Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

INDIA: This Goa Couple Grow Their Veggies & Fish Without Using Soil or Chemicals!

On 185 square meters of greenhouse and rooftop garden, in their house at Dona Paula, Panaji, they produce 120 kilograms of fish a year and grow 3,000 plants consisting of vegetables and fruits

AUTHOR: GUEST CONTRIBUTOR

December 1, 2020

Goa-based Peter Singh is 74-years-old, and his wife Neeno Kaur is 65. They are a power couple, setting an example of how to be self-reliant with food, and at the same time, converting biodegradable waste into something useful.

On 185 square meters of greenhouse and rooftop garden, in their house at Dona Paula, Panaji, they produce 120 kilograms of fish a year and grow 3,000 plants consisting of vegetables and fruits.

For the last four years, they have been practicing aquaponics at home, a combination of aquaculture (raising fish in tanks), with hydroponics (cultivating plants in water).

However, they do with a twist. “We do aquaponics with permaculture,” says Peter Singh, explaining his system to a bunch of enthusiasts earlier this year.

(L) Peter Singh in his air-conditioned greenhouse that has plants which require a cooler climate. (R) Ornamental fish are grown in a fish tank

He adds, “We compost our kitchen and garden waste and use it in our aquaponics. Plants are potted in a layer of gravel, 1/3rd of coco peat, and 2/3rd of compost. So, our plants get compost plus fish waste, which results in a higher yield. I don’t use any chemicals for this, and I am taking care of my waste and my food.”

One may wonder why they are doing it. For them, the answer is simple–they want to eat organic and be sure of how their food is grown.

Moreover, both have a background in agriculture.

“I was studying Mathematics at the Delhi University; the idea was to stay in Delhi, but then we thought of moving back to our farms in Jalandhar, Punjab. We worked on different forms of agriculture, in which different fruit and timber trees were planted, we did intercropping in the orchard of oilseeds and pulses, produced seeds for the national seed corporation, had a dairy farm, did beekeeping and even exported the honey,” explains Singh.

They moved to Goa seven years ago and found it difficult to source organic vegetables. The majority of the vegetables in the state come from the neighboring city of Belgaum in Karnataka. So, they decided to grow their food in this unique way.

“As we have limited space in Goa, we experimented and discovered aquaponics. We downloaded papers from universities, and read about it. And came up with this model,” says Singh.

They opine that they are still experimenting and bring in changes accordingly. As they have the technical know-how and a background in farming, they are quite confident of their system.

How this system works

Peter Singh explaining the model

This system of aquaponics which involves the fish tank, NFT pipes, (Nutrient Film Technique) which are used to grow vegetables, water-pumps, and artificial grow lights, may look complicated. But Singh makes it easier to understand. He has also made a model of this system that can fit in any balcony or even in any corner of the living room.

“This unit of 2 ft by 6 ft and 6 ft high, with artificial lighting of 200 watts uses 250 litres of water and can grow 180 plants. One can grow lettuce, kale, bok choy or any other vegetable. One fish tank can sustain five kilograms of fish mass so that you can have ten fresh-water fish of ½ kg each,” elaborates Singh.

The system works mainly on electricity, water, and fish waste.

Singh explains, “In a fish tank, the fish waste is mainly ammonia. In this system, aerators circulate the water and create a current. The fish waste settles at the bottom, and the pipes take this waste into the bio-filter, which breaks the ammonia into nitrates and nitrites for plants to use.”

The water gets further filtered and goes back to the fish. It also has aeroponic towers which work as the nursery of plants. It is also a space-saving system as it is vertical.

“Because of heavy nitrogen, green vegetables grow very well. We have lettuce, bok choy, and celery. Also, this system uses 10 percent of the water used in traditional soil-based farming, as water is constantly getting re-used. The only loss is in the evaporation. There’s no need of watering, no weeding, one only has to feed the fish twice a day,” says Neeno Kaur.

The entire system has three fish tanks on the ground floor. One is of 3,000 litres of water; second is 1,500 litres, and the third is 4,000 litres. They raise three types of fresh-water fish—rohu, catla, and chonak or sea bass. If one does not eat fish, Singh suggests using ornamental fish.

The rooftop garden

On their roof, they have a greenhouse of 12ft by 24ft, which has 2,000 plants. The greenhouse in the back garden is 6 ft by 16 ft and has 500 plants. A roof-top garden has 25 fruit trees, 300 onions, and an assortment of chillies, lemons, tomatoes, aloe, chives, creepers like ivy gourd, bottle gourd, cucumber, bitter gourd, ladyfinger, brinjal.

Along a boundary on the ground floor, they have mango, banana, and papaya. They also have an air-conditioned tunnel of 8 ft by 12 ft in their greenhouse, with 1,000 plants of lettuce, kale, bok choy, basil, parsley, cabbage, and broccoli. For the whole system, they spend around Rs 14,000 per month.

The aquaponics system doesn’t require cleaning of water as the water gets filtered in the process. And all the fittings are made by Singh himself. He has also part-time workers for about six hours a day. He adds, “We spend Rs 6,000 on electricity, Rs 4,000 on feeding the fish, and another Rs 4,000 on labour.”

They won the first prize for Most Innovative Stall at the Aqua Goa Mega Fish Festival 2020 held in February.

Agriculture expert from Goa, Miguel Braganza opines, “Peter Singh’s aquaponics is good for those who can afford it as the basic cost of the unit is Rs 30,000. Also, it is ideal for those who eat salads and continental cuisine.”

Regarding the cost, Singh states that it is high “because we pump water from the ground floor to the greenhouse on the roof. If it is on the same floor, this is much lower.”

They also have plans for solar panels and making fish feed at home to be self-sustainable. He adds, “If we automate the system, and put in solar power, then costing will go down substantially. We are also working on growing feed for fish. So our whole system becomes self-dependent.”

However, they are also trying to monetise from this system, by conducting two-day training programmes priced at Rs 5,000. Singh adds, “We also custom design and help set up aquaponics systems, of any scale, from small home systems to commercial systems, charging 10 per cent of the capital cost for the design.”

(L) Bok Choi grown in aeroponic towers. (R) Gourds grown on the roof.

Recently, they started selling these vegetables from their home. A basket contains two bunches of lettuce, a baby bok choy, three sticks of celery, sprigs of parsley, basil, and a small bunch of mint, priced at Rs 100. They will also add kale and Swiss chard to it. From next month, their air-conditioned model will produce about 300 packs of greens a month at Rs 120 each.

Singh and Kaur are hopeful that more people will learn from this system and eat healthy food as it is the need of the hour.

He concludes, “This method is independent of the weather, rain, hail, and sun; it is protected from predators and is the future of agriculture. It doesn’t need land, soil, or chemicals, and produces vegetables and fish wherever you are.”

Also Read: Experts Answer: Can a Hydroponics Farm Be a Good Business? Here’s How!

This shows that aquaponics could be next best thing in agriculture due to urbanisation and loss of agricultural land. It is estimated that the market of aquaponics will grow with the awareness to eat healthy food.

According to a report by Assocham and Ernst & Young, organic products market in India have been growing at a CAGR (Compound Annual Growth Rate) of 25 percent, expected to touch ₹10,000-₹12,000 crore by 2020 from the current market size of ₹ 4,000 crore. As aquaponics is a part of the organic market, the future looks bright for this new-age form of agriculture.

During the current nationwide lockdown to tackle COVID-19, Peter Singh is selling their produce once a week from their home by maintaining social distancing. He says, “We slowed down the sale of our produce in the first week, and worked out a weekly production schedule, which includes a weekly harvest and transplantation. This means we will be able to supply every week all year round.”

Lead photo: Peter Singh is 74, and his wife Neeno Kaur is 65. Together, they grow 3,000 plants on just 185 sqm by a method that’s independent of the rain, hail, and sun!

(Written by Arti Das and Edited by Shruti Singhal)

Sky-High Vegetables: Vertical Farming Sprouts In Singapore

Entrepreneur Jack Ng says he can produce five times as many vegetables as regular farming looking up instead of out. Half a ton of his Sky Greens bok choy and Chinese cabbages, grown inside 120 slender 30-foot towers, are already finding their way into Singapore's grocery stores

November 9, 2012

Singapore is taking local farming to the next level, literally, with the opening of its first commercial vertical farm.

