Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Breakthrough Biological Innovation – The Key To Profitable And Sustainable Vertical Farming

Vertical farming, first conceptualized in the late ’90s, is premised on the idea of “a farm within a skyscraper” where environmental conditions, nutrition, and lighting can be optimized

Algae-Based Biostimulants Improve Growth Velocity, Yield, And Quality

In Hydroponic And Aeroponic Indoor Farming

The rapid growth of urban agglomerations across the planet presents serious food security challenges. The US Census Bureau estimated that 80% of Americans lived in cities in 2015. Vertical farming is generally regarded as the most promising approach to supplying cities with fresh leafy greens, vegetables, and small fruits, but skeptics point out that we still have a long way to go before indoor “plant factories” can reach the scale and efficiencies that would make them a truly sustainable source of nutrition for millions of people.

Vertical farming, first conceptualized in the late ’90s, is premised on the idea of “a farm within a skyscraper” where environmental conditions, nutrition, and lighting can be optimized. Growing crops in layers instead of rows, usually employing hydroponics, is a concept that has seduced investors globally. We all see the advantages of growing our food locally - in shipping containers, in warehouses and maybe even in skyscrapers to reduce the need for trans-continental shipping, to generate employment and limit pesticide and chemical-input intensive outdoor farming.

The major barrier to the upscale of vertical farming is economic sustainability and this is mainly related to the energy costs associated with artificial lighting. Can local, vertically grown produce be sold affordably? Despite remarkable technological advances in lighting technology and automation and the availability of renewable energy, there is still an urgent need to develop innovative solutions to get vertical farming over the “tipping point” from a promising food security approach and into a real, long- term and indispensable part of urban food systems.

Doing More with Less

How can vertical farms use less energy and produce more and better? In Chicago, Back of the Yards Algae Sciences, a sustainable industrial biotechnology company, has been working on a simple but elegant solution; grow in less time. After almost 2 years of intensive research, they just published a paper demonstrating that an algae-derived biostimulant (a formulated biological material for improving plant growth) shortened the time between planting and harvesting hydroponically grown red leaf and green leaf lettuce by six days. Since traditionally farmed, outdoor-gown lettuce is currently three-to-five times less expensive to grow than vertically farmed lettuce, a shortened growing period may have significant implications for the economic sustainability of vertical farming as it reduces energy inputs and labor costs.

This breakthrough research was based on the concept of trying to translate the amazing interaction between plants and their soil environments into hydroponic and aeroponic systems. The team was already developing a proprietary Spirulina (blue-green algae) extract for the food and alternative protein markets and began to explore whether phycocyanin, a protein-pigment complex that acts as a key regulator of photosynthesis in blue-green algae, could play a similar role in plants growth.

A series of experiments produced evidence that a phycocyanin-rich Spirulina extract worked as a biostimulant in hydroponics, improving growth, yield, and quality of lettuce while cutting maturation time by 6 days-or 21%-compared to control groups. The faster-growing treatment groups also produced 12.5% more lettuce and were 22% better at photosynthesis than control groups. The treated lettuce was more robust; a mean increase of 2.6cm in leaf length and 2.2cm in basal stem diameter compared to the untreated lettuce was observed and. In the shelf-life test, wilting was seen 2-3 days after it was observed in control groups.

Treatment groups were brighter green (specifically 17% brighter and 75% greener) and better tasting. They had firmer texture, a stronger aroma, and more intense flavor than the untreated group, according to an independent certification company. Using analytical chemistry techniques, the team also examined nutrient content by comparing flavonoid-antioxidant levels in control and experimental groups. Their findings suggested experimental groups were more nutrient-rich, where one flavonoid, Quercetin, had a mean increase of 30% in the treated lettuce.

What it Means

Back of the Yards Algae Sciences was working to cut growing time in hydroponically grown lettuce using a biostimulant to give vertical farmers a new avenue for reducing energy inputs. They were successful and also happened to find that Spirulina extract biostimulants improved color, vigor, nutrient content, and preservation. These product quality findings will support vertical farming in improving profitability by ensuring better selling prices. But perhaps the most exciting aspect of developing natural biostimulants specifically for vertical farming is the possibility to extend the indoor farming sector into row crops as food staples (wheat, soy, corn), ensuring not only better and more secure food supplies for urban populations, but also protecting the environment.

This research is available at: https://www.preprints.org/manuscript/202011.0354/v1

For further information – www.algaesciences.com

Tobias Speaks To The Importance His Organization Places On Transparency And Visionary Thinking

To kick off Season 2 in grand style, I'm excited to share my conversation with Tobias Peggs, CEO of Square Roots, an indoor urban farming company that connects people in cities to local, real food. In this episode, Harry and Tobias discuss the growing demand for a more efficient global food system

THIS WEEK'S EPISODE

To kick off Season 2 in grand style, I'm excited to share my conversation with Tobias Peggs, CEO of Square Roots, an indoor urban farming company that connects people in cities to local, real food. In this episode, Harry and Tobias discuss the growing demand for a more efficient global food system.

Tobias speaks to the importance his organization places on transparency and visionary thinking as well as future initiatives he and his team are currently planning.

Ceres combines smart greenhouse design with customized climate control technology to build sustainable growing environments for year-round production. They work with their customers and clients every step of the way, from helping to secure funding to providing growing data. Whether you're a commercial entrepreneur, an educator, or someone looking for a rewarding hobby, visit ceresgreenhousesolutions.com to get started on your greenhouse goals.

This week's recap was compiled by our newest team member Daniel Dray, an environmental engineer living in New York City with a passion for urban agriculture. He'll be taking over the reigns of the newsletter as well.

Daniel became interested in the vertical farming industry early in the Covid-19 pandemic when access to fresh and healthy food was challenged. To make a positive impact on the world, Daniel hopes to contribute to the local food movement through the vertical farming industry.

The Top 5 Hydroponic Growing Mediums You Should Use

Hydroponics is a farming method that doesn’t require soil to grow plants or foods. Soil is not used in this form of farming. Other hydroponic growing mediums are used instead

Hydroponics is a farming method that doesn’t require soil to grow plants or foods. Soil is not used in this form of farming. Other hydroponic growing mediums are used instead. This article is going to cover the five best hydroponic growing mediums to use for your garden.

Perlite

Perlite is a volcanic rock that is exposed to high heat to turn it into a lightweight, porous medium. You can mix perlite in with other mediums or use it on its own. This porous medium is well known for its high water retention ability, and it is effective at retaining oxygen due to its porousness. The downside to perlite is that it is lightweight, which can cause it to float in high water settings like with ebb-and-flow systems. It’s better to use perlite in hydroponic systems with draining systems.

Coco Coir

Coco coir is one of the hydroponic growing mediums that has become more popular to use. Coco coir is grounded coconut husks and is a reusable medium, which helps create less waste. This medium effectively retains water to help hydrate your plants and is a great medium for beginners since it looks like soil. However, it isn’t soil and still requires nutrients and a controlled pH level.

Clay Pellets

Clay pellets are another popular hydroponic growing medium because of its porous material. A benefit of using clay pellets is that they are pH neutral, and they quickly soak up excess moisture. Clay pellets are reusable as long as you clean them between every growth cycle. It’s best to use clay pellets when you’re having issues with draining, but be careful clay pellets can drain and dry very quickly, which may dry out your roots.

Starter Plugs

Starter plugs are a newer hydroponic growing medium that is made from organic compost. This sponge medium is useful when you are growing seedlings or cloning, so you can later incorporate them into your hydroponic systems.

Rockwool

Many hydroponic growers use rockwool as their go-to medium. Rockwool is a melted rock that’s spun to create thin, long fibers, which are pressed into a cube shape. You will have to balance its pH before using it by soaking it in pH balanced water. Since it retains water so effectively, you will have to make sure it doesn’t oversaturate your plants. It’s an effective medium to use to ensure your plants get a majority of the necessary nutrients. However, it isn’t a biodegradable medium, and you do have to balance the pH before each use.

