Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

How A Rooftop Farm Feeds A City

How A Rooftop Farm Feeds A City

You all probably know my love for greenhouses, local food and educating city folk on where their food comes from.

Last night, I just put on another ted talk to watch whilst I cooked dinner, and decided to simply click on one of the ‘recommended’ videos that popped up on Youtube. My mood went from average to incredibly happy, in a matter of seconds. THANKS Youtube, you have impressed me once again.

This Ted talk video merged all these passions of mine, into one.

Greenhouses formed the major part of my first job as a graduate. I loved observing how the crops were growing in a protected environment, and how different growing techniques influenced the quality and yield gained. My Australian boss was Dutch, so understandably I learned a lot on the processes involved with growing a good greenhouse crop, from this expert.

Local food, as outlined in the video, is something that ‘is not new’ but something we miss in urban populations. I love growing my own veg at home, and consider myself to know quite a bit about agriculture, however, I cringe a bit, every time I visit a farm to see waste, or hear of food getting wasted. In the Montreal rooftop greenhouse outlined in the video, there is very little food waste, as produce is eaten very soon after production, with minimal transportation. Incredible.

Educating city folk on where food comes from, my final passion, really needn’t even be an issue. Hearing towards the end of the video, that urbanites were picking their own food and reducing the need for not only food miles, but resources, whilst seeding sustainability by knowing their food, just gave me so many warm fuzzies- we definitely need more of this.

So in this Ted Talk, Mohamed Hage, a Lebanese born Montreal-dweller, educates us on the disconnect I observe daily, and how to address it, by utilizing the ‘underwear’ of the building- the roof.

Sustainable agriculture means recycling water, optimizing energy use and growing without any synthetic pesticides, herbicides or fungicides. It doesn’t just stop at the farm.

- Water conservation: Recirculation of irrigation water and capturing rain water

- Pest control: Biocontrols take care of harmful pests

- Saving energy: Using half the energy to heat

- Compost: Composting organic waste on-site

- Freshness: Delivering the same day produce is harvested

Here is his business if you’d like to read more: http://lufa.com/en/ Please do- it’s an amazing website and concept.

Here we go, Canadians, once again, bawse.

Who else is up for greenhouses on supermarket/community centre rooves? Who would like to help me instigate this technology in Australia’s largest cities of Sydney and Melbourne?

HELP SPREAD THESE LITTLE SEEDS OF SUSTAINABILITY FOR ME!

Peace,

Jess

Innovator Uses Technology To Build Urban Micro-Farms

Innovator Uses Technology To Build Urban Micro-Farms

Former resident’s Cityblooms firm working on sustainable food solutions.

By Aleese Kopf - Daily News Staff Writer

Nick Halmos, the son of Palm Beach resident Vicki Halmos, recently received an Innovator of the Year Award for his company Cityblooms and its work for sustainable food solutions in Santa Cruz, Calif. Halmos is seen here at his mother’s home Thursday in Palm Beach.

(Michael Ares / Daily News)

Posted: 6:30 a.m. Monday, March 27, 2017

Nick Halmos, son of longtime Palm Beacher Vicki Halmos, recently was recognized for his work to fight food insecurity.

Halmos, 37, grew up on the island and attended Palm Beach Day Academy. He now lives in Santa Cruz, Calif., and is CEO and founder of Cityblooms, a company that uses technology to create controlled, micro-farms in urban environments.

Cityblooms farms grow in an enclosed environment with automated controls for temperature and water use. Farm management software keeps track of crop schedules and maintenance.

Last week, Halmos was named Innovator of the Year by Event Santa Cruz at its annual NEXTies awards show that honors individuals and businesses who inspire the Santa Cruz community.

Halmos, a graduate of Brown University with a law degree from Vanderbilt, was recently in town and shared what his company is about and why its work is important.

How did you become interested in farms and growing things?

I first became interested in urban agriculture in an entrepreneurship class (my undergraduate focus) at Brown. At that time (2001), global warming issues were finally getting mainstream attention. I became keenly interested in the business case for improving supply-chain inefficiencies in our food system by learning to grow food in the underutilized nooks and crannies of the urban environment. In other words, what would happen if we could bring the farm to the people and measure seed to fork in yards, rather than miles?

What was your first project?

