Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How Can 'Aquaponics' Farming Help Create Sustainable Food Systems?

Millions of people around the world go hungry every year, due to lack of access to healthy food and the effects of climate change on agricultural development

By Jaxx Artz

APRIL 23, 2021

Aquaponics has the potential to help people who are food insecure take control of the food system

Why Global Citizens Should Care

Millions of people around the world go hungry every year, due to lack of access to healthy food and the effects of climate change on agricultural development. Aquaponics is a sustainable growing method that has the potential to put food production into the hands of the people who experience food insecurity, giving them autonomy in controlling their access to safe and nutritious produce. Join us by taking action to strengthen our food systems and protect the planet here.

Global Citizens everywhere are increasingly recognizing the need for more sustainable career options to increase global food security.

According to a 2020 report from UNICEF on the state of food security and nutrition in the world, almost 690 million people went hungry in 2019, or 8.9% of the world population. This is due, in part, to the high costs associated with eating nutritiously, the lack of access to healthy food, and the effects of climate change devastating agricultural production systems.

As more government leaders commit to becoming carbon neutral by 2050, and more people choose to change their habits (like eating less meat) to reduce their carbon footprint, methods of food production that promote a harmonious relationship between humans and the environment are becoming more common.

One of these methods involves fish.

Aquaponics farming is a method of sustainable agriculture that forms a symbiotic relationship between fish and plants. It involves the use of a fish tank placed below a grow bed for plants, where the main input to the system is fish food.

When the fish produce waste, it is cycled out of the fish tank into the grow bed, where bacteria transform ammonia into nitrates that plants need to grow. The water is then filtered and returned to the fish tank, aiding in the highly optimized, zero-waste process of farming fish and plants together.

Yemi Amu, founder and director of Oko Farms in Brooklyn, New York, working on the outdoor aquaponics farm. Photo courtesy of Oko Farms.

The practice of aquaponic gardening can be traced back centuries. In central Mexico around 1000 AD, the Aztec people developed a technique known as chinampa to expand their growing efforts to the surface of lakes and ponds, according to the Permaculture Research Institute. By weaving together logs and sticks to create a “floating farm,” the Aztecs used water from the lakes and waste produced by fish to nourish crops.

Aquaponics also has roots in Southeast Asia, where farmers cultivated rice and fish concurrently, according to the United Nations' Food and Agriculture Organization. The practice of raising fish in rice fields became one of the best examples of polyculture farming as a method of sustainability.

Photo courtesy of Oko Farms.

In recent years, aquaponics has increasingly been chosen as a growing option for urban farmers, or those who practice agriculture in cities and must rely on vertical farming techniques when faced with less land area. Many of these aquaponics farmers choose to produce food for their communities, particularly in areas where economic inequalities threaten household food security.

Around the world, the environmental impacts of climate change are preventing low-income people from accessing sufficient, safe, and nutritious foods. To improve global food systems and decrease food insecurity, it is more important than ever for people to practice sustainable agricultural development.

To learn more about how aquaponics can aid in the production of sustainable food systems, Global Citizen spoke to Yemi Amu, founder, and director of Oko Farms, an aquaponics farm and learning center in Brooklyn, New York.

Global Citizen: Tell me a little about your background and how you became interested in agriculture.

Yemi Amu: My background is in nutrition and behavior modification. I spent a lot of my time at the beginning of my career really using a hands-on approach to guiding people to adopting healthy dietary habits and trying to understand what the barriers are. Things like knowing how to cook ... can be a barrier for people, and knowing what food to buy from the grocery store.

I also happened, at one point, to be working with a formerly homeless population, and for that particular group going out into the world — like leaving the neighborhood, going to the grocery store to shop — it was not practical for them. They are dealing with anxiety, and [going from] being chronically homeless to living in an apartment [is] a huge adjustment that most people don’t understand.

After working with them, I found that they were only eating well when I was preparing the food for them. When I wasn’t involved, they weren’t going on their own to get healthy food. And so after going back and forth with my colleagues, who were social workers, we decided, hey, you know what, the roof of the building where the residents lived would be a great place to grow food because it was intended to be a green roof. We decided, “Why not turn that into a farm?” and really that’s how my farming career started.

So how did your interest in aquaponics specifically come about?

I discovered aquaponics while I was on the roof. I learned how to farm along with the residents and had to learn about seasonal growing, what it’s like to grow in a soil-less environment, and how to grow in raised beds. I’m from Nigeria. I grew up in a city, in Lagos, and so the idea of people farming in a city wasn’t weird. But farming in New York City? It seemed so different, and so learning about aquaponics and how you don’t have to worry about watering plants, I just found it fascinating.

I started visiting farms around the country just to see how aquaponics works in practice and make sense of it. I saw how it could play a really big role in not just feeding people but also raising awareness about alternative agricultural methods. Around 2011, hydroponics [using nutrient-rich water for agriculture instead of soil] was becoming popular, and I thought it was so great to throw aquaponics in the mix. The system can work indoors or outdoors, it saves water, and Oko Farms was built a couple of years later.

Aquaponics is also a throwback to other cultures that have used it in the past. In Peru, in China — so many cultures around the world had these models that were rooted in the idea of raising animals and plants together. It was industrial agriculture that saw people no longer raising animals and plants in tandem, so it’s great that we can bring this centuries-old model back to the urban environment.

For people who experience drought, or live in an urban environment — can aquaponics improve food access, or be used in conjunction with other methods of sustainable agriculture?

I mean, this isn't a one-size-fits-all model. Aquaponics can absolutely be used in conjunction [with other methods of sustainable agriculture].

It’s not that there is anything wrong with soil, but we are living in a very complex environment. There are barriers for many communities to access food, like not having space to grow food, and aquaponics systems can be set up to address these barriers and ecological issues.

Aquaponics, in my experience, lends itself better to small-scale production. And I think that we can ultimately guarantee food security for those of us that live in urban areas. It doesn’t require a lot of land, it saves water. Water access is limited for a lot of people around the world, and we use a lot of water in agriculture specifically. Aquaponics can address this problem because it requires very little input of water.

Your work at Oko Farms emphasizes education, specifically around helping people learn to grow their own food, in food sovereignty. Can you speak to why that is important in the production of sustainable food systems?

I haven’t seen our current system support people, empower people, or ensure food security. Giving people the tools to [control their access to food] is important. Our workshop model supports people in building their own aquaponics system, and in an urban environment, it is important for us to have a space to teach the public about food systems.

At Oko, we donate some of the produce we grow, and then we sell some of it at farmers’ markets in the area. Sometimes people come to the farm and buy produce off the farm — they know it’s grown here. Aquaponics has helped us develop that system as we look to feed ourselves sustainably, or just feed ourselves, period.

This interview has been edited and condensed for clarity.

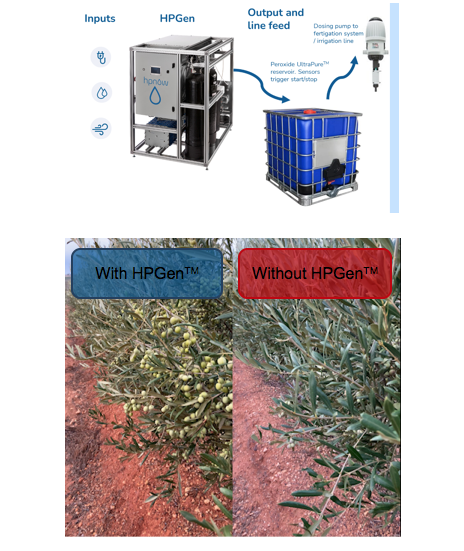

Peroxide UltraPure™ Produced Directly On-Site Improves Growth And Yield In Super-Intensive Olive Plantation

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions

Successful Implementation of HPGen™

At 160 ha Olive Plantation In Alentejo, Portugal

The Alentejo region in Portugal is known for its long sunny days, which create ideal conditions for the growth of high-quality olives. Irrigation water in the region is sourced from the Alqueva dam, and especially in the summer months, it accumulates a high quantity of organic matter (algae, bacteria). This caused a problem for growers in the region specifically with drippers clogging, irrigation uniformity, and soil oxygenation. To address this situation, one of the largest olive plantation companies in the region, with more than 2000 ha, turned to NaanDanJain Ibérica and HPNow for help in a super-intensive plantation of young olive trees (2 years old) of 160 hectares.