Knowing which hydroponic growing mediums to use can be a tough choice since there are so many options available. If you want to learn more about innovative farming methods, sign up for our microgreens class to learn more! Or, you can become a patron member to See Behind the Greens, where you’ll witness how food can be grown in closets, kitchen counters, living rooms, and more so you can learn how to do it too!

#hydroponicgrowingmedium #hydroponicgrowingsubstrate #bestmediatogrow #growmedia #rockwool #starterplugs #cococoir #perlite #claypellets #growingmedium #growmedium #growsubstrate

INTERVIEW AND PODCAST: A Bigger Slice of The Pie – The Growth of Urban Agritech

Having been closely embedded in the urban agritech sector for many years, Mark’s perspective carries with it a wealth of global exposure and experience. He is, furthermore, committed to delivering a greater profile for the UK in this market

EDITION 4 Mark Horler

Chair of UKUAT

Having been closely embedded in the urban agritech sector for many years, Mark’s perspective carries with it a wealth of global exposure and experience. He is, furthermore, committed to delivering a greater profile for the UK in this market. He talks to us about the part the UK has to play in the expansion of agritech across both a local and global context, considering the opportunities being brought to bear for this emerging agricultural approach. We discuss the merits of competition versus collaboration and the ways in which the two approaches can be respectively utilised to increase extent to which urban agritech can thrive as part of the wider agricultural ecosystem.

Interview

Q) Can you share some background to the founding vision for UKUAT?

I previously worked with an international organisation in the vertical farming space and it led me to conclude that we needed organisations which reflect overarching principles but are more ‘on the ground’ in terms of how they operate.

UKUAT started three and half years ago with five people on the phone informally keeping each other updated about what we were doing, sharing events and talking about how we could collaborate.

It grew organically and became an informal organization with regular meetings. This year we became a formalised non-profit organisation pursuing our goals more seriously. UKUAT is based around familiar principles of: engaging with policy; with education; research and expertise; and collaboration across the urban agritech community. We have approximately 60 members: half are organisational members, which comprises commercial organisations like IGS, universities and research groups, and the other half are individuals such as academics, policy developers and those really interested in this space.

Q) You have been involved in the urban agritech sector for several years. How has sector interest grown, as well as broader consumer interest?

There is growing interest in the sector, in fact it is growing pretty quickly now. It was slower in the UK initially but there are a bunch of drivers moving it forward now: Brexit, climate change and food resilience more generally, so it has begun to accelerate rapidly.

From a consumer perspective, the topic which seems to be driving everything is localism and even hyper-localism. People are interested in this and like the ideas of transparency and sustainability. Knowing where your food comes from is driving interest in agritech solutions, the key ones being vertical farming (based more on volume) and rooftop greenhouse approach (based more on how and where produce is being delivered).

Q) What are the challenges facing the urban agritech sector? And what are the opportunities?

Everything depends on context, geographical placement and above all else what you are doing it for – be that commercial, educational, or social value. This drives how your whole business or organization will operate. There are numerous challenges such as high CAPEX and OPEX as well as policy questions around planning and subsidies and how those interact with your company or project. However, the industry is aware of these challenges and is really starting to address them. As a result, we believe there will be an explosion of opportunity to really expand this industry out quickly.

“We believe there will be an explosion of opportunity to really expand this industry out pretty quickly.”

Q) Which will further the development of the CEA and urban agritech industries in your opinion – greater collaboration or greater competition?

It is a bit of both. I prefer to refer to it like a ‘pie’. When greater competition is introduced, there is a struggle to gain a greater proportion of the pie. The role of the UKUAT, and indeed greater collaboration, is to make that pie bigger overall.

Cooperation happens in a pre-competitive space in areas such as research, education and policy, allowing everybody to move forward together. This is necessary, otherwise you end up with people reinventing the wheel and addressing same challenges over and over again. Collaboration allows people to move forward together in many areas, but still compete on price, product, branding, IP – whatever it may be – but they just do that with a raised baseline from which to operate.

“Collaboration allows people to move forward together in many areas, but still compete … with a raised base line with which to operate.”

Q) Should there be more discussion and co-working between urban and town planners and agritech innovators?

Yes, this is a critical area and one we are working hard on. We want to end up with a typology of use classes which will work for urban and town planners. They want to know easily what requirements and resources will be needed, what solutions might look like and then where to put them. Their job is ultimately to make a reasonable or reasoned decision about whether to approve or propose fitting something in, and there’s work we’re doing to support this.

That sort of typology could be applicable in a variety of scenarios including a rooftop farm, a new build or a retrofit, façade or whatever it might be; what power requirements it might have for example. Having an awareness of all these elements would then allow planners to make informed decisions about how a scheme would work. This would then end up (ideally) with a smarter system where a company will go and talk to a town planner or these types of solutions would be considered earlier if a city council has a site on which it wants to build. Developers would then be able to consider these too and include urban agritech more comfortably.

Q) What is the role of the retailer in the wider adoption of urban agritech approaches? What is the role of the retailer in the wider adoption of urban agritech approaches?

With the retailer, it is a question of scale. There are two ways of doing urban agriculture. There is small scale, hyper-local growing microgreens for a local restaurant or shop, and then at the other end of the scale, you have really big vertical farms in the sort of peri-urban space which you would site next to a distribution center so it can go straight into the logistical distribution for a large retailer. Either way, the goal of any produce grower is to deliver their product to a consumer.

Q) In the UK how do we compare to other countries in our approach to adopting and developing urban agri approaches? Are there other countries or regions we can be learning from?

There are two ends of a scale here. At one end you might see Singapore or China where the drive is coming from central government which dedicates time and money to move it forward. However, the weakness of that is approach that it tends to be a bit heavy on mandating exactly what happens and can become a bit inflexible.

On the other end of the scale, you have the US free-market approach which is flexible and has a profusion of people looking into the feasibility of this kind of approach. However, the risk here is that if these innovative growing schemes struggle to receive wider support and are only operational in the free market, it becomes very challenging to compete with other, more established, forms of food production.

I think the challenge in the UK is to figure out a ‘best of both worlds’ approach. If we are going to put public money into this sort of technology, we need to ensure that it allows for flexibility and innovation which the free market is the ideal background for. However, we simultaneously need to support it adequately so innovative forms of agritech can get a foothold before we can start looking at how we use this as part of a wider food system to achieve certain societal goals.

It is trying to find the sweet spot.

“We need to support it adequately… and start looking at how we use this as part of a wider food system to achieve certain societal goals.”

Q) You are also part of the FarmTech Society, which is based in Belgium. How is it working with organisations and governments to move forward greater agricultural and food production methods and approaches?

The FarmTech Society (FTS) is based in Brussels nominally but we have people in Europe and US (www.farmtechsociety.org). It works on three core principles of education, standardisation and policy. It takes a strategic view and looks at the really big questions for agritech. For example, on the standardisation point it has developed a partnership with Global GAP to look at sustainability standards across the industry. In education, it is working on a project with Erasmus Plus to develop an accreditation scheme.

These wider overarching principles are developed at an international level and organisations such as UKUAT look to implement or adapt them at local level. At FTS, we want to create a network of networks. The organisation’s aim is to mirror place-based context in each individual region and feed that up into a wider process through which we can generate discussion and drive policy or industry change to feedback down to the regional level.

“With the FarmTech Society we want to create a network of networks.”

Q) What role does education have to play in furthering the wider adoption of urban agritech?

You could hardly think of a more important thing. We want to be involved at a primary and secondary level and want to be part of STEM adoption. We want to share the wonder of this technology and show kids how food is and can be produced. Green Bronx Machine in New York, a school garden programme which uses urban agriculture to connect pupils with where their food comes from, is an example of where this has been done really well. Beyond schools there are two specific areas of educational development: vocational training or the higher education route. Both are hugely important and as an industry set to expand over time, we will need a workforce of people with demonstrable and certified skills that allow them to operate those technologies. Within higher education the core skills going forward will need to focus on technical, management and strategic level, research or developing new technologies.

