lettuce is harvested at UVI. (UVI photo)

The University of the Virgin Islands Agriculture Experiment Station is featured in the August issue of National Geographic, one of the leading magazines on science, geography, history, and world culture.

The ag station, which features an aquaculture program, is spotlighted in the magazine’s Explore Decoder section. Accompanying graphics illustrate the principles of aquaponic design and operation, according to a news release issued by the university.

The online component of the publication includes a video demonstrating how vegetables can be grown through aquaponics.

UVI, a land grant institution, has been a leading public university researching aquaponics and has a great depth of knowledge and experience in the field. The program, which began in 1979, boasts a facility spanning 1.95 acres on UVI’s St. Croix campus.

Donald Bailey, research specialist in the aquaculture program, began assisting National Geographic journalists with the story in April, providing them with information and illustration for the home-scale system that is included in the issue.

“Throughout the collaboration, I realized from the lead writer, illustrator and editor that they needed accurate and precise information, clearly stated, so that magazine readers would not be misinformed or misled,” Bailey said. “I’m happy with the final product, including the drawing of the UVI Aquaponic System in the upper right corner of the illustration.”

Research Specialist Donald Bailey (UVI photo)

Among the illustrations included is a drawing of the UVI Commercial Aquaponic System. The main illustration shows a home-scale system that includes the main components of a well-designed aquaponic system: a separate fish rearing tank, solid waste removal, deep water channel hydroponics with floating rafts, continuous aeration and water flow.

Six detailed steps lead the reader through the system processes with illustration focus points highlighting nitrification, the natural process of water purification and seedling/vegetable production.

Vegetable production is the primary benefit of aquaponics, as it contributes to cleaning the water for reuse in fish production and provides valuable revenue for the operation, according to the UVI news release.

“Through its research, the AES Aquaculture Program developed a sustainable design with reliable operating procedures that can be scaled for home and hobby use or commercial production,” Bailey said. “The magazine illustrates a home-scale system with the necessary components for continuous operation and production of fish and vegetables. We hope that the home-scale system can be adopted by more Virgin Islanders.”

The university saw the expansion of the aquaculture program with the development of research and demonstration systems in aquaponic and biofloc systems and cage culture in watershed ponds in 1979 when James Rakocy joined the university. It also hosted annual workshops drawing budding agriculturists from all over the world to learn how to set up systems for home or commercial use.

The August 2019 issue of National Geographic is available in both St. Croix and St. Thomas campus libraries.

Kimbal Musk’s Goal: Grow Fresh Food In Containers In Every American City

Musk’s newest venture — alongside his co-founder Tobias Peggs — combines food and technology to empower the next generation of farmers. Square Roots is a seed-to-sales urban farm, connecting people in cities to locally grown whole foods. The farm also runs a farmer-training program, which creates opportunities for more people to become urban farmers.

August 22, 2019

Kimbal Musk | SUSAN FRANCE

Standing out in Boulder is not an easy thing to do. From famed world athletes to politicians, the city has its share of notable residents, but when a 6-foot-4-inch man wearing a cowboy hat walks around town, people notice. Some know who he is; some don’t. It’s Kimbal Musk, food entrepreneur and owner of The Kitchen restaurant chain.

Musk’s newest venture — alongside his co-founder Tobias Peggs — combines food and technology to empower the next generation of farmers. Square Roots is a seed-to-sales urban farm, connecting people in cities to locally grown whole foods. The farm also runs a farmer-training program, which creates opportunities for more people to become urban farmers.

Currently, Square Roots farmers grow a variety of fresh herbs in indoor, vertical farms inside containers, right in the heart of Brooklyn. They hand-harvest, self-package and deliver to retail stores across New York City. The herbs are non-GMO and pesticide-free, developed through human-centered farming technology that surrounds farmers with data, insights and tools so they can grow high-quality food, all year-round, using the fewest resources possible.

The system uses a water-efficient hydroponic growing system within vertical modular farms in shipping containers, which means there is no need for pesticides. Plus, Musk says, it requires about one-tenth the amount of water compared to traditional gardening.

Musk started to really think about urban gardening 16 years ago when he opened The Kitchen in Boulder alongside partner and chef Hugo Matheson. According to Musk, they worked with local farmers from the beginning because the food simply tasted better. Along the way, they ended up learning about the sustainability ethos and how much local farmers care about the land, as well as how important it was to have local food production.

The idea behind Square Roots, Musk says, was to create something that would enable the best quality herbs while empowering young farmers to grow food in the city.

“Most of our young farmers are in big cities,” Musk says. “They are not in the countryside.”

But every new technology comes with a cloud of doubts and skepticism, and Square Roots is not immune. Critics have questioned whether or not Square Roots will require more fossil fuel energy to grow food inside, as well as the limits to the type of food that can be produced without soil, and the unrealistic possibility of feeding millions of people with a technology that cannot produce food for the masses.

Musk says that Square Roots’ electricity consumption is mitigated because the containers use electricity at night when power plants have excess energy.

“The energy is being produced anyway,” Musk says. “The farms don’t pull more energy from the grid, which allows us to get electricity at a much lower price.”

For farmer Maxwell Carmack, a Square Roots graduate, the future of vertical farming seems promising. Aware of the critics, he says the carbon footprint of the transportation and refrigeration costs currently in use to move food across the country is worse than the electricity needed to run the indoor farms. Still, he is looking forward to incorporating sustainable energy production technologies to the industry of vertical farming to take it to the “next step.”

While critics may think it will be impossible to feed cities out of containers, Carmack, an engineer who decided to stay on with Square Roots after graduating the program, is excited to prove them wrong.

“I spend my time making all of the marginal gains that can add up,” he says. “In fact, in the past year we’ve doubled the production. I see improvement every day. In the end, as an engineer, I care about what might be possible and not what might not.”

Since its founding two and half years ago, the Square Roots program has graduated 30 people, and many graduates have taken the path of entrepreneurship, from rooftop garden installations to catering. And it’s expanding, as urban farmers in Grand Rapids, Michigan, will soon start producing fresh herbs as well.

Musk says the ultimate goal over the next 10 years is to have Square Roots systems in every U.S. city and to graduate around a thousand new urban food farmers, while continuing to improve the technology. While he’s aware that Square Roots can’t feed America alone, he hopes it’s the start of a vertical revolution with its roots in Boulder.

Mastronardi, DeJoria Launch GIVE Partnership In Middle East

Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

NEWS PROVIDED BY

Aug 19, 2019

KINGSVILLE, ON, Aug. 19, 2019 /PRNewswire/ - Mastronardi Produce Ltd.®, North America's leading grower and distributor of greenhouse produce, and visionary John Paul DeJoria have selected the Middle East as the first market in which to develop the world's largest and most technologically advanced indoor farming project.

Green International Ventures LLC (GIVE)'s Middle East location will be the world's largest and most technologically advanced indoor farming project. (CNW Group/Mastronardi Produce Ltd.)