Entrepreneur Jack Ng says he can produce five times as many vegetables as regular farming looking up instead of out. Half a ton of his Sky Greens bok choy and Chinese cabbages, grown inside 120 slender 30-foot towers, are already finding their way into Singapore's grocery stores.

The idea behind vertical farming is simple: Think of skyscrapers with vegetables climbing along the windows. Or a library-sized greenhouse with racks of cascading vegetables instead of books.

Ng's technology is called "A-Go-Gro," and it looks a lot like a 30-foot tall Ferris wheel for plants. Trays of Chinese vegetables are stacked inside an aluminum A-frame, and a belt rotates them so that the plants receive equal light, good airflow, and irrigation. The whole system has a footprint of only about 60 square feet or the size of an average bathroom.

Troughs of bok choy stack up vertically at the 30-feet urban farm in Singapore. The veggies rotate along the A-frame to ensure they receive even light. Courtesy of MNDSingapore.

Advocates, whose ranks are growing in cities from New York City to Sweden, say vertical farming has a handful of advantages over other forms of urban horticulture. More plants can squeeze into tight city spaces, and fresh produce can grow right next to grocery stores, potentially reducing transportation costs, carbon dioxide emissions, and risk of spoilage. Plus, most vertical farms are indoors, so plants are sheltered from shifting weather and damaging pests.

But is vertical farming just a design fad, or could it be the next frontier of urban agriculture? That depends on your angle — and location.

Implementing these "farmscrapers" on a commercial scale has been challenging, and making them economical has been almost impossible.

It's still up for debate whether vertical farms are more efficient at producing food than traditional greenhouses, says Gene Giacomelli, a plant scientist at the University of Arizona, who directs their the Controlled Environment Agriculture Center.

The limiting factor is light. The total food produced depends on the amount of light reaching plants. Although vertical farms can hold more plants, they still receive just about the same quantity of sunlight as horizontal greenhouses.

"The plants have to share the existing light, and they just grow more slowly," Giacomelli tells The Salt. "You can't amplify the sun."

For American cities, like New York and Chicago, Giacomelli thinks putting plain-old greenhouses on rooftops could be just as efficient as vertical farms – and a lot easier to implement.

In fact, two companies are already working on that approach. Gotham Greens is producing pesticide-free lettuce and basil for restaurants and retailers from rooftop greenhouses in Brooklyn, while Lufa Farms grows 23 veggie varieties in a 31,000-foot greenhouse atop a Montreal office building.

But for the island of Singapore, where real estate is a premium, vertical farming might be the most viable option. "Singapore could be a special case, where land value is so exceptionally high, that you have no choice but to go vertically," Giacomelli says.

An illustration of the 177-feet vertical farm by Plantagon currently in the works for Linkoping, Sweden.

The Sky Greens vegetables are "flying off the shelves," reports Channel NewsAsia — perhaps because the vertical veggies are fresher than most available in Singapore, which imports most of its produce from China, Malaysia, and the U.S. They do, however, cost about 5 to 10 percent more than regular greens.

"The prices are still reasonable and the vegetables are very fresh and very crispy," Rolasind Tan, a consumer, told Channel NewsAsia. "Sometimes, with imported food, you don't know what happens at farms there."

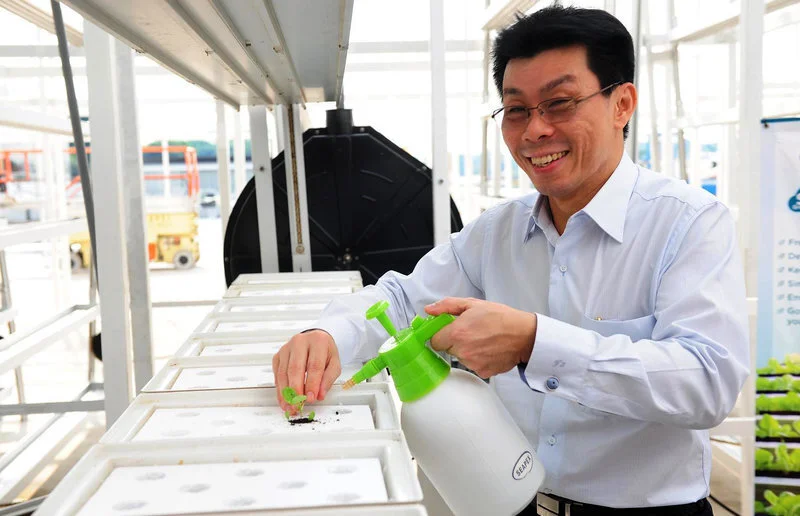

Lead photo: Senior Minister of State Lee Yi Shyan transplants some leafy green seedlings at the grand opening of Singapore's first commercial vertical farm. Courtesy of MNDSingapore.

SWEDEN: Vinnova Grants Swegreen And Research Partners 9,1 MSEK Funding For An AI-driven Vertical Farming Project

Nov 13, 2020

Swegreen, RISE Research Institutes of Sweden and Mälardalen University team up in an innovation and research cluster named AIFood - From Farm to Fork.

Swedish AgTech rising star Swegreen, together with research partners RISE and Mälardales University, secures funding from Vinnova, for a 9,1 MSEK project aiming to develop further Swegreens’ platform for AI-driven vertical farming and to evolve a digitalized supply chain from farm to fork.

The research partners Swegreen, Mälardalen University and RISE Research Institutes of Sweden, have teamed up together to digitalize the urban farming industry and restructure the urban food industry towards climate neutrality by help of Artificial Intelligence. The core for the partners research is Swegreens’ innovation for hyper-local vertical farming and building connected and circular models for integration of those facilities in host buildings.

The cluster started off earlier this year with the project ‘NeigbourFood’, funded with 2 MSEK by Swedish Innovation Agency Vinnova, to further develop a data-driven monitoring and optimization for precision farming in closed-loop indoor environment for Swegreen’s offer for Farming as a Service FaaS. The clusters' new project, called ‘AIFood’, has now been granted with 9,1 MSEK, corresponding to approx. 1 Million USD, to enhance the local and sustainable food production systems in urban environments with help of digital technologies.

– A data-driven approach on Vertical Farming has been Swegreens’ main focus from day one, and sustainability is embedded in our DNA as a greentech company, Andreas Dahlin, CEO of Swegreen, says.

– Hand in hand with our technological development, our concrete collaboration with the leading research and academic institutions of Sweden gives us the upper hand to lead this industry’s development as a spearhead enterprise – and our partnership with RISE and Mälardalen University keeps our position on the edge of the development, globally speaking, Andreas Dahlin continues.

The call ‘AI in the service of the climate’ has been launched by the Swedish Innovation Agency Vinnova to support initiatives that focus on use of Artificial Intelligence for minimizing various industries' climate-negative impact. The agricultural and food sector accounts for 30% of the global GHG emissions, and vertical farming can create urban symbiosis as a key factor for resource efficiency and integration of farming facilities into urban infrastructure for significant global greenhouse gas emission cutback.

The ‘AIFood’ project runs for two years and focuses on a proof of concept for autonomous orchestration of vertical farming facilities modeling, and on development of an AI-based platform for precision farming, integration of vertical farms into host buildings, and autonomous interaction of the production facilities with the after-harvest actors.

Dr. Baran Cürüklü, from Mälardalen University – a vibrant AI development academic center – is the Project Lead for the cluster.

– AI can go beyond narrow and specific contributions. In this project, our aim is to demonstrate that complex and intricate systems can be orchestrated by AI, and contribute to rapid transition to a more sustainable agriculture, and even innovative services connecting the whole chain from producer to citizens, says Dr. Baran Cürüklü.

The project has a close collaboration with two other national project platforms as reference groups: Sharing Cities Sweden, a national platform for sharing economy with four testbeds in Stockholm, Umeå, Gothenburg, and Lund and a cluster called Fastighetsdatalabb which focuses on data-related advancement of the real-estate sector.

Dr. Charlie Gullström, a senior researcher at RISE, Sweden’s major research institution and head of Sharing Cities Sweden’s Stockholm testbed, plays an indispensable role in this project. She convenes an interdisciplinary climate panel connected to this project including household name researchers who focus on the climate aspect of the project. Dr. Alex Jonsson from RISE is another senior researcher that attends to the needs for the project from a technical perspective.