HPNow, together with its channel partner NaanDanJain Ibérica, were able to identify this accumulation of organic matter from the dam in the drip irrigation lines which led to two main issues:

1. Organic matter was blocking a substantial amount of drippers, and as a consequence, the trees did not receive all water and fertilizer that they should.

2. The organic matter consumed dissolved oxygen in the water, another essential nutrient for proper tree development.

These two issues led to a slower tree development, which was very visible in this young plantation and threatened the viability of the operation.

To correct this situation, an HPGen™ system was installed at the plantation, producing Peroxide UltraPure™ that was injected in the drip lines of half of the plantation (80 ha). The other 80 ha did not receive any dosing.

Peroxide UltraPure™ had a dual effect in the olive field:

1. Oxidation of organic matter in the lines, which kept the drippers free of clogging and allowed plants to receive all the required water and fertilizer.

2. After Peroxide UltraPure™ is used for oxidation of organic matter, it becomes water and oxygen. This extra oxygen increases levels of dissolved oxygen in water, which acts as a nutrient and has a positive impact on the development of the root system and plant health.

The response of the trees was monitored for a full growing season. The trees in the section with Peroxide UltraPure™ clearly had more vegetative growth, and the coloration on the leaves was also deeper, indicating improved nutrient absorption. When comparing yields, Peroxide UltraPure™ resulted in higher production.

The farm manager expressed his enthusiasm about the solution: “With the HPGen system the olive trees look better, healthier, and all drippers are working. I noticed a much better irrigation uniformity, which translates to higher production”.

Better growth, higher yields

With those results, the olive trees are well irrigated and receive the nutrients they require, which clearly contributes to better growth and higher olive yields. The results are explained by the oxidizing power of Peroxide UltraPure™, which will keep irrigation lines clear, while oxidizing organic matter in the irrigation lines and making extra oxygen available to the crop. This ensures irrigation lines are clean and drippers flowing, getting water and fertilizer uniformly throughout the field while at the same time improving plant nutrition.

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas, and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in the on-site generation of hydrogen peroxide and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

Urban Farmers Captured On Canvas

“Re-Enchanting the City,” an exhibition in Chelsea, highlights the visual record of the many vibrant local farms, community gardens, and rooftop plantings around the city by the artist Elizabeth Downer Riker

An Exhibition by The Painter Elizabeth Downer Riker

Documents A Decade of Urban Gardening

April 26, 2021

“Re-Enchanting the City,” an exhibition in Chelsea, highlights the visual record of the many vibrant local farms, community gardens, and rooftop plantings around the city by the artist Elizabeth Downer Riker. About 10 years ago she started painting rooftop farms in Long Island City, Queens, and parts of Brooklyn, and then took her oils and canvas to other neighborhoods in the city, and even upstate. The exhibition features 20 of her works, and they are for sale, from $1,000 to $2,200.

“Re-Enchanting the City: Greening New York City,” April 27 through May 22, Ceres Gallery, 547 West 27th Street, Suite 201, 212-947-6100, ceresgallery.org.

Follow NYT Food on Twitter and NYT Cooking on Instagram, Facebook, and Pinterest. Get regular updates from NYT Cooking, with recipe suggestions, cooking tips, and shopping advice.

Florence Fabricant is a food and wine writer. She writes the weekly Front Burner and Off the Menu columns, as well as the Pairings column, which appears alongside the monthly wine reviews. She has also written 12 cookbooks.

Lead photo: “Bird’s-Eye View of Brooklyn Grange-Future,” a portrait of the Brooklyn Grange rooftop farm.Credit...Elizabeth Downer Riker

Kalera Announces The First Harvest For Atlanta Vertical Farming Facility That Will Produce Over 10 Million Heads of Lettuce Per Year

The new facility will supply schools, restaurants, grocery stores, hospitals, retailers, and more with safe, fresh, nutrient-dense, locally-grown greens

The new facility will supply schools, restaurants, grocery stores, hospitals, retailers, and more with safe, fresh, nutrient-dense, locally-grown greens

April 27, 2021

Source: Kalera

ATLANTA, April 27, 2021 (GLOBE NEWSWIRE) -- Kalera (Euronext Growth Oslo ticker KAL, Bloomberg: KSLLF), one of the fastest-growing US vertical farming companies in the world and a leader in plant science for producing high-quality produce in controlled environments, today celebrated their first harvest in their Atlanta-area facility. Its largest farm to date — and the largest vertical farm in the Southeastern United States — the facility is 77 thousand square-feet and has the capability of producing over 10 million heads of lettuce per year. Located in Forest Park, GA, the farm was built in just eleven months thanks in large part to the company’s modular building approach and has created dozens of new jobs in the Atlanta area.

“Our new Atlanta facility is open and performing in line with our expectations and we are eager to begin offering our local, fresh, safe, sustainable greens to the Georgia market,” said Daniel Malechuk, CEO of Kalera. “Our customers are telling us that there has never been a better time to ensure supply continuity, locally, than now and we are grateful Kalera can provide this.”

Kalera’s optimized nutrient and light recipes allow them to grow high-quality, pesticide-free, non-GMO produce at accelerated growth cycles. Planting at the Atlanta facility began in early March, and the first harvest began successfully last week. Kalera has so far experienced optimal operating efficiencies in Atlanta, particularly in terms of lighting productivity. All growth systems, environmental equipment, and technology have operated effectively since opening the facility on March 11. Due to strong sales indications in the region from both retail and foodservice customers, Kalera is implementing a faster ramp-up schedule than originally planned.

The facility’s location near the urban center of Atlanta cuts down on travel times for retailers, restaurants, and other customers who want access to the freshest, non-GMO, clean living lettuces and microgreens. Royal Food Service, a leading produce distributor in the state, is one of Kalera’s top partners bringing “pick-to-plate” greens to restaurants, hotels, schools, and other businesses including Ansley Golf Club, The Ritz-Carlton at Reynolds, Lake Oconee, The Georgia World Congress Center, several restaurants and many others. The lettuce is also available on the shelves of Publix Supermarkets.

“As the former Governor of Georgia, I could not be more excited that Kalera’s delicious greens are now available in the Atlanta area,” said Sonny Perdue, former U.S. Secretary of Agriculture, who joined Kalera’s Board of Directors earlier this year. “Kalera is leading the pack in a booming vertical farming industry. It’s a perfect example of the power of American innovation, creativity, and entrepreneurship to develop different, innovative ways to grow and provide food at home and around the globe.”

Kalera currently operates three growing facilities – two in Orlando and one in Atlanta and is building facilities in Houston, Denver, Columbus, Seattle, Minnesota, and Hawaii. Kalera is the only controlled environment agriculture company with coast-to-coast facilities being constructed, offering grocers, restaurants, theme parks, airports, and other businesses nationwide reliable access to locally grown clean, safe, nutritious, price-stable, long-lasting greens. Once all of these farms are operational, the total projected yield is several tens of millions of heads of lettuce per year. Kalera uses a closed-loop irrigation system which enables its plants to grow while consuming 95% less water compared to field farming.