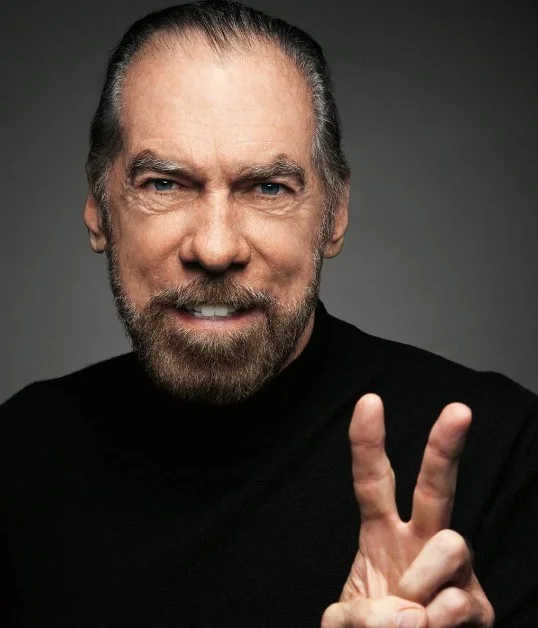

John Paul DeJoria (CNW Group/Mastronardi Produce Ltd.)

.Paul Mastronardi (CNW Group/Mastronardi Produce Ltd.)

The newly formed company, Green International Ventures LLC (GIVE), will make locally grown fresh produce more widely available around the globe via its proprietary Advanced High-Density Farming System. This will be the first project for the groundbreaking GIVE venture, and it will reduce the Middle East's dependence on imported food, create a sustainable source of local employment, and significantly increase the region's non-petroleum-based exports.

"As pioneers in the greenhouse industry, we are passionate about increasing access to local, sustainably grown fruits and vegetables," says Paul Mastronardi, President and CEO, and the fourth-generation family member to lead Mastronardi Produce. "Our first location in the Middle East will allow us to reach over half the world's population in less than 8 hours, and this is just the start. Look for more global locations as we continue to scale to meet the growing need for food security, safety, and sustainability."

GIVE will also support the integration of modern AgTech initiatives into the local farming community and expand knowledge of sustainable agricultural techniques by establishing a permanent Research and Development facility in the region.

"It has long been my passion to help feed the world's population," says John Paul DeJoria. "The introduction of this revolutionary model in the Middle East is the first step of many towards increasing global access to sustainably grown fruits and vegetables."

All GIVE projects use innovative Advanced High-Density Farming Systems that incorporate a multitude of cutting-edge growing systems, such as water-saving irrigation and energy-efficient lighting, and they take advantage of advanced automation and robotic devices, AI processes for predictive analysis, and real-time crop and soil monitoring.

Produce grown in these innovative AgTech systems will be marketed under the SUNSET® brand. Known for award-winning flavor, innovation, and packaging, SUNSET's many exclusive labels include Campari®, the world's first branded tomato, and the uniquely colorful Aloha™ pepper.

SUNSET of Holland® will be the first distributor for the GIVE partnership.

About Paul Mastronardi and Mastronardi Produce Limited

Paul Mastronardi is the President and CEO of Mastronardi Produce, which recently received the prestigious honor of being named one of "Canada's Best Managed Companies" for the 10th consecutive year. In 2016, Paul was named Produce Person of the Year at the United Fresh Convention & Exposition in Chicago, USA, and in 2013, he was named Ernst & Young's "Entrepreneur of the Year" for Ontario.

Mastronardi Produce, the leading greenhouse company in North America, grows and sells flavorful, world-class tomatoes, peppers, cucumbers, and berries under the Sunset® brand. As pioneers in revolutionary greenhouse technology, they focus on sustainable non-GMO growing practices, recognizing that what is good for the environment, is good for business.

About John Paul DeJoria

John Paul DeJoria is a serial entrepreneur, philanthropist, business leader, and mentor with a true rags-to-riches story. Once homeless, he overcame adversity, and went on to build two billion-dollar brands—leading professional hair care manufacturer, John Paul Mitchell Systems, and Patrón Spirits—and several global enterprises. He started his first company, John Paul Mitchell Systems, with partner Paul Mitchell and a borrowed $700. He remains true to his motto, "success unshared is failure," and dedicates himself to numerous charitable causes through his philanthropy hub, JP's Peace, Love & Happiness Foundation, and he has committed to donate more than half of his wealth to philanthropy through his signing of Bill Gates and Warren Buffet's "The Giving Pledge."

SOURCE Mastronardi Produce Ltd.

Related Links

US: Purdue University Workshop To Feature Hydroponic Technology - September 5, 2019

The fourth annual Greenhouse and Indoor Hydroponics Workshop will be from 8 a.m. to 3 p.m. Sept. 5 on the Purdue University campus

Ashley Langreck AgriNews Publications

JulY 31, 2019

Krishna Nemali examines hydroponically grown lettuce in the horticulture and landscape architecture greenhouse at Purdue University. Provided photo/Purdue University

WEST LAFAYETTE, Ind. — The fourth annual Greenhouse and Indoor Hydroponics Workshop will be from 8 a.m. to 3 p.m. Sept. 5 on the Purdue University campus.

The workshop, which is sponsored by Purdue Extension, Purdue’s Department of Horticulture and Landscape Architecture and the Indiana State Department of Agriculture, will focus on teaching attendees about hydroponic production technology.

Lori Jolly-Brown, who is serves as the Extension events and communications coordinator for the horticulture and landscape architecture department, said the morning session of the workshop will focus on how to get started in hydroponics, where to purchase and find materials, how to fertilize plants, ways to keep bugs away and a wide variety of other topics.

After lunch, Jolly-Brown said, attendees will have the chance to tour one of Purdue’s state-of-the-art greenhouses and indoor hydroponic facilities, while also having the opportunity to participate in hands-on activities.

Jolly-Brown said individuals will be able to interact with workshop organizer Krishna Nemali, a Purdue assistant professor and a controlled environment agriculture Extension specialist.

“They will get to see Nemali’s hydroponic research and vertical farming displays,” Jolly-Brown said.

Jolly-Brown said the workshop is geared toward commercial producers and growers, those just getting started in hydroponics, as well as those who are involved in hydroponics production technology as a hobby.

To register for the workshop, visit https://bit.ly/2OjqTBn.

Ashley Langreck can be reached at 800-426-9438, ext. 192, or alangreck@agrinews-pubs.com.

Follow her on Twitter at: @AgNews_Langreck.

Choosing Your First Hydroponic System

For growers trying out hydroponics for the first time, choosing the best system can be a daunting task. Are you up for the challenge? Take our quiz to find out, then read on to learn about several low-maintenance hydro systems and determine which one is right for you.

Lacey Macri | August 13, 2019

Takeaway: For growers trying out hydroponics for the first time, choosing the best system can be a daunting task. Are you up for the challenge? Take our quiz to find out, then read on to learn about several low-maintenance hydro systems and determine which one is right for you.

As laws and climates change and mentalities shift towards living more sustainably, an increasing number of people are joining the grow revolution and bringing things indoors so they can grow year-round. Selecting your first indoor garden set-up can be difficult with all the options available, each with its own set of pros and cons.

Depending on your unique set of circumstances, certain set-ups may be more valuable to you than others. Take this short quiz to find out if you’re ready for hydroponics, then read on to dial in the specifics.