Dr. Gullström adds:

– I believe that urban food production can speed up climate transition because it has the potential to engage citizens in local consumption and circular business models that both reduce food waste and unnecessary transports. AI allows us to explore how to complement existing agricultural systems by actively involving stakeholders in the value chain as a whole. In this way, AIFOOD really points the way to a new green deal.

Sepehr Mousavi, Chief Innovation Officer of Swegreen remarks:

– We are proud of this collaboration with leading Swedish research institutions and researchers and see it as a successful model for how a private entity could collaborate with academia and offer its assets as a research infrastructure for the good of the whole industry, in a planet and prosperity win-win model.

– This green transformation of the food sector is dependent on empowering factors such as innovation and circularity enhancement, a connectivity-based and data-driven approach through the whole chain; and the application of Artificial Intelligence as an exponential enabler. Autonomous control of the vertical farming facilities for maximum resource efficiency, scalability and preciseness of operations is of extreme and fundamental importance for both the industry and our company to move forward, adds Sepehr Mousavi.

Sepehr Mousavi

Chief Innovation Officer

+46(0)733140043

Tags#AI#SweGreen#ArtificialIntelligence#smartcities#foodtech#faas#Viablecities#RISE#MälardalenUniversity#agriculture

This 2-Acre Vertical Farm Produces More Than ‘Flat Farms’ That Are Using 720 Acres

The company’s method for growing greens, like baby kale and lettuce, on giant vertical racks, moved around by robotics recently garnered $400 million in investment capital from the likes of SoftBank, Amazon CEO Jeff Bezos, and former Google chairman Eric Schmidt

By Andy Corbley

Nov 24, 2020

Another massively successful vertical farming startup is pushing the future of farming towards the sky, literally and figuratively.

From an ag-tech startup named Plenty, a two-acre indoor vertical farm produces yields that would normally require a 720-acre ‘flat farm’—and it can be done with 95% less water.

Saving water is critical in an agricultural state like arid California, where Plenty is set to supply fresh produce for 430 Albertsons grocery stores.

Plenty

The vision is truly one out of Star Trek, with Plenty’s use of robotics and artificial intelligence to ensure perfect plants year-round.

The reasons to support indoor vertical farming are varied, ranging from climate-related benefits to removing cumbersome logistical challenges like long-distance transportation.

The company’s website says the technology “frees agriculture from the constraints of weather, seasons, time, distance, pests, natural disasters, and climate” that makes GMO-free nutrient-rich plants at scale with “extraordinary flavor.”

Perhaps that is why Driscoll’s, America’s largest fresh berry farmers, have agreed to grow their strawberries year-round in Plenty’s expanding portfolio of vertical farms.

And investors are seeing the potential of seeding their own portfolios with Plenty.

The company’s method for growing greens, like baby kale and lettuce, on giant vertical racks, moved around by robotics recently garnered $400 million in investment capital from the likes of SoftBank, Amazon CEO Jeff Bezos, and former Google chairman Eric Schmidt.

Time to grow

Reductions in transportation chains would eliminate millions of tons of CO2 every year, since instead of importing produce into city centers from farms across the country or the world, you could order it from a warehouse on the edge of town.

Furthermore, Plenty’s farms grow non-GMO crops without the use of pesticides or herbicides, and recycle every drop of water that’s not used, making them extremely friendly to the environment—except for their power usage.

A spokesperson told GNN they were using 100% renewable energy for their flagship farm in San Francisco, to keep emissions down.

Bathed in sun-mimicking LED lights in climate-controlled spaces year-round, the farm ensures veggies grow at an astounding rate, which produces 350-times more food per acre.

Supply-chain breakdowns resulting from COVID-19 and natural disruptions like this year’s California wildfires, demonstrate the need for a predictable and durable supply of produce can only come from vertical farming, says Nate Storey, co-founder of Plenty.

This will be all the more important if continual warming of the planet leads to droughts or other climate-related disruptions that can’t be overcome by farmers and biologists attempting to make crops more climate and drought-resistant.

MORE: The Largest Urban Rooftop Farm in the World is Now Bearing Fruit (and More) in Paris

Furthermore, vegetables and fruits contain far more micronutrients than cereals, but they also spoil fast and therefore are more expensive. Nations and inner cities that have to import all fresh produce places the poorest in the society at an extreme disadvantage nutritionally speaking. Vertical farming could be the way to solve that problem permanently.

Not only that, Plenty told GNN they have introduced new packaging that is not only made of recycled plastic, it is 100% recyclable, and it keeps food fresh longer to cut food waste.

TAGS Innovation Technology California Food Agriculture Eco-Friendly

GoodLeaf Produce Gets ‘Ontario Made’ Designation

Nutrient-dense microgreens and baby greens are harvested daily at GoodLeaf Farms’ innovative indoor vertical farm in Guelph, Ont., using sustainable practices and the latest technology

November 26, 2020

Food in Canada Staff

GoodLeaf Farms entire product line of healthy, Ontario-grown leafy greens has been approved for the Ontario Made designation.

Nutrient-dense microgreens and baby greens are harvested daily at GoodLeaf Farms’ innovative indoor vertical farm in Guelph, Ont., using sustainable practices and the latest technology. Because the farm is indoors, using specialized LED lighting to mimic the rays of the spring sun to optimize photosynthesis, the fully automated farm gives Ontario residents the chance to enjoy fresh local food year-round.

“We are proud to grow and package our fresh microgreens and baby greens right here in Ontario,” says Jacquie Needham, Accounts Manager with GoodLeaf Farms.

“Ontario is a leader in agricultural innovation, and our farm leans heavily on innovation to offer what is often the only Ontario option in a mostly imported produce aisle, particularly during the winter.”

The Ontario Made program, created by the Canadian Manufacturers & Exporters (CME), is supported by the government of Ontario and aims to promote and support locally-made products in the midst of the province’s economic recovery. A label has also been developed to help consumers easily identify, access, and purchase products that are made in Ontario.

The GoodLeaf Farms produce designated as Ontario Made are its Asian Micro Blend, Spicy Mustard Medley, Pea Shoots, Micro Arugula, Baby Arugula, and Baby Kale.

“The COVID-19 pandemic has put a spotlight on the importance of local food,” says Jacquie. “Ontarians are looking for more local food options. It is fresher, tastes better, and is packed with nutrients. The Ontario Made designation will help them identify those choices in the grocery store.”

GoodLeaf’s leafy greens can be found at Loblaws, Fortinos, Longo’s, Zehrs, Your Independent Grocer, and Whole Foods stores across Ontario.

Search GoodLeaf Farms produce and other Ontario Made products at supportontariomade.ca.

Join the conversation on social media using the hashtags #OntarioMade and #SupportOntarioMade.

SINGAPORE: Planting The Seeds For The Future of Farming

Agritech Startup I.F.F.I. Is Injecting

Science And Technology Into Agriculture

Mr. Lim (left) saw a big business opportunity in urban agriculture and its importance in food sustainability. He decided to start I.F.F.I. with Mr. Tham (right), who now heads the subsidiary as its chief executive.

BT PHOTO: YEN MENG JIIN

NELSON Lim, who co-founded an agritech startup in Singapore, likes to joke that his crops are incredibly pampered.

"They have to have the right food and the right water, they 'listen' to music, and they even get 'massaged' with wind from a fan," he said with a laugh.

His company I.F.F.I. intends to lead the charge in precision farming, an approach in agriculture where crops are researched and monitored to receive exactly what they need for optimal growth.

"You can control everything - how hard or soft you want your vegetable to be, the nutrition level, the sweetness level and much more. This is no magic. It's all due to science and technology," he said.

Tech solutions not only help to improve the yield and quality of crops but address the perennial challenge of manpower, which is one of the largest cost factors in urban farming.

At I.F.F.I's indoor showroom in Tuas, a robotic arm performs seeding, transplanting, and vision checks on areas such as seed quality, plant growth, and pre-harvest plant condition.

The company uses the Internet of Things (IoT) software to help with remote monitoring, while a special water treatment system reduces bacteria growth and improves yield rate.