Recently, Kalera also acquired Vindara, a seed company that uses genomics, machine learning, and computational biology along with traditional breeding methods to meet the market need for produce that is non-GMO, nutritious, high-yielding, and delicious. Explicitly intended for the new high-tech indoor growing environments, Vindara seeds offer growers the opportunity to capitalize on significantly higher yield potential, production efficiencies, and product customization — in a fraction of the time through reducing the grow cycle.

ABOUT KALERA

Kalera is a technology-driven vertical farming company with unique growing methods combining optimized nutrients and light recipes, precise environmental controls, and cleanroom standards to produce safe, highly nutritious, pesticide-free, non-GMO vegetables with consistently high quality and longer shelf life year-round. The company’s high-yield, automated, data-driven hydroponic production facilities have been designed for rapid rollout with industry-leading payback times to grow vegetables faster, cleaner, at a lower cost, and with less environmental impact.

Media Contact

Molly Antos

Phone: (847) 848-2090

Email: molly@dadascope.com

US: NEBRASKA - The Bay, Beyond School Bells Launch Youth-Focused 'Freight Farm'

In partnership with Beyond School Bells, The Bay is launching The Greenery, a self-contained hydroponic farm housed in a repurposed shipping container

Apr 25, 2021

A 40-foot-long shipping container in the parking lot of The Bay will soon be filled with a whole lot of green.

In partnership with Beyond School Bells, The Bay is launching The Greenery, a self-contained hydroponic farm housed in a repurposed shipping container. Members of Beyond School Bells and The Bay gathered with local leaders Saturday to officially launch the program.

Much like The Bay’s other youth-focused programs, The Greenery is designed to allow students access to engaging, hands-on activities — in this case growing food.

“We are thrilled about the opportunity to be able to turn kids on to sustainable agriculture,” said Andrew Norman, executive director and co-founder of The Bay’s parent organization Rabble Mill. “A lot of the kids in our neighborhood have never seen anything like this; none of us have.”

The Greenery setup is designed by the Boston-based company Freight Farms. Beyond School Bells was able to purchase the unit through a partnership with the Ben Hormel Harris Foundation, said state Sen. Anna Wishart, the director of partnerships for Beyond School Bells. Several local companies and individuals donated their time to help get it up and running.

Through vertical planting that doesn’t require soil, the shipping container is able to house 13,000 plants at a time, or about as much food as a 2.5-acre farm. Throughout the container are thousands of red and blue LED lights that can be precisely controlled through the trailer’s high-tech programming to provide the perfect amount and color of light for each plant, said Doak Field, director of operations at Freight Farms.

The setup is also water-efficient, as the water that flows throughout the trailer is repumped through the cycle.

“Everything is just way more efficient than growing outside,” Field said. “You can get the exact science down to whatever you need to grow.”

Field said the team hopes to start planting the container within the next two weeks and is planning to start with greens such as lettuces and kale, as well as herbs.

The program leaders plan to sell the food grown at the Greenery at local farmers’ markets or through weekly community-supported agriculture projects. They'll also source produce to local restaurants.

While many of the similar freight farm projects that have popped up across the country have been for-profit and run by adults, Lincoln’s will be one of only a few that are not-for-profit and youth-focused, Wishart said.

Beyond School Bells works statewide to provide after-school opportunities for students like The Greenery, she said.

“Our goal is to ensure that every kid, no matter where they grow up in Nebraska, has access to quality out-of-school programming and this freight farm is absolutely an example of that,” she said.

The project will offer an opportunity for students to learn a variety of skills, Wishart said, and University of Nebraska-Lincoln honor students will also play a role in mentoring younger students working on the project.

“This also creates an incredible platform for youth to learn entrepreneurship and about sustainable, high-tech agriculture and future careers in that space,” Wishart said.

The Greenery project is part of a series of environmental-focused projects across the state that Beyond School Bells is working on, the organization's network lead Jeff Cole said.

“This will be the crown jewel,” he said. “But we're already starting to do investments in rural Nebraska around outdoor classrooms, environmental education, and a series of other things across the state.”

Lincoln Mayor Leirion Gaylor Baird said she sees the project as an example of innovative, environmentally friendly solutions that can help move the city forward.

“This is such a wonderful demonstration of how we can take better care of the Earth, create greater value for everyone in our community and hand something on to the next generation, something that they can have a leadership role in,” Gaylor Baird said.

Lead Photo: Jeff Cole of Beyond School Bells talks to visitors about the Greenery, a 40-foot-long shipping container that will operate as a high-tech hydroponic farm at The Bay. The container has space to vertically grow over 13,000 plants — the equivalent of a 2.5-acre farm. FRANCIS GARDLER, Journal Star

USA: BALTIMORE - Hydroponic Operation Supplies High-End Restaurants

Growing vegetables in a shipping container have opened new marketing opportunities for a Baltimore County farm

Art Petrosemolo, Southeastern Pennsylvania Correspondent

Apr 23, 2021

Growing vegetables in a shipping container have opened new marketing opportunities for a Baltimore County farm.

The hydroponic growing system has allowed Karma Farm to sell fresh produce regardless of the season to high-end restaurants in Baltimore and Washington.

“Today we are delivering leafy greens and herbs year-round to a growing customer base,” said Jon Shaw, founder of the family operation.

The farm, which makes multiple weekly deliveries to 27 customers, has picked up clients through word of mouth and sampling visits arranged with chefs who find the farm on social media.

“Well-known chefs talk and move from restaurant to restaurant ... and they have brought us with them,” Shaw said.

The farm got its start just over a decade ago when Shaw was growing produce on 5 acres, both outside and in hoop houses, for retail sale as well as a nearly 100-member CSA.

Karma Farm purchased a freight container vertical hydroponics Leafy Green Machine from Freight Farms in Boston in 2017. Photo by Art Petrosemolo

Jon’s 28-year old son, Nat, learned the business from his dad as a teenager, and in the past few years he has helped Karma Farm pivot to the new customer base, embracing the new ag technologies.

Nat, now the farm’s hydroponic production manager, researched vertical growing in insulated shipping containers while he was studying entrepreneurship at the University of Baltimore and thought the year-round production method would be a good fit.

“Hydroponic container farming is still relatively new and is being introduced to farmers in parts of the country where short growing seasons, weather, and soil conditions make profitable, small family farming difficult,” he said.

With a feasibility study completed and a new focus for the business, the Shaws purchased a Leafy Green Machine container in 2017 from Freight Farms in Boston. The container is 40 feet long by 8 feet wide.

“These are the insulated type of refrigerated containers used to ship fresh produce across the country,” Nat said.

With delivery and setup, the container cost about $100,000.

Lead photo: Nat Shaw, left, and his dad, Karma Farm owner Jon Shaw, stand in their freight container.

USA: Zenat Begum Turned A Bustling Brooklyn Street Corner Into A Working Greenhouse

She reached out to Jasper Kerbs of the Cooper Union Garden Project and, with the help of several volunteers, the structure was erected in October of last year. The shop is utilizing one of the city’s outdoor vending permits and they’re in the midst of harvesting this month

The owner of Playground Coffee Shop transformed the cafe’s outdoor dining space into a project centered around care, creativity, and community

April 21, 2021

“I’m inviting people that I love to come and dress up the facade,” Zenat says of the greenhouse's verdant mural by artist Tiffany Baker. “I’m inviting people that I really respect to come and build these things because we deserve the best.”Image courtesy of Zenat Begum

To understand how a fully functioning greenhouse ended up at the busy intersection of Quincy Street and Bedford Avenue in Bed-Stuy, Brooklyn, it’s important to get to know Zenat Begum, the owner of Playground Coffee Shop.

Zenat opened the shop back in 2016, in a space that previously housed her father’s hardware store, and quickly expanded to include the Playground Annex, which houses a radio station and bookstore, as well as Playground Youth, a nonprofit organization dedicated to issues confronting the community, including literacy and food equity.

