Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

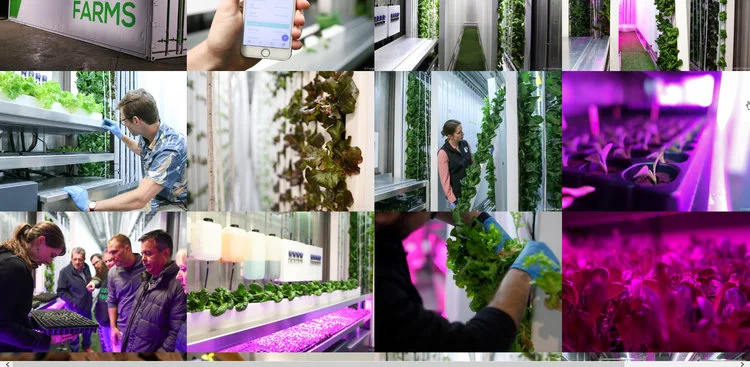

Is Indoor Farming The Answer to Agri-Woes? 80 Acres Farms Thinks So

Entrepreneurs and 80 Acres Farms co-founders Tisha Livingston and Mike Zelkind started their indoor farming journey after extensive work with food executives and farmers alike, hearing their struggles to produce quality food

By Mark Payne

June 20, 2019

Entrepreneurs and 80 Acres Farms co-founders Tisha Livingston and Mike Zelkind started their indoor farming journey after extensive work with food executives and farmers alike, hearing their struggles to produce quality food.

“There is a much better way to farm today, a much more effective way,” Zelkind said.

As you may have guessed, the duo believes indoor farming is the answer, solving issues related to the health of crops and the freshness of delivered food.

A tomato row. Courtesy Photo 80 Acres Farms.

“Our whole business model is that we will grow and harvest and deliver within a day to the region we’re in,” said 80 Acres Vice President of Marketing Rebecca Haders.

It works like this: 80 Acres grows most of its food hydroponically indoors, with “100 percent traceability from seed to package.” The company also eschews pesticides and controls the lighting where certain types of food are grown; with this much control, they can adjust the richness of the flavor of the produce.

Once a vegetable or fruit is ready to be harvested, it is delivered directly to one of the handful of grocery stores they work within the region, such as Whole Foods, Dorothy Lane Market and Jungle Jim’s International Market.

Hamilton vine. Courtesy Photo 80 Acres Farms.

Eliminating food miles is another goal of Zelkind and Livingston, who explained that when produce is hauled from Mexico or Canada or California, it effects the quality of the item.

“The only way to do [get produce to its destination] before it turns to mush is to pick before it’s ripe,” Zelkind said, resulting in food that’s missing critical nutrients and taste elements.

80 Acres work is not only trying to benefit the fruit and vegetables it grows, but also the environment. In fact, its farms utilize 97 percent less water than others, as well as renewable energy, in its work.

Basil grows under pink lights. Courtesy Photo 80 Acres Farms.

These results have resonated with investors, with 80 Acres announcing in January that it had received a $40 million investment from California-based private equity firm Virgo. The team will use the funds to build two farms in Hamilton in an effort to grow their operations in the region, ultimately creating what will be the first fully automated farms in the country.

Courtesy Photo 80 Acres Farms.

Canadian Aquaponics - Canada's Source For Aquaponic Information and News

Most aquaponic systems are single loop and fully recirculating. This means that the fish and plants exist in a single loop and share the same nutrient rich water

A place to learn and stay current with what's happening in the world of Aquaponics

TUESDAY, 18 JUNE 2019

Decoupled Aquaponics

Why Decoupled Aquaponics

Most aquaponic systems are single loop and fully recirculating. This means that the fish and plants exist in a single loop and share the same nutrient rich water. The reason these are the most popular is because they are simple to build and operate. But single loop systems are also a compromise because the plants, fish and bacteria must all be happy in the same solution. So for example, the temperature and pH levels must be maintained at levels that satisfy all the organisms, rather than being optimized for each.

pH is maintained in a range to satisfy fish, plants and bacteria in a single loop system

In a dual loop system, these parameters can be maintained optimally at different levels in each loop. Additionally, if something goes wrong, there are more options to address the situation without affecting everything in the system. So for example, if pests need to be treated on the plant side, it can be done without adversely affecting the fish.

How Decoupled Systems Work

A typical decoupled system consists of a stand-alone RAS (recirculating aquaculture system) loop and a hydroponic plant loop. The sludge from the RAS system is digested in the biological waste system which provides the nutrients for the hydroponic system. Using a digester makes the system more efficient because the nutrients plants need (aside from Nitrogen) are trapped in the solid waste. The aerobic digester (a fancy term for a simple tank with air-stones in it) mineralizes the solid waste, releasing the nutrients the plants need.

A Simple Decoupled System

A small decoupled system can be very easy to build and operate. If an AST bead filter is used, the fish loop is reduced to two components (fish tank and bead filter) because bead filter combines both bio-filtration and very efficient mechanical filtration. It also makes the system very easy to maintain and operate because it is self-cleaning. The following video shows simple the decoupled system can be with an AST bead filter.

The Heart of the System: AST Polygeyser Bead Filter

Although the video above shows a smaller endurance filter, the AST Polygeyser 3 cubic foot automatic backwash bead filter can be used to build a similar system that supports up to 60 m2 of plant area (900 gallon fish tank with up to 4.5 pounds of feed per day input).

Posted by JustAquaponics.ca at 20:28 Email ThisBlogThis!Share to TwitterShare to FacebookShare to Pinterest

Labels: Best Practices, Decoupled Aquaponics, Education, Mineralization, Reference

US (FL): Aeroponic Tower Gardens Introduced to Student Learning Experience

By using aeroponic Tower Gardens created by LA Urban Farms, Gator Dining Services is exploring how to do food production in or around the dining halls

Urban agriculture can provide healthy, local food in more populated areas through home vegetable gardens, farmer’s markets, backyard poultry, and other production methods. This growing trend has extended to the University of Florida’s Gator Dining Services in a partnership with the Field & Fork Campus Food Program.

By using aeroponic Tower Gardens created by LA Urban Farms, Gator Dining Services is exploring how to do food production in or around the dining halls. The vertical towers pump water through the center to bathe plant roots as plants grow in small pots. The design is meant to be space, energy and water efficient. The towers were donated by LA Urban Farms, a Gator-owned business, to the Field & Fork Farm and Gardens for a class in the UF/IFAS College of Agricultural and Life Sciences (CALS) in spring 2018.

CALS student Garrett Noonan with the Field & Fork aeroponic tower at Gator Dining Services. (Tyler Jones, UF/IFAS)

“It’s using the campus as a living laboratory and collaborating with UF and industry partners,” said Anna Prizzia, director of Field & Fork. “We’re meeting an educational need while exploring the potential of a long-term project.”

Gator Dining Services visitors can see the aeroponic Tower Gardens now. Four towers are installed at the following locations: one at Fresh Food Company (near Broward Hall), one at Gator Corner Dining Center (near North Hall) and two at the Otis Hawkins Center near Pugh Hall. The herbs and leafy greens will be donated to the Alan and Cathy Hitchcock Field & Fork Pantry.

“Since this is a new project, we plan on seeing how the summer goes before making future plans,” said Kayla Caselli-Bido, sustainability manager for Gator Dining Services. “Growing food in the aeroponic towers exemplifies Gator Dining Services’ responsible sourcing and waste minimization pillars as part of our Green Thread sustainability platform.”

Before graduating in 2018 from CALS as an animal sciences major, Caselli-Bido interned with Field & Fork for a year and a half. Growing up in the suburbs of Miami, Florida, Caselli-Bido said her hands-on experience with agriculture came from the Field & Fork Campus Food Program. In addition to her internship, she took an Urban Agriculture and Food Systems experiential learning course based at the Field & Fork Farm and Gardens. These opportunities positioned her well for her current role at Gator Dining Services.

“Without Field & Fork, I would not have found my passion for agriculture and sustainability,” Caselli-Bido said.