1) Do you have limited start-up cash?

a) Yes

b) Not necessarily

2) Do you see this as a long-term hobby or just temporary?

a) Temporary

b) Long-term hobby

3) Do you have plenty of time available to spend on this each day?

a) Yes

b) No

4) Do you live in a region with frequent power outages?

a) Yes

b) No

5) Do you want to grow organically or in a sterile environment?

a) Organic

b) Sterile

6) Are you eager to get started right away?

a) Yes

b) No rush

7) Will the growroom be in a rural area subject to many pest infestations?

a) Not sure

b) Yes

8) Is it important to you to keep your growroom as clean as possible at all times?

a) Not a factor

b) Definitely

Results

Tally up the number of answers you responded to with A versus B. If you answered more questions with A, you might be better off with a traditional, soil-based system. If you answered more questions with B, hydroponics may be for you. Even if your answers were mixed, there might be a hydro system listed here that fits your bill perfectly.

Read also: Hydroponics: Pros and Cons of Hydroponic Gardening

Ebb & Flow

Ebb and flow systems have long been recognized as classic hydroponic systems. An ebb and flow system consists of a shallow table with a centralized flood and drain system that is hooked up to timers to control the feed schedule. An overflow valve is also installed to control the height of the water that is flooded onto the tray that holds the plants.

Once the plant tray is flooded for a set amount of time, the water drains back into the reservoir, which is usually placed beneath the table. There are many benefits to choosing this type of system, including the ability to move plants around if they become crowded, and how easy it is to set up and customize your system based on spatial and financial limitations.

Drawbacks include a few slightly higher risk factors than other methods. If you live in a region with frequent power outages, this might be the least desirable option for you, as plants rely solely on the pump delivering the nutrient-rich water to them on a strict time schedule.

If you are out and about and are unable to get to your growroom in a timely manner, plants can die in a matter of hours. However, many plants are resilient, so if you open up your tent to see wilted, sad-looking plants, it is worth trying to resuscitate them by watering them immediately, as you may be pleasantly surprised.

Water Culture

Some water culture systems are visually similar to ebb and flow systems, but they operate somewhat differently. A traditional water culture system consists of a vessel that is flooded but never drained.

The plants may float around in the water in Styrofoam rafts, or they might be held in net pots positioned directly above the water with their roots suspended indefinitely in the water below, which is usually referred to as deep water culture. Plants are exposed to a nutrient-enriched water source at all times. To avoid suffocating plants, the water must be properly oxygenated with air pumps and air stones.

One benefit to water culture is being able to run your nutrient solution at a lower concentration, since the food source is ever-present and plants are free to feed as they need. One of the most serious drawbacks is the threat of diseases.

Because roots are constantly exposed to the solution, whatever is in that solution—good or bad—will propagate quickly. Some common, serious threats include fusarium, root rot and pythium. You can use products like hypochlorous acid, or H2O2, to help prevent the development of water-borne pathogens.

Aeroponics

Similar to water culture, the roots of plants in aeroponic systems are also suspended, but instead of being immersed in the water, they are hanging in the air. The nutrient-rich solution is then misted periodically from a reservoir onto roots. Plants are often held up by flexible, firm neoprene collars instead of grow media.

Aeroponics is one of the cleanest, most sterile ways to grow. Without grow media, there aren’t as many locations for bacteria to hide. The absence of grow media also allows the plants to grow as quickly as possible without any limits to the span of their root mass. These conditions make aeroponics one of the most preferred cloning options available, as fresh cuttings are highly susceptible to various diseases and prone to failure.

One limitation is that many plants will eventually outgrow their original system, so they will have to be transplanted. Unless you’re growing lettuce or basil, you will have to have something lined up for when that happens. While it is possible to grow mature plants in an aeroponic system, some plant strains may have higher demands for water and nutrients than the misting environment can viably deliver.

Nutrient Film Technique

Most hydroponic systems are hybrids, and nutrient film technique (NFT) systems are no different. This set-up may require a bit more experience than the rest, but its results are typically superior. Every system has its shortcomings, which usually evolve from a lack of one of three things: air, water or nutrients. The beauty of NFT is that all three of these essentials are abundantly available at all times.

Typically, people think of NFT as a hollowed-out, cylindrical tube on a downward slope that houses the channels that carry nutrients and water. Plants are spaced proportionally and placed in the holes on the upper surface of the tube. Grow media is not necessary and like aeroponics, growers may use neoprene collars or something similar to hold plants in place.

Nutrient-rich solution is pumped from a reservoir, usually located at the base of the channel and then directed up to the highest part of the channels and allowed to flow continuously downstream through the roots. The unused water may then drain directly back into the reservoir for recirculation. When NFT is done right, it can be the best in its class. However, dialing in all the details is something that only comes from experience.

Drip System

Drip systems are one of the most popular hydroponic methods. Similar to NFT, plants on a drip system may be placed on a slanted table to direct nutrient solution overflow into a recovery or non-recovery system. In recovery drip systems, the solution not absorbed by plants will ultimately drain directly back into the original reservoir, while the water that drains into a non-recovery system is considered wastewater.

The dripline is controlled by a submersible pump that supplies nutrient solution around the base of each plant directly onto the grow media. Common grow media used in this technique include stonewool, clay pebbles and coco. Stonewool and coco allow growers to irrigate less frequently, as they tend to hold enough moisture to keep plants adequately hydrated in between drip cycles. Clay pebbles make nutrient management easier in situations where the drip is more constant.

Drip systems are popular for their easy and affordable set-ups, and high level of control over how plants are fed. On the other hand, drip systems are more prone to fluctuations in pH and EC, as these levels are less stable in recirculating systems.

One of the goals of hydroponics is running a fully automated system. With all the plug-and-play systems available, there is bound to be something for everyone. When selecting a system, keep in mind it isn’t always about which method is best overall, but rather which method will work best for you. Don’t be afraid to try something new.

Written by Lacey Macri

Lacey Macri works as head of sales at CleanGrow, focusing her time on business development within the company. She received a bachelor’s degree in communications and psychology from the University of California, Davis, in 2011, where she worked at the California Aggie student newspaper on campus. Full Bio

'Lettuce' Start A New Container Farming Venture

Essentially the company manufacturer purpose-built containers (sea containers don't work) housing a hydroponics system to vertically grow any number of products.

Ken Wilson 17 August 2019

Modular Farms Australia director James Pateras.

ON the surface you might think hydroponics farming is for somebody else to try.

But at last week's TECHSPO, Modular Farms Australia director James Pateras, laid out a tantalising case for the technology to be a niche business on any Australian farm.

A former Victorian dairy farmer and a Deakin University graduate majoring in economics and finance, Mr Pateras is now firmly ensconced in a vertical farming system, growing herbs, and making money.

He also is a director of Modular Farms Australia, which is linked to its Canadian parent in Ontario.

Essentially the company manufacturer purpose-built containers (sea containers don't work) housing a hydroponics system to vertically grow any number of products.

Being modular, additional modules are available for multiple uses.

"One of the secrets of producing quality product is lighting and our company has partnered with world-leading experts in LED lighting, plant health sciences, and indoor agriculture to re-think the container farm from scratch," Mr Pateras said.