After graduating from Brown, I stayed in Providence and started to collaborate with some of my friends who had just graduated from RISD [Rhode Island School of Design]. They were interested in urban renewal. I was interested in urban farming. So together we built the first “shipping container farm” by building a hydroponic system inside an old shipping container. We set up operations at an abandoned steel mill and that project ran for three years, growing basil for restaurants in the Italian district of Providence.

What was your first Cityblooms success story?

It must have been my proximity to major technology and agricultural centers (i.e. Silicon Valley and Salinas), but by 2011, I once again found myself keenly interested in the technology of growing food. I spun the Cityblooms effort back up inside a barn where we built almost 50 prototypes and filed four patents before we drew the attention of one of the large technology companies in the Bay Area (Plantronics) that was interested in hosting an installation to grow fresh produce for its campus eatery. This gave us the incredible opportunity to put some of our ideas into action and make a big push forward with our technology.

That first “food growing robot” has been remarkably successful and has produced over 100 different varieties of crops in the three years since our first harvest. It was not long before other organizations were contacting us about similar projects. Over the course of the last three years, we have been fortunate to work with companies as large as Apple and as small as our local community organizations. In the process, we have learned how to create intensive food-producing systems in a variety of underutilized urban settings such as parking lots, rooftops, and warehouses. We have also been fortunate to be able to deploy our technology in more traditional agricultural settings, such as the greenhouses of Central California.

Why are you passionate about this topic?

The Cityblooms team is passionate about contributing to the transformation of our food system. With a global population projected to reach 9 billion by 2050, global agricultural output must increase by 70 percent. As Nobel Prize winner Normal Borlaug pointed out, over the next 50 years we have to produce more food than we have in the past 10,000 years. Considering the impressive sustainability gains created by efficient and local food production, there will be the opportunity to grow certain classes of highly perishable crops in a much more decentralized, and community oriented, fashion than the status quo. This will not be the single silver bullet that solves this tremendous challenge, but it will be a part of the larger solution.

How can residents and businesses contribute to food sustainability?

There are many fruits and vegetables sold in Palm Beach stores that travel thousands of miles. This not only has a negative impact on the environment, but also food that travels long distances can be of inferior quality to locally sourced products. For example, many types of green vegetables can lose up to half of their beneficial nutrients after only a few days in packaging.

Palm Beach residents can help this transformation of our food system by supporting locally grown products. Consumers should embrace the seasonality of fresh produce items. Look at the packaging on your food, and pay attention to where it is from. Vote with your wallets and buy local. As the demand for local food products increases, local farms will spring up to meet that demand.

Toronto’s Urban Farming Residence Will Bridge the Gap Between Housing and Agriculture

Toronto’s Urban Farming Residence Will Bridge the Gap Between Housing and Agriculture

- 14:00 - 25 March, 2017

- by Osman Bari

With the ever-expanding global population, cities around the world today are caught in the midst of mass urbanization; the resultant problems are the topic of much of the current architectural discourse. From these trends stems the challenges of providing adequate amounts of both housing and urban green space, and by extension, providing adequate food production. In order to address this divide, Toronto will soon be home to The Plant – a mixed-use community revolving around sustainable residential urban farming and social responsibility in the Queen Street West neighborhood.

“It might seem extreme, but we orientated this entire project around our connection to food,” says Curated Properties partner Gary Eisen, one of the developers involved in the project. “It’s our guiding principle and the result is a building that lives and breathes and offers a better quality of life to the people who will live and work here. The Plant is a community that fits with the foodie culture that has come to define Queen West.”

Developed by Curated Properties and Windmill Developments, both of which have ample experience with prior sustainable projects in the area, The Plant is to be a beacon for sustainability and “agri-tecture,” located at the former site of Dufflet Bakery, one of Toronto’s most innovative food production companies.

With retail outlets at street level and offices on the second floor, the intention is to appeal to businesses and tenants that share the project's ideals. Additionally, single- and two-story residences are available on upper floors, each with its own custom micro-garden beds to supply the residents with fresh herbs.

The shallow floor plates allow ample sunlight into the units, while spacious latticed terraces and balconies can accommodate furniture, plants, and a barbecue. Communal food-focused programs include an internal greenhouse as a nursery for plants and seeds, as well as an industrial kitchen for shared food production and hosting events.