Racks for the crops are also customized to different heights and sizes for precision farming, while a customized light spectrum was designed so that crops are cultivated in an optimum way.

I.F.F.I. was founded a year ago as a subsidiary of TranZplus, a precision machinery and components manufacturer.

TranZplus was one of the main vendors for Panasonic Factory Solutions Asia Pacific (PFSAP), when Panasonic began venturing into indoor farming five to six years ago and needed to manufacture some racks.

It was then that Mr. Lim, who was then TranZplus' chief executive, met Alfred Tham, the deputy general manager of PFSAP's agricultural unit. Mr. Lim saw a big business opportunity in urban agriculture and its importance in food sustainability.

He decided to start I.F.F.I. (which stands for Indoor Farm Factory Innovation) with Mr. Tham, who now heads the subsidiary as its chief executive.

Mega farm with mega ambition

I.F.F.I. was one of only nine urban farms that were offered a total of S$39.4 million in grants by the Singapore Food Agency in August to support local food production.

The company is planning to launch a 38,000 square foot mega indoor farm by the middle of next year. The farm, which is under development at JTC Space @ Tuas, is expected to churn out 800 kg to 1,000 kg of produce per day. It will be able to accommodate about 12 layers of racks for crops, Mr. Tham said.

Mr Lim described the current Covid-19 crisis as a "wake-up call for everyone". With the pandemic sparking concerns over food security and protectionism by food-producing nations, Singapore's ability to rely on local resources has become more important than ever, he said.

The city-state has a "30 by 30" goal to produce 30 percent of nutritional needs locally by 2030. The current figure stands at less than 10 percent.

Vertical indoor farming will be a huge driver of this growth because of its ability to maximize the use of space in land-scarce Singapore, Mr. Lim said.

I.F.F.I's ambitions are not limited to the borders of Singapore. In food-producing countries that are dependent on seasonal crops, the company sees opportunities in helping enterprises and traditional farmers grow their produce indoors under controlled conditions all year round.

The startup's core business model would be to serve as consultants and designers to businesses looking to set up urban farms. It is currently in discussion with three potential clients - one is in traditional farming and looking to automate some processes, another is in the logistics industry and the third is in the marine sector.

In February, I.F.F.I. signed a memorandum of understanding with a manufacturing company in China to set up a joint venture called I.F.F.I. China. The China facility will feature an indoor farm, a salad cafe with produce from the farm, and a gym facility.

The company also has a collaboration with Singapore firm Pure Active Water, which distributes the French patented ActivH2O water treatment technology.

A few investors have already approached I.F.F.I. and shown "great interest", said Mr. Tham. The company is currently in negotiation with them.

Talent and education

One of the company's biggest goals is to spark interest in farming and help drive research in this sector.

"You don't see many people studying hard to try to go into farming," Mr Lim said with a wry smile.

"Can you imagine if we put 'hiring for a farmer' in our job scope? It's a finished game!"

Thankfully, educational institutions have been working closely with the government and private sector to teach youth about the newest farming technologies.

Mr Tham, for instance, is an associate lecturer at Republic Polytechnic for the school's diploma in urban agricultural technology.

I.F.F.I. plans to dedicate a space within its upcoming mega farm for a training and R&D center. The center will host workshops, seminars, institute courses, and research collaborations for crop recipes and farming methods.

A farm-to-table cafe parked next to a cultivation showroom is also in the works, with the aim to let consumers appreciate the value of fresh homegrown indoor crops.

I.F.F.I's parent company TranZplus has about 50 staff, and Mr. Tham, Mr. Lim, and I.F.F.I general manager Dorothy Wong are the key members leading the subsidiary.

As the company expands on its ambitions, I.F.F.I plans to hire 30 to 40 staff, mostly for its mega farm.

"We want to change the mindset of people, and how they look at farming," Mr Tham said. "Farming can also be very sexy!"

Benefits of Vertical Agriculture And Hydroponics

With a growing population and resource needs, the availability of arable land is going to decrease substantially. Consequently, such rapidly pressing needs should be matched by a higher rate of food production

Reviewed by Emily Henderson, B.Sc.

It is estimated that 11 percent, or 1.5 billion hectares, of the world’s land is used for crop production, which represents over a third of the total land suitable for crop production. With a growing population and resource needs, the availability of arable land is going to decrease substantially. Consequently, such rapidly pressing needs should be matched by a higher rate of food production.

What alternative solutions are there and what would they provide?

Throughout modern agriculture, conventional systems use large amounts of space, freshwater, fertilizer, and pesticides to maximize yield production and crop health to ensure food security, which unsustainable when looking into a future of widespread environmental and socioeconomic change.

In response, contemporary methods need to evolve to meet the current and predicted requirements of a growing world population.

Alternative solutions include the use of structural modifications such as vertical agriculture as well as entire systems by incorporating elements such as hydroponics, aeroponic, and aquaponics.

These strategies do not require fertile land to be effective, they require less water and space compared with the conventional agricultural systems and are able to increase the yield per unit of area. Additionally, these strategies use significantly fewer agrichemicals, which are potentially harmful to humans and animals.

As such, two strategies that hold promising interests is the implementation of vertical agricultural systems as well as hydroponics.

Integrating verticality into the design of agricultural systems

Agricultural systems have typically been spread over large spans of land as far as the eye can see. The reduction in arable land as well as the increase in demand to house growing populations, however, means that such strategies need to be reconsidered.

Rather than horizontal systems, large vertical walls covered crops can be used instead. These vertical layouts can employ soil, water, or air-powered systems to manage crops, and can be contained in greenhouses, warehouses, or other such facilities.

As a result, vertical agricultural systems, also known as verticulture, can encompass varying sizes and be located within many different areas from the middle of highly urbanized cities to more suburban or rural areas. The verticality aspect can also enhance nutrient and water flow, helping to reuse costly resources in a much better way than traditional methods, as demonstrated by an Indonesian research team in a study published earlier this year.

The potential location of vertical systems means that the cost of transport is nearly nullified as consumers may access them within urban areas. Moreover, the enclosed feature of verticulture means that pests and parasites are easily controlled, reducing the use of pesticides to a minimum. Finally, the reduction in space required means that there is a significant increase in yield per area, holding extensive potential for a future world of urbanization.

Despite such benefits, several limitations persist. Specifically, it is currently difficult and expensive to construct and manage such systems, which has limited their popularity. Some additional costs are also to be considered, particularly the artificial lighting that is required to help the plants grow. However, technological advances may help reduce the economic pressure of sustaining vertical systems as well as improve the overall efficiency of implementing these systems.

The development of hydroponic strategies

The transformation of agricultural systems may also include changes in applied strategies. For instance, transitioning from primary soil-based systems may provide a range of advantages, particularly in a world undergoing considerable changes in environmental conditions.

In particular, the advent of hydroponic systems represents a strategy of soilless agriculture since it uses mineral nutrient solutions in aqueous solvents to grow crops.

By relying essentially on water and nutrients, hydroponic systems are able to reduce the requirement of space and pesticides. Crop demands for nutrients and water can be controlled precisely to optimize growth and adjust to other conditions. Additionally, hydroponics can be used with other strategies, such as verticulture, and be used to address additional non-agricultural issues in urban areas.

Indeed, not only are hydroponic systems easily manageable, but they can also help mitigate issues of sanitation and animal waste processing. For instance, a recent study by African researchers earlier this year demonstrated how treated municipal wastewater can be used to establish hydroponic systems that produce healthy and sustainable crops for consumption. Additionally, a German study from 2016 designed a double recirculating system based on fish waste as fertilizer for tomato plants, with very promising results.

Nonetheless, hydroponic systems rely heavily on water and management measures, making it an expensive solution even to this day. It is therefore difficult to implement such systems at much larger scales, particularly as water scarcity is increasingly frequent and severe in many regions around the globe. In response, the combination of hydroponics with other strategies including recirculating systems or vertical designs may hold additional potential.

Image Credit: Peter Acker/Shutterstock.com

Alternative strategies in an era of global environmental and socioeconomic changes

Conventional agricultural systems have considerable dependencies on space and resources. Using strategies such as vertical designs and elements including hydroponics could be sustainable alternatives as they require less water, less fertilizer, and less space. Such benefits are key to consider in a rapidly changing world, particularly in terms of saving space and energy.