The aeroponic towers project has provided an additional internship experience for a CALS student. Garrett Noonan, a senior plant science major, came to UF after serving 13 years in the U.S. Army.

“In my experiences in all the countries I visited, I saw how food security was used as a political weapon,” Noonan said. “This had a profound effect on me as a soldier. What I saw first-hand pushed me to choose this career path in sustainable crop production.”

As an intern with Field & Fork and Gator Dining Services, Noonan conducts basic maintenance on the aeroponic towers. His tasks include measuring the growth rate of plants, refilling the tower with water, checking for insects and collecting data to help Gator Dining Services assess the long-term viability of the towers.

“I’m most excited for the future that this project could bring as far as fundamentally changing the way we grow food,” Noonan said. “These kinds of innovations can change the landscape of agriculture.”

Bowery Farming: Expanding Assortment Outside Lettuce and Leafy Greens

It is one of the favourite topics for critics of indoor farming: how will you feed the world with lettuce? The team with Bowery Farming doesn’t see it as its primarily goal to feed all of the world, but is expanding its produce assortment anyhow

"Just Because It's Possible To Grow A Crop Indoors

Doesn't Mean You Should Do it"

It is one of the favourite topics for critics of indoor farming: how will you feed the world with lettuce? The team with Bowery Farming doesn’t see it as its primarily goal to feed all of the world, but is expanding its produce assortment anyhow. Yesterday at the Indoor AgTech in New York, Bowery Farming Founder & CEO Irving Fain explained how the company is trying out new products like radishes, turnips and kohlrabi, all grown in their own controlled environment. “We’re still excited and see many more opportunities for the leafy greens and herbs market, but have aspirations outside this area as well.”

Irving Fain & Tom Colicchio at Indoor AgTech

Flavor

At the Indoor AgTech Innovation Summit, the role and future of indoor farming is discussed. While there are many challenges, in the talk with Irving Fain and Tom Colicchio, chef and founder of Crafted Hospitality, it became clear that there are new opportunities for indoor farms through partnerships. Tom explained how years ago he would have dismissed any food grown hydroponically, as he believed it not to be any good or tasteful at all - but had his view changed after learning about the flavors that can be achieved with indoor farming, based on the crop recipe.

Tom Colicchio and Bowery recently hosted an event with a group of chefs to try out the new vegetables grown by Bowery: radishes, turnips and kohlrabi. “The texture of the products is what shocked most,” Tom says, explaining how indoor grown products open up new opportunities for chefs. “You’re not just working with lettuce any more, you’re working with an ingredient of flavor that can play a role in your dish. What kind of flavor do you want and how do you use it? We’re having to train chefs on this.”

Scaling up

Bowery Farming opened up their first farm in 2017 in New York, and recently announced a $95 million Series B funding round last year, totaling $122.5M raised to-date. They developed their own software system, BoweryOS, and plans to use their capital to scale their operation in new cities, Irving explained. Also product differentiation is on the agenda, which Irving shared this week. “We expect to look back on this time, when it will seem obvious that indoor agriculture takes care of an enormous part of produce found in the grocery store. Right now, a lot of crops beyond leafy greens are grown outdoors, but the future is to look much more indoors when it comes to produce as another option.”

Economically viable model

High in flavor, grown in a responsible way and answering climate change are some of the arguments called out for this. That said, Irving emphasizes that the focus is still on having an economical model. “There are many crops that you can grow indoors that will not be economical. Pineapples for example - we will not be your source for that,” he laughs. “Well, maybe someday - but just that it is possible to grow a crop indoors doesn’t mean you should do it. In the end it is an economic business case.”

That’s also his answer to critics saying indoor farms grow only high-end products and leafy greens and need to make their business more broad to remain viable. “It’s easy to forget how innovation goes. Look back at the start of the companies that we take for granted nowadays. Following Amazon, cashier-less grocery stores are popping up all over the city right now, but in 1994 Amazon was just a place selling books on something called the internet. Journeys don’t unfold in a couple of years - and the same thing goes for our industry. We believe there are many more opportunities outside leafy greens and even though we are still excited and see many opportunities for herbs and leafy greens, we also have aspirations outside this area. We see many other crops - fruiting crops, vine crops - flourishing in our environment. We want to move there quickly but also want to move in the right way.”

For more information:

Bowery Farming

boweryfarming.com

contact@boweryfarming.com

Publication date: 6/21/2019

Author: Arlette Sijmonsma

© HortiDaily.com

Balance Grille Founders Building Aquaponics Farm In Downtown Toledo

A simplified supply chain, lower food prices and increased quality control are are just three benefits expected from a daring venture by the founders of Toledo-based Balance Pan-Asian Grille

March 9, 2018 | by S.A. Whitehead

A simplified supply chain, lower food prices and increased quality control are are just three benefits expected from a daring venture by the founders of Toledo-based Balance Pan-Asian Grille. Prakash Karamchandani and HoChan Jang are building an 8,600-square-foot aquaponics farm in the middle of downtown Toledo, Ohio, next to the chain's newest location opening this month on Summit Street.

Kale and rainbow swiss chard in the R&D facility's deep water channel setup being used at Toledo aquaponics farm, which is controlled environment agriculture, using no pesticides, allowing immediate consumption of produce. Photo by Jeff Kamp of Plur Films.

Aquaponics is an efficient system of farming that uses fish to cultivate plants, which, in turn, helps purify the water.

And even though it's innovative and very "green," plunking down one of these farms in the middle of the Rust Belt city's downtown may not seem like the choice location for such an operation,

Karamchandani said, for Balance Grille, it's just about perfect.

"Our customers know not just where our ingredients are sourced, they can visit the facility and view the production happen," he said in an interview with QSRWeb, referring to the farm's location adjacent the brand's newest restaurant. "Our brand is gaining visibility in multiple channels, including grocery stores and our brand is differentiated."

The venture has taken about two years, a lot of creative thinking and cutting through miles of red tape with both the property owners and the city of Toledo, but if things work out as planned, the farm promises big payoffs.

"We will be able to offer local organic produce year-round in Ohio's climate," Karamchandani said. "We are connected deeper in our community with new relationships, including with children's science and learning museum, Imagination Station, which will be organizing educational tours for school children and adults."

It may sound like a lofty goal for the four-unit chain, but these restaurateurs like to embrace innovation. Last year, for example, they instituted a "managerless" form of restaurant operation, so this kind of project is right in line with the way these two University of Toledo graduates think.

Of course, QSRweb wanted to know more, so check out our recent interview with Karamchandani.

Q: Local sourcing is a huge demand now from restaurant brands and this certainly is right in line with that. Why was that important enough to your brand to go to the somewhat extreme lengths of operating your own aquaponics facility?

A: I realize "local" has been a buzzword in our industry for several years now, and it's almost becoming cliché. [But] going back to our roots, as restaurateurs, we want to nourish our neighbors/community. From a nutrition perspective, the faster we can get product from the field to the store, the better overall quality we offer to our customers.

From an economic perspective, we're keeping the dollars within our community. From a culinary perspective, we have a direct connection to producers allowing for some really unique opportunities compared to standard "big box" distributors.

Q: When and why did you decide to go for an aquaponics facility?

A: We decided to continue vertical integration in late 2015. We had an existing dry-stock warehouse and distribution servicing our three area restaurants. We added cold refrigerated storage and delivery capability and found we could help a few small producers with their local delivery route.

One of our producers specialized in microgreens and we connected with the aquaponics method of food production, the balanced relationship between fish and plants. Over approximately a year, we began to play with a couple of R&D prototype systems to try and grow a variety of ingredients outside of the microgreens we use on our menu.

Space in the farm was limited (an old warehouse, under 1,700 square feet), so we were unable to move beyond the testing phase. But, we were hooked. In 2017, we purchased the farming operation, formed an operating partnership, and began to develop plans for a production-level facility.

Q: Why downtown Toledo and where are you in the development process?