“I believe in Bed-Stuy. I believe in myself. I believe in the shop. I believe in the greenhouse,” says Playground Coffee Shop owner Zenat Begum. “These are things that are active radical attempts. We are imagining our futures because these things aren’t going to be built for us.”Image courtesy of Zenat Begum

Providing for the community is fundamental to each project that the Playground team takes on. “Every time we do something, we change and raise the bar of what should be done in our communities,” Zenat explains. “I’m talking about being able to keep implementing this really large notion and understanding of entrepreneurship into taking care of your communities.”

Shortly after the pandemic hit, Playground got to work on several mutual aid projects. The team established a take-one-leave-one library that distributes works exclusively by writers of color, assembled a network of volunteers distributing PPE and essential supplies at Black Lives Matter protests, and they worked with organizers to create a network of community fridges providing free produce 24 hours a day.

It was while working on the fridge project that the idea for the greenhouse began to crystalize, in realizing that fundamentally addressing the issues surrounding food sovereignty wasn’t, as she says, “as simple as just donating a fridge.”

Zenat cites the statistics: One in three kids in New York City are food insecure, and one in 10 in public schools experience homelessness. She probed further, looking at obesity and food deserts and gentrification. “Let’s reel it back: Why aren’t there programs that support Black and brown families who can’t support their children with adequate nourishment and nutrition?”

“It made me really frustrated. We need to have a plot of land that grows for this. We need to get an actual farm to be able to grow food for this,” Zenat says. And never having built a greenhouse before didn’t scare her off. “I don’t really have the tools,” she thought. “But I also know that, for the understanding that I have and the experience that I’ve had growing up in New York, I know what a New Yorker deserves, which is a lot more.”

She reached out to Jasper Kerbs of the Cooper Union Garden Project and, with the help of several volunteers, the structure was erected in October of last year. The shop is utilizing one of the city’s outdoor vending permits and they’re in the midst of harvesting this month.

When they’re able to resume programming, Zenat intends to teach kids in the neighborhood how to get involved and have plots so they can start growing together. “The most important thing about this is that this will be an opportunity for kids who live in Bed-Stuy to see food growing, to show them that there is life that starts at fertilizing and that we can be involved in the process of food distribution and food harvesting from the very beginning.”

“Our greenhouse is straight up on the street. I want people to see that these structures have to and should exist.”Image courtesy of Zenat Begum

And she acknowledges the responsibility and history that comes with this endeavor. “We’re on stolen land right now,” Zenat says. “We’re thinking about farming practices that date back to East Asia, which is where my family is from, and sharecropping that was implemented during the period just after slavery, which is one of the darkest times in history, period. But with all of those tragedies and travesties occurring, there is this sense of land and relationship that we have that we need to bring back to ourselves. It’s ancestral, of course, and it’s spiritual, but most importantly it’s territorial. Why is it that Black and brown people have a hard time with housing and food insecurity when we have literally created some of the most adequate and sophisticated food systems in the world? Our bodies are used to actually supply people with this type of food and nourishment.”

“So there’s many things that we’re addressing here, but I only hope that at surface level we’re talking about things that actually make a difference, which is ultimately feeding children.”

In true Playground style, the greenhouse is one of many initiatives in the works—from financial literacy courses and book clubs to bystander intervention trainings. Given Zenat’s dedication, there’s no doubt they’ll come to fruition. “The way that I love New York is so poetic. I’m like one of those gnarly girlfriends, ‘Did you eat today? Do you want water?’” She asks the city: “Did you eat today, New York? Do you want water? Do you want a pillow?”

If you’d like to support Playground Youth, there is a fundraiser underway for programming and operational costs.

CEA Food Safety Coalition Launches First-Ever Food Safety Standard For Indoor-Grown Produce

The CEA Food Safety Coalition was founded in 2019 to represent the interests of CEA leafy greens growers in developing credible and appropriate food safety standards while educating consumers and regulators alike on the value of controlled environment agriculture

The Coalition, founded by industry leaders in greenhouse and indoor farming, developed the food safety addendum to address the unique attributes of CEA-grown leafy greens

WASHINGTON, DC, April 28, 2021 -- The CEA Food Safety Coalition, comprised of leaders in the controlled environment agriculture industry, today announced the first-ever food safety certification program specifically for CEA-grown leafy greens. Effective immediately, members of the Coalition can choose to be assessed for the CEA Leafy Greens Module, and upon successful completion will be allowed to use the CEA food-safe seal on certified product packaging. The Leafy Greens Module is measured against science-based criteria and is an add-on to existing compliance with an underlying Global Food Safety Initiative (GFSI) recognized food safety standard. To learn more about the certification and auditing process, click here.

Traditional food safety risk profiles include examining the physical hazards and microbial hazards from water use, herbicide, and pesticide use, and impact from animals and animal byproducts, many elements that do not impact CEA growers in the same way, if at all. The CEA Leafy Greens Module enables CEA growers to distinguish produce grown indoors while ensuring the highest standard of quality and compliance is achieved.

“Current food safety standards were written for the field, and many do not address the unique attributes of controlled, indoor environments,” said Marni Karlin, executive director of the Coalition. “This new certification process and the accompanying on-pack seal helps to unify CEA growers while also differentiating them from traditional field agriculture. It also better informs consumers and provides a quick-glance image to know when produce has been grown safely indoors, with a high standard of quality and without some of the hazards of the field, such as potential contamination from animal byproducts.”

Controlled environment agriculture takes a technology-based approach to produce optimal growing conditions inside controlled environments such as greenhouses and indoor vertical farms. Plants are typically grown year-round using hydroponic, aeroponic or aquaponic methods, without the need for pesticides and unaffected by climate or weather.

The certification program is available to all CEA FSC members for a nominal cost and must be completed on an annual basis. CEA growers can be assessed for multiple sites across four key areas:

Hazard analysis: use of water, nutrients, growing media, seeds, inputs, site control and other relevant factors

Water: all contact with the plant and with food contact surfaces. The use of recirculating water will require a continuing hazard analysis. Will also require zone-based environmental monitoring based on company-specific risk assessment.

Site control / Infrastructure / System Design: all food contact surfaces and adjacent food contact surfaces, including plant containers. Will also assess associated farm physical hazards, including lighting, robotics, sensors, equipment and utensils, etc.

Pesticide Use / Testing: the use of pesticides or herbicides during the plant life cycle.

“The CEA industry is rapidly expanding and predicted to support more than 10% of US vegetable and herb production by 2025,” said Rebecca Anderson, technical key account manager for GLOBALG.A.P. North America. “The CEA FSC Leafy Green Module will set a new industry standard for CEA-grown produce while driving consumer awareness of the innovations happening in indoor agriculture today.”

First conceived in 2019 to distinguish CEA-produced greens from field-grown greens that have been at the epicenter of many industry-crippling recalls, the Coalition successfully worked to educate the CDC and FDA about the limited risk of contamination for indoor produced leafy greens, ensuring CEA-produced leafy greens remained on store shelves during later lettuce recalls.

In addition to overseeing development and revisions to the CEA Leafy Greens Module and seal, the Coalition’s mission includes spearheading research development that supports the industry and championing CEA-grown produce as a critical component of safe and secure domestic food supply. Founding members include AeroFarms, Bowery Farming, BrightFarms, Little Leaf Farms, Plenty, Revol Greens, Superior Fresh, and Vertical Field.

About the CEA Food Safety Coalition

The CEA Food Safety Coalition was founded in 2019 to represent the interests of CEA leafy greens growers in developing credible and appropriate food safety standards while educating consumers and regulators alike on the value of controlled environment agriculture. The CEA Food Safety Coalition is headquartered in Washington, DC, and represents companies with facilities and distribution in over 21 states.