Rising global temperatures and the increased frequency, as well as the severity of extreme weather events, has considerable implications for crop production around the world. Moreover, geographic regions that are predicted to undergo the most environmental changes are ones that are already under socioeconomic stress, therefore exacerbating existing disparities. In response, alternative strategies that incorporate elements of sustainability are urgently required.

However, many limitations remain when considering alternative agricultural systems. In particular, the cost-effectiveness of designing and implementing such strategies may be out of reach of many regions. In response, technological advances are expected to improve our understanding of crop management and reduce the costs of strategy implementation, which can directly help to inform sustainable strategies to increase efficiency and decrease reliance on resources.

Ultimately, strategies are likely to be used in combination to complement one another and reduce the limitations that may occur. Such a coalition of strategies holds promising potential for addressing current as well as future socioeconomic and environmental challenges, yet considerable research is still required to refine such a cause.

References

Ichwan, N. et al. (2020) ‘Shallot’s growth and production under sub-surface irrigation in vertical agriculture (verticulture) system’, IOP Conference Series: Earth and Environmental Science. IOP Publishing, 454, p. 12044. doi: 10.1088/1755-1315/454/1/012044.

Magwaza, S. T. et al. (2020) ‘Hydroponic technology as decentralized system for domestic wastewater treatment and vegetable production in urban agriculture: A review’, Science of The Total Environment, 698, p. 134154. doi: 10.1016/j.scitotenv.2019.134154.

Suhl, J. et al. (2016) ‘Advanced aquaponics: Evaluation of intensive tomato production in aquaponics vs. conventional hydroponics’, Agricultural Water Management, 178, pp. 335–344. doi: 10.1016/j.agwat.2016.10.013.

Download PDF Copy

Further Reading

Artificial Intelligence could help the agriculture industry meet increasing food demands

Leaf litter converted to biochar could reduce N20 emissions from vegetable fields

The use of natural hydrogels in food and agriculture practices

Lead photo: Image Credit: YEINISM/Shutterstock.com

Last Updated: Nov 26, 2020

Scottish Technology Firm, IGS, Named As A 2020 Red Herring Top 100 North America Winner

IGS is an agritech innovator delivering state-of-the-art vertical farming technology designed to help producers improve the productivity of their crops – including yield, quality and consistency – whilst dramatically driving down the cost of power and labour

30 November 2020

Scottish-based agritech and smart spaces business, IGS Limited, has been named amongst the winners of Red Herring’s Top 100 North America 2020 event, which recognises some of the world’s most exciting and innovative technology companies.

IGS is an agritech innovator delivering state-of-the-art vertical farming technology designed to help producers improve the productivity of their crops – including yield, quality and consistency – whilst dramatically driving down the cost of power and labour. The company was shortlisted from thousands of entries before being invited to present at Red Herring’s virtual conference on November 17th and 18th where they were selected to join the final 100 winners.

Previous winners of the awards include household names such as Alibaba, Kakao, Skype, Spotify, Twitter and YouTube.

David Farquhar, CEO of IGS, commented: “We are delighted to see IGS included in the Red Herring’s Top 100 North America 2020 list. It’s an incredible accolade for a relatively small company based in Scotland to have been recognised alongside major global players in the world of technology and innovation. This achievement is truly testament to the ingenuity and forward-thinking approach of our team.”

Industry experts, insiders and journalists who examined the entrants against a wide variety of criteria including financial performance, innovation, business strategy, and market penetration. Winners were selected from a wide variety of verticals, from FinTech and Artificial Intelligence to Security, IoT, and many more industries.

“2020’s crop of Top 100 winners has been among our most intriguing yet,” said Red Herring chairman Alex Vieux, “What has excited me most is to see so many people forging niches in high-tech and cutting-edge sectors. Some of the technical wizardry and first-rate business models showcased at the conference has been fantastic to learn about. We believe IGS embodies the drive, skill and passion on which tech thrives. IGS should be proud of its achievement - the competition was incredibly strong.”

A full list of the 2020 Red Herring Top 100 North America Winners is available here.

Ends

Notes to editors:

For more information: please contact Kate Forster on kate@intelligentgrowthsolutions.com / +44 7787 534999 or Georgia Lea on georgia@intelligentgrowthsolutions.com / +44 7897 539954.

About IGS:

Founded in 2013, IGS brought together decades of farming and engineering experience to create an agritech business with a vision to revolutionise the indoor growing market. Its commitment to innovation has continued apace and it has evolved the applications of its technology beyond agriculture to create solutions for a wide variety of indoor environments which enhance life for people, plants and animals.

IGS launched its first vertical farming demonstration facility in August 2018, based at the James Hutton Institute in Invergowrie.

For more information visit www.intelligentgrowthsolutions.com or connect with us on Twitter and LinkedIn.

A Look At Geoponic Technology For Vertical Farming

It involves growing plants within soil or an aggregate, which is probably the most familiar option to people who are not agriculture professionals

November 26, 2020

You’ve probably heard people talk about how vertical farms and their space-saving approaches to agriculture could help promote future food security and bring produce closer to those who consume it.

Many of today’s currently operating or planned vertical farms use hydroponic methods to grow the plants in water or aeroponic techniques where growers suspend the plants in the air and mist them. However, some vertical farms also use geoponic technology. It involves growing plants within soil or an aggregate, which is probably the most familiar option to people who are not agriculture professionals.

Here’s a glimpse at what’s possible when agricultural companies combine vertical farming with the latest options in geoponic technology.

Letting people pick their produce from the wall

When most shoppers visit the produce department in a grocery store, they pick items from shelves or bins. Such setups are still the most common across the world, but that could change due to geoponic technology that allows grocery stores to grow produce up their walls.

In New York, Evergreen Kosher Market introduced consumers to a 20-foot-high “wall farm,” where each offering sits in an individual pot. Shoppers can pick from a selection of arugula, basil, kale, lettuce, and cilantro. These products are pesticide-free and raised in soil free from bug exposure. Moreover, this type of farming yields a new crop every week, meaning the products are always in season for the people who want to buy them.

Getting optimal results with energy-efficient lights

Certain kinds of energy-efficient lights also cause positive effects for the crops. For example, the high-pressure sodium lights used in conventional horticultural lighting can get too hot and damage plants.

That’s why Canada’s GoodLeaf Community Farms used light-emitting diode (LED) options at its vertical farm. That way, the plants can grow as close as six inches from the light sources without encountering excessive warmth. The agricultural operation also uses a preset spectrum for the light output, specially chosen for providing an optimal level of brightness across the facility, which grows kale, broccoli, arugula, and peas in a peat-based medium.

Trying to solve the food crisis

People are increasingly concerned about the logistics associated with getting produce to individuals who live in urban areas or may otherwise have difficulty accessing nutritious foods. Many challenges exist.

For example, as produce travels to its destination, long routes can increase emissions that pollute the planet. Moreover, a shortage of available farmland could exacerbate food shortages for people everywhere.

One of the top advantages of vertical farming compared to other types is that it can happen in substantially smaller spaces than conventional agricultural efforts require. That feature makes it especially appropriate for the world’s sprawling areas that may not have expansive stretches of land to use for farming.

Statistics indicate that urban areas will likely contain 68% of the world’s population by 2050. People in some cities enjoy fresh produce through methods such as community-tended rooftop gardens. Geoponic vertical farms could offer another possibility.

One company sells shipping container-style gardens that can fit in parking lots and use geoponic technology. Destinations such as shopping centers and apartment complexes could start featuring those as competitive advantages. They’d give people quicker and more convenient access to produce than shopping in stores allows.

Sticking to soil-based methods while embracing new technologies

Most companies specializing in vertical farming mention their soil-free options. However, as the examples here show, geoponic-based methods can support non-horizontal agriculture methods, too. That reality could make some people more eager to get involved with this approach to growing food.

For example, many households have soil-based gardens in their backyards but are less familiar with hydroponic and aeroponic options that do not require dirt. If a person wants to get involved in vertical farming with a reduced learning curve, geoponic options could be their best bets.