It is also vitally important to educate consumers, policymakers, and those in the wider world. This is a very important communications exercise as you ultimately want people to know that these emerging technologies are safe and they can trust them. Beyond that, we want consumers to see the benefits that a better food experience can bring.

For more info go to: https://www.ukuat.org/

GUEST BIO

Mark Horler

Chair of UKUAT

Mark has been involved in the Vertical Farming industry for around eight years. He is the Founder & Chairman of UK Urban AgriTech (UKUAT), bringing together the leading companies, universities and individuals in the UK urban agritech industry. He is also Communications Manager at The FarmTech Society, the Co-Founder of The Soya Project, and does freelance consulting work across the industry.

In his work he has dealt extensively with industry standardisation, sustainability certification, vertical farming education and vertical farming policy. His expertise is in building networks and associations that maximise value for their members, and for the industry as a whole.

Mark’s primary interest is in taking a systemic overview of how vertical farming can be integrated with other systems, to deliver on its promises of regenerative food production and resilient societies.

Heliospectra And University of Tokyo Partnership To Boost Indoor Tomato Production

Not unlike what’s happening in the U.S., the average age of Japanese farmers is increasing, and with younger generations migrating to cities, traditional farming is facing a crisis

Posted by Brian Sparks

November 11, 2020

Japan already has approximately 200 lettuce factories using artificial light, and that number is expected to double by 2025. However, to date, plant factories have been unsuccessful in cultivating light-hungry vine crops such as tomatoes in indoor artificial light.

Heliospectra AB, a world leader in intelligent lighting technology for greenhouse and controlled plant growth environments, has formed a collaboration with the Institute for Sustainable Agro-ecosystem Services (ISAS) at the University of Tokyo. In an effort to redefine and unleash the potential of indoor tomato production, this is a joint research project with the University’s Institute for Sustainable Agro-ecosystem Services (ISAS), in collaboration with Associate Professor Wataru Yamori at the Agricultural Biology and Biogeochemistry Group, and Heliospectra Japan.

Not unlike what’s happening in the U.S., the average age of Japanese farmers is increasing, and with younger generations migrating to cities, traditional farming is facing a crisis. This is forcing the country to investigate new ways to produce food. Plant factories are scaling to meet consumer food demand, mainly in vegetable cultivation in both solar and artificial light environments, and the industry is growing. Japan already has approximately 200 lettuce factories using artificial light, and that number is expected to double by 2025. However, to date, plant factories have been unsuccessful in cultivating light-hungry vine crops such as tomatoes in indoor artificial light.

Working together, Heliospectra and ISAS are looking to build a business model for Japan’s plant factories and Plant Factory with Artificial Lighting (PFAL) organizations for indoor tomato cultivation. In the University lab, the professor and his students will be using Heliospectra’s MITRA linear. Designed by growers for growers, MITRA is ideal for high-light crops, with high-intensity light output and electrical efficacy of up to 2.8 µmol/J.

“We are very excited to be a part of this research together with Dr. Yamori and the ISAS at the University of Tokyo. Over the years, Heliospectra has conducted research on light’s effect on tomatoes in indoor facilities with great results,” says Yasuhiro Suzuki, General Manager of Heliospectra Japan. “We now look forward to further expanding our knowledge and developing more effective indoor cultivation of tomatoes for commercial use. We look forward to collaborating with the university and sharing with the world our knowledge of growing tomatoes indoors.”

The collaboration presents an opportunity for growing healthy, nutritious vine crops indoors on a global scale, and it is a strategically important installation for Heliospectra Japan as it builds its local market presence.

Brian Sparks is senior editor of Greenhouse Grower and editor of Greenhouse Grower Technology. See all author stories here.

Introducing Our New Website!

We can bring farms to almost any space, including your home and office! Check out our new Home Farm and Office Farm offerings showcased on our website. You can also find out about how we started out and keep up to date with our blogs and events!

Due to the lockdown we've wound down farm operations for the time being, but we've been using the time to work on a number of exciting developments. 🥁 One of those is a new and improved website, which you can a first look at here!

We can bring farms to almost any space, including your home and office! Check out our new Home Farm and Office Farm offerings showcased on our website. You can also find out about how we started out and keep up to date with our blogs and events!

Click here to explore our new site.

New OEM -Agreement For Shelf-And-Lighting Panels For Industrial Vertical Farming

The strategic partnership between Senmatic and LED iBond is based on Senmatic’s in-depth knowledge of LED grow lights and software solutions for industrial vertical farming and LED iBond’s unique LED technology platform

Danish-based companies Senmatic and LED iBond International have entered a strategic OEM-partnership for delivery of shelves with built-in grow light to advance the industrial vertical farming industry – a production method globally foreseen to gain currency among producers in the future.

Senmatic and LED iBond International have entered a strategic partnership for OEM delivery of shelves with built-in grow light to be included in Senmatic’s offering of industrial vertical farming solutions. In vertical farming you utilize the cubic meters by planting in layers rather than the square meters, as traditionally done with row upon row of plants and crops.

The new vertical farming shelves are based on LED iBond’s patented lighting fixture, which combines superior cooling characteristics and minimal space requirements with a high carrying capacity.

Photo by: LED iBond

The strategic partnership between Senmatic and LED iBond is based on Senmatic’s in-depth knowledge of LED grow lights and software solutions for industrial vertical farming and LED iBond’s unique LED technology platform.

- We have more than 40 years of experience with indoor plant production. We will combine LED iBond’s super-slim and energy-efficient shelf-and-lighting panels with our controllers and software to create a multifunctional vertical farming solution with best-in-class growth conditions for industrial indoor horticulture. This new partnership with LED iBond will further contribute to our growth in the vertical farming market, so we are very pleased indeed for this opportunity to join forces with LED iBond, says Mads Nychel, CEO at Senmatic.

The joint vertical farming offering is planned to launch at the end of Q4 2020.

Autogrow Challenges Other Industry Players To Publish APIs

“To date, large industry players have not publicly published APIs’, but our argument is that it’s your data - you should be able to do what you want with it,” says Chief Technology Officer Jonathan Morgan

Autogrow is calling for more public APIs (Application Programming Interface), giving increased access for growers to their own data, and fostering faster innovation in the Controlled Environment Agriculture industry.

“To date, large industry players have not publicly published APIs’, but our argument is that it’s your data - you should be able to do what you want with it,” says Chief Technology Officer Jonathan Morgan.

“There can be a protectionist approach to development to dissuade people from building their own versions or integrating other products. But you will never keep up with all the customer requests or in the same timeframe as the 15 other companies working on the same improvements in the market. Access equals innovation - simple as that.”

Autogrow's FarmRoad has launched their public API on a new Developer Portal which is product agnostic and welcomes all industry players. This will allow growers to use the platform to build a ‘best of breed’ solution for their operation, no matter what their current technology providers are.

“You don’t have to rip and replace your existing technology. You just need to use an API to connect it to FarmRoad and then see all your information in one place. You can also give third parties secure access to specific areas of your information – keeping control of what you want them to see.”

“As innovation accelerates it creates a unique challenge of being able to centralize all of your data in one place – regardless of the source. We’ve been offering public APIs for over three years and are certainly the leaders when it comes to cloud technology,” notes Mr. Morgan.

Initially, the FarmRoad Developer Portal will give access to:

Measurements: Over 39 different measurement data types related to the environment and crop registration.

Events: Capturing key events or notes for example pest detection or spray regimes.

Farms/compartments/sectors: Get the full picture from different areas of the farm. Giving comparative studies, trends or with permission-based access.