A: We located the new farm next to our flagship Downtown Toledo Ohio location opening Q1 2018. Its footprint is 8600 square feet, and located in the first-floor retail area of a historic parking garage in the heart of the commercial district. As of the end of February 2018, our space is in the demolition phase of construction while we complete permit approval with the City of Toledo.

Q: So how does this work and what will be grown there?

A: The grow facility will be comprised of the plant grow space, a small tank room/workshop and an office. The plant grow space will be comprised of 15-by-36-foot rack systems, each three to four tiers tall, depending on ceiling height.

Each tier will house specific grow systems with LED grow-spectrum lighting. Racks will be specialized in deep-water channel, dutch-bucket style, and thin-film channel type grow systems. We will be able to section off areas to adjust temperature and humidity, so racks can be grouped and specialized for a specific crop.

Our crops will include leafy greens, micro greens, living and harvest herbs and certain fruiting vegetables (primarily peppers and tomatoes), although we can theoretically produce nearly any crop that grows above ground. We will also have 4-by-600g tanks used to raise tilapia fish, which will be sold live for pond/lake stocking or algae control, not for consumption. In the future, we hope to add freshwater prawn/shrimp propagation to the system.

"Our customers know not just where our ingredients are sourced, they can visit the facility and view the production happen. ... We are connected deeper in our community with new relationships, including with children's science and learning museum, Imagination Station, which will be organizing educational tours for school children and adults."

Q: Operationally, how much will the farm cost to run and how is that being incorporated into your expenses and balance sheet?

A: We have modeled the operating overhead, labor, and debt service into our crop sales internally to our own restaurants, which account for 70 percent of the facility's initial production capacity. Fully burdened, we are conservatively anticipating a 10 percent reduction in ingredient cost from the restaurant's perspective. The remaining 30-plus percent of production capacity will primarily generate profit for the company.

Q: Why aquaponics as opposed to other types of agriculture?

A: Aquaponics, like hydroponics, allows for year-round growth and consistent crop harvest, perfect for restaurant supply purposes. [Likewise], hydroponics often uses chemical fertilizer and has a high water waste ratio. This combination's runoff would add to an existing algae problem in our area of Lake Erie, similar to traditional field or hoop-house type agriculture.

Aquaponics is differentiated because it is inherently organic: Feed the fish, and allow the plants to act as the water's filter. On an ongoing basis, regarding water waste we are only adding water to offset the system's natural evaporation, a few gallons per day.

Q: Where have you turned for expert input on this operation and making it work business-wise?

A: Our operating partner is obviously a great resource. But our area has a rich agricultural heritage, and we have community resources like the Center for Innovative Food Technology and Agricultural Incubator, less than 30 minutes away. We have also visited multiple commercial aquaponics facilities in the Midwest to learn from their experiences and acquire best practices.

Q: Are you aware of other restaurant brands globally using an aquaponics farm for sourcing?

A: As of this interview, we are unaware of any restaurant brands vertically integrated to the degree we are. Generally, we don't make it a practice to watch other restaurant brands. Our goal has always been to focus on our own cultural values. If we are missing out on a similar effort, we'd love to connect and share insights!

Q: Where do you see this going in the future and how will you measure for success?

A: If Balance Farms continues to be a successful part of our brand, we plan to add an aquaponics facility to each metro area we grow to. We will be watching basic financial and operational metrics, including profit margin, the effect on our restaurant's P&L and volume of product produced.

Our only advice (to others in the business) is to follow your passion where it leads you.

Topics: Sustainability

Award-winning veteran print and broadcast journalist, Shelly Whitehead, has spent most of the last 30 years reporting for TV and newspapers, including the former Kentucky and Cincinnati Post and a number of network news affiliates nationally. She brings her cumulative experience as a multimedia storyteller and video producer to the web-based pages of Pizzamarketplace.com and QSRweb.com after a lifelong “love affair” with reporting the stories behind the businesses that make our world go ‘round. Ms. Whitehead is driven to find and share news of the many professional passions people take to work with them every day in the pizza and quick-service restaurant industry. She is particularly interested in the growing role of sustainable agriculture and nutrition in food service worldwide and is always ready to move on great story ideas and news tips.

Career Opportunity: Head Hydroponics Grower - Grand Rapids, Michigan

Career Opportunity: Head Hydroponics Grower

Company: Mac & Fulton Talent Partners

Location: Grand Rapids, MI

Career Opportunity:

M&F Talent has a client in CEA crop production that is looking to onboard a new Head Grower. The position will focus on the commercial production of leafy greens and herbs in hydroponics systems. Our client is passionate about sustainable development as well as the creation of more nutritious food sources Moreover, they are on the cutting-edge of greenhouse cultivation techniques and have plans for exponential growth in the coming years.

Company Bio:

Mac & Fulton Talent Partners is the most knowledgeable and attentive recruiting agency in cannabis, hydroponics, and horticulture. As such, our business aligns itself with those individuals passionate about pushing the industry forward with skill, knowledge, and integrity.

M&F Talent approaches each of our business relationships with a partnership mentality based on trust and transparency. Looking to the future, we will continue to push for progression in the industry by setting high standards of follow-through and timeliness. With both clients and candidates, this level of excellence will help lay a solid foundation for growth and progress.

Our client is looking for a passionate and dedicated Head Grower to compliment their already growing team. This key position is responsible for all growing operations including water chemistry, food safety, biologicals, and growth strategies.

Contact & Info:

If you, or someone you may know, would like to learn about these exciting job opportunities in more detail, please follow this link:

Head Hydroponics Grower: https://mandfconsultants.com/jobs/head-grower-hydro-produce-michigan/.

To learn more about Mac & Fulton Talent Partners, please visit their website at www.mandfconsultants.com or contact them at info@mandfconsultants.com.

The Steep Climb of Vertical Farms And Where Urban Ag Might Be Revolutionary

Square Roots is an urban farming accelerator — empowering 1,000’s of millennials to join the real food revolution. Our goal is to enable a whole new generation of real food entrepreneurs, ready to build thriving, responsible businesses. The opportunities in front of them will be endless

By Marc Brazeau | June 13th 2019

A few years back in an essay titled: “Why I’m empowering 1,000’s of millennials to become #realfood entrepreneurs through Vertical Farming”, Elon Musk’s younger brother Kimball announced that he was going to invest in urban farm incubators in multiple cities. While there is certainly room for vertical farms in urban food systems to supply hydroponic greens and herbs to upscale grocers and restaurants, Musk’s ambitions go far beyond that.

The Kitchen’s mission is to strengthen communities by bringing local, real food to everyone. With our commitment to local food sourcing, our restaurants have become major catalysts for local food economies — across Colorado, Chicago, and now Memphis — serving real food to over 1 million guests a year. Meanwhile, our non-profit The Kitchen Community has built 300 Learning Gardens across the country — inspiring 150,000 kids each day as we get them outdoors and teach them about real food.

But the impact of those initiatives are a drop in the ocean compared to what’s needed. By 2050, 9 billion people will live on our planet, and 70% of them will live in cities. These people need food. And the data is clear: they will want local, real food.

The industrial food system will not solve this problem (more Deep Fried Twinkies, anyone?). Instead, finding the right solution presents an extraordinary opportunity for new entrepreneurs. As I’ve said before, “Food is the new internet.” I know the next generation is excited to join the #realfood revolution, and shape the future.

That’s why I’m thrilled to introduce a new company in The Kitchen’s family: Square Roots.

Introducing Square Roots

Square Roots is an urban farming accelerator — empowering 1,000’s of millennials to join the real food revolution. Our goal is to enable a whole new generation of real food entrepreneurs, ready to build thriving, responsible businesses. The opportunities in front of them will be endless.

Square Roots creates campuses of climate-controlled, indoor, hydroponic vertical farms, right in the hearts of our biggest cities. On these campuses, we train young entrepreneurs to grow non-GMO, fresh, tasty, real food all year round, and sell locally. And we coach them to create forward-thinking companies that — like The Kitchen — strengthen communities by bringing local, real food to everyone.

