Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Rooftop Greenhouse Agrotopia Is Taking Shape

Little by little, the roof greenhouse on the crate shed of the REO Auction in Roeselare is taking shape. Compared to the very first visible work, there is already a real greenhouse on the roof, as greenhouse builder Deforche Construct shared recently

Little by little, the roof greenhouse on the crate shed of the REO Auction in Roeselare is taking shape. Compared to the very first visible work, there is already a real greenhouse on the roof, as greenhouse builder Deforche Construct shared recently.

After the Christmas break, the construction team went back to work. The project is scheduled for June 2021, but the official opening is due August this year. After that, the greenhouse will be ready for the 'Festival of the Future' which will be held in Roeselare in September, they shared in a LinkedIn update.

Stijn Cappon (Deforche Construct), Francis Vancraeynest (Deforche Construct), Johan Vermeulen (Maïs Automatisering), and Jago van Bergen (Van Bergen Kolpa Architects) at the laying of the first pile for the project in July 2019. Deforche is constructing the greenhouse, whilst Maïs Automatisering will take care of the technical completion of the greenhouse. Van Bergen Kolpa Architecten has designed the jagged façade and the twelve-meter high greenhouse as a landmark.

Vegetable garden

The REO Auction is located in the heart of West Flanders. "The vegetable garden of Western Europe", the initiators say. The rooftop greenhouse offers space for both leafy and fruiting vegetables. In co-creation projects, suppliers, knowledge institutes, governments, growers, and technology companies are included in crop research. The first processes have already been set up, such as cultivation on water with densely sown crops and vertical farming.

All greenhouse departments will be equipped with LED artificial lighting and a specific climate control system that relies even more on all the knowledge of plant physiology. The greenhouse will be 8000 square meters and will be 8.4 meters separate from the first floor, on the roof of the crate shed.

Vertical cloths are used as shields between the departments, preventing light from radiating into the environment. This is particularly relevant when growing vertically. The rooftop greenhouse does not have its own heating installation: heat is provided by the municipal waste incinerator MIROM and by auction REO.

Festival of the Future

As was recently announced, the Province of West Flanders has chosen the rooftop greenhouse as the location for the 'Festival of the Future'. Three editions will take place between 2021 and 2025. The first edition is planned from 23 September to 3 October 2021.

A document with 'eye-catchers' from the multi-annual budget of the province reads: "At the foot of the rooftop greenhouse there will be built a universe of experience. During two weekends, the general public will be able to discover the agriculture, biodiversity, and food of the future in an exciting journey through an export space. Besides, an attractive and widely accessible evening program will be prepared.

During the week, schools will also be involved, through original workshops. Workshops on computational learning for primary and secondary education, for instance, will be organized. The students will here learn to build a 'Mini-Agrotopia'".

According to the province, the project is characterized by an 'intensive co-creation course of the Province of West Flanders, Inagro, TUA West, POM West Flanders, PTI and the education expertise cell of the Province of West Flanders'. The West Flemish colleges VIVES and HOWEST also 'actively contribute' to the development of the Festival.

Some history

Dominiek Keersebilck of the REO Auction told more about Agrotopia in an interview that appeared earlier in Primeur. The arrival of the rooftop greenhouse is a new step in the history of the auction, he says.

REO Veiling was founded on 20 July 1942 by 27 professional horticulturists from "Roeselare and surroundings" (REO). Due to WW II they had to wait until November 21, 1944, for the first auction day. The story of the REO Auction started in a small shed of a potato trader in the center of Roeselare. After that, the auction moved five times to cope with the increasing supply of horticultural products from West Flanders.

In 1978, REO auction introduced block sales. Also, 1983 was an important year because in that year a simultaneous sale was organized with the Centrale voor Glasgroenten in Sint-Katelijne-Waver for the first time. In 1987 the board of directors decided to build a new and larger auction complex at the current address at the Oostnieuwkerksesteenweg. The new complex was taken into use on 1 April 1991 and officially inaugurated on 24 May.

Rooftop greenhouse

The old auction buildings on the Diksmuidsesteenweg made way for the current packaging department, and a new crate shed was built on the adjoining Vuylsteke site, which was put into use at the end of 2015. A rooftop greenhouse is currently being built on the roof of this packaging shed.

Agrotopia

According to commercial director Dominiek Keersebilck, a lot has changed in recent years. "The REO Auction has seen an increase in turnover and the volume of product sold in recent years. Whereas we have achieved record sales in recent years, this will probably not happen this year due to the corona crisis. This in no way means that there will be no further development on our site. At the moment there is indeed the development of the rooftop greenhouse called "Agrotopia".

The rooftop greenhouse is meant for research and with this technical knowledge, we want to anchor horticulture, here in West Flanders. Also, space can be made for other forms of horticulture, such as vertical farming and urban crop. The rooftop greenhouse allows research into vertical horticulture along a wall of 12 meters high and in the meantime, other innovative cultivation possibilities, such as the cultivation of leafy crops in containers, are also under consideration.”

This article originates from our Dutch magain Primeur - www.agfprimeur.nl.

For more information:

REO Veiling

www.reo-veiling.be

info@reo.be

Publication date: Thu 7 Jan 2021

Joint UAE-Israel Food And Water Security Conference Announced

The first-ever UAE-Israel food security summit will take place later this month, bringing together Israeli food and water security companies and investors from the UAE

Could Israel’s success story of “making the desert bloom” boost food security in the UAE?

BY GULF BUSINESS STAFF

JANUARY 6, 2021

The first-ever UAE-Israel food security summit will take place later this month, bringing together Israeli food and water security companies and investors from the UAE.

GoforUAE-Israel Food Security Investment Conference will have experts from both countries explore strategic partnerships and capital market opportunities. This event aims to improve the productivity of desert environments in the Middle East and worldwide.

To be held on January 18, the online conference will address pertinent issues in agriculture and food security such as precision agriculture, desert farming, development of resilient species, advanced storage solutions, and more.

“Our mission for this event is to introduce emerging technologies that can facilitate the UAE access to food security solutions in the long term”, said Edouard Cukierman, chairman of Cukierman Investment House and Managing Partner at Catalyst Funds.

“Since its founding in 1948, Israel has never stopped inventing agricultural technologies that greatly improve farming everywhere, especially in arid areas. Israel gladly shares its experience, innovations and achievements in this field with the rest of the world. With Similar weather, conditions and water scarcity to the UAE, and 60 percent of Israel’s land covered by the Negev desert, Israel and the UAE can jointly make an impact on desert farming to enable quality, available food in the Middle East and worldwide,” he added.

Read: Israeli tech companies make debut at Gitex 2020

Hundreds of investors from the UAE have already registered for the conference to explore some of Israel’s most promising and innovative solutions for food and water security and agtech, the organizers said.

Participating Israel firms include Saturas, a pioneer of in-tree water intelligence systems based on water monitoring from within the plant. Saturas can then offer tailored irrigation based on the crop’s real-time water needs, resulting in efficient water use.

Also taking part is Ramat Negev Research & Development, an R&D center that develops agro-technical methods suitable for desert conditions. Ramat Negev R&D has recently established a new ag-tech innovation center jointly with Arieli Capital to boost Negev agriculture through co-developing with emerging startups.

Register Here

2020’s Indoor Farm Venture Capital Bonanza

"The industry raised US$565mm in 2020. This figure excludes several notable rounds where the amounts raised were not publicly disclosed," says Nicola Kerslake, CEO of Contain

In the face of a dismal year, indoor agriculture saw record fundraising from venture capital and other private investors in 2020. "The industry raised US$565mm in 2020. This figure excludes several notable rounds where the amounts raised were not publicly disclosed," says Nicola Kerslake, CEO of Contain.

"New Jersey-based vertical farmer AeroFarms was one of four recipients of funding from the Abu Dhabi Investment Office for its Dubai farm. Late in the year, automated vertical farmer 80 Acres raised a round from British bank Barclays. Elsewhere, at-home kit provider Back to the Roots added a prominent Saudi sustainable ag supporter to its existing investor list for an October 2020 round. Even without these rounds, 2020’s total was up nearly 50% on 2019 and represents a record for the industry, besting 2017’s US$391mm," states Nicola.