“This is just the beginning for what FarmRoad will be able to offer. With API availability, growers will be able to create their own custom applications alongside the work we are doing. It’s a great developer community which can evolve and scale as businesses and the industry changes.”

For more information on the FarmRoad Developer Portal - https://farmroad.io/developer

For more information on the API documentation - https://developer.farmroad.io/

For more information on Yield Prediction by FarmRoad - https://www.farmroad.io/

11 Nov 2020

Hi-Tech Vertical Farm Could Produce A Third of Leafy Greens And Create 30 Jobs

Wayne Furbert, the Cabinet Office minister, said the state-of-the-art farm could also reduce the cost of food production and create up to 30 jobs

November 13, 2020

Wayne Furbert, the Minister for the Cabinet Office (Photograph by Blaire Simmons)

A vertical farm could produce almost one-third of Bermuda’s demand for leafy greens – the equivalent of 200 acres of farmland, it was revealed today.

Wayne Furbert, the Cabinet Office minister, said the state-of-the-art farm could also reduce the cost of food production and create up to 30 jobs.

Mr. Furbert added the Government was close to finalizing plans for the development and finance for the project.

He said: “Vertical farming will utilize the latest technology to grow leafy greens in a controlled environment.”

“The aim of this venture is to reduce the cost of food to the general public, reduce the reliance on imported leafy greens, and boost employment in Bermuda.”

Vertical farming involves the production of crops in a controlled environment, usually indoors.

It also uses techniques such as hydroponics instead of soil and the crops grow in stacked layers.

Mr. Furbert said the hi-tech farm would be “environmentally sound”, use 95 percent less water than conventional production, and no pesticides.

He added: “A key component of this project, and in line with the Government’s vision to create a nation of owners, will be to allow Bermudians to invest in this entity so that they can enjoy the benefits of ownership of local food production.”

According to environmental studies, there are about 760 acres of land available for farming in Bermuda, although only 365 were being actively worked.

The plans will be presented to the Cabinet Committee for Economic Development next week.

Mr. Furbert also fleshed out plans for a proposed fish processing center, a drive to attract technology companies to the island, and a bid to expand the intellectual property industry.

He said: “The shoreside fisheries complex will be the operational center of a new, long-anticipated enterprise that will transform and reposition Bermuda’s commercial fisheries sector.

“It will be a purpose-built facility where fish will be cleaned and processed for sale to the Bermuda market.

“This facility is just the start of our ambitions and while targeted towards local consumption, it has the potential to grow into international exports.”

Mr. Furbert said that the aim of technology companies was to “create a hub wherein technology companies can set up and conduct their business right here in Bermuda in a business-friendly environment”.

He added: “We have recently been engaged in very fruitful discussions with global tech companies about relocating to Bermuda.”

Mr. Furbert said that Government was examining how to overhaul legislation “to remove bureaucracy and red tape”.

He highlighted that changes had already meant the arrival of 58 technology workers from Pakistan.

Mr. Furbert said: “They are part of a very large and successful technology company and it is our hope that this will be the genesis of their setting up business long-term in Bermuda and training and hiring Bermudians.”

He added further amendments to legislation would make Bermuda an attractive location for international companies that wanted to register trademarks and copyrights.

Mr. Furbert said: “We have adopted a phased approach to overhauling our intellectual property legislation and by the Spring of 2021 we shall have achieved significant enhancements in this realm.

“These are just a few of the major initiatives the Cabinet Ministry is forging ahead with in the next year or so, and I am very optimistic that we shall succeed in generating positive economic activity as a result.”

WEBINAR: The Importance of Light Quality In CEA Systems

Spectrum has an important impact on plant growth, morphology, and development. Plants have evolved a sophisticated photoreceptor system capable of perceiving small changes on the light spectrum

Date: November 19, 2020

Time: 2 p.m. - 3 p.m. EDT

Presented by: Ricardo Hernandez (NCSU)

Click Here to Register

Spectrum has an important impact on plant growth, morphology, and development. Plants have evolved a sophisticated photoreceptor system capable of perceiving small changes on the light spectrum. Plants use spectral changes as information to adapt and increase survival and reproduction. Therefore, by understanding plant-light interactions, we are able to use light as a tool to change plant responses to meet human needs. This presentation will outline the importance of light quality and provide examples of the commercial applicability of spectral manipulation.

Dr. Ricardo Hernandez is an assistant professor at North Carolina State University focused on Controlled Environment Agriculture research and teaching (https://ceh.cals.ncsu.edu/). He has worked in the field of spectral optimization for over 10 years. In addition to his academic appointment, Ricardo is also a co-founder of two start-ups focused on the use of controlled environment technology and strategies to produce young plants.

Special thanks to our Industry partners

Join today

If you have any questions or would like to know more about GLASE, please contact its executive director Erico Mattos at em796@cornell.edu

Advancing Indoor Farming In Asia – Intelligent Growth Solutions Ltd - Interview

Ahead of the virtual Asia-Pacific Agri-Food Innovation Summit, we caught up with David Farquhar, CEO at IGS about advancing indoor farming systems in Asia, new projects on the horizon, and working with governments to scale up controlled environment agriculture.

Ahead of the virtual Asia-Pacific Agri-Food Innovation Summit, we caught up with David Farquhar, CEO at IGS about advancing indoor farming systems in Asia, new projects on the horizon, and working with governments to scale up controlled environment agriculture.

FIND OUT MORE

David Farquhar, CEO, IGS

What role can indoor farming play in delivering greater sustainability and resilience to Asia’s urban food systems, especially post-COVID?

The resilience of food supply chains has been tested to the limit throughout 2020 in the wake of COVID-19 and has brought very quickly to the fore the food security challenges Asia and most other regions will face with climate change. Now is the time to be focusing very clearly on local (urban and peri-urban) food production to ensure greater self-sufficiency and less reliance on imports. Greater adoption of agricultural technologies is imperative to ensure optimum use of available space, be it urban, industrial or uncultivatable land, all of these are spaces that can be used to introduce more indoor farming methods. As part of the agricultural ecosystem, this will deliver a far more controlled and sustainable method for producing fresh, homegrown crops, probably amounting to something like 25-30% of a fully balanced diet.

Does the APAC market offer particular opportunities or challenges for scaling urban/indoor farming, compared to other global markets? What particular projects is IGS excited about in this region? What progress has already been made?

Asia-Pacific has a very different climate across its expanse, which makes it hard to compare easily with other regions. The population in these regions is significant and growing substantially which puts food security very high on the agenda, highlighting the importance of finding new ways to produce and complement the existing agricultural ecosystem. In addition to growing populations, land and water scarcity are also becoming significant in certain geographies and this makes indoor farming – which requires a much smaller footprint and utilizes a fraction of the water typically required to produce crops – a very interesting proposition. This has led to some exciting collaborations between commercial and government bodies. For example, in Singapore and Hong Kong, where land is very scarce and expensive, there is a demand for alternative options of producing food. The appetite for indoor and alternative growing methods is highlighted in Singapore’s 30 by 30 initiative, aiming to reduce import reliance and expand food self-sustainability.

In terms of exciting projects, we are delighted to be working with Eden Towers (https://eden-towers.com/) a very ambitious new entrant to the national and regional food chains that are re-localizing across APAC. Based in Jakarta and privately financed, they have major plans for regional expansion with sites planned already in Singapore, Australia, and Indonesia. The first location will be Perth, Western Australia, and the initial farm is under manufacture for imminent deployment. This is what we believe to be the first of many in this region. We are in advanced discussions across the APAC region with existing growers and other prospects and are currently trialing a range of crops specific to the cuisine and tastes of the population. These are progressing very well in our system and producing some very tasty results. We have other customers in the pipeline with projects in Singapore, India, and Polynesia.

What partnerships and collaborations are needed to scale controlled environment agriculture in Asia? What types of organizations are you keen to connect with at the Asia-Pacific Agri-Food Innovation Summit in November?