The real and imagined impacts and potential of vertical farms had very much been on my mind. Just the week before, a friend on Facebook shared a story on the amazing ecological efficiencies of a new vertical farm and asked “Is this stuff real or is it just hype?”

The article asked “Considering it uses 95% less water than regular farms, could vertical farming be the future of agriculture?” and told the story of a vertical farm in Newark, NJ in an old laser tag facility. At AeroFarms in Newark, New Jersey, crops are stacked more than 30 feet high in a 30,000 square foot space that was formerly a laser tag arena. They use aeroponic technology, which involves misting the roots of the plants, using an astonishing 95% less water than more conventional farming methods. David Rosenberg, CEO of AeroFarms told Seeker, “Typically, in indoor growing, the roots sit in water, and one tries to oxygenate the water.

Our key inventor realized that if we mist nutrition to the root structure, then the roots have a better oxygenation.” AeroFarms doesn’t use any pesticides or herbicides either. The plants are grown in a reusable cloth made from recycled plastic, so no soil is needed to grow them. They also use a system of specialized LED lighting instead of natural sunlight, reducing their energy footprint even further. “A lot of people say ‘Sunless? Wait. Plants need sun.’ In fact the plants don’t need yellow spectrum. So we’re able to reduce our energy footprint by doing things like reducing certain types of spectrum,” Rosenberg said. IT’S ALWAYS SALAD GREENS I would say that it’s mostly hype, certainly not revolutionary.

These projects always center on salad greens and herbs, crops that sell at a premium, and deliver very few calories, but a lot of water. Crops require light, water and a growing medium – three things in abundance at low prices on rural farms in the form of sun, rain, and soil. The economics of paying for light and rain, plus the economics of real estate are such that these projects cannot pencil out for any crops other than high end greens and vegetables. There is a reason why so much of the innovation in hydroponic growing systems came out of marijuana production.

The ROI per square foot is far greater than for oats. The future of urban farming is in crickets and other insects, mushrooms and other fungi, algaes and yeasts, and in vitro meat. If you want to go beyond premium salad greens and herbs, you need to focus crops or herds that don’t require lots of space, water or sunlight. More importantly, if you really want to lower the impact of food production, urban farming needs be able to close nutrient cycles in dramatic ways. The exception might be in cities like Detroit, where a collapsing urban footprint changes the economics of the real estate.

As a city economy grows, agglomeration increases the productivity per square foot, driving up rents which leads to the necessity of greater productivity per square foot. If urban farming catches on, it requires more square feet, driving up rents, requiring greater productivity per square foot, driving up the required productivity per square foot driving up the price required to be charged per square foot of product. TLDR: this model cannot work for barley, oats, canola, cowpeas, black beans, soybeans, pinto beans or any other serious sources of calories or protein in an urban setting. The revolution is not going to be powered by expensive salad greens. Tamar Haspel helpfully chimed into that discussion to share an article she did for the Washington Post on the ledger of environmental challenges and benefit of vertical farming. In terms of growing lettuce greens she tallied the use of less land, less water, less fertilizer and less pesticides as four environmental benefits of vertical farming.

On the down side, she pointed out that one of the biggest trade off was foregoing solar power for electricity. However, unless the vertical farm is powered by nuclear or renewables or both there is one big sticking point: But before you shell out for the microgreens, there are a couple of disadvantages. The first is that you’ll have to shell out a lot, and the second gets at the heart of the inevitable trade-off between planet and people: the carbon footprint. If you farm the old-fashioned way, you take advantage of a reliable, eternal, gloriously free source of energy: the sun. Take your plants inside, and you have to provide that energy yourself. In the world of agriculture, there are opinions about every kind of system for growing every kind of crop, so it’s refreshing that the pivotal issue of vertical farming — energy use — boils down to something more reliable: math.

There’s no getting around the fact that plants need a certain minimum amount of light. In vertical farms, that light generally is provided efficiently, but, even so, replacing the sun is an energy-intensive business. Louis Albright, director of Cornell University’s Controlled Environment Agriculture program, has run the numbers: Each kilogram of indoor lettuce has a climate cost of four kilograms of carbon dioxide. And that’s just for the lighting. Indoor farms often need humidity control, ventilation, heating, cooling or all of the above. … Let’s compare that with field-grown lettuce. Climate cost varies according to conditions, but the estimates I found indicate that indoor lettuce production has a carbon footprint some 7 to 20 times greater than that of outdoor lettuce production. Indoor lettuce is a carbon Sasquatch.

She goes on to explain that with more efficient lighting systems and access to nuclear and renewable energy sources, vertically grown lettuce can close a big part of that gap, but it’s still a steep climb. Before moving on to the reasons why I’m enthusiastic about farming crickets and other insects, mushrooms and other fungi, algaes and yeasts in urban settings, I want to circle back to the economics of real estate that serves as the stake through the heart of mass scale vertical farming of traditional crops.

A LITTLE PERSPECTIVE ON SCALE

First let’s put some things in perspective about scale. One of the larger well known urban rooftop farm in New York City is 42,000 square feet. 42,000 square feet sounds like a lot of square feet. But retail and office space is measured in square feet.

Farms are measured in acres and 42,000 square feet is pretty much one acre. 0.964187 acres to be exact. New York state has 7 Million acres of farm land across 36,000 farms. That’s just the state of New York, which isn’t a particularly rural state. Urban real estate is denominated in square feet. Farms are denominated in acres. Field corn (not grown for ethanol) accounts for some for over 50 million acres of farm land. Wheat, another 50 million acres. That’s 100 million acres just in two major grains. But lets put that aside. Nobody thinks were are going to grow corn and wheat in urban vertical farms, I just think it’s important to start with a baseline of the scale of the footprint of where most of our calories come from. And if you think we should be getting less of our calories from corn and wheat – and I’d agree with you – just keep in mind that no other crops come close on calories per acre, so any shift away from corn and wheat is going to drive that 100 million number upwards.

Let’s look at the crops that make up the core calories of a healthy diet. Barley accounts for 3.2 million acres. Lentils, dried beans and peas 2.7 million acres. Rice – 2.6 million acres. Vegetables – 4.1 million acres and half of that is potatoes, sweet corn and tomatoes. Orchards and berries – 5.4 million. 18 million acres total or 756 Billion square feet.

Let’s grant these vertical farms the wildly ambitious ability to increase yield by a third and say that shifting 10% of production into vertical farms would be a substantial impact. That would require 50 Billion square feet of urban real estate. (This is what tomato harvest looks like at a consequential scale. 75% of tomatoes are used for processed products, salsa, sauces, soups, etc. If you really want to impact the food system you need to be thinking about production on this scale. That’s a lot of square feet of real estate in any city.)

ECONOMIES OF AGGLOMERATION

Now let’s back up to the point we made about real estate prices and productivity. As cities grow bigger and denser productivity rises. Similar firms cluster and generate a base of workers who circulate among them increasing knowledge and competence. Travel times are lower, so a delivery van can make more stops per hour in a city than in a suburb or rural community. With more customers in there base, firms can grow larger and take advantages of economies of scale.

This is what is called agglomeration in economics. Agglomeration makes for productive, vibrant cities, but it also drives up rents. Which further puts pressure on firms to increase the productivity out of each square foot of real estate that they own or lease. To increase productivity per square foot firms can either produce more units or charge more per unit. This is why expensive herbs and greens are the only products that currently make sense in vertical farms. Now imagine what it would mean to add demand for another 50 billion square feet of real estate to US cities. Scaling up the operations of vertical farms would COMPOUND the pressure to produce crops that they can sell at high prices.

While proponents often claim that as more vertical farms come on line, prices will come down, for most crops the economics of cities tell us that the opposite is true. So the economics of urban real estate are stacked against vertical farms except in places like Detroit where the urban footprint in shrinking and there is massive slack in the real estate market. But the economics for vertical farms are even steeper when we take comparative advantage into account.