“The choices we make as developers dictate the lifestyle available to the people that live in our buildings. Urban living used to mean choosing between being a cool neighborhood full of amenities or having enough land to cultivate a robust garden,” states Adam Ochshorn, also a partner at Curated Properties. “When you consider two-thirds of all humans will soon be city-dwellers, having to choose between an urban residence or the ability to comfortably grow your herbs and vegetables no longer makes sense.”

The 10-story building, which was designed by which was designed by KOHN SHNIER architects and SMW Architects, alongside interior designers +tongtong, is currently under construction. Its developers hope it will serve as an example of how Toronto’s local expertise and promotion of sustainable ideals can help push the city in the right direction, and address the key concerns of food production and urban living that architecture faces today.

Rooftop Farming: How Nature Flourishes On London's Skyline - Plus The Top 5 Edibles For Beginners

Rooftop Farming: How Nature Flourishes On London's Skyline - Plus The Top 5 Edibles For Beginners

25 MARCH 2017 • 8:00AM

The winter purslane at the five star Rosewood Hotel in Holborn is excellent. Served immediately after picking, it is sweet and fresh. Amandine Chaignot, the hotel’s Executive Chef, tells me it’s the best crop they've ever had. However, I’m not eating it in the marble-walled serenity of the restaurant, but in the wind and drizzle on Rosewood’s roof, where it is grown in one of Bee London's rooftop gardens.

The Rosewood London is one of three rooftop farms in the part of London that is calling itself Midtown – the pocket of buses, offices and chain food outlets between Bloomsbury, Holborn and Clerkenwell. Another is sandwiched on a terrace on the first floor of an office block and a third is perched on top of Le Cordon Bleu cookery school, which overlooks the gently peaked roof of the British Museum.

Winter purslane at the Rosewood London CREDIT: RII SCHROER

Bee London, which represents 320 businesses across the area, is working with the Wildlife Trust to design and deliver greening projects to Midtown, helping to tackle air quality and urban sustainability. The rooftop gardens are one example of this. Sean Gifford of Sky Farmers Ltd, who works on Bee London's gardens, hopes the initiative will also change the way people see food by growing it locally.

In a city, that means making the most of every bit of space available – and it transpires that the tops of large buildings provide a lot of room to grow.

Gifford has transformed these wind-blown, sun-exposed spaces into enormous container gardens. Although the Bee London team sets up the farms in the first place (a more complicated process than it may sound – you try hefting 18 tonnes of compost in 20 kilogram bags through a five star hotel) and maintains them, much of the tending is done by volunteers from the buildings they sit on.

In the case of Le Cordon Bleu and The Rosewood London that would be chefs, who are learning about their ingredients in the process, but at the office block it’s lawyers who roll up their sleeves on their lunch break.

Head Gardener for Bee London Sean Gifford at the beehive at Le Cordon Bleu” CREDIT: RII SCHROER

Gifford has mastered a number of ingenious ways to grow in urban landscapes all year round. While I'm touring the rooftop farms on a particularly unpleasant day in early February, there is a lot of life going on.

Mustard, 'Arctic King' lettuce and rainbow chard emerge from the re-appropriated recycling crates which comprise many of the planters (they are cheap, eco-friendly in their re-use and, essentially, lightweight.

With holes drilled in the bottom they are perfect for small crops), three-cornered leekstumble over the sides of containers and mintputs on a good show against the cold.

While the country bemoans a courgette crisis, mizuna, green-in-snow, buckler leaf sorrel and lambs lettuce thrive in these most unlikely of gardens.

Biodiversity is a big part of Bee London's ethos, and as well as the planting and pest-control being chemical-free (although owing to Soil Association restrictions on acknowledging container gardens, the farms aren’t officially “organic”), these urban farms also house wormeries and beehives. Small plots of nettles are allowed to grow because their stems, over winter, provide “homes for allies” – the ladybirds Gifford bought online, were delivered in a box, and now dine on the aphids in the garden.

While the modest greenhouse at the office block currently houses a lemon tree, in the summer it will produce 1,500 vegetable seedlings.

But Gifford recommends Organic Plants as a provider of a diverse range of quality plug plants, and for rookies wanting to grow at home they are perfect, bundling up plants by seasonality to take some of the confusion out of growing produce.