In this wider region, we recognize the important role that governments more broadly have to play in supporting and driving the food security and sustainability agenda. In Singapore for example we have talked closely with the Economic and Development Board (EDB) and the Singapore Food Agency (SFA), who are aiming to draw investment, research, and development into Singapore-based companies.

At November’s event, we hope to connect with existing and established growers, as well as entrepreneurs looking to set up farms or expend their existing horticulture operations. We also welcome further interaction with the EDB and SFA, as well as those operating in real estate and commercial property investment.

Finally, we are keen to identify regional sources of investment capital and asset finance on behalf of our customers seeking to establish agri-tech operations.

What key insights will you be looking out for personally at the summit?

I am very interested to know what emphasis is being put on clear and open data-driven discussions about payback timescales from investment in agri-food technologies. We know that there are technologies with varying approaches, sizes, and challenges to address, but ultimately these solutions need to be sustainable, scalable, and operationally reliable. However, they need to be commercially sound and that is something I am very keen to discuss further.

Join David online at the virtual Asia-Pacific Agri-Food Innovation Summit and watch his panel debate on ‘Success Factors for Scaling Vertical Farming Operations’ on November 19.

For more information about IGS, follow them on LinkedIn, Twitter, and YouTube.

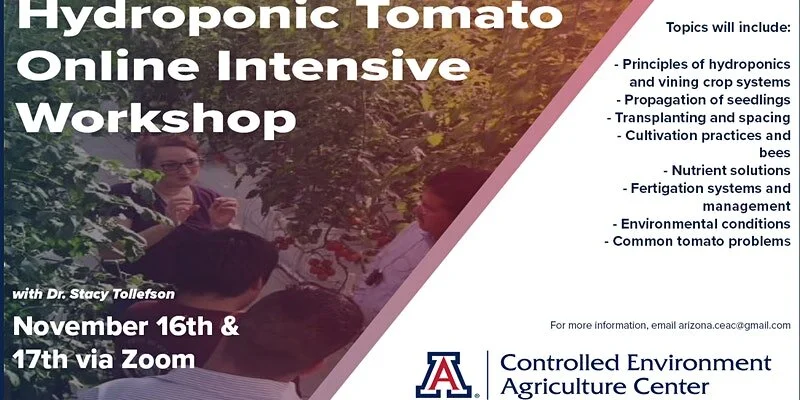

University of Arizona CEAC Hydroponic Online Intensive Workshop

Taught by Dr. Stacy Tollefson, this two-day event is perfect for novice growers and will be packed with tons of critical information and research discoveries that UA-CEAC has assembled into their courses and programs for over 20 years

Are you interested in growing tomatoes hydroponically? Join the University of Arizona Controlled Environment Agriculture Center for the Hydroponic Online Intensive Workshop – November 16 & 17 via Zoom.

Taught by Dr. Stacy Tollefson, this two-day event is perfect for novice growers and will be packed with tons of critical information and research discoveries that UA-CEAC has assembled into their courses and programs for over 20 years. You will get access to numerous lecture materials, personal question follow-ups, certificate of completion, and tons of knowledge!

Click Here to Register!

Limited seats are available. For questions, please email arizona.ceac@gmail.com

Tags Online Events Online Classes #agriculture #tomato #greenhouse #tomatoes #hydroponics #controlledenvironment #controlled_environment_ag #indoor_agriculture

How iFarm Vertical Farms Save Water

In many places around the world, for example in the Middle East, water resources are limited and their price is high. Reducing water consumption on a vertical farm in such regions can have a very positive economic and environmental impact

Generally, vertical farming uses 95% less water than traditional farming. At iFarm we have improved this indicator.

In many places around the world, for example in the Middle East, water resources are limited and their price is high. Reducing water consumption on a vertical farm in such regions can have a very positive economic and environmental impact. iFarm engineers have recently developed and patented a dehumidification system allowing to reuse the water that farm plants evaporate during growth.

How does it work? Let's take a look at a vertical farm with a cultivation area of 1000 m2. It produces 2.5 tons of fresh salads and herbs every month. To get such a yield, you need 2020 liters of water daily, most of which — 1400 liters — is used for plant nutrition. However, the daily actual water consumption is almost three times less. 2020 liters are poured into the system once, and then the "engineering magic" begins.

At iFarm vertical farms we use flow hydroponics, i.e the roots of plants are constantly placed in the nutrient solution and consume it whenever they need, getting all the macro- and microelements in the right ratio and concentration.

From 1400 liters of the water, plants use only 80 liters for weight gain (consumption of nutrients from a larger volume is a prerequisite). The remaining 1 320 liters the plants simply evaporate. In the process of transpiration, a lettuce leaf can evaporate an amount of water that exceeds its own weight many times. We collect this water with air conditioners and dehumidifiers, purify it and reuse it in production, maintaining the optimal humidity inside at 70%.

The second "source" of water on the farm is the water supply system — another 700 liters are collected from it and then run through a special filtration unit, resulting in 560 liters of purified and 140 liters of untreated water. The latter is collected in a special tank for technical needs (washing hands, pallets, floors, etc.).

Thus in order to save water, we started collecting it from air conditioners and dehumidifiers that were originally designed to maintain optimal moisture on the farm. This approach allows the production to use only 700 liters of tap water per day, which is three times less than growing plants in conventional hydroponic greenhouses.

We are currently improving the automation of the nutrient solution replacement. The system will determine what macro- and microelements are missing in the trays at a given time and adjust them. According to the calculations of engineers, this will reduce the number of times the sewerage has to be drained completely and almost halve its consumption — from 360 liters to 150 liters. The amount of tap water required by a vertical farm to produce delicious and reach yields then will be just 440 liters, which is five times less than what a hydroponic greenhouse needs.

16.10.2020

RII And ACEEE Awarded USDA Grant To Transform Controlled Environment Agriculture Toward Resource Conservation And Efficiency

“As an industry-leading indoor vertical farming company with two farms and over 126,000 sq. ft. of growing space which can produce over 500,000 lbs. of fresh food each year, Fifth Season is committed to this exciting project,” said Grant Vandenbussche, Chief Category Officer, Fifth Season

Washington, D.C. (November 9, 2020) – Resource Innovation Institute (RII) and the American Council for an Energy-Efficient Economy (ACEEE) will receive nearly $600,000 over three years from the Conservation Innovation Grants (CIG) program at the United States Department of Agriculture’s Natural Resources Conservation Service. The project was one of 24 projects selected for the 2020 program. RII and ACEEE will jointly implement the project through 2023.

Authorized by the 2002 Farm Bill, the CIG program helps develop the tools, technologies, and strategies to support next-generation conservation efforts on working lands and develop market-based solutions to resource challenges.

The awarded proposal, titled Data-Driven Market Transformation for Controlled Environment Agriculture, will characterize key performance indicators, baseline data, and facility-level benchmarking for controlled environmental agriculture facilities. The project will develop a comprehensive suite of data tools, coupled with a market intervention strategy to address barriers to energy conservation, adoption of energy-efficient technologies, access to energy use data, and best practices.

“We’ve been assessing energy and water use in the energy-intensive cannabis cultivation sector for years and have built a set of vetted tools and resources that will now be extended to the broader controlled environment agriculture marketplace,” said Derek Smith, Executive Director of Resource Innovation Institute. “We appreciate the support of the USDA as well as leading producers, supply chain actors, universities, utilities, governments, standards organizations, and other project partners.”

“Market transformation is a proven strategy for creating and sustaining energy efficiency improvements in energy-intensive market sectors,” said Jennifer Amann, ACEEE’s Buildings Program Director. “With USDA’s support, we’ll engage leading CEA market actors, utilities, and policymakers to demonstrate market transformation’s potential to drive resource efficiency in the fast-growing and innovative CEA market.”