Credits: Contain

According to Nicola, vertical and greenhouse farms again represented the bulk of funding, thanks to large rounds from majors such as Bright Farms (US$100mm), Gotham Greens (US$87mm), InFarm (US$170mm), and Plenty Ag (US$140mm). Outside of this, a notable trend was that industry suppliers are now beginning to interest investors. For instance, greenhouse computer vision tech provider iUNU raised a $7mm round led by frequent agriculture investors S2G Ventures and Ceres Partners. Contain Inc, the fintech platform that I lead, has itself been a part of this trend, raising a funding round from the US and European investors at the tail end of 2020.

"This resurgence can be traced to several factors. Most important is the lure of all manner of sustainable agriculture in a world where everyone seemed to become food-obsessed during lockdowns. Increasing industry participation from large produce buyers has also played a part, as they’re seen as an indication of the industry’s viability by venture capital investors," Nicola adds.

In addition, venture capital funds are typically thematic investors, and COVID rendered several of these themes obsolete and encouraged venture capitalists to pivot to new ones. "For example, some parts of the ultra-hot sharing economy theme that spawned companies like Uber suddenly look less alluring when consumers are loath to share space. Meanwhile, themes around health and wellness became far more attractive, benefiting adjacent industries such as indoor agriculture," Nicola affirms.

Credits: Contain

"Going forward, venture capital funds still have plenty of dry powder for investment, after a healthy fundraising environment for them in 2020", says Nicola. Industry researcher PitchBook says that funds raised by venture capital firms rose by nearly a quarter over 2019 levels.[1] The year’s strong IPO (stock market listing) market helped, with tech favourites like AirBNB and DoorDash going public. Indoor agriculture remains a minority sport for investors, 2020’s record haul represents less than that raised in the year by stock trading app Robinhood alone. Nicola adds: "Given this, it’s perfectly possible that we may see another record-breaking year for indoor agriculture in 2021."

For more information:

Contain

nicola@contain.ag

www.contain.ag

5 Jan 2021

Author: ebekka Boekhout

© VRerticalFarmDaily.com

Polygreens Podcast Episode: 008 -CO2 GRO

CO2 from a gas tank and water from the facility source are plugged into the Aqueous CO2 Infusion System, which comes as an in-situ system or can be integrated into booms

CO2 from a gas tank and water from the facility source are plugged into the Aqueous CO2 Infusion System, which comes as an in-situ system or can be integrated into booms. The CO2 completely dissolves in the water creating a saturated aqueous CO2 solution.

The aqueous CO2 solution is targeted directly on to the plant's leaves by misting micro droplets that create an aqueous CO2 film on leaf's surface. This film isolates the leaf surface from the atmosphere and creates a diffusion gradient that favors the transport of CO2 into the leaf and other gasses out of the leaf.

The carbon is used by the plant for photosynthesis to grow and the oxygen is given off to the atmosphere.

Listen

Nick Greens

The Nick Greens Grow Team has participated in many changes since they started developing indoor controlled agricultural environments in 2010. Our goal is to expand the vertical farming industry by helping ag-entrepreneurs manage their businesses better, avoid common mistakes, and improve crop yields based on what we have observed and developed over the past decade.

YouTube

Year-Round Under-Glass Herb Cultivation In The Heart of Berlin

ECF Farmsystems uses innovative LED lighting solutions from Fluence for today’s herb cultivation in the heart of Berlin

Urban Farming Using LEDs From Fluence by OSRAM

ECF Farmsystems uses innovative LED lighting solutions from Fluence for today’s herb cultivation in the heart of Berlin. An innovative urban farm, ECF Farm Berlin (ECF Farmsystems) uses techniques for greenhouse and vertical cultivation of basil. The farm also uses aquaponics to naturally fertilize the crops, the produce of which then goes to Rewe, Germany's second-largest supermarket chain.

Less space and more production is the name of the game at ECF Farmsystems: comprehensive lighting solutions, from growing to greenhouse culture, enable the year-round production of uniform, aromatic basil plants.

Modern agriculture thanks to LED lighting / Image: Osram

Urban cultivation from seed to finished product

On-site propagation on VertiCCs, a racking system for vertical cultivation developed by ECF Farmsystems, increases production by 35% with the same footprint and optimized supply chain from seed to finished product.

The system also ensures consistent, uniform products. This is because ECF Farmsystems completely controls the entire growing cycle with less pest infestation and more accurate yield forecasting. In addition, the VYPR lighting systems offer higher-quality light spectra compared to conventional lamp systems. In addition, thanks to VYPR solutions, greenhouse growing is no longer seasonal, as efficient crop lighting provides uniform plants with consistent productivity, regardless of local weather.

With Fluence's RAZR Series, ECF Farmsystems achieves more effective operations and a 35% increase in production without the need for new construction or remodeling. By expanding vertical growing in the plant nursery, which eliminates the need to invest in additional growing space/facilities, ECF Farmsystems saves important emission costs. Propagation on VertiCCs systems with RAZR exposure allows ECF Farmsystems to control the entire growth cycle, better manage pests, and now calculate yields more accurately.

The new RAZR module will be available in January 2021.

For more information:

fluence.science/webinars

https://en.ecf-farm.de/

https://www.osram.com/os/applications/horticulture-lighting/index.jsp

Publication date: Thu 7 Jan 2021

“There Is Abundant Liquidity But A Lack of Solid Business Cases”

“I come across many vertical farming concepts. There are some very interesting developments going on in the market. Especially for investors, because vertical farming is future-focused”

“I come across many vertical farming concepts. There are some very interesting developments going on in the market. Especially for investors, because vertical farming is future-focused,” says Jobbe Jorna, Founder and Managing Partner at Upstream Capital. The Amsterdam-based organization advisory boutique is specialized in helping companies realize their full potential with performance improvement and corporate finance.

“Multiple investors are looking into (inter)national vertical farming projects. There’s abundant liquidity but a lack of solid business cases.” According to Jobbe, as a result of the pandemic investors are becoming increasingly critical, also in the Netherlands. They take more time for a thorough analysis, walking through the entire process teaming up closely with stakeholders. In the end, this is only beneficial for farmers because it contributes to the design, build, finance, maintain, and operate a solid foundation to build a successful farm upon.

Jobbe Jorna

Sharp review of business cases

Jobbe says that there are three common mistakes that he comes across frequently when reviewing business cases. Firstly, farmers need to develop a strategic competitive advantage with sufficient upside potential. The business case has to be scalable. Secondly, the value proposition has to be validated, tested, and ready-to-market. “Don’t put too much R&D into it, Bear in mind, an idea does not immediately make a working concept. Let alone a winning go-to-market proposition that can be achieved,” Jobbe adds.

“Investors want to see a rock-solid value proposition with upside potential and a powerful management team with strategic business partners, backing up the company. Most investors don’t go onboard if there isn’t a worthy team with a strong and proven track record.” Finally, farmers should look outside the box as in horizontal integration within the value chain, long-term off-take contracts. In the past, we successfully realized sustainable energy projects in greenhouses driven by long-term contracts at a middle price. In this way, we can secure the business case against crop price fluctuations. As a result, the business case attracts more interest from potential financiers, in the wide range of business angels and investors to banks.”

Key takeaways

Cultivation is your core, says Jobbe, then start with the end in mind. Who is the end customer, what are the current needs, and what are tomorrow’s needs? Rethink the value chain and develop your own eco-system of strategic partners. Farmers need to their homework. Start in time, as it’s more challenging than people think. You need to have a rock-solid business plan in place prior to approach potential investors.

Jobbe says that when a business plan is solid enough, farmers should put together a game plan before going out and start to approach potential investors. “If that’s done too early, your process, time and wallet for that matter will take a sufficient hit. When growers are in a negotiation phase with investors, they should follow a structured approach. Keep your options open, your eye on the ball as the negotiation window is a moving target and always respect your walk-away point. Especially now, during the pandemic, growers should not be seduced by an unfair proposal.”

For more information:

Upstream Capital

Jobbe Jorna, Founder and managing partner

+316 1518 4909

jobbe.jorna@upstreamcapital.nl

www.upstreamcapital.nl

Publication date: Thu 7 Jan 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

RSVP - Indoor Ag Science Cafe January 12th 11:00 AM Eastern Time

"Considerations For Marketing Vertical Farm Food Products To Consumers"

January Indoor Ag Science Cafe

January 12th Tuesday 11:00 AM Eastern

Please Sign Up, Thank You!