The rooftop farms provide inspiration for those who think small spaces put a stop to growing food. The garden on top of Le Cordon Bleu is tiny, but possibly my favourite. A huge rosemary bush grows joyfully in the warm, cake-scented air that puffs endlessly out of the cookery school’s extractor fans. “It flowers four times a year”, Gifford says.

There’s also stevia, the leaves of which taste 130 times sweeter than sugar (I know because Gifford is very enthusiastic in making me eat everything possible), and is happily overwintering despite hailing from South America.

Fennel loves its windy, sun-exposed situation and there’s a self-seeded gorse bush just beyond the rail where health and safety stops humans from going. As a result, it is massive. Proof, perhaps, that nature can choose to flourish in urban environments, if only it is given half a chance.

For more urban gardening, follow Alice on Instagram.com/noughticulture

A Future Farming Industry Grows In Brooklyn

A Future Farming Industry Grows In Brooklyn

The startup Square Roots is training the next generation of urban farmers in a Bed-Stuy parking lot.

By Alexander C. Kaufman, Joseph Erbentraut

ROOKLYN, New York ― Tobias Peggs is already cultivating leafy vegetables out of purple-lit shipping containers in the parking lot of an old Pfizer factory, just blocks from the projects where the rapper Jay-Z grew up.

What he needs to grow now is an industry.

Eight months ago, Peggs co-founded Square Roots ― a startup that coaches and equips would-be urban farmers with growing materials in repurposed 320-square-foot metal crates. He launched the venture with food and tech entrepreneur Kimbal Musk, the younger brother of Tesla and SpaceX CEO Elon Musk.

Now, 10 farmers are enrolled in Square Roots’ Brooklyn farming program, Peggs and Musk have launched a new delivery service for home-grown salad greens, and they’re deciding where to expand next.

“If we have a campus like this in every city, everyone can buy food from a local farmer,” said Peggs, 45, said as he showed The Huffington Post around his operation.

Located in the shadow of the Marcy Houses, a public housing complex in Brooklyn’s Bedford-Stuyvesant neighborhood, the former pharmaceutical plant that houses Square Roots now also provides office space for scientific research ventures and startups that ferment kombucha and kimchi, make high-end slushies and Madagascan chocolate, and even grow live oysters.

Peggs is Square Roots’ chief executive, and he has lofty plans to topple the industrial giants that dominate grocery aisles. “This is a very long-term play, to bring real food to everyone and unleash, basically, the next generation of leaders in food.”

“Ambitious,” he added with a laugh.

Square Roots was launched under the umbrella of The Kitchen LLC, Musk’s equally ambitious chain of farm-to-table eateries that he hopes will one day take over the food industry sector that TGI Friday’s and Applebee’s currently dominate.

Musk, 44, draws his inspiration from Chipotle Mexican Grill, where he serves as a board member. Chipotle leveraged its use of fresh, non-genetically modified ingredients to become a major rival of McDonald’s, despite charging higher prices. The Kitchen, which has three different restaurant concepts, operates primarily out of the American heartland, with nearly a dozen locations in Chicago, Memphis and throughout the state of Colorado. Another restaurant is slated to open in Indianapolis this year.

Musk and his colleagues are looking at all of those cities as the next possible site for a Square Roots campus.

“My heart is in Memphis, so if it were up to me, that’d be our next city,” Musk told HuffPost on Thursday, stressing that it’s ultimately up to Peggs. He wants to see Square Roots expand rapidly. “We are planning on doing this with thousands of kids a year within a few years.”

If we have a campus like this in every city, everyone can buy food from a local farmer.Tobias Peggs, chief executive of Square Roots

In Colorado, where The Kitchen is headquartered, it’s easy to get local produce, meat and alcohol. But that’s not true in a lot of major cities. That’s the niche Square Roots wants to fill. The company is the country’s first major indoor farming “accelerator” ― Silicon Valley parlance for firms that offer educational training, space and capital to bootstrapped entrepreneurs.

Enrollees complete an eight-week boot camp before setting up shop in one of Square Roots’ 10 shipping containers. They then have the next 10 months to grow vegetables and come up with novel ideas to sell them. Square Roots makes money by taking a cut of the revenue. If an idea takes off, Square Roots buys a stake in the company and introduces the farmer to other investors.