COMPARATIVE ADVANTAGE

Comparative advantage is an economic concept that most people have heard of but very few understand and a vanishingly small number of people “get” on an intuitive level. That’s because it is one of the most counter-intuitive concepts in economics and I balk at the headache of even attempting to put it across when I think I’ve probably already made my case as to why I don’t expect vertical farms to catch on beyond expensive herbs and greens (and maybe some heirloom tomatoes and peppers). But it’s an important concept to understand in general and for the case I’d like to make for why I think the future of urban agriculture is in mushroom and cricket farming, black soldier flies, algaes and yeasts, and in vitro meat production.

The economist Paul Krugman once called comparative advantage “Ricardo’s Difficult Idea” in an essay in which he explains why a concept formalized in 1817 by the philospher and political economist David Ricardo remains so poorly understood, if not outright resisted, even by economic sophisticates. The idea of comparative advantage — with its implication that trade between two nations normally raises the real incomes of both — is, like evolution via natural selection, a concept that seems simple and compelling to those who understand it. Yet anyone who becomes involved in discussions of international trade beyond the narrow circle of academic economists quickly realizes that it must be, in some sense, a very difficult concept indeed.

I am not talking here about the problem of communicating the case for free trade to crudely anti-intellectual opponents, people who simply dislike the idea of ideas. The persistence of that sort of opposition, like the persistence of creationism, is a different sort of question, and requires a different sort of discussion. What I am concerned with here are the views of intellectuals, people who do value ideas, but somehow find this particular idea impossible to grasp.

My objective in this essay is to try to explain why intellectuals who are interested in economic issues so consistently balk at the concept of comparative advantage. Why do journalists who have a reputation as deep thinkers about world affairs begin squirming in their seats if you try to explain how trade can lead to mutually beneficial specialization? Why is it virtually impossible to get a discussion of comparative advantage, not only onto newspaper op-ed pages, but even into magazines that cheerfully publish long discussions of the work of Jacques Derrida? Why do policy wonks who will happily watch hundreds of hours of talking heads droning on about the global economy refuse to sit still for the ten minutes or so it takes to explain Ricardo?

Against that backdrop let me apply my meager talents to see if I can pound this into your thick skulls with any greater efficacy. Here goes.

Ricardo provided a simple two country model to show the math at work here. Consider two countries, England and Portugal, producing two identical products but at different rates of productivity.

WIKIPEDIA: In this illustration, England could commit 100 hours of labor to produce one unit of cloth, or produce 5/6ths units of wine. Meanwhile, in comparison, Portugal could commit 90 hours of labor to produce one unit of cloth, or produce 9/8ths units of wine. So, Portugal possesses an absolute advantage in producing cloth due to fewer labor hours, and England has a comparative advantage due to lower opportunity cost.

In the absence of trade, England requires 220 hours of work to both produce and consume one unit each of cloth and wine while Portugal requires 170 hours of work to produce and consume the same quantities.

England is more efficient at producing cloth than wine, and Portugal is more efficient at producing wine than cloth. So, if each country specializes in the good for which it has a comparative advantage, then the global production of both goods increases, for England can spend 220 labor hours to produce 2.2 units of cloth while Portugal can spend 170 hours to produce 2.125 units of wine. Moreover, if both countries specialize in the above manner and England trades a unit of its cloth for 5/6ths to 9/8ths units of Portugal’s wine, then both countries can consume at least a unit each of cloth and wine, with 0 to 0.2 units of cloth and 0 to 0.125 units of wine remaining in each respective country to be consumed or exported.

Consequently, both England and Portugal can consume more wine and cloth under free trade than in autarky.

To share an embarrassing story from my past, at the last union I worked for I had a boss who was a supremely talented union organizer and I was going through a personal rough patch and not firing on all cylinders, though I was still OK at my job. But he was constantly frustrated with me and just wanted to push me aside and do my job for me, because he could do my job better than I could. And he could – he was just much more talented at union organizing than I was, especially during that sad chapter of my life. But he didn’t because, not only was he much better at my job than I was, he was much, much better at HIS JOB than I was.

So it made more sense of him to concentrate on doing his job – supervising me and another ten organizers than to split his time doing his job and my job (and assigning me the minor parts of his job that he wouldn’t have time to do). In the neighborhood I grew up in, software engineers frequently paid thirteen year old kids to mow a lawn in an hour that they could mow in 45 minutes. But if they were going to put in one more hour of effort that week, it was better spent working as a highly paid software engineer, not out competing thirteen year old’s who mowed grass to buy grass.

So think of a simple economy composed of the city of Los Angeles and California’s Central Valley where both produce movies and tomatoes. Even if Los Angeles could produce tomatoes somewhat more efficiently than the Central Valley, the theory of comparative advantage tells us that they should still stick with movies and let Central Valley deal with tomatoes – they will both be better off. Likewise if we imagine an economy of New York City and Iowa, where they both produce business services and corn, even if NYC can do corn better than Iowa, they should stick with business services, where they are heavy weight champion. These are simple models and there are all sorts of situations and examples where comparative advantage doesn’t work in a clean, frictionless, straightforward way.

But any narrative which attempt to make the case that vertical farms are the next big thing in agriculture needs to deal with comparative advantage rather than sidestep, ignore or dismiss the issue. To beat this horse a bit closer to death, here is Krugman on trying to make a charitable interpretation of those who seem to be in denial about the power of comparative advantage: Surely, we have argued, the problem is one of different dialects or jargon, not sheer lack of comprehension. What these critics must be trying to do is draw attention to the ways in which comparative advantage may fail to work out in practice. After all, economists are familiar with a number of reasons why the gains from free trade may not work out quite as easily as in the simplest Ricardian model.

External economies may mean underinvestment in import-competing sectors; imperfect competition may lead to a strategic competition over industry rents; because of distortions in domestic labor markets, imports may reduce wages or cause unemployment; and so on. And even if national income rises as a result of trade, the distribution of income within a country may shift in a way that hurts large groups. In short, there are a number of sophisticated extensions to and qualifications of the model introduced in the first few chapters of the undergraduate textbook – typically covered later in the book. Which is to say that, standard economics is not ignorant of all the reasons you may come up with for trying to dismiss the implications of comparative advantages just because you can’t shake the idea that vertical farms are a neat idea and wouldn’t it be cool if cities were self-sufficient in food production.

We’ll look at some examples of where cities would have comparative advantage going forward in terms of local food production. I think these are areas where Kimball Musk’s 1000’s of millennials will ultimately find greater success. But first we need to look at the one big advantage an urban setting brings to agricultural production.

THE NUTRIENT CYCLE

When you grow a crop, the plant takes nutrients, most notably the old NPK – nitrogen, phosphorus and potassium out of the soil to feed and construct itself. When the crop is harvested a lot of those nutrients go with them and they need to be replaced in the soil. This creates a problem that is solved by planting nitrogen fixing legumes and adding fertilizers, either synthetic fertilizers or manures. But they have to come from somewhere – and that somewhere is generally somewhere not on the farm. Meanwhile, the nutrients have been shipped in our simple model economies from the Central Valley to Los Angeles and from Iowa to New York City.

The people eat the nutrients and then deposit the nutrients into the trash, compost bins or their toilet. This creates a waste management problem. Nitrogen management is a huge issue in agriculture, but the nutrient cycle problem that most keeps the deep thinkers up at night is phosphorus. It’s pretty easy and getting easier to pull nitrogen out of the air to fertilize crops. We have an effectively infinite supply of potassium. However, we are running out of phosphorus that we can mine. Eventually, and the sooner the better, we need to figure out how to close the nutrient loop that mostly ends when food reaches our cities. The modes of food production that close that loop will be the ones that make the greatest impact, both ecologically and economically. That’s why I think the future of urban agriculture will be in crickets and other insects, mushrooms and other fungi, algaes and yeasts, and in vitro meat.

CRICKETS:

Crickets grow to maturity in 3-4 weeks, so they do not take a lot of space to produce prodigous amounts of protein. Protein per acre is a threshold measure in food security.