"Considerations For Marketing Vertical Farm Food

Products To Consumers"

Dr. Bridget Behe

Michigan State University

Please sign up so that you will receive Zoom link info.

Indoor Ag Science Cafe is an open discussion forum, planned and organized by OptimIA project team supported by USDA SCRI grants.

Sign Up Here

Improving The Profitability And Economic Sustainability of Vertical Farms

“According to our research, most vertical farms are focused on lighting as a means of improving yield and growth speed,” says Rob Agterberg, Partner at Back of the Yard Algae Sciences (BYAS)

“According to our research, most vertical farms are focused on lighting as a means of improving yield and growth speed,” says Rob Agterberg, Partner at Back of the Yard Algae Sciences (BYAS).

“However, not enough vertical farms are looking at innovative ways of growing faster and better. Through our research, we’ve discovered that certain algal proteins improve the photosynthetic process and this results in a biostimulant effect and also improves taste, aroma, shelf life and nutrient value in vertically farmed crops such as lettuce."

The biostimulant research

Algae biostimulant

“At BYAS we’re creating ingredients such as alternative proteins, food colorants, made from microalgae. We have a patented, unique, zero-waste production process that enables us to extract food ingredients and alternative proteins from microalgae,” says Marc Peter Geytenbeek, Partner at BYAS. The company has been researching its biostimulant for vertical farming the past 2 years and recently published a scientific article outlining a number of breakthrough results. Currently, the biostimulant is being tested by vertical farming companies, including across the world.

Saving time and money

Rob states that about two-thirds of vertical farms are struggling to be economically viable, due to their high capital expenditures. He says: “Our research has shown that lettuce growth increases after adding the biostimulant. This increase results in up to 20% shorter growth cycles, saving on lighting and therefore energy and labor costs. We think that our biostimulant can be a huge boost to make vertical farms more economically sustainable.”

Sustainable works

“Surprisingly, the biostimulant can be made from algae grown on agriculture waste streams,” says Rob. The biostimulant is organic and GRAS (generally recognized as safe). What is particularly interesting to vertical farming is the fact that the biostimulant is an extract, so there is no need to administer a live bacteria or fungus into a hydroponic system. BYAS is committed to the circular economy - sustainable re-use of resources. This can be found in the production processes that are zero-waste and use very little energy.

For more information:

Back of the Yard Algae Sciences

Marc Geytenbeek, Partner

marc.geytenbeek@algaesciences.com

www.algaesciences.com

Rob Agterberg, Partner

rob.agterberg@algaesciences.com

www.algaesciences.com

Publication date: Wed 6 Jan 2021

Author: Rebekka Boekhout

© VerticalFarmDaily.com

JPFA Offering Online Training Course On Plant Factories

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now

English Training Course on Artificial Lighting In February

The Japan Plant Factory Association is starting a new online English-language training course on Plant Factories with Artificial Lighting (PFAL) in February and is receiving applications now.

The JPFA 2021 online training course on PFALs scheduled for February 18 – March 11 comprises introductory classes and special content designed for participants to acquire practical knowledge and expertise. The learning event follows its first online English-language training course that was offered last year.

Click here to view the course brochure.

All interested parties in plant factories or vertical farms can seize this opportunity as the course is not only available for JPFA members but also for non-JPFA members. The JPFA is a nonprofit organization committed to advancing controlled-environment agriculture.

The lecturers include Toyoki Kozai, honorary president of the JPFA and former president and professor emeritus of Chiba University, who is known as the father of plant factories. Introductory classes will cover such topics as current PFALs and forthcoming technologies as well as environmental effects on plants. Special content will allow participants to learn practical methods.

The course will also provide participants with a virtual tour to a commercial, large-scale PFAL and exhibitions by companies in the PFAL and related businesses. Although participants cannot get together as in on-site courses, the course’s platform allows them to enjoy interacting with other attendees and representatives of exhibitors. Also, a live question-and-answer session is planned for participants to deepen their understanding.

“Thank you so much for the opportunity to look deeper into this ‘industry,’ which is likely to reshape our future soon,” a Romanian participant of the 2020 course said.

Because the course is online, it may be easier to attend it than an on-site one, especially for those who live outside Japan.

Click here to apply for the course.

Vertical Farms Bear Fruit

Engineering perishable crops for use in indoor farms promises to expand the adoption of this high-yielding, efficient means of food production

Cathryn A. O’Sullivan, C. Lynne McIntyre, Ian B. Dry,

Susan M. Hani, Zvi Hochman & Graham D. Bonnett

Nature Biotechnology volume 38, pages160–162(2020) Cite this article

Engineering perishable crops for use in indoor farms promises to expand the adoption of this high-yielding, efficient means of food production.

Climate-controlled farms, including vertical indoor farms and greenhouses, have the potential to improve food security for the growing number of city dwellers worldwide. However, only leafy greens and herbs are grown commercially in most indoor farms1. If indoor farming is to realize its potential to increase fruit and vegetable production globally, the diversity of crops that can be grown indoors must increase. In this issue, Kwon et al.2 showcases the application of genetic technologies to modify both plant architecture and flowering times in tomatoes and groundcherries. This is an important example of how to expand the diversity of crops that can be grown in vertical farms.

Urban farming includes conventional soil-based outdoor smallholder farms, rooftop farms, greenhouses, and indoor, light-emitting diode (LED)-lit vertical farms. Urban agriculture accounts for 5–10% of global production of legumes, tubers, and vegetables, and is, therefore, an important source of income for producers and of food for their consumers3. Urban farms occupy less land than traditional farms, partly because of the higher cost of urban land compared with rural land. Recently, investment in sophisticated climate-controlled farms has increased. The most advanced of these are indoor, vertical, soil-less systems that have hydroponics or aeroponics culture setups with temperature and humidity controls, LED grow lights, automated nutrient dosing, pH controls, and CO2 enrichment.

Urban farms (indoor, greenhouses, or netted areas) in which the growing conditions are controlled can achieve substantially higher yields per unit area (kg/m2) than field farms while consuming orders of magnitude less water4. Stacking plants vertically indoors further increases the yield per unit area. Climate control can enable year-round harvests of high-quality, locally grown produce out of season. Crops grown indoors are not exposed to extremes of heat or cold, frosts, hail, drought, or flood. Fully enclosed farms physically exclude pests and diseases, resulting in a reduction in the use of fungicides and pesticides. Finally, growing perishable crops closer to consumers can shorten supply chains, reduce transportation and the associated economic and environmental costs of food miles, decrease storage times and provide consumers with products that have a longer shelf life.