“I visualize opening Fortune magazine in 2050, and there’s a list of the top 100 food companies in America,” Peggs said. “No. 1 is Square Roots. And the other 99 have all been set up by folks who graduated from Square Roots.”

Indoor and vertical farming, essentially a techy subset of greenhouse agriculture, has recently attracted entrepreneurs competing to develop new hardware and the most energy- and water-efficient growing systems.

The benefits of growing indoors are numerous. Farmers don’t need pesticides or herbicides to ward off unwanted pests. They evade droughts, temperature shifts, whipping winds and flooding rains, all of which are becoming more destructive and erratic as greenhouse gases warm the planet and alter the climate. They are free from environmental contaminants ― a big plus in places like Japan, where, since the 2011 Fukushima Daiichi nuclear disaster, people fear radiation poisoning from food grown outdoors.

And on a baseline level, vegetables grown indoors under precise conditions can be bred to taste better. Peggs said one Square Roots farmer who is cultivating shiso, a red-leafed mint, used data on the climate in Hokkaido, Japan’s breadbasket northernmost island, to replicate conditions there. Instead of raising crops in one country and shipping them to another to be eaten, farmers could cut out the financial and environmental costs of transportation and grow even exotic produce in the dead of a New York winter.

“Let’s say the best basil you ever had was on vacation in Italy in 2006,” Peggs said. “You could look up the data on rainfall, temperatures and weather and grow basil in those exact same conditions.”

In September, Square Roots began working with the U.S. Department of Agriculture to rewrite criteria for government-backed loans, making them more accessible to indoor, urban growers.

The USDA postponed a meeting with Peggs scheduled for Thursday afternoon, hours after agriculture secretary nominee Sonny Perdue testified before a Senate hearing. The USDA did not respond to questions on Friday about the status of changes to the loan applications.

“We want these kids to know they’ll be getting a loan, and they’ll have to pay it back and have to build a business and make money for themselves all in the space of one year,” Musk said. “It’s a loan, not a grant. It’s not a handout; these are real businesses.”

Ten shipping containers like this house Square Roots’ local farming initiative in Brooklyn, New York.

ALEXANDER C. KAUFMAN/THE HUFFINGTON POST

Lettuce and arugula grow on long, vertical trays in the glow of purple LED lights.

ALEXANDER C. KAUFMAN/THE HUFFINGTON POST

A Q & A With The Urban Farmers Behind Farm LA

A Q & A With The Urban Farmers Behind Farm LA

On Their Obsession With Lima Beans And Their plans To Plant Gardens On Abandoned Properties

BY JENNA CHANDLER@JENNAKCHANDLER MAR 24, 2017, 9:30AM PDT

Arlan J. Wood and Emily Gleicher, with their dogs Buck Rogers and Ham Hock, at home in Frogtown.

Every piece of Emily Gleicher and Arlan J. Wood’s yard in Frogtown is used for gardening. The couple grows a myriad of produce, from white sage to sunflowers to strawberry corn to dragon fruit to the most detested vegetable of childhood: lima beans.

The bounty supplements their diet. They make popcorn, salads, citronella oil, and hot sauce, which Wood has named “Caliente Culo.” But it’s the lima beans that help support Farm LA, the nonprofit they founded in May 2015 to turn abandoned and derelict lots into urban gardens for neighbors to enjoy. They sell the legumes in mason jars at farmers markets along with recipes for mashed lima beans and lima bean hummus.

Their love for gardening started after Gleicher relocated from New York City to Los Angeles. She was happy to get away from the cramped, dense neighborhood of Greenpoint, so they took full advantage of their yard in Northeast LA. Gleicher also quickly took notice of the empty lots dotting their neighborhood.

“There are quite a bit of unbuildable hillsides, quite a bit of yucky abandoned properties. We know it’s challenging to fill those properties, because they have their imperfections,” she said. “Why not do something cool with it?”

Gleicher and Wood invited us to their home on a drizzly Tuesday morning. We sat on the porch and talked about how the city might encourage more urban farming, why they love lima beans so much, and their (sometimes emotional) quest to find more land.

Why Lima Beans?