Find more information at http://ceafoodsafety.org/.

Press contact information

Lizi Sprague

ceafoodsafety@songuepr.com

2020 Sustainability Report Highlights AppHarvest’s Impact

“Resiliency is at the core of our beliefs at AppHarvest because farming as we’ve known it is broken and not sustainable for the planet,” said Founder & CEO Jonathan Webb

On A Mission To Redefine Agriculture

Titled “Feed the Future,” our 2020 Sustainability Report is now available for view and outlines our efforts to create positive environmental change in agriculture, empower employees and improve the communities in which we operate.

“Resiliency is at the core of our beliefs at AppHarvest because farming as we’ve known it is broken and not sustainable for the planet,” said Founder & CEO Jonathan Webb. “We’re solving for the variables that make our food system unreliable, such as extreme weather, droughts, fire or contamination. Our team built one of the world’s largest facilities in the midst of a global pandemic.”

This Earth Day, we’re detailing our progress toward three distinct impact goals as we work to establish a reliable, climate-resilient domestic food supply:

Drive positive environmental change in agriculture: Our first high-tech indoor farm grows more with fewer resources and contributes to a climate-resilient, domestic food supply. With our strategic location in Central Appalachia, we can reach 70% of the U.S. population within a day’s drive. The location reduces diesel used for transportation as much as 80% compared to produce trucked from Mexico or the Southwest of the U.S. Our operations are also designed to use 90% less water than open-field agriculture with 100% recycled rainwater, zero chemical pesticides, and zero agricultural runoff.

Empower individuals in Appalachia: To us, ‘empowering individuals’ means creating a life-changing experience for employees and their families. As of March 31, 2021, we have created 500 jobs with 100% of employees verified to be paid a living wage plus a comprehensive benefits package that is considered best-in-class in the agriculture sector. We also make each employee a stakeholder in the company’s success by providing equity-based incentives.

Improve the communities in which we operate: Our plans call for more than tripling our investment in Appalachia to reach almost $1 billion in capital invested by 2025. We're also working with Eastern Kentucky high schools to incorporate AgTech curriculum and provide high-tech container farms that offer students a hands-on opportunity to grow their own food and learn about nutrition. In fact, we opened another container farm today. Read more below.

“Consumers are more educated than ever, and they use that knowledge to support organizations, like AppHarvest, that have the best interests of all stakeholders in mind by putting people and planet first,” said AppHarvest President David Lee.

The complete Sustainability Report can be downloaded here.

“When You Start Growing Upwards, There’s More To Consider Than Verticality”

The Massachusetts-based company manufactures the Agrify Vertical Farming Unit (VFU), a stackable, multi-tiered cultivation chamber designed to increase yields while improving harvest consistency and quality

“Vertical farming technology has really focused on the utilization of the vertical space," says David Kessler, Chief Science Officer at Agrify. "To that end, the environmental management is left to the operator who needs to choose a system and integrate it cohesively; this is a major undertaking. Agrify has a systems-engineered solution to enable vertical growing without needing to figure out all the other obstacles."

The Massachusetts-based company manufactures the Agrify Vertical Farming Unit (VFU), a stackable, multi-tiered cultivation chamber designed to increase yields while improving harvest consistency and quality. Also delivering on improved biosecurity and environmental control over the crop, a single unit has two tiers, and three units can be stacked for six total levels of canopy.

According to David, the transition towards taller vertical farms has made environmental control difficult as the high planting density increases total transpiration and the height of the building results in air temperature stratification. The Agrify VFU is an enclosed cultivation chamber and is monitored and controlled remotely using Agrify’s software. This enclosed climate-controlled design affords operators enhanced environmental management, and is one of the key features distinguishing the Agrify VFU from other vertical racking systems, according to David.

While the VFU was specifically designed for cannabis and hemp production, Agrify first began by producing leafy greens, which David says allowed the company to accrue significant experience in optimizing the environment to increase production.

“When you’re growing leafy greens as opposed to high-value medicinal herbs, the profit margins are quite slim. This form of economics sharpened our swords and forced us to become experts at controlling cultivation environments, with a keen eye towards production costs,” says David.

Smart design for grower safety

Occupational safety is an increasingly important subject in vertical farming, specifically in tall installations relying on manual labor. Scissor lifts are common in the horticultural industry but can be precarious when used in tight spaces at full extension. With vertical farming pushing the boundaries on height, it is important that employees’ safety be prioritized. According to David, Agrify has designed its farming units with employees in mind by incorporating an integrated catwalk into the system’s design and ensuring that its units can be solidly connected.

“When you start growing upwards, moving all of that biomass is cumbersome and can reduce workflow efficiency while increasing risk to employees. Our cultivation chambers are roughly 4’ by 8’ by 9.5’ tall and can be stacked side-by-side with a catwalk in between. This gives employees more safety and flexibility to work standing or sitting,” says David.

Automation in the Agrify VFU

According to David, the Agrify VFU is automated to control irrigation, fertigation, sanitation processes, lighting, humidity control, etc. The VFU control system also allows growers to collect roughly 100 data points per chamber per hour and a minimum of 850,000 data points per year. Features in the software then allow the grower to run daily analyses both within and between chambers. David explains that having enclosed chambers also facilitate this data collection and use as growers can implement different growing conditions in different chambers then compare the resulting outcomes to determine the best production conditions.

Moving forward, Agrify is looking to integrate cameras, artificial intelligence and machine learning into its systems to enable the consistent recreation of precise environmental conditions and proactive crop management.

“We believe that the future will not necessarily be in autonomous production but in computer-aided production. Machine vision will allow 24/7 crop monitoring rather than the typical weekly pest scouting, as an example. With our software, we’re capturing the data as well as providing the tools to analyze it and act on it.

For more information:

David Kessler, CSO

Agrify Corp.

David.kessler@agrify.com

www.agrify.com

23 Apr 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

USA: NEW JERSEY - AeroFarms Expands Global Headquarters To Support Growth And Innovation

Indoor vertical farming leader continues commitment to Newark as it expands presence within the community

April 23, 2021

Indoor vertical farming leader continues commitment to Newark as it expands presence within the community

Co-Founder & CEO David Rosenberg recognized as ROI-NJ Top Technology Influencer

AeroFarms, a certified B Corporation and leader in indoor vertical farming, today announced that the Company has received its certificate of occupancy for expansion of its global headquarters in Newark, New Jersey. To support its corporate expansion, AeroFarms recently completed the build-out of an additional 25,000 square feet at its headquarters for new office space and more expansive R&D and Innovation Centers of Excellence.

In 2015, AeroFarms partnered closely with the City of Newark and the New Jersey Economic Development Authority (NJEDA), to relocate its headquarters to Newark from the Finger Lakes region of New York with the goal of creating more than 75 year-round jobs in the local community. Today, AeroFarms employs in Newark more than 150 team members, and the Company is delivering on its vision of not only serving the broader New York metro area but also serving as the global epicenter for large scale commercial indoor vertical farming and the latest in breakthrough proprietary technologies addressing some of the world’s most pressing agricultural challenges.

AeroFarms has been leading the way for innovation and technology breakthroughs since its inception and will continue to build on this legacy through continued R&D and infrastructure to maintain its leadership position as the Company scales. Earlier this week, AeroFarms Co-Founder and CEO David Rosenberg was recognized as a Top Technology Influencer by New Jersey media outlet ROI-NJ, further demonstrating the Company’s leadership in technology and innovation.

"New Jersey and Newark have been the perfect home for AeroFarms to recruit the best talent for horticulture, engineering, data science, operations, and food safety enabling us to reimagine agriculture in the Garden State," said Rosenberg. "We are scaling farms around the world, partnering closely with major multi-national retailers, and our newly expanded global headquarters will be a showcase for our transformative work and innovation that will further drive our mission to grow the best plants possible for the betterment of humanity."