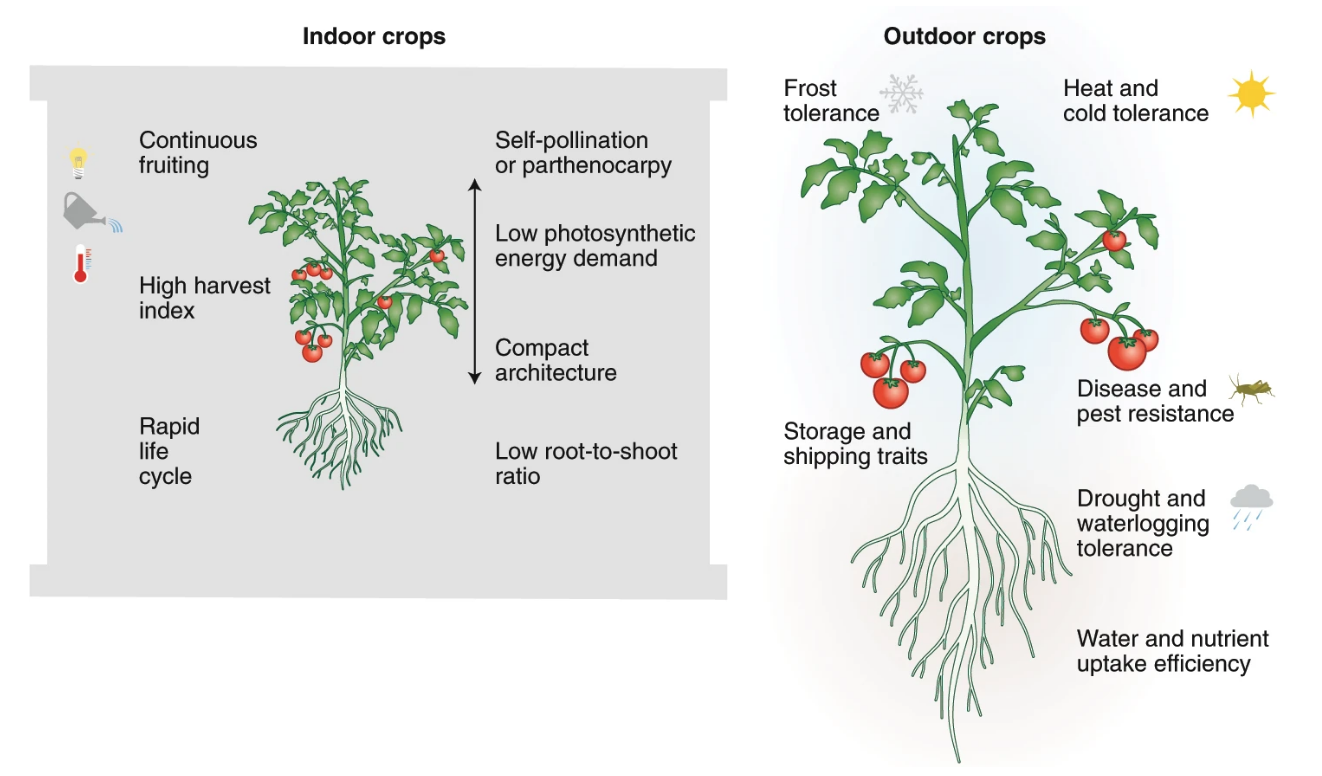

Leafy crops currently grown in vertical indoor farms are small in stature, have short times to harvest, have a high harvest index (all the aboveground biomass is harvested, unlike with fruits) and relatively low photosynthetic energy demand, and grow well in soil-less systems. These crops are also high in value per unit weight, which is a requirement for high-tech farms to be economically viable. Yet the value of leafy crops for food security is debatable. Most fruit and vegetable crops (including tubers and legumes) are not well suited to indoor, climate-controlled farms, and developing appropriate varieties will require optimization of several traits (Fig. 1). Indoor fruit crops need short life cycles, continuous flowering, low root-to-shoot ratio, increased performance under low photosynthetic energy input, and desirable consumer traits, including taste, color, texture, and specific nutrient contents.

In previous work, researchers have changed the architecture of grapevine by exploiting a naturally occurring mutation5 and of kiwifruit by applying gene editing6. In the present study, Kwon et al.2 engineered dwarf tomato and ground cherry plants by targeting a newly identified internode locus (SlER) and stacking this trait with mutations for compact growth habit and rapid flowering (SP5G) and for precocious flowering (SP). By editing three genes and using CRISPR–Cas9 for forward and reverse genetics, they rapidly altered a plant phenotype for indoor production.

The edited tomato varieties are well suited to indoor farming systems. Kwon et al.2 confirmed that the plants expressed the target traits of small stature, early yield, and rapid cycling both in traditional, soil-based field trials and in a commercial vertical farm under LED lights. They also found that, although the tomatoes produced were slightly smaller than for the wild type, each plant produced more fruit, and they had a similar sugar content (an important quality indicator) to the wild-type variety.

In this2 and previous5,6 reports on engineering dwarf crops, the plants exhibit continuous and/or precocious flowering, which greatly increases productivity and enables year-round production. Notably, different sets of genes were modified in tomato and groundcherry, grapevines, and kiwifruit to create the dwarf varieties. So, engineering indoor-farm-friendly plants of other species, such as pepper or cucumber, for example, may require different genetic changes. Even if there are several potential ways to engineer or breed dwarf, continuously flowering plants, the set of genes identified and targeted by researchers so far2,5,6 is likely to prove a useful starting point in a range of species.

For indoor farming to be broadly adopted, the capital and operating costs of climate-controlled farms must be reduced, or they will benefit only the wealthiest communities. These technologically advanced systems are capital intensive and out of the reach of most growers. The energy costs of crops grown in indoor farms far surpass those of field-grown crops7. The development of cheaper, more efficient LEDs was a crucial advance8, but other factors, such as linkage to renewable energy and waste heat reuse, are needed to further improve system economics. Urban farms are well placed to reduce waste by closing loops for water and nutrients, as well as energy, but more innovation is needed to make the recycling of urban waste into growing systems safe, efficient, and economical.

Agronomic research is required to assess how much climate control is needed to optimize crop management. In Australia, for example, greenhouses in peri-urban zones may be more appropriate than indoor farms in urban areas, because the climate is warm, with plenty of sunlight, and restrictions on available land are not extreme. In developing countries, research is needed to assess what capacity there is for smallholders in urban and peri-urban areas to benefit from intensifying production systems and what level of technology is appropriate. Advanced indoor farms are not likely to be feasible for many smallholders because of the associated costs, but there may be ways to use adapted crops in lower-tech, lower-cost systems, such as shaded structures with hydroponics, to increase yields and mitigate weather-related problems.

Although it is unlikely that indoor farms will provide all our staple dry goods (such as wheat and rice), they could increase the production of perishable fruits and vegetables, such as tomatoes, berries, capsicums, and spices. These horticultural products are a crucial source of vitamins, minerals, and fiber. Any plant that has high value and is eaten fresh could be grown indoors, but in many cases will be commercially viable only if genetic innovations such as those reported in Kwon et al.2 can be more broadly applied.

Fruits and vegetables that grow on bushes or vines (tomato, strawberry, raspberry, blueberry, cucumber, capsicum, grapes, kiwifruit) are likely to be most readily adapted for indoor farms, but high-value specialist crops (hops, vanilla, saffron, coffee) and medicinal or cosmetic crops (seaweed, echinacea) might be next.

One day, it is conceivable that even small trees (chocolate, mango, almonds) may be grown indoors. Importantly, the adaptation of a wide variety of plants for indoor cultivation could ensure that these crops can still be harvested in a future with an uncertain climate. Other products, such as medicinal cannabis, and insects and algae, which are used as alternative protein sources, are already being produced in indoor farms9.

Urban agriculture has existed for centuries, but the climate-controlled urban farming industry remains in its infancy. Interdisciplinary research in genetics, plant biology and physiology, agronomics, farming systems, engineering, and physics will be needed to improve the cost-effectiveness and productivity of modern urban farms. Broad-acre farmers and consumers have benefited from knowledge provided by agricultural researchers over centuries. Urban agriculture must receive similar support if it is to help feed growing urban populations in the face of increasing climate variability.

References

1. Benke, K. & Tomkins, B. Sustain. Sci. Pract. Policy 13, 13–26 (2017).

2. Kwon, C.-T. et al. Nat. Biotechnol. https://doi.org/10.1038/s41587-019-0361-2 (2019).

3. Clinton, N. et al. Earths Future 6, 40–60 (2018).

4. O’Sullivan, C. A., Bonnett, G. D., McIntyre, C. L., Hochman, Z. & Wasson, A. P. Agric. Syst. 174, 133–144 (2019).

5. Boss, P. K. & Thomas, M. R. Nature 416, 847–850 (2002).

6. Varkonyi-Gasic, E. et al. Plant Biotechnol. J. 17, 869–880 (2019).

7. Graamans, L., Baeza, E., van den Dobbelsteen, A., Tsafaras, I. & Stanghellini, C. Agric. Syst. 160, 31–43 (2018).

8. Kozai, T., Fujiwara, K. & Runkle, E. LED Lighting for Urban Agriculture. (Springer, Singapore, 2016).

9. Specht, K. et al. Sustainability 11, 4315 (2019).

Author information

Affiliations

CSIRO Agriculture and Food, Queensland Biosciences Precinct, St. Lucia, Queensland, Australia

Cathryn A. O’Sullivan, C. Lynne McIntyre, Ian B. Dry, Susan M. Hani, Zvi Hochman & Graham D. Bonnett

Corresponding author

Correspondence to Cathryn A. O’Sullivan.