"We focus entirely on plant health and farmer return on investment (ROI), which was one of the first questions Mr Pateras answered after his talk.

"The downside is we use a lot of energy in our enterprise but balancing the costs is the fact we are producing a high value product which we can supply virtually on demand year-round," he said.

"And to mitigate power costs it could be supplemented by on-farm energy, either solar or biomass.

His company also supplied cold storage units to maintain freshness until product was transported to clients.

"It's a closed loop system and we have a particular LED light recipe that enhances the quality of produce we market," he said.

Mr Pateras also reiterated the diminishing amount of arable land available throughout the world for farming practices.

"So, for example, we can grow 44,000 lettuce heads a year in a 36 square metre space," he said.

"The land needed to achieve that would be 1000 square metres.

"So vertical farming is making more efficient use of land with year-round supply and scalability.

"There already is work going on to produce rice by hydroponics so as technology improves there may be a way to grow our main line crops the same way.

"But at the moment opportunities exist to grow fresh produce and compete on quality and timing."

Another business opportunity for farmers existed with using biomass.

Department of Primary Industry and Regional Development (DPIRD) researcher Ron Masters said biomass was a realistic cash crop for farmers.

"Biomass on farms would mainly come from animal waste, crop residues or purpose-grown crops," he said.

"It's a renewable resource which reduces the carbon footprint and has the potential to be a substitutive product.

"For example, it could be used for carbon offsets or as a substitution for diesel and ethanol fuels.

"Biomass can be used to create steam for industrial uses or for a generator, bio-hydrogen, biochar and plastics.

"But I think the big winner for farmers will be using it for high value chemicals."

Though Mr Masters didn't expand on this subject, it is well known that sugar constitutes 75 per cent of all biomass, and it can be obtained from many different sources such as cane, beet and corn.

Even wood and straw can be processed into sugars that can be converted to chemicals.

Mr Masters also said renewable diesel would "probably" be the next big thing before renewable chemicals.

"The hidden gem is oil mallees," he said.

"Things have changed since the early days and we now have a commercial operator in Kochi Oil at Darkan which is processing the oil mallees.

"The resultant biomass is there to collect to power a greenhouse system, for example."

Have a commercial operator in the State makes such a proposition more viable."

Mr Masters said that overseas, biomass was a big business in making bio-hydrogen, nitrogenous fertilisers, plastics and used as a wood replacement.

When asked about the potential for canola oil, Mr Masters said there was "massive investment" internationally in canola as a first generation biofuel.

"WA has ignored this area for a long, long time but the opportunities are there," he said.

Artemis, Publisher of State of Indoor Farming Report, Launches First Annual Global Ag Report Survey

The Artemis Global Ag Report will gather industry insights around challenges and opportunities for the farming industry as in past years, however, this next survey will be open to all specialty crop cultivators—across international, enterprise, indoor/outdoor, hemp and cannabis operations

This year, we’re excited to announce a brand new iteration of the State of Indoor Farming Report: the Artemis Global Ag Report.

The Artemis Global Ag Report will gather industry insights around challenges and opportunities for the farming industry as in past years, however, this next survey will be open to all specialty crop cultivators—across international, enterprise, indoor/outdoor, hemp and cannabis operations. We decided to expand the scope of the survey and report to deepen its value and utility as a resource for our industry.

The survey is open for submissions starting today Wednesday, August 21 and will close Tuesday, October 15. The survey takes about 15 minutes to complete, and the 2019 report will be released later this year.

Also, all survey participants have the chance to obtain an audit from the Artemis resident Regulatory Compliance Specialist. (5 participants will be awarded the opportunity after the survey closes on Oct 15th, 2019.)

START SURVEY

We welcome you to join us in building a valuable record of global agriculture insights in an effort to realize a stronger, safer supply chain for our industry. Share this survey with your colleagues and community, the more participation in the Artemis Global Ag Report the better a report for everyone. Trust us—we know data.

Best,

The Artemis Team

CubicFarm® Systems Corp. Announces The Appointment of Chris Ericson As The Company’s Newest Board Member

“I am delighted to welcome Chris to our board”, stated Dave Dinesen, CEO & Director of CubicFarm® Systems Corp. “Chris is a wonderful addition to our company and helps to strengthen the existing bond with Nu Skin, which has invested in our technology in connection with its development efforts for ingredient sourcing

Vancouver, BC--(AccessWire – Aug 19, 2019) – CubicFarm® Systems Corp. (TSXV: CUB) (“CubicFarms” or the “Company”) is very pleased to announce Chris Ericson has been appointed to our board of directors.

“I am delighted to welcome Chris to our board”, stated Dave Dinesen, CEO & Director of CubicFarm® Systems Corp. “Chris is a wonderful addition to our company and helps to strengthen the existing bond with Nu Skin, which has invested in our technology in connection with its development efforts for ingredient sourcing. Chris has enjoyed a diverse business life, spanning a wide range of experiences and responsibilities in a number of countries. As the current VP of Business Development with Nu Skin, Chris is responsible for driving long-term value for Nu Skin through the development of strategic business relationships. CubicFarms looks forward to Chris playing an active role in helping to guide and influence our growth and future development into new markets.”

Since joining Nu Skin in 2015 Ericson has led its Global Internal Audit team as VP of Internal Audit and before that served as the Director of Internal Controls. Ericson also has more than a decade of experience in the professional services group of PricewaterhouseCoopers (PwC), where he advised and worked closely with senior management and leadership teams of multinational, public companies.

Chris earned Bachelor of Science and Master of Accountancy degrees from Brigham Young University with minor degrees in Japanese and Management of Information Systems.

“I am very excited to join the board of CubicFarms as we develop the tremendous opportunities that exist in Automated Controlled Environment Agriculture (CEA). Nu Skin and CubicFarms enjoy an excellent relationship and are working together to drive agricultural sustainability, food security and pure ingredient sourcing”, said Chris Ericson

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Hydroponic Farms Use Less Land, Water To Grow Vegetables

Growing lettuce and other leafy greens indoors is gaining traction nationwide, as such big players as New Jersey-based Aero Farms and Bowery, are producing huge quantities in giant warehouses fueled by millions of dollars in investment

By Susan Salisbury For The Palm Beach Post

August 12, 2019

Green Life Farms’ hydroponic greenhouse occupies nearly 3 acres. It expects to yield 750,000 pounds of premium leaf green produce throughout the year, said Mike Ferree, vice president. The greens are grown, harvested and packaged onsite. [CONTRIBUTED BY HYDRONOV}

Greenhouses Allow Year-Round Growing

And Protection From Freezes And Extreme Rainfall.

Growing lettuce and other leafy greens indoors is gaining traction nationwide, as such big players as New Jersey-based Aero Farms and Bowery, are producing huge quantities in giant warehouses fueled by millions of dollars in investment.

The push comes as farmland becomes increasingly expensive and in short supply, and consumers demand locally grown produce that’s fresher because it hasn’t been transported hundreds of miles.