AeroFarms has a long history of community involvement, including partnering with Ironbound Community Corporation and NJ Reentry Program, which offers career opportunities to those previously incarcerated. In addition, AeroFarms has made an impact with its Community Farms, working with partners such as Newark-based Philips Academy Charter School and their EcoSpaces program. The Company also partnered with the City of Jersey City and the World Economic Forum’s Healthy Cities and Communities initiative for the first-ever municipal indoor vertical farming program, consisting of ten vertical farms throughout Jersey City located in senior centers, schools, public housing complexes, and municipal buildings. The ten sites will grow 19,000 pounds of vegetables annually, using targeted aeroponics water mist and minimal electricity, and the food will be provided to the community for no cost.

About AeroFarms

Since 2004, AeroFarms has been leading the way for indoor vertical farming and championing transformational innovation for agriculture. On a mission to grow the best plants possible for the betterment of humanity, AeroFarms is a Certified B Corporation Company with global headquarters in Newark, New Jersey, United States. Named one of the World’s Most Innovative Companies by Fast Company two years in a row and one of TIME’s Best Inventions, AeroFarms patented, award-winning indoor vertical farming technology provides the perfect conditions for healthy plants to thrive, taking agriculture to a new level of precision, food safety, and productivity while using up to 95% less water and no pesticides versus traditional field farming. AeroFarms enables local production to safely grow all year round for its commercial retail brand that offers peak flavor always®. In addition, through its proprietary growing technology platform, AeroFarms has developed multi-year strategic partnerships ranging from government to major Fortune 500 companies to help uniquely solve agriculture supply chain needs. For additional information, visit: https://aerofarms.com/.

On March 26, 2021, AeroFarms announced a definitive business combination agreement with Spring Valley Acquisition Corp. (Nasdaq: SV). Upon the closing of the business combination, AeroFarms will become publicly traded on Nasdaq under the new ticker symbol "ARFM". Additional information about the transaction can be viewed here: https://aerofarms.com/investors/

No Offer or Solicitation

This press release does not constitute an offer to sell or a solicitation of an offer to buy, or the solicitation of any vote or approval in any jurisdiction in connection with a proposed potential business combination among Spring Valley and AeroFarms or any related transactions, nor shall there be any sale, issuance or transfer of securities in any jurisdiction where, or to any person to whom, such offer, solicitation or sale may be unlawful. Any offering of securities or solicitation of votes regarding the proposed transaction will be made only by means of a proxy statement/prospectus that complies with applicable rules and regulations promulgated under the Securities Act of 1933, as amended (the "Securities Act"), and Securities Exchange Act of 1934, as amended, or pursuant to an exemption from the Securities Act or in a transaction not subject to the registration requirements of the Securities Act.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as "believe," "may," "will," "estimate," "continue," "anticipate," "intend," "expect," "should," "would," "plan," "predict," "potential," "seem," "seek," "future," "outlook," and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this presentation, regarding Spring Valley’s proposed acquisition of AeroFarms, Spring Valley’s ability to consummate the transaction, the benefits of the transaction, and the combined company’s future financial performance, as well as the combined company’s strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward-looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of the respective management of AeroFarms and Spring Valley and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AeroFarms and Spring Valley. These forward-looking statements are subject to a number of risks and uncertainties, including changes in domestic and foreign business, market, financial, political, and legal conditions; the inability of the parties to successfully or timely consummate the proposed transaction, including the risk that any regulatory approvals are not obtained, are delayed or are subject to unanticipated conditions that could adversely affect the combined company or the expected benefits of the proposed transaction or that the approval of the stockholders of Spring Valley or AeroFarms is not obtained; failure to realize the anticipated benefits of the proposed transaction; risks relating to the uncertainty of the projected financial information with respect to AeroFarms; risks related to the expansion of AeroFarms’ business and the timing of expected business milestones; the effects of competition on AeroFarms’ business; the ability of Spring Valley or AeroFarms to issue equity or equity-linked securities or obtain debt financing in connection with the proposed transaction or in the future, and those factors discussed in Spring Valley’s final prospectus dated November 25, 2020 under the heading "Risk Factors," and other documents Spring Valley has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that neither Spring Valley nor AeroFarms presently knows, or that Spring Valley nor AeroFarms currently believe are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect Spring Valley’s and AeroFarms’ expectations, plans, or forecasts of future events and views as of the date of this press release. Spring Valley and AeroFarms anticipate that subsequent events and developments will cause Spring Valley’s and AeroFarms’ assessments to change. However, while Spring Valley and AeroFarms may elect to update these forward-looking statements at some point in the future, Spring Valley and AeroFarms specifically disclaim any obligation to do so. These forward-looking statements should not be relied upon as representing Spring Valley’s and AeroFarms’ assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210423005283/en/

Contacts

AeroFarms Contacts

Investor Relations:

Jeff Sonnek

ICR

Jeff.Sonnek@icrinc.com

1-646-277-1263

Media Relations:

Marc Oshima

AeroFarms

MarcOshima@AeroFarms.com

1-917-673-4602

10 New Trends In CEA In 2021 And Beyond

The world of controlled environment agriculture (CEA) is continuing to develop at an accelerated rate. In line with Agritecture’s mission “to accelerate climate-smart agriculture strategies,” we’ve decided to share our top predictions for the future of CEA for 2021 and beyond

22-04-2021 | Agritecture

The world of controlled environment agriculture (CEA) is continuing to develop at an accelerated rate. In line with Agritecture’s mission “to accelerate climate-smart agriculture strategies,” we’ve decided to share our top predictions for the future of CEA for 2021 and beyond.

This post is a follow-up to Agritecture’s post on the “10 New Trends In Hydroponics: What To Expect In 2017 And Beyond”.

Here are our top 10 predictions:

#1: Strawberries

In a sea of vertical farmers producing leafy greens, we’ve noticed sights shifting to strawberry production. While strawberries were initially difficult to produce given on-the-ground concerns like pests, fungal diseases, and weeding, growing vertically has allowed for easier harvesting and limited damage to the fruit. According to Agritecture’s Founder & CEO, Henry Gordon-Smith, “Strawberries are the hot new product for indoor growers because they can charge a lot for the best ones, they’re desired year-round, and the freshness and flavor are very noticeable,” being made more achievable by vertical farming.

Image sourced from Oishii

As of late last year, Driscoll’s and Plenty announced a partnership to grow strawberries indoors. We’re seeing increasing interest in high-quality strawberries with Oishii Berry’s $50m Series A fundraising for bee-assisted, carbon-neutral strawberry cultivation. In response to this growing interest, Agritecture’s Director of Operations, Yara Nagi, comments that “there is an interesting opportunity for growing strawberries hydroponically, especially for countries that import a majority of their strawberries. In order for strawberries to be exported to another country, they typically have to be harvested early. So, being able to grow them locally and in a controlled environment translates to better quality strawberries with a longer shelf-life. Other than the fact that growing strawberries hydroponically has become more and more efficient, the price point for strawberries can be relatively high when compared to other products grown in an indoor environment.”

#2: Breeding Seeds For Vertical Farms

As of recently, we’ve noticed a growing interest in breeding seeds for vertical farms. In February 2021, Kalera acquired Vindara Inc., a company developing non-GMO seeds for vertical indoor farms. Kasveista’s story of producing high-quality seeds and seedlings of open-source varieties for vertical farming similarly showcases this change in the industry.

Agritecture’s Lead Agronomist, David Ceaser, comments that “to date, crops grown in vertical farms have been grown using plant genetics developed for outdoor or greenhouse production. Environmental conditions in vertical farms are quite different from those environments, and so, plants respond differently. As genetics for vertical farms are developed, yields of current crops will improve greatly, and new crops will be successfully introduced into the vertical farm platform.”