“Agricultural innovation has long played a key role in Oregon’s rural economy, and has made countless contributions to our state for generations,” said Oregon’s U.S. Senator Jeff Merkley, who serves as the top Democrat on the Senate Appropriations subcommittee that funds the USDA. “I’m pleased that this funding will help Oregonians keep us at the cutting edge of the newest technology in sustainable agriculture, and I will continue to partner with our state’s researchers and farmers to make sure Oregon agriculture continues to thrive.”

“The world’s population is increasing, but available agricultural land is decreasing. Through science and innovation, we can help farmers improve the health of their operations and productivity on their lands while protecting the natural resources we all depend on,” said Natural Resources Conservation Service Acting Chief Kevin Norton. “The new systems, tools, and technologies being developed through CIG are helping us ensure the longevity of American agriculture.”

Additional support includes:

Fifth Season

“As an industry-leading indoor vertical farming company with two farms and over 126,000 sq. ft. of growing space which can produce over 500,000 lbs. of fresh food each year, Fifth Season is committed to this exciting project,” said Grant Vandenbussche, Chief Category Officer, Fifth Season. “We will benchmark the resource efficiency performance of our facilities, evaluate potential efficiency upgrades, and be featured in case studies demonstrating the financial and environmental results of our projects.”

Fluence by OSRAM

Fluence is a leading global provider of energy-efficient LED lighting solutions for commercial agriculture production. Fluence regularly contributes to RII’s cultivation guidance and serves as an industry-leading voice for RII on efficient energy consumption for LED lighting in CEA facilities. “We are increasingly observing global growers commit to more energy-efficient cultivation solutions at their facilities,” said Corinne Wilder, Vice President of Global Business Operations for Fluence. “This grant underscores the important work RII has already done for growers and we will enthusiastically recruit cultivators to engage with this project to not only help improve the efficiency of their own operations but those of the entire CEA industry.”

Grodan

“For more than 50 years, Grodan has developed Precision Growing methods proven to reduce water and nutrient use while maximizing crop quality and yield. Vertical farms and greenhouses are critical to the future of global food and medicine production as well as minimizing resource usage with technologies such as recirculation,” said Gonneke Gerkema, North American Business Director, Grodan. “This project collaboration brings together several key companies who share the same vision of industry benchmarking combined with Data-Driven decision making to generate water-use efficiencies that will benefit the cultivators, the industry, and indeed the environment.”

Northwest Power & Conservation Council

“Indoor agriculture is a significant part of the driving force behind forecast growing electric loads in agriculture,'' said Ben Kujala, Director of Power Planning, Northwest Power & Conservation Council. “The Council supports looking for opportunities for cost-effective energy efficiency and demand management within the growing indoor agriculture sector as part of its power planning and conservation responsibilities. As project advisor, Council staff commit to engage and educate stakeholders.”

For more information, go to ResourceInnovation.org/CEA. To schedule an interview with an RII representative, please contact Ellie Malone at ellie@themaverickpr.com or 262-337-3312.

About Resource Innovation Institute: Advancing Resource Efficiency to Cultivate a Better Agricultural Future

Resource Innovation Institute (RII) is a non-profit organization whose mission is to advance resource efficiency to cultivate a better agricultural future. Founded in 2016 to address the resource impacts of cannabis cultivation, RII is extending its services to other energy-intensive horticultural sectors. Its PowerScore benchmarking platform represents the world’s largest dataset on indoor agriculture energy use. RII’s Technical Advisory Council, which includes a Policy Working Group and a Utility Working Group, is the leading multi-disciplinary body assessing the environmental impacts and best practices associated with cultivation resource issues. RII’s Board of Directors includes the American Council for an Energy Efficient Economy (ACEEE) and a former board member of the US Green Building Council. RII is funded by utilities, foundations, governments and industry leaders. Visit our website at ResourceInnovation.org. Follow us on LinkedIn, Facebook, Twitter and Instagram.

# # #

VIDEO: We Use An Exceptional Amount of Land To Grow Food For Sows. Vertical Farms Could Change That If We Used Them To Grow Cow Feed

While most other vertical farms focus on growing salad greens for city dwellers, the new system is designed to tackle another challenge: the environmental footprint of growing feed for livestock

[Photo: Grōv Technologies]

Inside a new tent-like building on a large dairy farm west of Provo, Utah, tall towers stacked with trays of wheatgrass grow food for the cows outside. While most other vertical farms focus on growing salad greens for city dwellers, the new system is designed to tackle another challenge: the environmental footprint of growing feed for livestock.

A single tower in the growing system, from a startup called Grōv Technologies, takes up a little more than 850 square feet on the ground. But it can grow as much wheat or barley grass as 35 to 50 acres of farmland, the company says. Right now, an inordinate amount of land in the contiguous U.S.—around 780 million acres, or 41% of the total area—is used to grow feed for farm animals, either on pastures or through growing crops. And the demand continues to grow. “The availability of arable land, especially for animal feed, is shrinking,” says Steve Lindsley, president of Grōv Technologies.

[Photo: Grōv Technologies]

In some areas, that means forests are being cut or burned down to make room for crops to feed cows or chickens. “There’s clearly an environmental benefit that we think can be profound when you think about deforestation around the world,” Lindsley says. Grōv’s technology also significantly saves water, using around 5% of what is used in conventional farming. Additionally, it can reduce the distance to transport animal feed—China, for example, which has been buying agricultural land all over the world to grow food for its own animals, including in the U.S., is one of the startup’s key markets. The company plans to sell its systems to farms raising dairy and beef cattle to grow feed directly for their own animals.

[Photo: Grōv Technologies]

The farm in Utah, called Bateman’s Dairy Farm, is the first to test the new technology. Inside the new building, 10 towers, each around 25 feet tall, are filled with wheatgrass. Everything is automated: A robot plants four pounds of seeds in each tray and then sends it into the system, where sensors monitor conditions to give the crop the light and water it needs until it’s harvested automatically. “In an average of six and a half days, we have the crop,” Lindsley says.

Grōv provides support, but the system is designed to operate on its own, without any additional labor needed from the farmer. The system is also designed to minimize operating costs. The startup’s custom lights, for example, don’t put out heat, avoiding the large air-conditioning bills that are necessary in some other indoor farms. (The company says that the system can also run on renewable energy, and it plans to reach net-zero emissions by 2025.)

In early tests with hundreds of cows in 2019, the dairy found that the feed was more nutritious than its standard feed; the cows ate less, helping save money while producing the same amount of milk. Grōv estimates that farmers can break even on their investment in the technology in three years. As climate change progresses, growing indoors can also help mitigate risk from increasing droughts, heatwaves, floods, wind storms, and other extreme weather conditions.

The technology isn’t intended to fully replace conventional farming, but to provide one portion of the mix of food that cattle eat. At the farm in Utah, the new pilot system will provide 15% of the food for around 2,000 cows. But even replacing a fraction of conventional farming has the potential to make a meaningful difference. (That’s especially true if some farmland could be reforested, helping suck up excess carbon from the atmosphere to fight climate change.)

Lindsley argues that the environmental benefits could help dairy and beef farmers compete in a world where an increasing number of consumers are turning to plant-based foods. “The industry can utilize this technology as a counterpunch, really, to some of the lab-based protein efforts or the competitive efforts that are trying to pull people away from beef and/or dairy products,” he says.

ABOUT THE AUTHOR

Adele Peters is a staff writer at Fast Company who focuses on solutions to some of the world's largest problems, from climate change to homelessness. Previously, she worked with GOOD, BioLite, and the Sustainable Products and Solutions program at UC Berkeley, and contributed to the second edition of the bestselling book "Worldchanging: A User's Guide for the 21st Century."