In Palm Beach County two new hydroponic farms—Green Life Farms and Patagonia Green Leaf— are being launched in greenhouses off U.S. 441 west of the Lake Worth Beach/Boynton Beach area. Hydroponic farming uses no soil. Instead, crops are grown in perlite, coconut fiber or nutrient-rich water in a controlled and enclosed environment.

Art Kirstein, agricultural economic development coordinator with the Palm Beach County Cooperative Extension Service, said that hydroponic farming offers advantages such as year-round growing, increased capacity on a smaller amount of land and protection from freezes and weather events such as extreme rainfall.

Green Life Farms harvested its first crop of baby arugula, baby romaine and baby spinach in mid-July. Its greenhouse occupies nearly 3 acres and will yield approximately 750,000 pounds of premium leaf green produce throughout the year, said Mike Ferree, vice president.

Baby romaine lettuce grows in the Green Life Farms hydroponic greenhouse off U.S. 441 west of Lake Worth Beach. The company has spent $15 million on the facility.

The greens are grown, harvested and packaged onsite, then picked up or shipped directly from the farm. They are also GMO and pesticide-free.

Green Life’s head grower, Greg Graft, said the produce is mechanically harvested using an automated system.

The first crop is not available for sale. Once Green Life begins official commercial production, products will be available at local grocery stores, restaurants and other locations, Graft said.

Green Life chose Palm Beach County for its large consumer market, proximity to sales partners and an agriculture-friendly environment, Graft said. It has invested $15 million so far.

Green Life uses a deep-water floating raft technology from Hydronov, an Ashley, Ind.-based leader in the hydroponic industry with more than 30 years of experience.

The floating raft system helps to conserve water, using the oxygenated clean water in which the plants grow as a conveyor system. Green Life will be able to produce 18 harvests each year and use 90 percent less water than conventional farming.

Patagonia Green Leaf, about a mile south of Green Life, is a hydroponic farm on a former plant nursery. It’s owned by the Canosa family. They’ve farmed in the traditional way in Argentina for 10 years.

The first phase of 10 greenhouses totaling 30,000 square feet is completed. The initial crop of baby greens will be planted soon, with harvesting expected by late September.

“The idea is to harvest and deliver the product within 24 hours,” said Juan Ignacio Canosa, who lives in Boca Raton.

After visiting Miami and Fort Lauderdale on vacations, the family started coming to Boca Raton. Last year they bought 5 acres from Boynton Botanicals, whose owner was retiring.

Plants will be grown pesticide-free using a system known as NFT, (nutrient film technique) from Arcata, Calif.-based AmHydro. A pump delivers fertilized water to the growing trays, flows over the plants’ roots, then drains back into the reservoir and is recycled.

Robert Hochmuth, regional extension agent with the University of Florida’s North Florida Research and Education Center, said since the early 2000s, the number of acres of produce grown in greenhouses and other structures in Florida has increased five-fold to more than 500 acres.

Producing in protected structures extends the season and reduces insects and diseases, Hochmuth said.

“You can be a consistent supplier in the marketplace over a long period of time,” Hochmuth said.

Most of the hydroponic farms in Florida are less than an acre and tend to cater to local markets.

Hochmuth said hydroponic growing is attracting people who are new to farming.

“Because they are going with high-value specialty crops, the likelihood of profitability makes sense,” Hochmuth said.

Of course, greenhouses and other facilities are at risk of being destroyed during hurricanes or high winds. Hochmuth advises removing the plastic from the structures prior to storms because it acts as a sail.

Hydroponic farming isn’t new to Palm Beach County. Walter Ross founded Farmhouse Tomatoes west of Lake Worth in 1996 and grows heirloom tomatoes in 160,000-square-feet of greenhouses from Nov. 1 through June 30.

BREAKING NEWS: Crop One Holdings And Sananbio Announce Strategic Partnership To Jointly Develop Vertical Farms

Crop One Holdings (Crop One), a leading global vertical farm operator, and Sino-Science North America Photobiotech (SNAP), one of the largest vertical farm technology providers in the world, have formed a strategic partnership to jointly develop future vertical farm projects. SNAP is the owner of SANANBIO®, affiliated and supported by the largest producer of top-quality, ultra-high bright LED wafers and chips

August 20, 2019

OAKLAND, Calif.--(BUSINESS WIRE)--Crop One Holdings (Crop One), a leading global vertical farm operator, and Sino-Science North America Photobiotech (SNAP), one of the largest vertical farm technology providers in the world, have formed a strategic partnership to jointly develop future vertical farm projects. SNAP is the owner of SANANBIO®, affiliated and supported by the largest producer of top-quality, ultra-high bright LED wafers and chips.

For future projects developed jointly, Crop One will lead project development and plant operations, contributing its best-in-class plant science and controls technology, and SNAP will provide LED lighting and its proprietary modular growing systems and next-generation, fully automated vertical farm system, UPLIFTTM (Unmanned Platform of Lean & Intelligent Farming Technology). Crop One will license its plant science and controls technology to projects and both parties will contribute technology, equipment, know-how and financing.

Sonia Lo, Crop One’s Chief Executive Officer, commented, “We are thrilled to collaborate with SNAP in developing our combined pipeline of vertical farming projects. This partnership is a validation of our company and strategy, and significantly expands both Crop One and SNAP’s breadth and reach in the vertical farming sector while leveraging our respective strengths. We are long time, happy users of SNAP’s LED lights and believe its growing suite of best-in-breed hardware solutions is the perfect complement to our software, controls and plant science technology. Importantly, we share the same approach to pursuing an asset-light model to building vertical farms that is focused on scale, cost and energy efficiency.

“Successful vertical farms require a broad array of expertise and capabilities to operate efficiently and effectively, and we expect strategic partnerships between market participants with best-in-class complementary resources will become an increasingly important way for the leaders in the space to accelerate growth. Most vertical farm assets are owned by infrastructure investors, and technology companies such as Crop One and SNAP are enabling those owners to achieve the best return on their assets without the burden of technology development and management.”

Michael Yates, Sananbio U.S.’s Vice President of Technology Sales, added, “On a combined basis, we believe Crop One and SNAP’s pipeline in vertical farms is the largest in North America, with the potential to serve a full range from large wholesale to specialty retail customers across the continent with mega-farms capable of producing three or more tons of crops per day. As a proven leader in the vertical farming sector, Crop One is the ideal partner for us. They have a demonstrated track record of success in operating vertical farms at scale. The company’s partnership with Emirates Flight Catering to build the world’s largest vertical farm underscores the success of Crop One’s model and plant science technology, which address the most critical issue in vertical farming – optimizing plant growth with higher yields, at lower costs.

“Our LED products and growing systems are backed by many years of research in plant physiology and semiconductors and supported by a team of professionals with deep expertise in manufacturing, quality control, and sales and marketing. In combination, Crop One and SNAP will be able to provide a complete suite of solutions, from growing systems and technologies to crop development and production, which we believe is a significant competitive advantage. We are very excited about this strategic partnership with Crop One and look forward to starting our first project soon.”