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

O’Sullivan, C.A., McIntyre, C.L., Dry, I.B. et al. Vertical farms bear fruit. Nat Biotechnol 38, 160–162 (2020). https://doi.org/10.1038/s41587-019-0400-z

Published14 January 2020

Issue DateFebruary 2020

Share this article

Anyone you share the following link with will be able to read this content:

Get shareable link

Provided by the Springer Nature SharedIt content-sharing initiative

Subjects

Further reading

Food First: COVID-19 Outbreak and Cities Lockdown a Booster for a Wider Vision on Urban Agriculture

Giuseppe Pulighe

& Flavio Lupia

Sustainability (2020)

Water management beyond the fortressed COVID-19 world: considerations for the long-term

Katherine A. Daniell

UNITED KINGDOM: Work Could Start Soon On Futuristic Derbyshire Food Hub

Planning application in for scheme, which would create 5,000 jobs

Planning Application In For Scheme, Which Would Create 5,000 Jobs

BY ZENA HAWLEY

7 JAN 2021

This is how the SmartParc campus would look (Image: Ashtonsmith)

When you subscribe we will use the information you provide to send you these newsletters. Sometimes they’ll include recommendations for other related newsletters or services we offer.

Food production could be in full swing by the end of the year at a giant new Derbyshire industrial site.

That's if a planning application submitted by SmartParc gets the go-ahead in the near future.

The company has applied to create a 155-acre, hi-tech food manufacturing campus on the former Celanese site at Spondon.

It will provide state-of-the-art manufacturing facilities, start-up incubation units, and a potential location for a food manufacturing technology centre of excellence.

The idea is to combine purpose-built food production units and a central distribution facility bringing food producers together on one campus. In the process, it is expected to create up to 5,000 direct jobs.

The company's ambition is to provide a sustainable blueprint for the industry. This will harness the latest developments such as vertical farming and smart technology to improve production and energy efficiency, reducing costs, and increasing competitive advantage for the site's tenants.

Vertical farming is a new development and is where crops are grown indoors in stacked layers, mitigating the vagaries of the weather and eliminating the need for pesticides.

This is an example of vertical farming (Image: SmartParc)

Jackie Wild, SmartParc chief executive, said: "We are delighted to take another step forward in our plans to put Derby at the heart of the UK’s future in sustainable, efficient food manufacturing.

Is A Rainwater Harvesting System Suitable For Hydroponic Lettuce Cultivation?

The aim of this study was to determine the suitability of a rainwater harvesting system to cover the water demand for indoor hydroponic lettuce cultivation located in Wrocław, Poland

The aim of this study was to determine the suitability of a rainwater harvesting system to cover the water demand for indoor hydroponic lettuce cultivation located in Wrocław, Poland.

The analysis was performed on the basis of the recorded rainfall in Wrocław in 2000–2019. The analyzed cultivation is located in a hall with an area of 300 m2, where the lettuce is grown vertically by the hydroponic method.

The calculations of the rainwater harvesting (RWH) system were carried out considering the selection of the tank capacity for the collected water. The operation of the water storage is simulated using a yield after spillage (YAS) algorithm.

It was evident that the proposed system might be an auxiliary system that relieves the water supply network or supports other water recovery systems (e.g., the water vapor condensation in a cross-flow heat exchanger operating as an element of the air conditioning system, proposed in Part 1 of this study).

The harvesting system for the selected vertical farming indoor hall covers an average of 35.9% of water needs and allows a saving of 146,510 L of water annually for the cultivation. An average water demand coverage increases up to 90.4%, which allows a saving of 340,300 L per year when the RWH system is combined with water recovery from exhaust air from the hall.

Click here to access the complete study.

4 Jan 2021

Abandoned Spaces And Automation: What To Expect For Indoor Farming in 2021

Controlled-environment agriculture — also simply known as indoor farming — had a big year both in terms of activity and investment dollars

Controlled-environment agriculture — also simply known as indoor farming — had a big year both in terms of activity and investment dollars. While once we might have questioned the sector’s economic viability and ability to actually feed a growing global population, a lot of those doubts have diminished and indoor ag in its many forms now has an important role in our future food system.

What that role is, however, will continue to evolve over time. Here are a few thoughts on how that will happen over the next 12 months.

More automation.

Automation isn’t new to controlled-environment agriculture, but its presence as a part of indoor farming operations has increased over the last several months and will continue to in the next year.

In the context of controlled-environment farming, automation can refer to any kind of technology that removes manual human labor from the growing process. In some cases that includes robots that plant and harvest greens or move trays of produce around the farm. More often, though, automation refers to software that can calculate the optimal environmental temperature for each plant, know when plants need to be fed and harvested, and handle many other calculations that would otherwise require a person to have horticultural and technological (hardware and software) expertise.

Moving into 2021, we’ll definitely see a few more robots buzzing around the indoor farm. But the bulk of automation will be about software.

More grocery store partnerships.

Many large-scale indoor farms started out selling their leafy green wares to restaurants and hotels. The pandemic, of course, put a hold on that in 2020, and controlled-environment agriculture operations had to look elsewhere for customers.

Enter the grocery store. From container farms at local markets to Kalera’s partnership with Publix stores across the U.S., more indoor farming companies are growing their greens either onsite at grocery stores or within throwing distance of them.

This could in turn help bring the cost of greens grown on high-tech farms down, since the shipping and distribution steps will be less resource intensive in many cases and nonexistent in others.

More underutilized space.

One of my favorite stories from 2020 was this one, about a company called Wilder Fields that turned an abandoned Target store in south Chicago into a massive indoor farm.

Many companies are constructing their own facilities from the ground up, while others stick to smaller scale container farms that are a bit more mobile. Finding existing space, such as an abandoned big box retailer, seems a logical middle ground, and one we’ll likely see more of as companies work to lower costs and keep their environmental footprint down.

Predictions pieces, of course, are always a bit of a crapshoot, and even if the above forecasts turn out to be true, they’ll be but a smattering of the activity that will happen for controlled-environment ag in 2021.

FILED UNDER: AG TECH BUSINESS OF FOOD DELIVERY & COMMERCE FEATURED FOODTECH

AppHarvest Hires Impossible Foods’ David Lee As President

Lee brings track record capitalizing on innovative disruption to meet consumer demand

Lee brings track record capitalizing on innovative disruption to meet consumer demand

MOREHEAD, Ky., Jan. 7, 2021 – AppHarvest, the leading AgTech company building some of the country’s largest indoor farms and combining conventional agriculture techniques with cutting-edge technology to grow affordable, nutritious fruits and vegetables at scale, has appointed David Lee president, reporting to Founder & CEO Jonathan Webb effective Jan. 25.

In this newly created role, Lee will develop strategy and engage in operations management, leading the sales, marketing and finance functions as AppHarvest continues to grow as a sustainable fresh foods company.

Lee will join AppHarvest from Impossible Foods where he has served as chief financial officer since December 2015. He is credited with significant growth accomplishments at Impossible Foods including securing more than $1.3 billion in funding to accelerate manufacturing, product development and distribution into key national grocery, restaurant, and hospitality venues; and to expand in international markets. Additionally, Lee served as chief operating officer of Impossible Foods from 2015 to 2019, during a period of significant transformation for the company. Lee has served on the board of

directors of AppHarvest since August of 2020 and will continue to serve in that role after the closing of the previously announced business combination of AppHarvest with Novus Capital Corporation (Nasdaq: NOVS).

“David Lee brings decades of experience across retail and consumer industries driving business transformation and optimizing organizational effectiveness from Del Monte to Zynga to Impossible Foods,” said AppHarvest Founder & CEO Jonathan Webb. “His skillset will help us build AppHarvest into an iconic brand and sustainable foods company that disrupts traditional agriculture to deliver responsibly grown American products with social impact,” Webb said.

“AppHarvest offers a unique solution to building a more resilient and responsible food system. I have seen firsthand that when given sustainable options, consumers will be the market force that helps address climate change and food supply issues, ensuring success of companies that are putting the planet first, and I am eager to invest my time in a mission-driven company with so much potential to grow.”

In January, AppHarvest expects to begin the first harvest from its flagship farm – a 60-acre facility growing tomatoes – in Morehead, Ky. The company has two additional facilities under construction – a similar 60-plus acre facility outside Richmond, Ky., and a 15-acre facility to grow leafy greens in Berea, Ky. AppHarvest also is planning for more facilities across Kentucky and Central Appalachia, with nine potential projects in the pipeline through 2025.