SANANBIO ARK, The Mobile Farm For All Climates That Supplies Communities With Fresh Local Food

SANANBIO, a leading vertical farming solution provider announces the availability of its climate-controlled mobile farm for growers globally

November 4th, 2020—SANANBIO, a leading vertical farming solution provider announces the availability of its climate controlled mobile farm for growers globally.

“3,300-4,400 lbs of cucumbers, 7,700 lbs of arugula, and 8,000 lbs of lettuce. These are the proven annual yields that we’re confident to announce,” said Zhan Zhuo, co-founder and CEO of SANANBIO, “We ‘produce’ turnkey farms and this one is mobile.” It adapts to any climate thanks to its thermal insulation systems with a thermal conductivity below 0.024w/(m·K). One of the mobile farms operated as usual in a coldness of -40℉ in northern China, sustaining local communities with local produces at a reduced carbon footprint. It is shocking to find that our food travel 1,500 miles on average before reaching our plate.

The CO2 generated, and the nutrients lost during the transportation, can’t be good for the planet or human beings. That’s why local food is advocated. “The ready-to-use farm is the solution we offer to regions where the environment is too harsh to support stable agricultural production,” said Zhan.

To streamline the farming experience, the designer simplifies the start-up procedures to a single plug-in motion: power it up through a connector on the exterior and then even hydroponic beginners are set to grow. Moreover, growers can monitor and control farm metrics simply by moving fingertips on their phone.

“By simplifying modern agriculture, we offer more farming opportunities for kids and urban dwellers. We have a mobile farm deployed in a Malaysian suburb where kids from the neighborhood frequent the farm for hands-on hydroponic experience. It’s a perfect bonding time when families go there to pick their own salad ingredients. As a Photobiotech company, we’re nurturing a new generation of growers,” said Zhan.

For more info about the mobile farm, please visit www.sananbio.com/ark.

About SANANBIO

SANANBIO is a joint-venture by Sanan Optoelectronics, one of the world’s largest LED manufacturers, and the Institute of Botany of Chinese Academy of Sciences, a leading institute in plant science. Comprised of LED experts and plant scientists, SANANBIO is able to provide simple CEA solutions for growers globally. The RADIX, a Reddot award winner, has been widely endorsed by growers in more than twenty countries.

America Is Hungrier Than Ever For Sustainable Food Systems. Can We Build Them?

In the spring of 2020, many small farms across the U.S. found themselves in a bittersweet predicament. Restrictions aimed at slowing the spread of the coronavirus were forcing restaurants — major buyers for the local farms that serve urban areas — to shut down

November 2, 2020

In the spring of 2020, many small farms across the U.S. found themselves in a bittersweet predicament. Restrictions aimed at slowing the spread of the coronavirus were forcing restaurants — major buyers for the local farms that serve urban areas — to shut down. The loss of these key customers might have wiped out many of these local growers, if not for another COVID-19-induced phenomenon: individual shoppers started calling — and calling — and calling.

"The farms we work with are seeing a huge spike in demand [for direct sales]," Dan Miller, CEO, and founder of the crowdfunding platform Steward, told me when we spoke by phone in early April. "But now they have to quickly switch their businesses to meet that demand." So Miller, who launched the platform in the fall of 2019 to provide funding to small, sustainably run farms — operations often underserved by traditional finance — soon found himself expanding Steward’s services to help these same farmers shift their business model.

Stories of small farms pivoting their operations on a dime were easy to find in the early months of the pandemic: these farmers worked overtime to meet customer demand, added services such as online ordering and home delivery, and jumped into action to prop up community food banks struggling to serve an influx of the newly unemployed. Compared to the industrialized and supersized food system most Americans live with — represented by rivers of wasted milk and COVID-19 outbreaks at meat-packing plants that killed more than 200 people — these distributed systems looked healthier, safer, and more environmentally sustainable than ever. They also looked more agile and resilient.

Crises often present an opportunity to reimagine current systems, so I wondered: Would that happen here, with food? Would the food consumption trends driven by the pandemic wind up as a paragraph in the history books — like the "victory gardens" of World War II — or could it lead to lasting change? And how do we transform this moment of crisis into a more resilient, sustainable, healthy, and just food system?

Crises often present an opportunity to reimagine current systems.

At GreenBiz Group’s virtual clean economy conference, VERGE 20, last week, speakers and participants addressed questions such as these, discussed how to make sure that these changes stick and identified what challenges stand in the way. During a session delving into lessons from the pandemic, panelists agreed that the No. 1 barrier to changing the current food system is financing.

"The financial services that are out there … are really not calibrated for the moment we’re in," said Janie Hipp, CEO of the Native American Agriculture Fund. "If we’re going to actually build an agile and resilient system going forward, then we have to invest in it."

One example of the financial challenges sustainable farms face comes in the form of crop insurance. If a farmer wants to transition a farm from conventional practices to organic or regenerative ones, costs are associated with that transition. However, insurance policies typically do not cover them, so the farmer is forced to take on the extra up-front costs and risk. The same holds true for traditional agriculture financing, developed for conventional farming. Loans are typically underwritten based on the equipment, inputs, volume, prices, and insurance coverage of conventional growers. These factors are different for organic and regenerative farmers, so the numbers often don’t work, resulting in loans being denied or unaffordable.

This increased access to capital could help scale the market, which hopefully would bring down the cost and make this more nutritious food more widely available, said Matthew Walker, managing director at S2G Ventures, a food systems-focused venture fund and mission investor.

"There’s a lot of work to be done to provide affordable nutrition … and allow those who are seeking to grow organic, or use any tech-enabled process that might be better for soil health, better for nutrition, to at least get started," he said.

This increased access to capital could help scale the market.

Making healthy food available in disadvantaged neighborhoods, where affordable, fresh vegetables are hard to come by, is the mission of the Green Bronx Machine, but founder Stephen Ritz — a VERGE keynote speaker — didn’t wait for systems change. Established in 2012, the program uses hydroponic and vertical farming technology at its indoor teaching farm at a South Bronx school, where kids learn how to grow and cook vegetables themselves.

Each week throughout the school year, the kids take home bags of groceries to their families. Green Bronx Machine also operates a "food for others" outdoor garden and summer youth employment program in the Bronx, which serves food-insecure families in the community. And it has various other partnerships and serves as a model for schools in other districts, including a program in more than 60 Chicago schools, sponsored by the foundation of Chicago Blackhawks captain Jonathan Toews, who joined Ritz on VERGE’s Building a Better Food System for America’s Cities panel.

Like the farmers who work with Steward, the Green Bronx Machine’s student farmers pivoted when the pandemic hit, Ritz said in his keynote.

"As COVID-19 brought the world to a standstill, it became the ultimate manifestation of three larger illnesses: racism; greed; and corruption," Ritz said. "And we found new ways to secure and distribute food to those who needed it most."

This has included providing weekly grocery delivery for 26 food-insecure patients at Memorial Sloan Kettering Hospital, who are recovering from cancer, and for 55 of the most vulnerable families in the Bronx, across a 26-mile route that includes walk-up buildings.

"The truth is children want to be part of the conversation. The truth is children don’t let differences divide them. The truth is children are smarter than you think," Ritz said.

As COVID-19 brought the world to a standstill, it became the ultimate manifestation of three larger illnesses: racism; greed; and corruption.

When New York was the epicenter of the pandemic — a place whereby May, the virus had killed more than 20,000 people, primarily in underprivileged neighborhoods such as the South Bronx — food grown by a bunch of kids was delivered to families who may not have eaten otherwise.

The Green Bronx Machine joined community farms, urban farms, and small family farms in offering a lifeline to their communities. They proved themselves resilient in a crisis, and their numbers are growing, but they remain a teeny, tiny part of the gargantuan American food system.

In 2017, there were 16,585 certified organic farms, a 17 percent increase from just a year earlier, according to the National Agricultural Statistics Service’s latest Organic Survey, released this month. These farms accounted for 5.5 million certified organic acres, an increase of 9 percent over 2016.