About Crop One Holdings

California-based Crop One Holdings is a vertical farming technology company that enables fresh produce to be grown in a sustainable manner for its customers. It operates two subsidiaries: FreshBox Farms in Millis, Mass., and a joint venture with Emirates Flight Catering in Dubai South, United Arab Emirates. Crop One has been in continuous commercial production longer than any other vertical farmer in North America. The company’s proprietary technology and plant science put it ahead of its competitors, producing crop yields among the highest of the industry, but at 25% to 50% of the capital cost of other vertical farming companies. To learn more, visit https://cropone.ag/.

About Sino-science North America Photobiotech Inc.

SANANBIO® is a trademark carried and backed by Sanan Sino-Science Photobiotech, a company invested by Sanan Optoelectronics, one of the world’s largest LED chip manufacturers. Supported by an elite R&D team comprised of plant scientists, researchers and engineers, Sananbio utilizes state-of-the-art technology that enables growers worldwide in the horticulture industry to increase the quality and quantity of their yields. Years of extensive research and real-world deployment and operations allow Sananbio to offer its customers proven, scalable, efficient and cost-effective solutions in LED horticulture lighting and Controlled Environment Agriculture vertical farming grow systems. Sananbio empowers growers with the technology and knowledge to achieve unprecedented results in farming operations. To learn more visit: http://sananbious.com/.

Africa: Progressive Farming Developments For The Indoor and Vertical Farming Industry

Urban Agri World 2019 will be taking place in 6 weeks! Don’t miss this international industry event incorporating Vertical Farming, Greenhouses and Controlled Environment Agriculture.

Get your conference ticket now.

Registration details can be found at the link below:

http://www.magentaglobalevents.com/urban-agriculture-verticalfarming-cea-africa-summit/Registration

Featured Speakers of the Week:

5 Key Reasons to Attend UAW 2019

1. Updates on the various forms of Indoor Vertical farming as an innovative methodology for vertical cultivation of agricultural products, which can also realize true zero-mile city food supply.

2. Find out how Vertical farming and Urban Agriculture, when designed and implemented appropriately, could offer sustainable and innovative solutions for improving food security.

3. Get the latest updates on initiatives countries are taking to incorporate Urban Agriculture, Indoor and Vertical Farming as part of a Local, Regional and National Food System.

4. Find out how Urban Agriculture and its various forms are encouraging youth to take-up farming.

5. This year we will also explore Future Markets Opportunities Beyond Produce, with burgeoning interest in the production of medicinal plants in controlled environment farms following the new rulings on cannabis production for medicinal use in several African countries.

PLUS: Farm Visit to Dube AgriZone

Africa’s first integrated perishables supply chain and the most technologically-advanced

future farming platform on the continent. It is host to the largest climate-controlled,

glass-covered growing area in Africa.

Now into its third successful year, Urban Agri World is the region's leading agriculture event focused on Agritech, Controlled Environment Agriculture and Indoor Farming. It brings together Growers, Investors, Produce Buyers, Academics, Policy Makers, Technology & System Integrators and CEA Business Owners.

Featuring practical sessions on the hottest topics, exhibits, lunch table discussions and unlimited networking opportunities, it connects services and solution providers from all over the world to serious local buyers and partners.

About Urban Agri World (UAW 2019)

Many countries and companies are expressing strong interest in vertical farming business & urban agriculture. It is a solution to the weather and pests problems, food security, climate change and environmental preservation challenges. Commercialization of vertical farming is catching on in Asia, Europe, USA, Russia & now Africa. Many private companies are interested in growing crops in hydroponic, aquaponics & aeroponics systems in warehouses, greenhouses, containers & high skyscrapers.

There is also a burgeoning interest in the production of medicinal plants in vertical farms following the new rulings on cannabis production for medicinal use. UAW 2019 will touch on the pressing issues pertaining to progressive farming developments for the Indoor and vertical farming industry.

Join Us At UAW 2019 As We Deliberate On Emerging Technologies

To Unlock The Potential For Agriculture

BrightFarms Names New CEO To Lead Expansion

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors

(Credit: BrightFarms )

AUTHOR: Jennifer Sweeney

Aug. 15, 2019

Dive Brief:

BrightFarms has hired Steve Platt has as its new CEO, according to a company press release. Company founder Paul Lightfoot will stay on as the packaged salad brand's president. Both men will sit on the company's board of directors.

Platt has spent his career working with CPG companies, most recently as CEO of yogurt brand Icelandic Provisions. Before that, he led Danone brands including Dannon, Oikos and YoCrunch.

Platt said in a statement that this is an exciting time to join the company as continues to expand nationally, and Lightfoot acknowledged Platt's "know-how" as a leader of CPG brands and his ability to take BrightFarms to the next level.

Dive Insight:

BrightFarms, which currently operates greenhouses in Illinois, Ohio, Pennsylvania and Virginia, recently announced plans to open three additional farms in Massachusetts, New York and North Carolina next year. The additional greenhouses are expected to break ground at the end of this year, with production kicking off in early 2020. The expansion shows that the company is ready for aggressive, national growth, and along with that comes the need for a new CEO with expertise to help the company scale.

During his career with national brands, Platt has had particular success with helping brands grow quickly. According to BrightFarms' press release, Platt was at Icelandic Provisions he grew the company to more than 6,500 retail stores and turned it into "the fastest-growing brand in dairy yogurt."

Platt's hire follows two other notable additions this year, both of which position BrightFarms for ongoing growth. In February, Steve Campione joined the company as Chief Financial Officer. Campione brought a background in finance and investment banking and spent a decade raising capital for companies looking to expand. BrightFarms added Brian Jenny as vice president of sales in May, filling a key role to lead business development.

The company is expanding its retail partnerships in areas where its greenhouses operate. As of January, BrightFarms' produce is available at Jungle Jim’s International Marketplace in Ohio, select Food Lion stores in Virginia, Dierbergs in St. Louis and more than 140 Tops Friendly Markets in New York, Pennsylvania and Vermont. BrightFarms also works with Misfits Market, a delivery service that ships imperfect produce to subscribers in Pennsylvania, New Jersey and Delaware.

Demand for products from companies like BrightFarms continues to grow as Americans prioritize locally grown food. Indoor farming startup Square Roots has partnered with food distributor Gordon Food Service to provide produce to Gordon customers, and vertical farming company AeroFarms recently raised $100 million in funding for expansion.

Recommended Reading:

GROCERY DIVE BrightFarms plans three new greenhouses

GROCERY DIVE BrightFarms expands its retail footprint

Eco Convergence Group Announces Corporate Name Change To Kalera, Breaks Ground On Largest Indoor Vertical Farming Facility In The Southeast

Last year, the company opened the first of several planned hydroponics HyCube growing centers with the completion of a facility located on the premises of the Orlando World Center Marriott

GlobeNewswire August 20, 2019

ORLANDO, Fla., Aug. 20, 2019 (GLOBE NEWSWIRE) -- Eco Convergence Group, a leader in indoor vertical farming, announces its official name change to Kalera today. In addition, Kalera also announces that it has begun construction of a state-of-the-art indoor growing facility in Orlando, which will provide an abundance of healthy, tasty greens for the hospitality, grocery, and food service industries.