Protein is ecologically expensive – carbs need carbon which is easily pulled from the air and converted into structure by photosynthesis – the nitrogen in the air is bound by very tight chemical bounds which require a lot of energy to break and put it to use. Lots of protein per square foot means cricket can pay urban rents in cities where heating costs are low (crickets like the temperature to stay above 25C). And the reason urban rents make sense is that cricket thrive on food waste. Current cricket production is geared to a higher end consumer product, which also makes paying the rent easier, but that requires a more uniform diet to achieve a more uniform tasting cricket. The big breakthrough from an environmental perspective and the ability to achieve impactful scale will be when cricket producers start selling affordable cricket feed to livestock and aquaculture producers.

That will allow cricket farms to be less fussy about what they feed the crickets and will create an economical way of cycling nutrients back to rural communities from cities that can complement the current practice of composting food waste and shipping the humus to farms from cities.

BLACK SOLDIER FLIES:

Even better at turning waste into usable protein is the black soldier fly larvae. The larvae can feed on human solid waste and drastically reduce the volume and weight, allowing it to be shipped as a fertile soil amendment while transforming the nutrients into protein which is ideal for livestock feed. Black soldier flies can also feeding food waste and reduce it to a soil amendment much faster than composting without producing the greenhouse gases that make composting environmentally problematic. One start up is taking the fruit and vegetable pulp waste from a local juicery and the day old bread from a bakery using the grubs to transform it into high quality animal feed.

Cities are full of these waste streams in dense supply chains. This kind of waste is currently mostly going to land fills where it creates greenhouse gases emissions.

MUSHROOMS:

Mushrooms are a vegetable crop that has one massive advantage over lettuces and hydroponic tomatoes and peppers in an indoor growing environment. Mushrooms don’t use photosynthesis and thus don’t require light to grow. This removes a major energy input in comparison. Another thing mushrooms have going for them is that they thrive in coffee grounds and our cities are producing massive amounts of spent coffee grounds that would be relatively easy to cordon off into new supply chains. After mushrooms are harvested, the mix of spent coffee grounds and mushroom roots makes a great soil amendment that can be marketed to suburban gardeners and peri-urban farms.

ALGAES AND YEASTS:

Algaes and yeasts are currently being used to produce previously expensive compounds and ingredients.

Sometimes developed by traditional breeding, sometimes via the techniques of synthetic biology, algaes and yeast have been used to produce replacements for palm oil which is environmentally disastrous by and large and for compounds like vanillin which we generally get from vanilla farms in environmentally fragile ecosystems. Algaes and yeasts are also used to produce pharmaceutical compounds. Currently sugars are used as the input for their growth and as the substrate they convert to more useful and valuable compounds, but current research and development is fairly quickly moving to make using a wider range of cellulosic biomass as a substrate more and more viable. Be one the look out for vegan milk, cheese and butter from this sector.

IN VITRO MEAT:

“Test tube meat” or vat grown meat is still a ways out in it developing an economically viable product, but it’s certainly coming.

I expect it to be used in sausage production before we get to a satisfying vat grown ribeye, but in vitro meat production fits our criteria for successful urban agriculture. You can produce a lot of valuable product in a relatively small space, without the need for light as an energy source and you can use urban waste streams as a valuable input. Now, I’m not saying that there aren’t going to be vertical farms that are successful in producing and selling high end lettuces, herbs, peppers and tomatoes. There will be. It will be a limited, upscale market, but that niche will work.

What I am saying is that those kinds of vertical farms will not ever achieve the kind of scale necessary to transform the food system in consequential ways. Nor do they do much to tackle the biggest challenges in the food system, which have to do with waste management and the nutrient cycle. The kinds of urban ag that will transform the food system and significantly reduce the environmental impacts of food production will be those that are not fighting against the economics of cities, but are leveraging the economics of cities. That means leveraging comparative advantage rather than trying to dismiss it.

Most of all, it means leveraging the dense supply chains and waste streams of valuable inputs that already exist in cities, rather than trying to replace the rain, sun, space, and soil that already exist on rural farms.

MORE ARTICLES

The Steep Climb Of Vertical Farms And Where Urban Ag Might Be Revolutionary

How I Learned To Stop Thinking For Myself And Get To The Right Answer (Part One)

ABOUT

Marc Brazeau edits the Food and Farm Discussion Lab. Twitter @eakcookwrite...

Marijuana Study Finds CBD Can Cause Liver Damage

Researchers at the University of Arkansas for Medical Science recently rolled up their sleeves to investigate CBD hepatotoxicity in mice.

Hemp oil, Hand holding bottle of Cannabis oil against Marijuana plant, CBD oil pipette. alternative remedy or medication,medicine concept | GETTY

June 18, 2019

Mike Adams Contributor

Vices I cover various facets of the cannabis culture.

Image Credit | Urine Drug Test

There is no denying that cannabidiol, more commonly referred to as CBD, is rapidly becoming more popular in the United States than sliced bread. It is a hot trend that got started several years ago after Dr. Sanja Gupta showed the nation in his documentary 'Weed 2' just how this non-intoxicating component of the cannabis plant was preventing epileptic children from having seizures.

Since then, CBD, a substance often touted as being safer than popping pills, has become highly revered as an alternative treatment for a variety of common ailments from anxiety to chronic pain. But a new study suggests that CBD may spawn its fair share of health issues. Specifically, scientists have learned that this substance could be damaging our livers in the same way as alcohol and other drugs.

Researchers at the University of Arkansas for Medical Science recently rolled up their sleeves to investigate CBD hepatotoxicity in mice. What they found was while this cannabis derivative is gaining significant recognition as of late in the world of wellness, people that use CBD are at an elevated risk for liver toxicity.

The findings, which were published earlier this year in the journal Molecules, suggest that while people may be using CBD as a safer alternative to conventional pain relievers, like acetaminophen, the compound may actually be just as harmful to their livers.

It is the methods used in this study that makes it most interesting.

First, researchers utilized all of the dosage and safety recommendations from a CBD-based drug known as Epidiolex. If this name sounds familiar, it should. Last year, the U.S. Food and Drug Administration approved it as a treatment for certain kinds of childhood epilepsy. It was a development that marked the first time in history that a cannabis-based medicine was approved for nationwide distribution in the United States.

Future of Indoor Grown Food Discussed At Indoor AgTech

What role will indoor-grown food be playing in the future and how will the vertical farming industry develop? There’s a lot going on

What role will indoor-grown food be playing in the future and how will the vertical farming industry develop? There’s a lot going on: Investors find their way into the industry, growing facilities are scaling up and collaborations are being formed these days. On the other hand, companies go out of business, there’s talk about a bubble and the profitability and scalability of the sector is questioned regularly. At the Indoor AgTech event, that kicked off yesterday in New York, the future of the industry and its relationship with retail and consumers is discussed.

Walter Robb

The Indoor AgTech event unites over 300 companies interested in this industry and coming from various parts of the fresh produce chain - from technical suppliers and breeders to growers and retailers - showing there’s a lot of interest in the market. Panel discussions and talks are to help the industry find its way into a durable future.

That there’s opportunities for indoor growing is emphasized by many speakers at the event. Walter Robb for example, former CEO of Whole Foods, sees a disruption in the food value chain that he never saw before and believes there are opportunities for indoor farms as the retail industry is urged to innovate as well and the importance of produce is high. He says indoor agriculture operators have to respond to these opportunities as well: by moving to favorable products and telling their story to retailers and consumers for example, but also by closing the last mile data and connecting the consumer to the grower, sharing also nutritional and story aspects.

Sanjeev Krishnan, Tobias Peggs, Caleb Harper & Danielle Gould

Transparency

Providing transparency was a recurring theme in more discussions on the first day of the Indoor AgTech. While on the one hand operators like Tobias Peggs with vertical farming company Square Roots explain how they’ve integrated their complete value chain from seed to retail and how almost 4 per cent of their packages get scanned by the consumer, providing data about the product, these individual closed chains are also defined as one of the challenges for the industry.