#3: Fully Automated Vertical Farms

If you know anything about vertical farming, you know that labor is expensive and that this form of intensive agriculture requires highly skilled labor. According to Gordon-Smith, “new fully automated vertical farms are emerging” to respond to this labor challenge. He questions whether they will actually work, given that costs are high and the technology is new. Does this development in vertical farming mean fewer jobs or a more skilled workforce? Fully automated vertical farms are inevitable but will they pay off?

In September 2020, Agritecture’s new equipment partner, Urban Crop Solutions, launched their Module-X Automated Vertical Farm.

#4: Floating Farms

It’s always a struggle to find open space for agriculture in built-up urban areas. In recent years, we’ve seen abandoned and unused spaces converted into urban farms. So, why not take farming to the waters too? While it may not seem like the most sensible place to run a farm, it severely reduces food miles and pollution caused by the transportation of food.

Image sourced from Oceanix

Aqua Ark is a company that has taken to the waters to create Amphibious Homes that integrate floating wetlands for food production. Oceanix is a similar company that creates modular and self-sustaining communities on the water for people who want to live sustainably across the nexus of energy, water, food, and waste. The Floating Farm in Rotterdam is a project designed “for a future where rising sea levels mean that farmland is increasingly out of action due to flooding”.

To learn more, check out Agritecture Studios, where ‘floating cities’ is a challenging area within our inaugural cohort of architects.

#5: New Financing Options For CEA Startups

Financing for CEA operations is incredibly challenging. These capital-intensive projects require a robust business plan, strong management team, and access to capital to ensure on-time delivery of construction. Within the last year, we’ve seen SPACs be the latest means for private companies to raise capital. For startups, SPACs aren’t exactly the best route. “A new wave of investment and crowdfunding platforms are providing startups with alternative access to capital,” says Agritecture’s Director of Business Development, Jeffrey Landau.

Through Agritecture Designer, we have a partnership with several of these financing vehicles whereby our software users can access unique discounts and other benefits with these platforms.

#6: Labor Bottlenecks

According to Agritecture’s Director of Business Development, Jeffrey Landau, “the number of greenhouses and vertical farms is growing rapidly. Yet, the number of trained professionals with CEA operating experience is not keeping up with this increasing demand. Agritecture has been working with Cornell University through a National Science Foundation and Agriculture and Food Research Initiative grant to study solutions to this challenge.”

In production systems, workloads often arrive too quickly for the production process and labor to manage. Although seemingly a small problem, the inefficiencies brought about can create delays and result in higher production costs. As a result, we need a highly trained workforce and more workforce development programs for CEA growers.

#7: Singapore, The New Hub For Urban Agriculture

As a country that imports over 90% of its fresh produce and has severe land scarcity limiting its agricultural options, Singapore was in serious need of CEA. This changed when the Government launched the Sustainable Singapore Blueprint. The objective is to develop 200ha of high-rise greenery by 2050, incentivize developers to include urban farms in their developments, integrate farming in mixed-use districts, and encourage the adoption of technologically advanced infrastructure and smart systems. Today, they have the best funding and planning in the sector.

Image sourced from Citiponics

Citiponics is one of Singapore’s first hydroponic rooftop farms, located on top of a carpark, a structure that services almost every neighborhood in Singapore. Sustenir Agriculture is another company farming in Singapore, creating indoor vertical farms that can retrofit into existing buildings. Natsuki’s Garden is another example of successful CEA operations in Singapore. It’s a greenhouse in the center of the city, occupying reused space in a former schoolyard.

Learn more about Singapore’s efforts here. Additionally, Agritecture recently wrote about several other cities that are paving the way for urban agriculture to thrive here.

#8: Architecture

The global pandemic continues to reshape our relationship with food. Challenged by a lack of food access and the declining retail real estate market, individuals have taken a new interest in growing their own food, in the comfort of their own homes. This interest in bringing food production closer to people’s homes is empowering architects to transcend the boundaries of traditional food production to integrate urban agriculture and AgTech into cities. This innovative step will help solve food supply and food access quandaries globally.

Agritecture Studios is working to empower architects to continue on this mission and be key stakeholders in shaping our food-secure futures.

#9: “Alternative Products” x CEA

Image sourced from Smallhold

CEA has a rap for only growing leafy greens. However, several commercial growers have scaled up recently to produce a variety of other specialty crops, including Smallhold (mushrooms), We Are The New Farmers (spirulina), Ynsect (insects), and Pure Salmon (aquaculture).

AgFunderNews groups all of these producers under the category of “novel farming” in their annual funding reports. Per their most recent report, novel farming startups raised more than $1.3B in private investment in 2020, a 16x increase from 2015.

#10: Rise Of Energy Producing Commercial Greenhouses

The high energy use in controlled environment agricultural operations has been a cause for concern from the beginning. Commercial greenhouses, in particular, are reshaping how we think of energy by producing it themselves. ClearVue Technologies installed their energy-generating photovoltaic glazing panels on the world-first clear solar glass greenhouse. TSO Greenhouses is another AgriTech company with the primary objective of maximizing greenhouse light management. There is a lot more research happening here at the university level to investigate some of the tradeoffs between upfront cost, maintenance, energy production, and crop yields. Wide-spread commercial adoption will be multiple years away - but is it 3 years or 10+ years?

There’s no doubt that there’s more to come for the CEA industry. Here at Agritecture, we are constantly combing through the latest research papers, new technology releases, and industry trends to ensure that our clients and software users are able to get creative, build a competitive advantage, but still have realistic goals. Build your first urban farm model today, or get in touch with us to see how we help organizations around the world plan smarter through custom services.

Source and Photo Courtesy of Agritecture

USA: TEXAS - Iron Ox Breaks Ground On New Robotic Growing Facility In Lockhart

The state-of-the-art indoor facility will be fully dedicated to growing techniques harnessing the power of robotics and intelligence, enabling Iron Ox to grow sustainable, local produce to serve the Texas community

By FOX 7 Austin Digital Team

April 22, 2021

California-based company Iron Ox held a groundbreaking ceremony for its new Lockhart facility in partnership with the Economic Development Corporation of Lockhart. (City of Lockhart)

LOCKHART, Texas - A new robotic growing facility is expected to bring over 100 jobs to the city of Lockhart.

Iron Ox, a California-based company that specialized in robotics and AI-enabled farming with a mission to solve food insecurity, has begun construction on a 535,000 square-foot indoor hydroponic farm in the city.

Once completed, the farm, which sits on 25 acres of agricultural land, will significantly increase Iron Ox’s growing capacity for fresh, clean, and healthy herbs, leafy greens, berries, and vine crops, says the company. The state-of-the-art indoor facility will be fully dedicated to growing techniques harnessing the power of robotics and intelligence, enabling Iron Ox to grow sustainable, local produce to serve the Texas community.

Iron Ox, a California-based company that specialized in robotics and AI-enabled farming with a mission to solve food insecurity, has begun construction on a 535,000-square-foot indoor hydroponic farm in the city. (City of Lockhart)

The company says that Lockhart is an ideal location for greenhouse agriculture given its ample sunlight, central location near many cities, and it’s proximity to several great universities.

The indoor farm is expected to cost over $10 million to develop, says Iron Ox, with 275,000 square feet of the project anticipated to be completed by the end of this year and 260,000 square feet of the project anticipated to complete by the beginning of 2022. In total, the project will create over 100 jobs.

"The addition of Iron Ox to the Lockhart business community represents synergy between our city’s storied history in agriculture and our growing technology sector," said Lockhart Mayor Lew White in a release. "The food and beverage processing industry is one of four business sectors Lockhart has targeted in its 5-year economic growth plan. Our city’s unique advantages align perfectly with the needs of companies like Iron Ox."