Last year, the company opened the first of several planned hydroponics HyCube growing centers with the completion of a facility located on the premises of the Orlando World Center Marriott. Kalera is now scaling operations to include a new growing facility, which will be the single largest indoor vertical farm of its kind in the Southeastern United States. Kalera will begin production at the new indoor farm sometime in Q4 of 2019 and is projected to grow over 5 million heads of lettuce annually.

“Our goal at Kalera is to harness plant and data science to deliver new economies of scale in agriculture, making it possible for more people to have access to high-quality, non-GMO, clean, nutritious food, locally grown without the use of pesticides—no matter the season,” said Cristian Toma, CEO of Kalera. “We have proven the technology and refined our production methods to a point where we are ready to scale up.”

Each plant grown in Kalera’s precisely controlled hydroponic facilities receives just the right amount of nutrients, filtered water and air, light, temperature, and humidity to achieve its dense, crisp, colorful, and delectable state. Kalera never uses any pesticides, insecticides, hormones, or GMOs. Unlike traditional farms, Kalera plants aren’t at risk for exposure to contaminants and pathogens in the soil, water, or air.

“Kalera produce is like none other—it’s not just delicious, it’s also clean and beautiful,” said Eric Martinez, Executive Chef, Orlando World Center Marriott Resort & Convention Center. “Having access to Kalera’s exceptional produce year-round opens up limitless possibilities to expand our menu and create new dishes that delight patrons. Many restaurants pride themselves on sourcing ingredients from farms 50 to 100 miles away. We are thrilled to say that we are sourcing our greens from 50 feet away."

Central to Kalera’s business is the idea of good science. The company is planting non-GMO seed, and has perfected over the past years plant and data science driven methods to optimize nutrient mixtures, light recipes, and environmental controls resulting in highly nutritious vegetables with consistent high quality year-round. Kalera is simply working with nature to give plants what they need to thrive, ensuring they reach their full growing and nutritive potential.

By using a closed loop irrigation system, Kalera’s plants grow while consuming 95% less water compared to field farming. Furthermore, the company utilizes cleanroom technology and processes to eliminate the use of chemicals and remove exposure to pathogens. With indoor facilities situated right where the demand is, Kalera is able to supply an abundance of produce locally, eliminating the need to travel long distances when shipping perishable products and ensuring the highest quality and freshness.

The new Orlando facility will deliver this high level of quality in abundance to the local market. The company plans for accelerated growth and will build additional facilities as production capacity is further expanded in the US and internationally.

About Kalera

Kalera is a technology-driven vertical farming company that excels in creating optimal conditions to grow delicious, nutritious, non-GMO produce that is free from pesticides and environmental pathogens. Kalera’s high-yield hydroponic production systems are automated, clean-room standard facilities. By utilizing unique methodologies that leverage plant and data technologies, Kalera creates optimal growing conditions for a variety of micro greens, year-round. The company is focused on reducing environmental impact and supplying produce to customers as close to the source as possible.

Elka Karl

Phone: 510-508-7328

Email: elka@dadascope.com

Meet Tigris, Our Largest Farm to Date

Plenty brought the farm indoors to create a better future for people and our planet. We need to triple the production of fruits and vegetables if we want to provide a healthy diet to everyone on the planet

August 2nd, 2019 By Plenty Farms

PLENTY - TIGRIS FARM

Plenty brought the farm indoors to create a better future for people and our planet. We need to triple the production of fruits and vegetables if we want to provide a healthy diet to everyone on the planet. This is an eye-opening statistic based on a Harvard study and data from the United Nations. Decades of research and development in outdoor farming have solved primarily for calories through yield gains while largely neglecting nutrients and flavor. This has led to the predominant global diet being low in nutrients and high in calories, driving the global pandemics of obesity and diabetes.

Farmers have relatively little control over the crops they grow. They select which seed, when to plant, and when to harvest. They can apply water, fertilizers, and chemicals to encourage growth and fend off pests. For crops to be profitable, they are typically chosen and grown to survive travel on trucks and for easy storage. Crops from different climates are shipped thousands of miles to customers. The end result is expensive, lower quality, and less delicious fruits and vegetables.

Plenty’s goal is to grow the best possible produce and to make it more accessible than ever before. We want to sustainably offer people the healthiest, happiest lives possible. Our new farm, code named Tigris, represents our largest and most ambitious leap forward. It demonstrates our ability to grow delicious produce using less than 5% of the water and less than 1% of the land compared to outdoor farms. By developing reliable, indoor, vertical farms that control everything our plants experience, we can reach people around the world with nutrient-rich fruits and vegetables that consumers will actually crave.

In order to change consumers expectations and to compete with flavorful processed foods, we grow the most delicious version of every crop that we sell. Can kale be decadent? Can mustard greens create the same binge response that we find in a bag of Doritos? Can we do this without genetic modification or pesticides? The short answer is a resounding yes. If you control the growing environment, you can find the world’s most delicious varieties and remove geography and seasonality as limitations.

Strawberries are more delicious in California because California is one of five Mediterranean climates in the world that has the ideal environment in which to grow produce. The Italian tomato isn’t the best because Italian farmers are magical, but because Italian tomatoes benefit from the most perfect tomato-growing environment in nature. Inside the walls of our indoor farms, Plenty is able to create the perfect environment for almost anyfruit or vegetable to create the perfect flavor. We can build local farms and replicate the ideal environment near any city in the world. By eliminating long-distance transportation, we can harvest and put these foods in consumer’s hands the same day.

Most importantly, Plenty can grow produce that people want to eat. The human brain evolved to associate flavor with nutrients. Many processed foods are engineered to have the flavors our brains crave, but lack the nutrients that our bodies need. The intense artificial flavors don’t actually satisfy our bodies and our cravings drive us to eat more calories than we need. There are many communities around the world where there is enough food, but without balanced nutrition the result is excess consumption that leads to obesity and related diseases. Plenty is reestablishing the connection between flavor and nutrients to put an end to this cycle.

Building a new form of agriculture at a scale that can impact people around the world while using fewer resources and delivering mind-blowing flavor and nutrition is incredibly difficult. At Plenty, we have assembled an amazing team of the world’s leading Plant Scientists, Flavor Experts, Hardware and Software Engineers, Growers, Operations experts, and people from many related fields. We have built dozens of farm prototypes to attack this challenge from every angle. We have grown hundreds of varieties of plants to find the highest yielding plants with flavors that will change expectations. Tigris isn’t just a story about robots or climate control or LED lights or hydroponics. It is the first instance of a new way of feeding people that can deliver on the promise of each of these individual technologies when every detail is optimized.

Inside Tigris is the technological opportunity to revolutionize human health. We give plants the perfect environment to be the best and most craveable versions of themselves, so that we can all be the best, most nourished versions of ourselves. I hope people enjoy the photos and videos of Tigris, but I really can’t wait for people to taste our amazing produce.

Nick Kalayjian

SVP of Engineering, Plenty

Superior Fresh Leading The Way In Aquaponics

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead

BY ADAM CAMPBELL | AUGUST 19, 2019

Nestled in the Coulee region of Wisconsin is one of the largest aquaponics facilities in the world. It sits on a 720-acre native restoration property and raises leafy greens as well as Atlantic salmon and Steelhead.