Gleicher: On our first Valentine’s Day, J., in cute-, fresh-, and frantic-boyfriend-mode, at the last minute went to CVS and got me barrettes, and a card, and a lima bean plant that, when it sprouted, said “I love you.” It never actually did sprout that way. That fueled our gardening mode. Our garden was in the works, and when he got that plant for me, we realized lima beans are drought tolerant. We love to grow them on teepees; they trellis up in really fun ways.

All of our lima beans are all from that one plant—every lima bean that’s in our kits. We’re probably third generation at this point.

So a lima bean plant from CVS kickstarted this operation?

Gleicher: We were already starting to fall in love with gardening and we were wanting to do something with the space we were seeing around LA. And, everyone kept telling us when we started, “You’ve got to have a product. You’ve got to have a business plan.” And we were like, “What do you mean? We’re nonprofit!” The lima beans help sustain our nonprofit. It’s not paying us. But it’s paying for snacks for our volunteers. The goal is to get larger spaces so we can grow more lima beans.

A row of potted apple trees in the side yard.

You recently spoke at a city commission meeting to advocate for the city of LA to adopt urban agricultural zones. What are those?

Gleicher: We’re a part of this urban agriculture working group that is run by the Los Angeles Food Policy Council. The council is all about food justice in LA, whether it’s legalizing street vending or keeping food accessible for lower income neighborhoods.

One thing they’re trying to push forward is the Urban Agricultural Zone Act. This act would give property tax breaks to land owners in the city with nothing livable on their parcels—if they partner with farmers like us or if they themselves start using those plots for urban agriculture, which can mean different things, so we’re working to define that with the food policy council.

Wood: There are plots everywhere, plots that are empty. A lot of that is due to red tape. For the Average Joe homeowner, they’re not really usable. So this would give an awesome incentive for them to go, “Oh my gosh, yes, take my hillside for blank number of years.” It saves them a lot on property taxes, and it’s a win-win for everybody.

So you have a list of properties that you’ve been scouting to turn into small farms, right?

Wood: We’ve been going to property tax auctionsfor a few years now.

Gleicher: It’s usually families who unfortunately can’t pay the property tax for whatever reason, and it goes to auction. We’ve found a few and gone but got outbid. It’s a touchy subject. It gets a little tearsy.

Wood: We invest a lot of time looking for the properties.

Gleicher: There was one in October and I think the titles will be public record soon for whoever did win it, and when this act is officially on the books and we can move forward, we want to go to those people, and say, “Hey we know you purchased this property in the auction. If you’re having a hard time building on it, please think of us.”

How else are you finding land?

Gleicher: People reach out to us. Some things we’ve had to say no to, because they’re not really in line with what we’re trying to do, like a property in Laurel Canyon. We want somewhere close to us. But it’s really about trying to stay in a food desert neighborhood, in a low-income neighborhood, a neighborhood that needs beautification. It’s more Northeast LA, and Boyle Heights, and Cypress Park, and Glassell Park.

I imagine someone might contact you to say, “Hey, there’s a vacant plot of land on my street, come plant a garden here.” Great. But maybe you can’t get ahold of the property owner. What other roadblocks are you hitting?

Wood: We’ve tried to do that several times, and it’s a doozy.

Gleicher: It’s public information, so it’s not so much that as it is getting people to get out of their comfort zones and do something that feels out of the norm for them. Some people are against change, some people are against bringing beauty to a neighborhood, because they think it brings other changes, like gentrification. So we’ve experienced a touch of that, too, and understandably so.

How do you convince property owners?

Gleicher: I go for the heart strings: “Wouldn’t you rather see something that can feed a community?”

Wood: “Or beautify a community?”

Gleicher: “Or feed a women’s shelter? And enrich your soil? Nothing is permanent. We’re not planting oak trees. If you ever want to change something, which we hope you wouldn’t, this could all be relocated or transplanted.” We need to work on our elevator pitch, but each property is so unique.

Lima beans could/should be the new kale, says Gleicher.

Tell us about the gardens you have already and where the food goes.

Gleicher: We have 11.5 sidewalk gardens now. (The .5 is a giant fig tree at Cafécito Organico in Frogtown.)

Wood: Soon to be 12. (The 12th will be a patch of barley planted at Frogtown Brewery.)