This impressive growth marks the continuation of a decade-long trend. And yet, certified organic acres still represent less than 1 percent of the total 911 million acres of American farmland. (Although I should add that the survey’s three-year lag does not provide an up-to-date picture, and farms that use organic or regenerative practices but have not been certified don’t get counted.)

The main challenges for these farms is getting the infrastructure and operational capacity in place to support a growing customer base.

Curious to see whether the direct sales demand Steward’s farmers saw in the spring was continuing to hold, I checked back in with Miller. By email, he told me that demand had held and offered an example from Fisheye Farms, an urban farm in Detroit. Fisheye, he reported, already has sold out their entire winter CSA and is fielding inquiries for spring. CSA stands for "community-supported agriculture," a system where customers buy "a share" of the farm. They pay a fixed rate to receive regular boxes of whatever’s in season. Every other week, from November through February, members of Fisheye’s winter CSA will receive spinach, kale, carrots, turnips, radishes, microgreens, and more. The cost is $300, or about $38 a week.

"The main challenges for these farms is getting the infrastructure and operational capacity in place to support a growing customer base," Miller said in his email. "Even the farmers with the most demand still need capital to run better, as they can’t finance everything they need just on cash flow."

In other words, to replicate and scale what these farms do, and build distributed food systems that are resilient, sustainable, healthy, and just, will take time, cooperation, and a lot of green.

Lead photo: by Oleg Demakov on Unsplash.

Infarm Raises $200 Million To Add “Farm” to Cities

heir environment-controlled and automated growing chambers grow food such as leafy greens inside the supermarket, so it’s fresh, without your food accumulating food miles

Infarm’s Israeli founders take on Berlin and the farm to table movement with high-tech farms.

Infarm, a company that grows fresh produce inside supermarkets, has recently announced a $170 million USD funding round to help the company expand across Europe. Their environment-controlled and automated growing chambers grow food such as leafy greens inside the supermarket, so it’s fresh, without your food accumulating food miles.

The company was founded by three Israelis in Berlin in 2013, and they announced this astounding investment achievement despite the Covid plague destroying global markets. Food, we understood, is something that must stay constant. The need for food which is grown locally, and available fresh now resonates at a time of uncertainty and the basic need for survival.

The company has raised $200 million USD total in their Series C round funding which was by LGT Lightstone, Hanaco, Bonnier, Haniel, and Latitude, Atomico, TriplePoint Capital, Mons Capital, and Astanor Ventures.

With a mix of equity and debt financing, the fresh capital brings Infarm’s total funding to date to more than $300 million, underscoring consumer and retailer appetite for Infarm’s approach to fresh, sustainable, and local food production in the wake of this year’s pandemic.

By 2025, Infarm’s farming fridge network is expected to reach more than 5,000,000 square feet to become the largest distributed hydroponic network in the world as it builds towards helping cities become self-sufficient in their food production. Competition includes Freight Farms in the US, and BrightFarms, also American.

“The coronavirus pandemic has put a global spotlight on the urgent agricultural and ecological challenges of our time,” says Erez Galonska, Co-founder and CEO of Infarm. His brother Guy Galonska is also a founder: “At Infarm, we believe there’s a better, healthier way to feed our cities: increasing access to fresh, pure, sustainable produce, grown as close as possible to people,” adds Erez.

The investment will be used to deepen the regional and local penetration of Infarm’s global farming network and complete development of Infarm’s new generation of vertical cloud-connected farms, capable of generating the crop-equivalent of acres of farmland and amplifying the diversity of produce currently available through vertical farming. Vertical farming is also known as hydroponic farming or controlled environment agriculture.

The technology has become developed and well-known over the years thanks to cannabis growers who used this energy-intensive and “stealth” mode of farming to grow cannabis with high concentrations of the active ingredient THC. When it was illegal to grow in Canada, young entrepreneurs were inspired by early blueprints from NASA and farming in space and found ways to set up a soil-less system in basements and closets. To their surprise, they could grow better quality cannabis, faster as inputs such as lighting, humidity, and nutrients could be tightly controlled.

And growing food became the next natural step for people who wanted to grow fresh food year-round even though it’s usually not cost-effective to grow tomatoes or lettuce this way unless you do it at scale.

Hydroponics and variations of it, using just water, a semi-solid coir medium or Styrofoam and/or with fish added, has become the promise for growing food in far-flung locations like Antarctica and food deserts where chocolate bars are available at bodegas, but fresh greens are not. This is according to mothers I have met in Harlem, New York. The hydroponic method is not that complicated at all in theory but in practice, it is hard to achieve good results without know-how in chemistry, engineering, and biology.

An integration of advanced engineering, software, and farming technology, the Infarm farms will save labour, land, water, energy, and food-miles, while contributing to a more sustainable food system, the company proposes.

Partnering with Aldi, Marks & Spencer, Sobeys

While companies like Farmigo founded in New York (also by an Israeli) wanted to put supermarkets out of business, in the past year Infarm has been working to keep them relevant and formed new partnerships with the world’s largest retailers, including Albert Heijn (Netherlands), Aldi Süd (Germany), COOP/Irma (Denmark), Empire Company Ltd (Sobeys, Safeway, Thrifty Foods – Canada), Kinokuniya (Japan), Kroger (United States), Marks & Spencer (United Kingdom) and Selfridges (United Kingdom).

With operations across 10 countries and 30 cities worldwide, Infarm harvests 500,000+ plants monthly, while using 99.5% less space than soil-based agriculture, some 95% less water, 90% less transport, and zero chemical pesticides. Today, 90% of the electricity use throughout the Infarm network is from renewable energy and the company has set a target to reach zero emissions from their production next year.

With the cost of lighting typically very high in hydroponics systems, I’d be curious to know how they will do that without buying carbon credits. Consider this Stanford research paper that mentioned the cost of hydroponic lettuce to be about 8KG of carbon compared to 150g if grown conventionally. The research is a few years old and certainly, there can be ways to improve energy efficiencies.

What organic farmers think?

Proponents of organic farming, regenerative agriculture, and permaculture don’t love hydroponics farming because it relies on petroleum-based fertilizers and nutrients as additives, and while there may be no or few bugs in the grow chambers, there is a risk of fungus and bacteria; in nature, there is always free natural sun (unless you are in Finland in the winter) and natural interactions between plant, soil; and even among small biota like mycorrhizal fungi which play a role in the uptake of micronutrients to the roots and the overall essence of what we call a plant. There is one school of thought that says the “organic” label can only be applied to soil-based farming. Lawyers are debating the issue now.

The answer will be somewhere in the middle. Like most things in life the middle way will help us. The dream is many one-acre regenerative farms to feed us healthily and to feed the planet too but meanwhile there is a gap. How do we feed everyone else who can’t afford to buy at Whole Foods?

We need to improve our local supply chain for food. When you live in a country like Israel, Egypt or Jordan with ample sun, growing food inside a supermarket fridge makes no sense, although hydroponics does. See this project in Jordan, funded by the USAID. Or the one that has changed lives in Harlem.

I had a hydroponics robotics venture (see this article on Bloomberg) and I took it to New York a few years ago and found myself running in circles trying to explain why eating local is good for the planet, it’s good for a circular economy that might one day be about survival. Venture Capitalists laughed at me. They said my technology and vision was a vitamin and not a bandaid –– “a nice to have” but not “a necessary to have”, especially in cities like New York. Then Covid thinking happened.

Here is what investors in Infarm say now (and kudos to the team who worked hard building physical farms and maintaining the pilots):

“We are excited to partner with the Infarm team to accelerate their urban vertical farm vision, ultimately creating a more sustainable food system for a growing population,” says Dharmash Mistry, Partner of LGT Lightstone: “With over $1bn of customer demand, partnerships with 17 of the top 50 global grocers, Infarm is set to revolutionise the market behind a unique ‘demand led’ modular business model.”