Superior Fresh, located in Hixton, WI, is taking sustainability to the next level. “The restoration property has been converted from conventional, monocrop agriculture into natural, native prairies and oak savannas,” said Nate Hefti, regional sales manager for Superior Fresh. “The fish-house and greenhouses are using state-of-the-art technology to efficiently raise fish and vegetables, giving us the opportunity to return the land back to its native state. All waste products from the facilities are composted onsite and used to enrich the poor soils that exist throughout the land.”

The water used to raise the salmon is cycled through to then fertilize the aquaponics facility, then cycled back again to the salmon tanks, meaning zero discharge of production water.

“By weight, for every one pound of salmon we produce we feed the fish 1.1 pounds of food. This equals nearly a one-to-one feed conversion ratio (FCR) but does not include the additional 10 pounds of produce we grow per one pound of fish food,” said Hefti. “Therefore, we have a FCR that is one-to-10, equaling one pound of fish food into the system and 10 pounds salmon and vegetables out.” For perspective, cattle has a food conversion ratio of approximately 10 to one, meaning every one pound of beef requires 10 pounds of cattle feed.

Currently the company is shipping up to 4,000 pounds of baby greens 1,000 pounds of head lettuce every day and is always looking at opportunities to expand into other markets to allow more people the opportunity to buy organic, safe, local fresh food. With nearly zero water discharge, the company believes facilities could be located anywhere on the planet, making it a readily available and safe local food source.

New York City’s Largest Rooftop Farm Sprouts Up In Brooklyn

In addition to growing produce, which will go to restaurants and farmers markets, the new facility — operated by Brooklyn Grange — offers a “Swiss army knife” of benefits for the city, according to co-founder Anastasia Plakias

August 13, 2019 | Scott Enman

Brooklyn Grange's newest farm in Sunset Park is the largest of its kind in New York City. Photo courtesy of Brooklyn Grange

Tomatoes, carrots and cucumbers are only a few of the many fresh options now growing on New York City’s largest rooftop farm: a 140,000-square-foot facility in Sunset Park.

In addition to growing produce, which will go to restaurants and farmers markets, the new facility — operated by Brooklyn Grange — offers a “Swiss army knife” of benefits for the city, according to co-founder Anastasia Plakias.

Environmentally, rooftop farms can cut energy costs, decrease combined-sewer-overflow, reduce urban heat island effect, create a habitat for wildlife, absorb air pollutants and lessen noise pollution.

The farm’s close proximity to Green-Wood Cemetery will also give migratory and native birds a place to take refuge.

Plakias said that while it’s difficult to stop New York from expanding upwards, residents could help the city grow in a different type of way.

“It’s impossible to ignore the piece of development in this city,” she told the Brooklyn Eagle. “Development will never cease in New York City. There will always be change happening, but we have an opportunity to influence the direction and shape that that change takes. Now is a really critical time for New York City to be a leader.”

The space at 850 Third Ave. is the company’s third farm. The first opened in 2010 in Long Island City, and the second came to the Brooklyn Navy Yard in 2012.

A paver system is installed at the Brooklyn Grange’s Sunset Park farm. Photo courtesy of Brooklyn Grange

The Sunset Park green roof acts like a giant sponge, managing roughly 175,000 gallons of storm water in a single rainfall — helping to reduce the amount of CSO entering New York’s waterways.

(The Brooklyn Navy Yard facility, in comparison, can manage about 100,000 gallons of water per storm.)

Because of its ability to reduce CSO, the roof was partially paid for by the Department of Environmental Protection’s Green Infrastructure Grant Program.

The new space, located adjacent to the Metropolitan Detention Center and overlooking the Sims Municipal Recycling, will also host weddings and other special occasions.

An event space and kitchen are currently under construction, and co-founder Ben Flanner said the farm would ideally host parties in the future using fresh herbs to garnish drinks.

Plants grow on the new farm. Photo by Ian C. Roberts

Borough President Eric Adams said that it was crucial for similar operations like Brooklyn Grange to open in low-income communities. “We don’t need fast food. We need farm food, and it’s right here in the heart of our city,” he said. “This is profitable to be able to grow food in an urban environment: Not only isolated in communities that are gentrified, but also in Brownsville, East New York and Bedford-Stuyvesant.

“There’s no reason we can’t have a Brooklyn Grange on the top of every NYCHA building so they can grow healthy food and live a healthy lifestyle. We can’t grow new land but we can better utilize our rooftops.”

The space, which officially opens on Sunday, will be open to the public every Sunday through October from 11 a.m. to 4 p.m.

Follow reporter Scott Enman on Twitter.

VIDEO: Can Vertical Farming Solve Asia’s Food Crisis?

The video takes an in-depth look at Sustenir agriculture, a vertical farm located in Singapore

Vice Asia released a new video on the vertical farming industry in Singapore. The video takes an in-depth look at Sustenir agriculture, a vertical farm located in Singapore. Only 1% of the land in Singapore is available for farming and as such growers need to look towards different solutions, like vertical farming, for food production.

You can watch the full video below.

Publication date: 8/12/2019

Six US States Sue EPA Over Pesticide

“A chlorpyrifos ban is long overdue given the overwhelming evidence that says this pesticide harms brain development in children,” Tracy Gregoire, a project coordinator at the Learning Disabilities Association of America, said in a statement

Health Concerns Not Addressed

Several states sued the Environmental Protection Agency (EPA) on Wednesday over the agency's decision to allow further use of a pesticide linked to brain damage. California, New York, Massachusetts, Washington, Maryland and Vermont argued in court documents that chlorpyrifos, a common pesticide, should be banned due to the dangers associated with it.

Earthjustice filed a similar lawsuit in the 9th Circuit Court of Appeals on behalf of groups advocating for environmentalists, farmworkers and people with learning disabilities.

“A chlorpyrifos ban is long overdue given the overwhelming evidence that says this pesticide harms brain development in children,” Tracy Gregoire, a project coordinator at the Learning Disabilities Association of America, said in a statement. “We are hopeful the courts will side with children who are now being exposed to irreparable, yet preventable harm.”

Chlorpyrifos, known on the market as Lorsban, is used on a wide variety of crops, including corn and cranberries. Farmers have called it the last line of defense against certain insects. But it has also been linked to learning and memory issues and prolonged nerve and muscle stimulation.

The EPA banned chlorpyrifos for household use in 2001 over concerns it would cause brain damage in children. EPA’s decision to allow continued use of chlorpyrifos came last month, the result of a court-ordered deadline to regulate the pesticide prompted by a lawsuit previously filed by Earthjustice.

EPA would not comment on the lawsuit but said those challenging the use of chlorpyrifos did not have enough data to demonstrate the product is not safe. The EPA said it would continue to review the safety of chlorpyrifos through 2022.

A month after former EPA Administrator Scott Pruitt began leading the department, the agency rejected an Obama-era recommendation from agency scientists to ban the pesticide. In the absence of EPA action, some states have moved to regulate chlorpyrifos on their own. Hawaii last year banned its use, and California and New York are considering a similar move.

Source: thehill.com

Publication date: 8/8/2019