All kinds of vertical farming approaches typically use sensors that ensure the crops get enough light, water, and nutrients. This lower-waste approach promotes a more sustainable future and could lead to higher yields throughout the year rather than in smaller seasonal windows.

For these reasons and others, vertical farming is worth following for the foreseeable future. It’ll undoubtedly be interesting to see the geoponic-specific use cases and companies that arrive on the market, too.

YouTube: Vertical Farming at NY Farm-to-Table Restaurant Amid COVID-19

Photo credit: The feature image is owned by Evergreen Kosher and Vertical Field. The plant close-up photo was taken by Kathleen Phillips for Texas A&M AgriLife Research. The photo showing a design engineer was prepared by This is Engineering.

Source: Evergreen Kosher press release on New Hope Network / Mark Halper (LEDs Magazine) / Aaron Reich (Jerusalem Post)

PODCAST: Learn About Urban Farming And The Technologies Fueling This Industry

We also talk about the brief history of hydroponics

Joe Swartz & Nick Greens | 11/27/2020

Learn about Urban Farming and the technologies fueling this industry. We also talk about the brief history of hydroponics.

Our new podcast called Polygreens Podcast with Joe Swartz from AmHydro and Nick Greens from Nick Greens Grow Team brings agriculture and technology together in educational episodes. This podcast is about hydroponics, greenhouse, urban farming, vertical indoor farming, and much more.

Getting eXcited For Xchange? Register Today!

“This event showcases where food is going in the future.” -Neshann C., sponsor, Xchange 2018 | New York, NY

Keynote Address: The Role of Carbon Markets in Advancing

Regenerative Agriculture

Announcing Our final Keynote Speaker

Katie Sullivan serves as Managing Director of IETA, the global multi-sector business voice for the intersection of markets and climate change. Katie currently sits on the Global Steering Committee for the World Bank’s Carbon Pricing Leadership Coalition (CPLC), Boards of the Climate Action Reserve (CAR) and the International CCS Knowledge Centre, and numerous Advisory Panels.

In 2019, Katie Sullivan was recognized as a Clean16 and Clean50 award recipient for contributing to Clean Capitalism Leadership in Canada.

Want to learn more about AgritectureXchange´s Complete Program?

See 2020 Program

Meaningful Connections

Global Leaders

Interactive platform

“[This] event showcases where food is going in the future.”

-Neshann C., sponsor, Xchange 2018 | New York, NY “

Very inspiring - because usually all of these organizations are working separately.” - Patricia G., Xchange 2018 | Santiago, Chile

Register Today

Sponsored By:

Spread Has Acquired GLOBALG.A.P. Certification At Its Kameoka Plant And Techno Farm Keihanna

Through acquiring the certification, in addition to existing efforts of food and workplace safety management, environmental sustainability and traceability, Spread has updated its processes to incorporate measures for mitigating the risk of infectious diseases, including the novel coronavirus

Spread, the Leading Company in Sustainable Agriculture, has Acquired GLOBALG.A.P. Certification at its Kameoka Plant and Techno Farm Keihanna to Provide Safe, Clean and Healthy Lettuce in the COVID-19 Era

Kyoto, Japan.–Spread Co., Ltd. (HQ: Kyoto, Japan; CEO: Shinji Inada, hereinafter “Spread”) has acquired the internationally recognized GLOBALG.A.P. certification for production management at its vertical farms: Kameoka Plant (Kameoka, Kyoto), a pioneer in reaching profitability at a large scale vertical farm, and next-generation Techno Farm Keihanna, which has successfully achieved major labor savings through unprecedented large scale automation.

Through acquiring the certification, in addition to existing efforts of food and workplace safety management, environmental sustainability, and traceability, Spread has updated its processes to incorporate measures for mitigating the risk of infectious diseases, including the novel coronavirus. Doing so has further reinforced Spread’s ability to produce and supply safe, clean, and healthy lettuce, even in the COVID-19 era.

Purpose of GLOBALG.A.P.’s Acquisition

GLOBALG.A.P. certification is increasingly being recognized as one of the global standards for sustainable agriculture. By acquiring GLOBALG.A.P. Spread strives to reassure retailers and consumers of the strength of its production system and the quality of its produce.

Effects of GLOBALG.A.P.’s Acquisition at Spread

・ Visualization of strict hygiene and product quality standards

・ Raising awareness of the employees through conducting labor safety courses and displaying related information via signs and notices

・ Communicating information about production system safety and environmental sustainability to the stakeholders

Future Developments

Moving forward, the labels of packaged lettuce products from Spread’s GLOBALG.A.P. certified factories will indicate this certification status with a GLOBALG.A.P. Number.

Spread will commit to the continuous enforcement of hygiene and safety management, and the promotion of environmental sustainability through the development of new technologies. By pursuing indoor vertical farming in collaboration with a variety of stakeholders and partners, Spread aims to create a sustainable society and contribute to the achievement of the SDGs.

GLOBALG.A.P. Overview

G.A.P. is a farm management program and stands for “Good Agricultural Practices.” GLOBALG.A.P. is an international certification that evaluates more than 200 items from the standpoint of food safety, environmental preservation, workplace safety, and traceability. It is demanded of producers, particularly in North America and Europe, when entering into business arrangements with large distributors, and also it is increasingly becoming a food procurement standard at international events.

Kameoka Plant, the Profitability Pioneer of Vertical Farming

Capacity:2.1t/day

Spread’s Kameoka Plant has cracked one of the toughest challenges in commercial vertical farming. Since starting operations in 2007, Spread has developed sophisticated technologies of environmental control, and significantly improved the overall operational efficiency at the Kameoka Plant. Together this has brought the yield rate to 97% and enabled Kameoka Plant to become profitable in 2013.

Techno Farm Keihanna. Massive labor savings thanks to automation Capacity:3t/day

Started operations in 2018. The first vertical farm to utilize next generation food production system Techno FarmTM. At the R&D facility attached to the farm, development of the new cultivation techniques, as well as AI and IoT systems is underway. As the mother plant of Techno FarmTM, Techno Farm Keihanna will serve as the foundation for the never-ending evolution of new technologies.

Innovative technologies, allowing for simultaneous increase in productivity and environmental sustainability:

・ Automated cultivation

・ Recycling of over 90% of the water, used in cultivation

・ Advanced technologies of environmental control

・ LED lighting, tailored for the usage in vertical farm

・ Upgrade in operational efficiency due to IT-based cultivation management system

Next Generation Food Production System Techno FarmTM

Developed by Spread with the help of partner companies, Techno FarmTM builds on the know-how refined at the Kameoka Plant in more than 10 years of its operation. Automated cultivation, water recycling and environmental control technologies specialized LED lighting as well as IoT and AI make for a simultaneous increase in productivity and environmental sustainability. Spread will continue to promote this technology as an essential part of sustainable agriculture.

Over 60 Million Packs Sold in Total*1

Vertically Farmed Vegetables Brand Vegetus

Under the concept of “Easy, Elegant, Full of Flavor”, Vegetus helps to add a fresh new color to dining tables around the world, striving to be sustainable lettuce, good for people and the Earth alike. It is a favorite of children who enjoy our lettuce. Spread’s current lineup includes 3 unique varieties: crunchy Frilly Lettuce, smooth and sweet Pleated Lettuce, and soft yet crispy Fringe Lettuce. Each of these delivers a clean and fresh taste and is rich in beta-carotene. *2

Due to being rich in varieties and extra clean, Vegetus is easy to prepare and fits into any meal, not only salads and sandwiches but brings an extra crunch to soups and other cooked foods.

URL:www.vege–tus.com (Japanese only)

Contribution to SDGs

Examples of Spread’s contribution

・ Goal 2: Zero Hunger – Promotion of sustainable food production

・ Goal 8: Decent Work and Economic Growth – Labor-saving through automation and digital transformation

・ Goal 12: Responsible Consumption and Production – Helping to reduce food loss due to most part of lettuce being edible

・ Goal 13: Climate Action – Promoting resilient agriculture

・ Goal 17: Partnerships for the Goals – Techno FarmTM Partnership Business

Spread contributes to the achievement of SDGs until 2030 through its efforts in vertical farming. Through innovative technologies and an efficient supply chain, it also strives to develop a Global Food Infrastructure and protect food security for the people of the world.