AppHarvest grows produce using 100 percent recycled rainwater and zero chemical pesticides. Its indoor farms are designed to use 90 percent less water with yields that are up to 30 times higher compared to traditional open-field agriculture on the same amount of land. Its location in Appalachia allows it to deliver a strong social impact by building a diversified economy in economically distressed areas of the country, while enabling its products to reach about 70 percent of the U.S. population within a single day’s drive. As a result, AppHarvest expects to deliver fresher fruits and vegetables, ripened on the vine for peak flavor and nutrition, and an 80 percent reduction in diesel consumption required for transportation as compared to produce shipped from Mexico and the Southwest of the U.S.

Lee holds an MBA from the University of Chicago and a BA from Harvard.

How is AppHarvest different from traditional agriculture companies?

- The company’s controlled environment agriculture facilities are designed to reduce water usage

by 90% due to unique circular irrigation systems connected with large-scale rainwater retention ponds. The system is designed to eliminate harmful agricultural runoff, which contributes to toxic algae blooms.

- Strong relationships with leading AgTech universities and companies in the Netherlands position AppHarvest as a leading applied technology agriculture company. The Netherlands has developed a significant high-tech greenhouse industry, becoming the world’s second-largest agricultural exporter despite having a land mass roughly equal in size to Eastern Kentucky. Earlier this year, AppHarvest led a landmark 17-organization agreement uniting Dutch and Kentucky governments, universities, and private companies, with all committing to building America's AgTech capital from within Appalachia.

- AppHarvest puts the planet and people first as a registered Benefit Corporation and has also been certified as a B Corp by an independent organization.

In just over two years, AppHarvest has attracted more than $150 million in investment into Central Appalachia and announced on September 29, 2020, its entry into a definitive agreement for a business combination with publicly-traded special purpose acquisition company Novus Capital Corporation (Nasdaq: NOVS). The combination, which is anticipated to close early in the first quarter of 2021, is expected to provide $475 million of gross proceeds to the company, including $375 million from a fully committed common stock PIPE at $10.00 per share anchored by existing and new investors – including Fidelity Management & Research Company LLC, Inclusive Capital, and Novus Capital Corporation. Upon closing of the transaction, the combined company will be named AppHarvest and is expected to remain listed on Nasdaq under the ticker symbol APPH.

AppHarvest’s investors include Revolution’s Rise of the Rest Seed Fund, Inclusive Capital Partners, Equilibrium, Narya Capital, Lupa Systems, Breyer Capital and Endeavor Catalyst. Endeavor selected AppHarvest Founder & CEO Jonathan Webb as an Endeavor Entrepreneur in 2019.

Board members include food icon Martha Stewart, Narya Capital Co-Founder and Partner JD Vance and impact investor Jeff Ubben.

About AppHarvest

AppHarvest is an applied technology company building some of the world’s largest indoor farms in Appalachia. The company combines conventional agricultural techniques with cutting-edge technology and is addressing key issues including improving access for all to nutritious food, farming more sustainably, building a home-grown food supply, and increasing investment in Appalachia. The company’s 60-acre Morehead, Ky. facility is among the largest indoor farms in the U.S.

For more information, visit AppHarvest.

Forward-Looking Statements

Certain statements included in this press release that are not historical facts are forward-looking statements for purposes of the safe harbor provisions under the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements generally are accompanied by words such as “believe,” “may,” “will,” “estimate,” “continue,” “anticipate,” “intend,” “expect,” “should,” “would,” “plan,” “predict,” “potential,” “seem,” “seek,” “future,” “outlook,” and similar expressions that predict or indicate future events or trends or that are not statements of historical matters. All statements, other than statements of present or historical fact included in this press release, regarding Novus Capital’s proposed acquisition of AppHarvest, Novus Capital’s ability to consummate the transaction, the benefits of the transaction and the combined company’s future financial performance, as well as the combined company’s growth plans and strategy, future operations, estimated financial position, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward- looking statements. These statements are based on various assumptions, whether or not identified in this press release, and on the current expectations of AppHarvest’s management and are not predictions of actual performance. These forward-looking statements are provided for illustrative purposes only and are not intended to serve as, and must not be relied on as, a guarantee, an assurance, a prediction, or a definitive statement of fact or probability. Actual events and circumstances are difficult or impossible to predict and will differ from assumptions. Many actual events and circumstances are beyond the control of AppHarvest. These forward-looking statements are subject to a number of risks and uncertainties, including those discussed in Novus Capital’s registration statement on Form S-4, filed with the SEC on October 9, 2020 (the “Registration Statement”), under the heading “Risk Factors,” and other documents Novus Capital has filed, or will file, with the SEC. If any of these risks materialize or our assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. In addition, forward-looking statements reflect AppHarvest’s expectations, plans, or forecasts of future events and views as of the date of this press release. AppHarvest anticipates that subsequent events and developments will cause its assessments to change. However, while

AppHarvest may elect to update these forward-looking statements at some point in the future, AppHarvest specifically disclaims any obligation to do so. These forward-looking statements should not be relied upon as representing AppHarvest’s assessments of any date subsequent to the date of this press release. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Important Information for Investors and Stockholders

In connection with the proposed transaction, Novus Capital has filed the Registration Statement with the SEC, which includes a preliminary proxy statement to be distributed to holders of Novus Capital’s common stock in connection with Novus Capital’s solicitation of proxies for the vote by Novus Capital’s stockholders with respect to the proposed transaction and other matters as described in the Registration Statement, as well as the prospectus relating to the offer of securities to be issued to AppHarvest’s stockholders in connection with the proposed transaction. After the Registration Statement has been declared effective, Novus Capital will mail a definitive proxy statement, when available, to its stockholders. Investors and security holders and other interested parties are urged to read the proxy statement/prospectus, any amendments thereto and any other documents filed with the SEC carefully and in their entirety when they become available because they will contain important information about Novus Capital, AppHarvest and the proposed transaction. Investors and security holders may obtain free copies of the preliminary proxy statement/prospectus and definitive proxy statement/prospectus (when available) and other documents filed with the SEC by Novus Capital through the website maintained by the SEC at http://www.sec.gov, or by directing a request to: Novus Capital Corporation, 8556 Oakmont Lane, Indianapolis, IN 46260. The information contained on, or that may be accessed through, the websites referenced in this press release is not incorporated by reference into, and is not a part of, this press release.

Participants in the Solicitation

Novus Capital and its directors and officers may be deemed participants in the solicitation of proxies of Novus Capital’s shareholders in connection with the proposed business combination. Security holders may obtain more detailed information regarding the names, affiliations and interests of certain of Novus Capital’s executive officers and directors in the solicitation by reading the Registration Statement and other relevant materials filed with the SEC in connection with the business combination when they become available. Information concerning the interests of Novus Capital’s participants in the solicitation, which may, in some cases, be different than those of their stockholders generally, is set forth in the Registration Statement.

Greenhouse Villages To Sprout In Metro Manila

The Agricultural Training Institute (ATI) recently partnered with four barangays in Caloocan and Quezon for the creation of greenhouse villages as part of the urban agriculture program of the government

Louise Maureen Simeon

12/22/2020

MANILA, Philippines — The Department of Agriculture will start establishing greenhouse villages in Metro Manila to help ensure a sustainable food supply in the country.

The Agricultural Training Institute (ATI) recently partnered with four barangays in Caloocan and Quezon for the creation of greenhouse villages as part of the urban agriculture program of the government.

Urban agriculture is one of the flagship programs of the Plant Plant Plant initiative of the DA to boost supply amid the pandemic.

Barangays 179 and 180 in Caloocan and barangays Payatas and Tandang Sora in Quezon City will serve as pilot areas for the project.

Under the partnership, ATI will provide funding assistance for the establishment of a greenhouse village per barangay.

This will feature one unit of high greenhouse with an administration office and storage area, one unit of seedling nursery with micro-sprinkler irrigation, and one unit of production area with drip kit irrigation system.

The agreement also calls for 10 sessions of training program from the construction phase until harvest time.

Through this, the DA and ATI aim to showcase doable technologies of protective farming systems.