“Many indoor farming companies state they are an R&D company, software supplier, distributor and building its own produce brands”, says Caleb Harper with the OpenAg Initiative, doubting whether these individual integrated chains will bring the trust that’s needed to upscale and further develop the industry. He pleads for companies specializing in one part of the value chain, optimizing and sharing information gathered, developing the industry and in that way bringing trust to both investors and consumers. “We are to learn from the mistakes made in the industry. Whether it’s the US, Japan or even the Netherlands, some problems are unique, but standards exist. The greenhouse industry scaled thanks to creating and sharing these standards.”

Today Martin Veenstra, Head of Global Strategy, Indoor Farming at Certhon will take part in the session From Pilot to Mainstream: Automation and Systems Design to Transform Horticulture.

Roel Janssen and Blake Lange with Signify show the recently launched Production Module and GrowWise Control System

Irving Fain & Tom Colicchio of Bowery Farming at Indoor AgTech

Driving the industry

Other topics discussed in the event include investing opportunities and what’s needed to get proper funding. Today more greenhouse operators are programmed and also more technical suppliers will share what they can bring to the industry. We will of course keep you updated and provide you with a photo report on Monday.

Publication date: 6/20/2019

Author: Arlette Sijmonsma

© HortiDaily.com

FarmTech Society Held First Constitutional Annual General Meeting

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing

The Farm Tech Society (FTS) is an international non-profit industry association that unites and supports the Controlled Environment Agriculture (CEA) industry, seeking to strengthen the sector through the development and implementation of resilient and future proof methods and technologies for indoor growing.

The FarmTech Society (FTS) held its first constitutional annual general meeting at Greentech Amsterdam 2019. Also, FTS entered into a partnership with the vertical farm institute (vfi). Both organizations focus on value generation for the CEA industry and help the sector to grow together.

FTS members also elected a new board of directors, as well as its new board of advisors. The new boards are elected for a period of two years, and the board of directors also appointed the daily management team:

Board of Directors

Chairman: Gus Van der Feltz (founding member)

Vice-chair: Yanni Garcia (founding member)

Vice-chair: Penny McBride (founding member)

Director: Adam Rosenbaum (founding member)

Director: Daniel Podmirseg - vertical farm institute

Director: Wythe Marschall - PhD candidate Harvard University

Director: Stefan Frey - FREYconsult

Board of Advisors

Maren Schoormanns - PRIVA

Nicole Thorpe - Cultinova

Enrico Costanzo - ILab AirLiquide

Stefanie Linzer - Valoya

Pierre Grootscholten - Grootscholten Consultancy

Ian Kanski - INTAG Systems

Daily management

Secretary-General: Thomas Zoellner (founding member)

Treasurer: Yanni Garcia (founding member)

Communication: Mark Horler - Soya Project / UKUAT

For more information:

FarmTech Society

Tom Zoellner

Urban Agriculture’ Leads Off A 26-Episode Weekly Video Series on Vegetable Production

Linked by Michael Levenston

Mitchell assembled a team of professors from California’s public universities with agricultural programs – UC Davis, Chico State, Fresno State and CalPoly San Luis Obispo – to pull together a series of videos designed to spark the interest and begin training future farmers and ag workers in sound agronomic, economic and environmental stewardship skills.

University of California

UC Agriculture and Natural Resources (UC ANR) YouTube

Each Monday morning from May 13 through Nov. 4, a new video will premiere in the playlist.

(Must see. Mike)

From Video:

Urban agriculture is proliferating across the state of California on both public and private lands, taking the form of school, community, church and backyard gardens, vertical and rooftop farms, for-profit and non-profit enterprises, as well as a whole suite of other food production methods.

These urban farms are transforming the landscape of food production, helping to address urban food insecurity, creating opportunities for micro-enterprise development, and educating our youth and the public about the value of growing and eating healthy foods. The value of urban farming is indisputable, as studies provide mounting evidence of the myriad social, economic, ecological, recreational, therapeutic, and nutritional benefits of urban agriculture.

Urban farming is emerging at a growing number of sites. It is very much in flux with respect to its many forms and implementation. It addresses a wide range of goals and it represents a very broad array of motivations. This video provides a general introductory overview of some of the variety of urban farms in California today. It highlights the work of thirteen urban farmers from Los Angeles through the Bay Area cities of Oakland, Berkeley, and Hayward.

This video captures the creativity, innovation and dedicated work that is underway on a wide range of urban agriculture fronts at this time in California. This is indeed a very exciting and challenging time for urban farmers. With an estimated 50% of our nation’s farmland projected to change hands in the coming ten years, new farmers and new farming models are going to be needed to meet the needs for food that we will have. Urban agriculture is likely to play a role in meeting these huge challenges.

Target Launches Same-Day Delivery Throughout U.S.

http://producenews.net/the-produce-news-today-s-headlines/26843-target-launches-same-day-delivery-throughout-u-s

JUNE 14, 2019

Looking to make the shopping experience easier for customers, same-day delivery shopped by Shipt is now available directly through Target.com.

“With same-day delivery now available directly within the Target.com experience, we’ve made it even easier for our guests to shop at Target — while still getting the great value, curated product assortment and helpful guest service they’ve come to expect,” said Dawn Block, senior vice president of digital.

Guests can now get 65,000 items delivered to their door in as soon as an hour with an order placed directly on Target.com. And there’s more perks: Guests can use their REDcard to pay, which gives them 5 percent off their purchases, and they can take advantage of weekly ad promos (like buy three items, get a $5 Target GiftCard).

For guests who want to try out Shipt’s delivery service, they can sign up for a free four-week trial or have the option to pay a $9.99 delivery fee for each order on Target.com, giving guests the benefits of same-day delivery without having to commit to an annual membership.

BREAKING NEWS: Autogrow Announces First Industry Collaboration With Ridder Group And NATIVE

The collaboration is made possible with the launch of Autogrow’s new farm management platform, FarmRoadTM, which was announced by CEO Darryn Keiller at the Indoor AgTech Summit in New York today

June 20, 2019 (NEW YORK): Global automation expert Autogrow has announced a collaboration with competitor Ridder Group and New York agriculture software firm NATIVE.

The collaboration is made possible with the launch of Autogrow’s new farm management platform, FarmRoadTM, which was announced by CEO Darryn Keiller at the Indoor AgTech Summit in New York today.

“FarmRoadTM was conceived to fulfil two broad purposes. A platform for autonomous farming and secondly as a way of bringing together all disparate technologies that farmers use into one unified management tool,” explains Mr. Keiller.

“To be truly unified you need to be open and work collaboratively across the industry with buy-in from existing major players. It’s a concept we advocated two years ago when we came out with the first open API (Application Programming Interface) and I’m pleased to be in a position to say the dream is now tangible.”

“We are ecstatic that Ridder has shown the foresight and faith in us, to support what we are doing and join us in showing the industry what is possible when true collaboration occurs.”

Both Autogrow and Ridder market automation solutions for Controlled Environment Agriculture (CEA) and both will be able to integrate with FarmRoadTM.

“The Ridder Group, developer of the HortiMaX greenhouse control systems for over 40 years, supports the initiative of Autogrow,” says Joep van den Bosch, Chief Innovation Officer, Ridder Group.

“Ridder believes strongly in a connected future where systems and data is shared for the benefit of optimizing the plants growing conditions and more efficient and sustainable greenhouse operations.”

“As an industry partner, Ridder will make it possible for growers to connect their Ridder climate control and irrigation systems to the FarmRoadTM platform.”

Alongside Ridder Group, Autogrow will also be collaborating with New York based Start-Up NATIVE.

“Equally as important as an established player showing vision, is new entrants to the industry who are also bringing innovation. What NATIVE are creating delivers a fundamental industry building block, which we will integrate with FarmRoadTM,” says Mr. Keiller.

The NATIVE platform connects farms with local buyers, maximizing the value of their harvests and helping both buyers and restaurants deliver on the promise and demand of locally sourced food.