*1 Actual numbers of lettuce, produced and sold by Spread

*2 Vegetus clears Japanese Ministry of Health, Labor and Welfare standards for the “betacarotene rich” vegetables. (equal or more than 600µg/100g)

[Contact information] Spread Co., Ltd.

Corporate Communication Department

E-mail: info@spread.co.jp

URL: www.spread.co.jp/en

Indoor Ag-Con Co-Locating With NGA Show in 2021 - The Event Will Be Held In Las Vegas At The Caesars Forum Convention Center

By co-locating with Indoor Ag-Con, we bring our attendees a new resource to meet consumer demand for transparent food sourcing, delivering just-picked produce year-round and, for those on the cutting edge, access to in-store growing operational resources

November 26, 2020

Posted by Chris Manning

The NGA Show, a trade show and conference for independent grocers, and Indoor Ag-Con, a agriculture conference, and trade show for the indoor and vertical farming industry, announced that they will co-locate in 2021 for the first time. The combined event will be held May 16-18, 2021, at the new Caesars Forum Convention Center in Las Vegas.

“The NGA Show, entering its 38th year, has established itself as the world’s premier educational and supplier resource serving the independent grocer community,” said Courtney Muller, chief corporate development and strategy officer with Clarion Events North America. “By co-locating with Indoor Ag-Con, we bring our attendees a new resource to meet consumer demand for transparent food sourcing, delivering just-picked produce year-round and, for those on the cutting edge, access to in-store growing operational resources. Ultimately, that means additional value for all of our customers and the industries overall.”

Indoor Ag-Con, launched in 2013, provides exhibitors and attendees with the latest technology and business strategies for growing crops in indoor systems, using hydroponic, aeroponic, and aquaponics techniques, bringing together growers, investors, chefs, produce buyers, academics, policymakers, industry suppliers and advocates.

“Indoor farming is an important segment that’s been on the rise for several years,” said Brian Sullivan, co-owner of Indoor Ag-Con. “The great energy and audience The NGA Show has cultivated will be key to our combined success as we work together to better serve our industries. We look forward to welcoming The NGA Show visitors and exhibitors, and we can’t wait for a successful show.”

“This is an exciting opportunity and what’s bound to be a successful industry-first event that delivers much more value to our members, customers, partners, and the markets we serve,” added Greg Ferrara, president, and CEO of the National Grocers Association.

The NGA Show and Indoor Ag-Con visitors will have access to all exhibits, and discounts will be available for cross-over educational event attendance.

For more information, click here.

Health protocols for the event can be found here.

Tags: Retail Grocery Ag-tech Events Technology Blockchain Technology

Produce events Indoor farming events

Inside AgTech Startup Evergreens Farms' Scalable Vertical Farms

Unlike typical hydroponic farming, Evergreens has a unique irrigation system that allows plants to grow in dense environments, which speeds up their growth cycle. The plants are grown in stacks, either next to each other or vertically atop one another

By Emma Campbell

November 25, 2020

Sometimes, the grass is greener on the other side.

Just ask Evergreens Farms, an agribusiness that’s bringing innovation to the farming industry. With patented vertical farming technology, the startup has invented a way to increase crop production year-round, while reducing costs, waste, and lengthy supply chains.

Unlike typical hydroponic farming, Evergreens has a unique irrigation system that allows plants to grow in dense environments, which speeds up their growth cycle. The plants are grown in stacks, either next to each other or vertically atop one another.

“We can grow 300 to 400 times the amount of product at the same square foot as compared to a field farm,” said founder and CEO Ahmad Zameli. “That's because we stack everything up and because the cycles are a lot faster than field farming.”

The company, which grows everything indoors, currently has four products: baby arugula, baby kale, an arugula-and-cress mix, and a brassica mix. The ability to grow produce indoors also allows for an increase in crop production, since the plants aren’t dependent on the seasons. Instead, the produce is grown year-round.

Zameli, who studied industrial engineering at Northeastern University, founded Evergreens in 2017. He originally planned to set the company up in the Middle East; Zameli is Lebanese and grew up in Saudi Arabia.

“My dream was to take indoor farming and bring it to the Middle East, specifically to Saudi Arabia—take it home because 90 percent, if not 100 percent, of all of our fresh food in Saudi Arabia is flown in from outside the country,” Zameli said. “The supply chain is really, really crazy. There's a lot of waste in the product, and the carbon footprint is massive.”

He initially wanted to buy indoor farming technology and grow food locally through a network of farms across the region. However, the farming technology that existed couldn’t operate at a large enough scale to turn a profit.

“If you really want to break into the larger food space, you need to be able to meet cost—cost of production to compete at wholesale, and not just in a niche distribution channel,” Zameli said. “Our mission is to create a piece of technology that's profitable to operate at a large scale and able to distribute food in wholesale markets.”

The company will now be focused on New England. Evergreens’ business model has also evolved. Rather than exclusively building and owning farms, Zameli and his team decided that to be able to scale effectively, they would need to partner with growers.

Zameli partnered with Northeastern University three years ago and has since built three farms on the school’s innovation campus in Burlington, Massachusetts. Evergreens is currently building its fourth farm off of the Burlington campus. This new farm will be the company’s first commercial, revenue-generating farm.

“Our farms are going to be gradually larger, they're all going to be in New England, and they're all going to be serving the New England region,” Zameli said. “The portfolio of crops that they're going to grow is going to change, it's going to expand over time... And the point of building those three is to kind of prove our technology and prove our marketability...Once we get to that point, we will then switch over our model and begin to franchise, where we will partner with growers and investors who are interested in operating technology like this.”

During the past three years, Evergreens Farm’s technology has reduced costs, waste and lengthy supply chains. With the company’s patented technology and unique irrigation method, the company has been able to grow plants in a production line method, thereby saving money on a key growing component—light.

“We're not lighting unused space, essentially ever,” Zameli said. “All of the light that we're giving the plants is being used by plants. It's not being absorbed by sunlight materials elsewhere.”

Evergreens also reduces two types of waste: water and food. First, the company never washes its produce, because the plants are not treated with pesticides, herbicides or fungicides. Evergreens also recaptures and reuses water, including atmospheric humidity, which reduces the farms’ water use by up to 99 percent.

For Evergreens, reducing food waste goes hand in hand with reducing lengthy supply chains. Typically, in conventional farming, when produce is transported by trucks, it can take approximately five to eight days before it reaches the grocery store. The produce changes hands as many as five times before it reaches its final destination, each time increasing the chance of introducing foodborne illnesses, degrading the flavor, and decreasing the shelf life, Zameli said.

According to Zameli, about half of all food harvested is thrown away before it reaches its final destination, a “shrink factor” that contributes immensely to food waste in agricultural supply chains.

“By being close to where the stuff is consumed, by being close to all of the grocery stores, we can deliver directly to them right after we harvest,” Zameli said. “Within hours of us putting the stuff into boxes, we ship it directly to the store, and it's on the shelf within 24 hours. Consumers can pick it up, and it's freshly harvested. It lasts two weeks longer in your fridge.”

Evergreens won the Ahold Delhaize Supply Chain Innovation Pitch Award earlier this year. It was also part of MassChallenge Boston’s 2020 cohort. The startup has raised $750,000 in pre-seed funding.

Evergreens Farms is one of BostInno’s 2020 Inno on Fire. Celebrate Evergreens and the other winners at our virtual awards ceremony on Dec. 3. Register here.

Lead photo: Zameli at work on Northeastern's Innovation Campus in Burlington, Massachusetts.

Matt Modoono/Northeastern University

Emma Campbell is a contributing writer for BostInno.

Greenhouse And Vertical Farming In New Jersey

Vertical and indoor farming ventures are versatile in the ways they can operate in the community by bringing fresh healthy foods, sustainable practices, and new opportunities for education and employment

New Jersey has a long agricultural history dating back to pre-colonial times, which is how it acquired its name as the “Garden State.” Traditional cultivation methods of NJ’s fertile land have earned New Jersey its spot as a top producer of several horticultural crops. New Jersey‘s cultivation of over 720,000 acres is thus seen as a vital part of a multi-billion-dollar industry totaling over $115 billion (2019). However, in recent years, the high cost of land and urban encroachment of farmlands has become a serious concern for the state. New Jersey has experienced the highest decline of farmland and rural open land in the United States.