The partnership also targets to increase the production of vegetables and to make these available in the barangay level throughout the year amid varying weather conditions.

DA’s urban agriculture program has been gaining positive feedback from more institutions as it continues to help stabilize food supply, foster social integration, and protect the environment through eco-friendly methods and innovative gardening methods.

It was launched in April as an immediate response to the food supply disruption due to the pandemic.

VIDEO: How 2 Hong Kong Pioneers’ Hi-Tech Robotic Arms Can Transform Traditional Industries And Research

Technology created at Jonathan Cheung’s Inovo Robotics performs repetitive tasks that can cultivate sustainable crops and process foods in automated kitchens

Technology created at Jonathan Cheung’s Inovo Robotics performs repetitive tasks that can cultivate sustainable crops and process foods in automated kitchens

Eric Wong has transformed lab experiments with Nikyang’s automated tools that allow researchers to carry out a more reliable and systematic analysis

7 January 2021

While robotic technology has been widely used by big manufacturing companies to increase productivity, the high cost of getting started means many smaller businesses have yet to take advantage of its huge potential.

However, Inovo Robotics, a Hong Kong-based technology start-up, is working to solve this problem.

Since it was founded in 2016, the robotics company has been developing solutions for small- and medium-sized enterprises to help them adapt to automation in their everyday business practices.

Jonathan Cheung, the co-founder of the start-up, says his goal is to “democratize robots” and develop tools for all businesses to help them improve efficiency and remain competitive.

By submitting, you consent to receiving marketing emails from SCMP. If you don't want these, tick here

“We found that there is such a big disconnect to the market for small businesses to be able to benefit from affordable and flexible robots,” he says.

“There are a lot of businesses that are struggling to get staff to do monotonous tasks, so what we’re developing is really a tool that enables them to take away repetitive work.”

Jonathan Cheung, the co-founder of Inovo Robotics, says high entry costs mean that many small businesses have yet to take full advantage of automation’s full potential.

Disrupting traditional industries

One of the applications of the robotic arms has seen them used around the clock to carry out repetitive tasks that help grow high-quality, pollution-free vegetables at a futuristic farm in Hong Kong’s Tai Po district.

The farm, operated by indoor farming company Farm66 since 2018, is located inside a 20,000-square-foot (1,860-square-metre) factory building.

The use of the robotic arms to automatically sow seeds and harvest plants helps the farm to produce up to 200 tonnes of organic fresh produce, including cherry tomatoes, cabbage and basil, which is sold online and delivered to the city’s supermarkets and restaurants.

“Robots really improve the efficiency and speed of the products that are being made,” Cheung says. “In this competitive world, there is always a desire to drive costs down.”

In the case of vertical farming, the technology means minimal space and manpower are needed for the farming process, offering a glimpse of how technology will be able to transform farming in future.

Besides the vertical farm, the technology has also been used in an automated kitchen, where it helps with food processing to ensure cooking consistency. Inovo Robotics is also teaming up with a programming company to develop a system for high-resolution 3D scanning.

Inovo Robotics’ technology is being used to cultivate fresh organic produce at Farm66’s futuristic indoor farm inside an industrial factory building in Hong Kong. Photo: Farm66

Popularising robots for everyday use

Before setting up his own venture, Cheung spent more than a decade working as an engineer, when he witnessed first-hand how robots can help businesses scale their operations.

In 2016, Cheung and a colleague co-founded Inovo Robotics to popularise the everyday use of robot technology by businesses.

Its launch product, Modular Arm, with an adjustable system of six fully rotatable joints, gives the robot the flexibility to reach different positions. The robot’s modularity also gives customers an easy mechanism to choose longer or shorter arms, depending on their configurations.

Cheung says while large manufacturing companies often require tools that can automate a repetitive task, smaller businesses look for collaborative robots that can work alongside staff to complete different jobs at the same time.

“Smaller businesses tend to have smaller batch sizes and tighter spaces,” he says. “That is where a collaborative robot really comes into its own.”

Jonathan Cheung says Inovo Robotics’ modular robot technology offers small businesses a variety of options thanks to its adjustable flexible joints and the choice of using shorter or longer arms.

Inovo Robotics currently has two offices at Hong Kong Science Park, a government-run start-up incubator, and London, in the United Kingdom, as it seeks to tap into both the Asia-Pacific and European markets.

Cheung says Hong Kong has proved an ideal location to scale up his business because of its proximity to hi-tech research and an abundance of talent.

“[We can] be close to our supply chain, which allows us to manage it closely and deliver the best product to our customers,” he says.

“At any point in Hong Kong, you are probably within 25km to five or 10 great universities,” he adds. “There is a wealth of talent to be able to tap into – there are only a few countries with that level of accessibility.”

Revolutionizing academic research

Another Hong Kong start-up, Nikyang, has also developed fully automated laboratory equipment to help academic researchers increase the reliability of data collected in experiments.

Today, its automation technology has been applied in many settings, such as research institutes and pharmaceutical and biotechnology companies.

The venture was founded by Hongkonger Eric Wong in 1999 with the initial goal of helping researchers in traditional Chinese medicine (TCM) to conduct analysis in a more systematic way.

“The basic dream of Nikyang was originally to pursue TCM research to gain a better understanding,” says Wong, who graduated with a master’s degree in biochemistry in Canada.

“I thought we needed a more standardized way of doing analysis in TCM to collect valid and precise information.”

Eric Wong, the founder of automation company Nikyang, says the use of robotic technology allows researchers to conduct more systematic analysis.

When he started his business journey by reaching out to laboratories in Hong Kong and mainland China, he realized that researchers wanted to use machines to help them follow the correct procedure as closely as possible while carrying out repetitive work.

However, many automated instruments available then lacked the ability to carry out different steps in lab research, he says, rendering them error-prone when applied in studies.

To solve the problem, Wong collaborated with Chemspeed, a Switzerland-based provider of lab equipment, in developing specific instruments for TCM research.

His team has integrated Chemspeed’s tools with robotic arms and wearables to increase collaboration between researchers and machines in conducting the analysis.

However, he realized the company would not be sustainable if it focused solely on serving the TCM industry, so he later diversified the business and began developing solutions for different settings.

In 2008, Nikyang began receiving orders from petrochemical companies in China, which gave Wong a lifeline to sustain his business and pursue his dream in TCM research.

The venture now places an emphasis on boosting effectiveness by providing an immerse lab experience.

Its SmartLab product, which is still under development, is set to integrate sensor technology, smart wearables, and cloud data management to help researchers work more efficiently with machines.

Nikyang’s SmartLab, which is still under development, will integrate sensor technology, smart wearables, and cloud data management so researchers can work more efficiently with machines. Photo: Nikyang

Nikyang has its headquarters at Hong Kong Science Park, where it carries out most of its research and development work. To tap into the China market, it has also opened branches in Beijing, Shanghai, and Guangzhou to sell its products.

Wong says Hong Kong has served as an ideal location to grow his company because of its connectivity with China and different parts of the world.

“Hong Kong is definitely unique in terms of being a super-connector between the East and the West,” he says.

The city’s world-class financial market and sound legal system have also helped start-ups in raising capital and developing ideas as they embark on their journey.

Pioneering spirit

Both Wong and Cheung believe it is important for aspiring innovators to be passionate about their business vision to help them overcome challenges when developing and selling the products.

Wong, who spent a decade before he found a way to make his business sustainable, says it was vital to remain dedicated because many innovators experience failures before they can get their businesses on track.

“You need to have passion and a big heart to accept failure, and [an] even bigger heart to think and take risks,” he says.

Eric Wong, who spent a decade before finding a way to make Nikyang sustainable, says aspiring innovators should be passionate about their business vision – and not focus only on profits.

Wong also advises young entrepreneurs not to look only at making profits if they want to make a difference in the world.

“Money is only a by-product,” he says, adding that many successful pioneers often have to make substantial investments before they are able to disrupt the industry.

Cheung agrees that innovators must feel empowered to turn ideas into reality.

“My advice is to really focus on the business model,” he says. “It’s a very, very difficult journey to go on, and it’s very, very rewarding as well. And it’s very important to make sure you stay true to what you believe in.

“Having an idea that you believe in wholeheartedly, that you are willing to give your time and commitment to, is a good validation that you are on the right track.”