“Our partnership with Autogrow will most benefit the growers and the farmers,” says Frank Pica, co-founder, NATIVE. “FarmRoadTM users can provide NATIVE with real-time data that verifies the quantity and quality of their harvests, and NATIVE will return the true market value of the products. NATIVE then provides an outlet for growers to bring their products to premium markets within their region.”

Autogrow will work closely with Ridder Group and NATIVE over the coming months during the pilot phase. The beginning of the journey in working collaboratively with producers and growers.

“The next iterations of FarmRoadTM include flower and fruiting identification through Machine Vision and AI to provide pollination rates and flower to fruit conversion performance. We will be extending the 3rd party integration to include finance, labor management, food security and more,” says Mr. Keiller.

More information can be found on www.farmroad.io

QUERIES

General queries: (e) info@farmroad.io

Media queries: Kylie Horomia, Autogrow Head of Communications (e) Kylie.horomia@autogrow.com

(w) www.farmroad.io

About Autogrow

Autogrow leverages the power of technology, data science and plant biology to provide indoor growers affordable, accessible and easy-to-use innovation – 24/7, anywhere in the world.

Our hardware, software and data solutions support growers and resellers in over 40 countries producing over 100 different crop types.

With over 25 years in business, we have a depth of experience and passionate, fun people creating original ideas and making them a reality for our growers.

About Ridder Group

Farmers and growers worldwide need to be able to adopt their own individual approach to efficient and sustainable controlled environment agriculture. This is the promise that Ridder, as an international family-owned company, fulfils by translating more than 65 years of Dutch agri-food expertise into adaptive technology and know-how that is tailored precisely to local needs and conditions.

At Ridder, the drive to innovate is in our DNA. We are also committed to finding the best possible solution. The balanced combination of these two characteristics has enabled Ridder to evolve into the experienced market leader in technical solutions for the horticulture, intensive livestock and crop storage sectors. Today, Ridder has customers in more than 100 countries, who receive support from international offices and a global partner network.

About NATIVE

NATIVE’s mission is to empower local growers by maximizing the value of their harvests and meet the rising demand for local, transparently sourced food. NATIVE integrates real-time technology throughout the agricultural supply chain to accelerate traceability, waste mitigation, and return on investment. For more information, please visit www.nativeag.io

Competitors Join Forces to Push The Industry Forward

“FarmRoadTM was conceived to fulfil two broad purposes. A platform for autonomous farming and secondly as a way of bringing together all disparate technologies that farmers use into one unified management tool,” explains Darryn

Autogrow and Ridder

In order for the industry to move forward, collaboration is necessary. That’s what Darryn Keiller, CEO with Autogrow, is convinced of. “Everybody is innovating, but innovating in silos. There’s no real sharing of advantages created for the broader industry - and that’s the only way of speeding up innovation.”

Launching FarmRoad on the Indoor AgTech yesterday!

To change this, Autogrow launched a new farm management platform: FarmRoad. The new platform was launched yesterday at the Indoor AgTech Summit in New York.

“FarmRoadTM was conceived to fulfil two broad purposes. A platform for autonomous farming and secondly as a way of bringing together all disparate technologies that farmers use into one unified management tool,” explains Darryn.

Autogrow aren’t just talking - they are doing what they say they are - and have also announced a collaboration with their competitor Ridder Group, which will make it possible for growers to connect their Ridder climate control and irrigation systems to the FarmRoadTM platform.

“To be truly unified you need to be open and work collaboratively across the industry with buy-in from existing major players. It’s a concept we advocated two years ago when we came out with the first open API (Application Programming Interface) and I’m pleased to be in a position to say the dream is now tangible.”

“We are ecstatic that Ridder has shown the foresight and faith in us, to support what we are doing and join us in showing the industry what is possible when true collaboration occurs.”

Both Autogrow and Ridder market automation solutions for Controlled Environment Agriculture (CEA) and both will be able to integrate with FarmRoadTM. Ridder Group, will make it possible for growers to connect their Ridder climate control and irrigation systems to the FarmRoadTM platform.

“The Ridder Group, developer of the HortiMaX greenhouse control systems for over 40 years, supports the initiative of Autogrow,” says Joep van den Bosch, Chief Innovation Officer, Ridder Group. “Ridder believes strongly in a connected future where systems and data is shared for the benefit of optimizing the plants growing conditions and more efficient and sustainable greenhouse operations.”

There are various developments in the industry causing Autogrow to start innovating in this direction. Darryn explains how there are roadblocks in the way when it comes to the adoption of Agtech including the knowledge base – with the average age of the farming community going up and limited knowledge sharing tools available.

In order to transfer knowledge and systemise it, making it possible to utilise new technology, they developed FarmRoadTM, making it possible to share knowledge and collaborate.

Autogrow CEO Darryn Keiller at the Auckland, NZ office

“There are many applications growers have to deal with at their farm. If it’s the cultivars or heating, or energy consumption - traceability, environmental effects, finance, labor. Part of our journey is unifying farm information and data for different farms and crops, including machine learning techniques, into one platform.”

Alongside Ridder Group, Autogrow will also be collaborating with New York based Start-Up NATIVE.

“Equally as important as an established player showing vision, is new entrants to the industry who are also bringing innovation. What NATIVE are creating delivers a fundamental industry building block, which we will integrate with FarmRoadTM,” says Darryn.

The NATIVE platform connects farms with local buyers, maximizing the value of their harvests and helping both buyers and restaurants deliver on the promise and demand of locally sourced food.

“Our partnership with Autogrow will most benefit the growers and the farmers,” says Frank Pica, co-founder, NATIVE. “FarmRoadTM users can provide NATIVE with real-time data that verifies the quantity and quality of their harvests, and Native will return the true market value of the products. NATIVE then provides an outlet for growers to bring their products to premium markets within their region.”

Autogrow will work closely with Ridder Group and NATIVE over the coming months during the pilot phase. The beginning of the journey in working collaboratively with producers and growers.

“The next iterations of FarmRoadTM include flower and fruiting identification through Machine Vision and AI to provide pollination rates and flower to fruit conversion performance. We will be extending the 3rd party integration to include finance, labor management, food security and more,” says Darryn.

For more information:

Kylie Horomia

Autogrow

kylie.horomia@autogrow.com

www.farmroad.io

SOLD - December, 2015 Freight Farm Premium - Computer Controlled Hydroponic Grow System - Southern Connecticut - $37,500

December, 2015 Freight Farm Premium Leafy Green Machine (LGM)

Manufacturer - Freight Farms

Location - Southern Connecticut

Price - $37,500

Description

Original owner well maintained December, 2015 LGM.

This LGM has been a reliable producer of healthy produce.

The Leafy Green Machine is a complete hydroponic growing system built entirely inside a shipping container with all the components needed for commercial food production. The system is designed and engineered for easy operation, allowing users of all backgrounds to immediately start growing.

Current Uses

• Perfect for starting a small produce business, growing for restaurants or supplementing existing produce production.

• Restauranter who wants to grow custom greens for rotating menus 365 days a year. Farm to Table? How about Parking Lot to Table!

• Universities and schools have created programs for students to learn to grow while supplementing dining facilities with fresh greens.

The Highest Standard in Controlled Environment Agriculture

• Pre-built system designed to maximize operational efficiency and streamline workflow

• Perfect environment is achievable 365 days a year, regardless of geographic location

• Automated scheduling reduces the amount of labor required to operate

• Remote monitoring & control capabilities through the Farmhand AppTM

Operation Requirements

Space- The LGM dimensions are 40’ x 8’ x 9.5’. We suggest putting the farm on either trap rock or a concrete pad.

Electrical- 60 amp, 120/240-volt single phase or 120/208V three phase connection.

Water- A designated water source is suggested such as a garden hose or hardline water plumbing.

Labor- 15 to 20 hours a week for farming and upkeep.

It is recommended growing smaller compact crops with a high turnover rate, like head and loose leaf lettuces, herbs and heartier greens like kale and swiss chard.

Crop Examples