Limited available farmland has pushed some producers into urban and peri-urban areas. Others have been enticed with investments and tax incentives to move operations to urban areas across the Garden State. Companies like AeroFarms, Bowery, and others have established themselves in New Jersey’s cities and are benefitting consumers with local fresh foods, offering employment opportunities, and championing urban development initiatives and partnerships.

In New Jersey, not only are we seeing an interesting mix of businesses large and small as part of a growing industry but also non-profits benefitting the populations they serve. Vertical and indoor farming ventures are versatile in the ways they can operate in the community by bringing fresh healthy foods, sustainable practices, and new opportunities for education and employment. We look forward to seeing how indoor farming continues to add to the rich history of agriculture in the state of New Jersey.

Read more about the New Jersey market on Indooragcenter.org

Tue 24 Nov 2020

CDC Updates E. coli Outbreak Numbers

There are now 39 cases in the E. coli O157:H7 outbreak, according to a CDC notice on Nov. 23. The previous number of ill people was 16, according to the CDC. Cases have been reported in 18 states; there have been no deaths

By CHRIS KOGER November 25, 2020

The Centers for Disease Control and Prevention has added 16 more people to an E. coli outbreak investigation of unknown origin.

There are now 39 cases in the E. coli O157:H7 outbreak, according to a CDC notice on Nov. 23. The previous number of ill people was 16, according to the CDC. Cases have been reported in 18 states; there have been no deaths.

The CDC and Food and Drug Administration are not advising people to avoid any particular food at this time.

“State and local public health officials are interviewing ill people to determine what they ate and other exposures in the week before they got sick,” according to the CDC’s Nov. 23 update. “Of the 22 ill people interviewed to date, all reported eating a variety of leafy greens, like spinach (16), romaine lettuce (15), iceberg lettuce (12), and mixed bag lettuce (8). No single type or brand of leafy greens or other food item has been identified as the source of this outbreak. CDC is not advising people to avoid any particular food at this time.

New Modular Scalable Indoor Vertical Farm Design

In addition to our 20,000 sq. ft. farm, we now offer a modular scalable farm system that can “start small and grow big” to meet increased demand

Green Sense Farms has been an early adopter and pioneer when it comes to indoor vertical farming. We built our first 20,000 sq. ft. indoor vertical farm in 2012 in Portage, IN. Controlled Environment Agriculture (CEA) has changed greatly since that first farm and so has our company. We started our journey focused on operating our indoor vegetable farm, selling lettuce, baby greens, herbs, and microgreens to grocery stores and produce companies in IN, IL, and MI. Since that time, we have leveraged our operating experience and evolved the company to provide contract research and farm design & build services on a global basis.

One of our recent innovations is the development of a modular scalable growing system using our proven grow technology. We found that our standard 20,000 sq. ft. farm can be cost-prohibitive in many parts of the world. We have also seen that many vertical farm companies “start big and grow small” making right-sizing a farm the key to being profitable.

In addition to our 20,000 sq. ft. farm, we now offer a modular scalable farm system that can “start small and grow big” to meet increased demand. After spending a year studying container farms to objectively understand their strengths and weakness, we came up with a better indoor grow design that includes:

• Touchless conveyance

• Improved IPM and automated sanitization

• Higher crop density and improved economics

• Can be operated with 2 employees plus a packing team

• Computer delivery of growing inputs and climate control with improved air circulation

• Can be housed in functionally obsolete industrial buildings with minimal tenant improvements.

Our modular scalable custom farms use shipping containers as a prefabricated low-cost structure to install the individual farm components. Components can be sold separately or as a system and include:

• Seeding line

• Germ / Nursery Room

• Grow Room

• Packing / Cooler

• Equipment Room, with CO2, fertigator, water treatment, water storage, and recirculation, HVAC, data collection, sensors, and automation controls.

It’s an honor and privileged to be part of CEA and watch it evolve from an idea into an industry. For more information on contract research or design and build services contact:

Robert Colangelo, Founding Farmer

VIDEO: CubicFarms Systems Corp. Announces $2.8 Million Sale of Commercial Scale Systems to Customer in Abbotsford, B.C.

The Company's commercial agreement with Aright for the sale of 16 CubicFarms machines includes 14 growing machines, two propagation machines, and an irrigation system, representing a total of approximately Cdn$2.8 million (including installation and shipping) in sales revenues to the Company

NEWS PROVIDED BY

Nov 23, 2020

The customer intends to evaluate the performance of the Company's technology in B.C. with the potential for international use in other countries where the customer operates

VANCOUVER, BC, Nov. 23, 2020,/CNW/ - CubicFarm® Systems Corp. (TSXV: CUB) ("CubicFarms" or the "Company"), a technology company developing and deploying technology to feed a changing world, announced today that its automated, controlled-environment growing system has been selected by Aright Greentech Canada Ltd. ("Aright"), a British Columbia-based agriculture investor-operator, to grow commercial quantities of fresh produce (the "Abbotsford agreement") for retail markets in the Abbotsford and Chilliwack regions in British Columbia, Canada.

Aright is an international company with interests in environmentally-focused companies in India and other countries, and this B.C. launch is a soft pilot for a potential future international roll-out.

Abbotsford Agreement

The Company's commercial agreement with Aright for the sale of 16 CubicFarms machines includes 14 growing machines, two propagation machines, and an irrigation system, representing a total of approximately Cdn$2.8 million (including installation and shipping) in sales revenues to the Company. The system is expected to be installed in Abbotsford by August 2021.

The Company has received a deposit from Aright with respect to the commercial agreement.

The Company's patented CubicFarms technology will enable Aright to grow high-quality foods, with predictable crop yields indoors, all year round.

Aright also plans to expand its systems after the successful completion of Phase 1 in Abbotsford.

CubicFarms CEO Dave Dinesen commented: "We believe the Abbotsford agreement with Aright helps to further validate the commercial upside of our technology. We are equally excited that Aright, through its parent company, has agreed to develop the Abbotsford site to serve the local market, and commence learning for potentially significant expansion into India. We are looking forward to a seamless collaboration between our teams to successfully grow high-quality, great-tasting, local produce here at home, and potentially in India."

Tanya Mehta, Founder & CEO of Aright, commented: "We are a family of impact operators and investors who aim to have a net positive impact on people, the community and the environment. As next-generation growers, we are driven to be a key player in innovation of AgTech that can feed the rising population through technologically advanced farms that can adapt and operate with consistent results. Planting and harvesting existing croplands on technologically advanced farms that consistently deliver food production without requiring new land is at the heart of this plan to work with CubicFarms. After thoroughly evaluating all available indoor growing options, we determined that it is in the best interests of Aright and our stakeholders to work with CubicFarms, which we predict will be beneficial to launch our BC operations, and to foster further innovations both in B.C. and internationally."

Potential Commercial Opportunities in India

CubicFarms and Aright India will launch a pilot project at Aright's Abbotsford location to assess CubicFarms machine production capabilities for a number of crop types.

After the evaluation is complete, it could culminate in a significant roll-out of the technology in the upcoming years. The potential India commercial opportunity will enable development and commercialization of the CubicFarms' technology, and align to Aright's focus on achieving wide-scale environmental efficiencies for urban areas.

The pilot and the potential commercial agreement with Aright India are not related to the signed commercial Abbotsford agreement, and performance of those units, between the Company and Aright.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

About CubicFarm® Systems Corp.

CubicFarm Systems Corp. ("CubicFarms") is a technology company developing and deploying technology to feed a changing world. Its proprietary technologies enable growers around the world to produce high quality, predictable crop yields. CubicFarms has two distinct technologies that address two distinct markets. The first technology is its CubicFarms™ system, which contains patented technology for growing leafy greens and other crops indoors, all year round. Using its unique, undulating-path growing system, the Company addresses the main challenges within the indoor farming industry by significantly reducing the need for physical labour and energy, and maximizing yield per cubic foot. CubicFarms leverages its patented technology by operating its own R&D facility in Pitt Meadows, British Columbia, selling the system to growers, licensing its technology, and providing vertical farming expertise to its customers.