Morning Studio is the commercial content team of the South China Morning Post (SCMP). It aims to engage readers through storytelling while enabling the brand behind the content to achieve its marketing objectives. The Morning Studio team consists of specialists in various areas such as journalism, multimedia graphics, video production, digital technology, and marketing.

SCOTLAND: Vertical Farming Research Gets Government Funding

EFFORTS to develop vertical farming technology are to get a share in £90million of UK Government funding allocated as part of its drive to get agriculture to 'net zero' carbon emissions by 2040

January 7, 2012

Political Affairs Editor

Light Science Technologies works with growers involved in vertical farming to provide solutions for controlled environment agriculture

EFFORTS to develop vertical farming technology are to get a share in £90million of UK Government funding allocated as part of its drive to get agriculture to 'net zero' carbon emissions by 2040.

Derby-based company Light Science Technologies is one of just 23 feasibility projects which will benefit from this cash pot from the UK’s innovation agency, Innovate UK, as part of its 'Transforming Food Production' challenge.

In partnership with Nottingham Trent University, LST will be leading the project to develop a growing sensor and transmission node for vertical farms over the next six months.

It is hoped that this ‘all in one’ indoor farm sensor will enable farms to monitor and control their environment by measuring key areas including light, water, air, temperature, humidity, oxygen, and soil to ensure optimal plant productivity and yield.

CEO of LST, Simon Deacon, said: “This is an especially important boost to our business. To be selected by Innovate UK is confirmation of the urgent need for more sustainable, productive, and cost-effective solutions in farming. Investment in UK technology and innovation in this sector is crucial in achieving a better approach to agricultural production and reducing emissions.”

Innovate UK executive chair Dr. Ian Campbell added: “There are many innovative projects in our latest feasibility competition showcasing ideas for improving productivity and cutting emissions that range across the whole agricultural sector, from arable to livestock, to sensor technology, and to new biopesticides. Our funding and support for these projects is ongoing.”

Grower To Flexible Packaging

Forward Greens' vertically farmed edible plants packaging was changed twice before finding the best metrics-based sustainable option, an OPP pillow pack

Forward Greens' vertically farmed edible plants packaging was changed twice before finding the best metrics-based sustainable option, an OPP pillow pack.

January 04, 2021

Sometimes the best of intentions doesn’t turn out as expected, which is why the phrase “if at first, you don’t succeed, try, try again” was crafted for those whose persistency pays off.

Taking that to heart was Forward Greens, an indoor “vertical farm” brand in Vancouver, WA, that went from PET clamshell packaging to tetrahedral-shaped oriented polypropylene bags to OPP pillow-pack bags. The final iteration was part of a major rebrand this year that centered on using the most sustainable packaging. Ken Kaneko, the company’s founder, and CEO provides answers regarding the packaging and decision-making process.

How did your sustainable journey begin?

Kaneko: Forward Greens’ process for developing a sustainable packaging solution for our greens started with researching waste stream management with local municipalities to understand how we could integrate with the existing infrastructure. Along with the Oregon Department of Environmental Quality and Portland Metro, we ran a Life Cycle Assessment (LCA) to understand the impact of production, logistics, and disposal for available packaging options. From this, we learned that material mass was the largest driver in carbon emissions and that most plastics, even compostable ones, are not accepted by the municipalities. After synthesizing all the information, we concluded that flexible plastic packaging demonstrated the lowest material mass and thus the lowest carbon emissions.

Forward Greens

It would be helpful to know more about your products and customers.

Kaneko: Forward Greens currently has 9 products across baby greens and microgreens, all delivered from farm to market within 48 hours of harvest. We’re unique in that it takes about 19 days from seed to market shelf for our baby greens and about 9 days from seed to market shelf for our microgreens.

Our target customer is anyone who is interested in locally grown, healthy greens — to use for salads, as ingredients, or toppings. We hope we attract those who are especially conscious of their impact on the environment, knowing that with our products, customers are not extraneously stressing the planet. That of course includes our packaging, but also in how we grow the plants themselves. Our sustainable indoor farming practices use 95% less water and 99% less land than outdoor agriculture. We skip the use of herbicides, pesticides and fungicides, and use only non-GMO seeds.

Why was the polymer choice made?

Kaneko: When we rebranded to Forward Greens this summer, we shifted from PET clamshell packaging to OPP flexible packaging to better reflect our mission. The OPP film uses 92% less plastic than traditional clamshells, 12 times less plastic, and produces eight times fewer carbon dioxide emissions compared to, for example, a recycled polypropylene tub.

Forward Greens

Comment on the tetrahedral design (seen above).

Kaneko: Forward Greens initially decided to adopt a tetrahedral shape for our packaging to help the product stand out, but also for two primary logistical reasons. First, the tetrahedral shape allows for more volumetric space for the greens with the same amount of plastic material. Second, the tetrahedral shape uniquely helps our greens stay safe and avoid getting crushed throughout the distribution process from farm customer’s plates.

Why didn’t that work and what was behind the change to the pillow pack?

Kaneko: There are a few reasons why Forward Greens decided to switch from the tetrahedral shape to the pillow pack. The primary reason is that retailers merchandise based on existing shelving units, which are often paid for by incumbent or slotted brands. Trying something new in that environment is very difficult, both for new brands and the retailers. Even though Forward Greens did receive initial buy-in from our retailers and staff, when it came time for the new packaging to rollout, it was more complicated to accommodate the new shape on the shelf than expected, so we adopted the pillow pack to streamline that process for everyone involved.

Forward Greens

Also, we used to be known as West Village Farms, but changed our brand to Forward Greens this summer to better reflect our dedication to sustainable practices and our hope to move the entire industry forward. The packaging change from our clamshells to the tetrahedral packaging shape was part of that brand launch. The most-recent package change from the tetrahedral shape to the pillow pack uses the same look that debuted this summer, but in the pillow-pack shape.

As an indoor farm, Forward Greens is constantly trying to improve yields and reduce production costs. Our recent switch from the tetrahedral packaging design to the pillow pack shape increased our content volume and net weight by 33%.

Talk about the timeframe for these changes.

Kaneko: The process for developing both our new packaging and rebrand as Forward Greens from West Village Farms was a huge undertaking. We began the initial planning and development for the new brand in late 2019. The new packaging and brand officially launched the summer of 2020 in the midst of the pandemic.

Switching from the tetrahedral shape to the pillow pack took about four months.

Can you credit the other companies involved?

Kaneko: We worked with Grady Britton, a Portland, OR-based marketing agency, to develop our new brand and packaging design. We wanted the new look to bring to life what we stand for, so the packaging reflects a love of community, food, and the planet while sparking joy. The new-look is vibrantly colorful, and part of that is because bagged greens is a crowded market. The new brand design stretches accepted notions of produce packaging design while ensuring the product still looks appetizing. The bag also offers a windowed look inside so customers can see how fresh the greens are.

What feedback have you received?

Kaneko: Forward Greens’ customers and retailers appreciated the effort and unique look of the new packaging shape. We may have just been a little bit ahead of the curve for the greens industry with the tetrahedral packaging shape.

What lessons did you learn in the past months?

Kaneko: Brands need to be selective about trying new things at retailer sites. There is a certain speed at which retailers move and it’s very different from the speed at which a company, like Forward Greens, moves. Regardless of the change back to the original pillow pack packaging shape, our fundamental goal is that our packaging has one of the lowest environmental impacts available, all while helping retailers merchandise our greens to the customers who want to buy our products.

TAGS: SUSTAINABLE PRACTICES SUSTAINABILITY EXTRUSION: FILM & SHEET

Iron Ox Announces Next Robotic Farm In Lockhart, TX

Iron Ox has purchased nearly 25 acres of land and plans to build a new, state-of-the-art facility on the property

November 6, 2020

LOCKHART, TX, — Iron Ox, a leader in robotics and AI-enabled farming with a mission to solve food insecurity, and the City of Lockhart, Texas today announced that Iron Ox will expand their operations to the city with plans to break ground on a new facility this December, bringing new tax revenue and jobs to Lockhart.

Since 2015, Iron Ox has developed hybrid robotic greenhouses that support a range of produce offerings. To bring those produce offerings to new communities, the company identified Texas as the next state in their national expansion plan with its favorable business environment and rich history of agriculture.