Lockhart Mayor Lew White (left) and Iron Ox co-founder and CEO Brandon Alexander stand next to a concept drawing of the new Iron Ox facility being built in Lockhart. (City of Lockhart)

Iron Ox expects to complete their first harvest and to begin delivering sustainable, local produce to select chefs and retailers throughout Texas by the end of this year. It is anticipated that Lockhart’s hydroponic facility will grow thousands of pounds of fresh fruits and vegetables. Each crop type is cared for by Iron Ox’s expert growers and empowered by a robotic growing process ensuring year-round consistency, quality, and flavor says the company.

"We have made it our mission to address food security by developing autonomous greenhouses that grow a variety of local and consistently delicious food for everyone", said Iron Ox CEO and co-founder Brandon Alexander. "We’re excited to begin development of our newest indoor farm here in Lockhart—our first out-of-state facility. We look forward to further developing ties to the local community and to expanding our partnerships and distribution channels throughout the state of Texas."

Iron Ox co-founder and CEO Brandon Alexander addresses people at the groundbreaking ceremony of the new Iron Ox facility in Lockhart. (City of Lockhart)

Focused on sustainable, scalable food production for a changing climate and an ever-growing population, the Iron Ox process eases the growing pressure of food waste and labor scarcity by providing a stable supply of fresh, nutritious food for local communities, says the company.

Iron Ox says it designed its growing system around the sun, an approach that uses less energy than other modern forms of farming. Their hydroponic growing system uses 90% less water over traditional farming while growing 30 times the amount of crops per acre of land, allowing Iron Ox to deliver on its mission to increase access to premium produce for everyone.

Iron Ox currently operates two hydroponic farms located in Gilroy and San Carlos, California.

Affinor Growers To Enter Aruban Market With Circular Farming Systems

Affinor Growers Inc. is nearly ready to plant its first seedlings and begin showcasing its vision of sustainable agriculture for a ten-year period

Green Cash Crop Funds

Leafy Greens Growth

Affinor Growers Inc. is nearly ready to plant its first seedlings and begin showcasing its vision of sustainable agriculture for a ten-year period. The company recently announced its lease agreement for a 15,000-square foot greenhouse.

The land is located in Abbotsford, British Columbia, and is reportedly divided between a 15,000-square foot greenhouse operation and a 12,000-square foot composting facility. With the Canadian spring beginning its transition into summer, Affinor Growers Inc. is looking forward to planting its first crops in the greenhouse by July 2021.

The new greenhouse site

Cannabis cuts profit margins differences

According to CEO and founder Nick Brusatore, the greenhouse will use vertical production techniques to maximize space efficiency in the greenhouse. The company currently plans to grow strawberries under one greenhouse bay, romaine lettuce under another bay, and eventually have a craft cannabis operation in another section. Affinor Growers is currently building out and getting ready to submit its craft cannabis license application to Health Canada but is content to begin with food crops for the time being. As Nick explains, his main goal in growing cannabis is to showcase sustainable production techniques and to increase the profitability of the entire system.

“We want to sustain our strawberry and romaine production, but food crops typically have lower margins. The high price of cannabis will allow us to grow even more strawberries and romaine lettuce by washing out the differences between profit margins. That way, we can deliver our products to the market at a good price and high quality.”

Greenhouse features

Continuing in its systems approach to agriculture, Affinor Growers Inc. also plans to reduce waste by composting organic materials and remediating its growing material. Altogether, the greenhouse and composting operation will allow the company to pursue its vision of high-quality, low-cost food production in a circular manner.

The greenhouse will also be completely automated, allowing the company to reduce labor costs by eliminating the need to move plants and materials manually. As Nick explains, the time between removing a crop from the greenhouse and replacing it with a new one takes a few minutes, as the plants are cut in the cooler and the soil replanted with new seedlings before being sent back into the greenhouse.

Vertically stacked cannabis

Entering Aruban market

While the 15,000-square foot greenhouse is located in British Columbia, the company is planning to take its vision into new markets and will begin with Aruba, according to Nick.

Nick explained that after having worked with the people and incorporating Vertical Designs Aruba VBA along with understanding the Country and Government needs after six years learning what is needed to mass-produce plant tissue, he has become attached to the country and has seen the need for circular farming systems. Affinor Growers Inc. will reportedly be building a farm near San Nicholas, in the southern region of Aruba.

Affinor Growers Inc. wants to work with Arubans to provide good jobs and economic benefits to the area. If all goes as Nick hopes, this project and others like it could increase tourism on Aruba’s southern side. Nick also explained that cannabis production is a possibility pending success in licensing application once the country’s laws and licensing are complete, this strategic move that will benefit agricultural capabilities in the long-term through the construction of infrastructure.

“We figured we would grow cannabis because the demand s high, so we can easily build-out. As the cannabis demand settles down globally over the next 5-10 years, the industry will have paid for massive food infrastructure without the government or taxpayers paying for it. In Aruba, we’re going to take a lot of that profit to create food infrastructure,” says Nick.

For more information:

Nick Brusatore, Founder and CEO

Affinor Growers

Publication date: Thu 22 Apr 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

Green Bronx Machine’s New TV Series on PBS/WNET In Partnership With NYC Schools

Stay tuned for more episodes in the coming weeks, with characters like Bobby the Bear, Sammy the Shark, and General Sequoia! And a very special episode in which the one and only Mr. Met teaches me how to dance

I’m so proud of Green Bronx Machine’s new TV series on PBS/WNET in partnership with NYC Schools. In fact, the New York State Education Department has been showcasing our content. Even the new Chancellor of New York City Department of Education has seen the show! Have you?

WATCH THE EPISODES!

Stay tuned for more episodes in the coming weeks, with characters like Bobby the Bear, Sammy the Shark, and General Sequoia! And a very special episode in which the one and only Mr. Met teaches me how to dance!

Every episode has a Big Word Alert, and we’d love to hear yours — give us some feedback about the show so far.

I’m excited to read your thoughts, and I’m even more excited for you to watch the new episodes on April 28th, May 5th, May 10th, and May 11th!

With love, your pal,

Brief: UAE’s Madar Farms Partners With UK Vertical Farming Startup IGS

UK vertical farming tech provider Intelligent Growth Solutions (IGS) has partnered with Madar Farms, which cultivates a variety of indoor crops with the objective of enhancing food security in the Middle East

April 22, 2021

UK vertical farming tech provider Intelligent Growth Solutions (IGS) has partnered with Madar Farms, which cultivates a variety of indoor crops with the objective of enhancing food security in the Middle East. [Disclosure: IGS has received investment from AgFunder, which is AFN‘s parent company.]

The Abu Dhabi-based startup aims to address local water scarcity by using IGS’ plug-and-play vertical farming platform, allowing it to grow leafy greens and herbs before expanding to other crop types.

Madar Farms is installing five of IGS’ Growth Towers, providing a growing space of 1,500 square meters. with the capacity to produce up to 30 tons of crop each year.

Why it matters:

Much of the Middle East experiences high daytime temperatures and little rain, making it a challenging environment for crop cultivation. Indoor farming has emerged as a possible solution for increasing plant production in the region without overburdening an already severely limited water supply.

Covid-19 and shifting regional relations have put agrifoodtech top of mind for the UAE – read more here

INTELLIGENT GROWTH SOLUTIONS - BEST LOGO .png year, the UAE announced a $100 million investment in indoor farming to tackle the fact that it imports 80% of the food that residents consume. Madar Farms was among four startups included in the project alongside US vertical farm operator AeroFarms – which just announced a SPAC deal that’ll see it go public – Dubai-based fertilizer firm RNZ, and US irrigation provider Responsive Drip.