Gleicher: In the residential areas, the food is for the block. The person providing the water certainly gets first dibs. But it’s to share with neighbors. It’s on them to take care of it. The spirit of this is, “this is for you, take it.” Eventually we want to put in signs that tell you how to take care of it and what each plant is. But for the most part it’s a little wild west right now.

For anyone who now feels inspired to start growing something, what do you recommend?

Gleicher: Herbs. Peppers. Lima beans do really well for us. I know. It sounds like we’re obsessed. But we are.

Urban Farmers Catch New Train

March 24, 2017

The urban farming movement is taking a new twist, or rather, is on a new track. Growers are producing crops in refitted freight train cars, using hydroponics and automated systems equipment.

Each former freight car costs $85,000, not including shipping, with each “controlled environment” container producing an estimated average annual profit of $39,000. A 320-square-foot car is capable of producing roughly what a three-acre farm could, while using 95% less water than traditional farms.

Boston-based Freight Farms, the manufacturer of the equipment, says the most popular destinations for the 7.5-ton high-tech freight cars are urban areas across the country. The movement recently expanded into Arizona, where two urban farmers are growing crops in the cars.

The goal is to bring viable, space-efficient farming techniques to all climates and skill levels year-round. Quality and sustainability is enhanced, since produce travels shorter distances too.

Canada’s Prime Minister Trudeau Visits Rooftop Lufa Farm

With the completion of its 3rd high-tech greenhouse, and its symbiosis with local farmers, Lufa Farms has grown into a compelling role model for sustainable urban agriculture.

Canada’s Prime Minister Trudeau Visits Rooftop Lufa Farm

Mar 24, 2017, 17:31 ET

With the completion of its 3rd high-tech greenhouse, and its symbiosis with local farmers, Lufa Farms has grown into a compelling role model for sustainable urban agriculture.

MONTREAL, March 24, 2017 /PRNewswire/ - Urban agriculture pioneer Lufa Farms has just finished a third highly automated greenhouse in the Montreal borough of Anjou. The Right Honourable Justin Trudeau was there to see it in full production.

The new 63,000 square foot rooftop greenhouse is a milestone in polyculture efficiency and produces over 40 varieties of urban-grown greens and vegetables, all year round. Lufa Farms' six years of rapid growth and its successes in rooftop greenhouse design, cooperation with local sustainability-focused farmers, and appeal to thousands of Montreal consumers, make it one of the most successful large-scale urban agriculture models in the world, demonstrating how to sustainably feed entire cities.

The Prime Minister was given a full tour of the new production facility by Lufa Farms founders Mohamed Hage and Lauren Rathmell. He witnessed first-hand the innovative complexity of the rooftop greenhouse, and even took time to harvest a basket of fresh greens for himself and his family.

The new rooftop greenhouse is a marvel in automation. It was designed by Dutch greenhouse innovators at KUBO, outfitted by Belgian greenhouse automation experts, Hortiplan, and includes advanced horticultural lighting systems from GE.

The construction of the new greenhouse was supported by Quebec financial partners Fonds de solidarité FTQ and La Financière agricole du Québec.

From one rooftop greenhouse to a new paradigm in urban agriculture

Lufa Farms began operating the world's first commercial-scale rooftop greenhouse in 2011. It was built with the goal of using sustainable irrigation, energy and growing systems for cultivation of pesticide-free produce. The first greenhouse, with 8 employees, produced more than 25 varieties of vegetables and delivered them, weekly, to a few hundred Montreal consumers.

The second Lufa Farms' rooftop greenhouse began operation in 2013. With it, the company introduced an online marketplace so that consumers could select and buy fresh Lufa Farms produce together with responsible produce, meat, dairy, bread, and more provided by hundreds of local farmers and foodmakers. The result is that consumers receive the freshest sustainably-grown goods, local farmers get a viable outlet for their products, and the city benefits from optimized land, water, and energy use.

A disruptive rethink of food production and distribution

The most recent greenhouse caps six years of steady growth and innovation. The Lufa Farms team now consists of more than 140 employees, grows over 70 different vegetable varieties, and delivers more than 10,000 food baskets every week of the year.

"We began this venture because of our passion for rooftop farming. We didn't start out as farmers and I'd never even grown a tomato before," says Lauren Rathmell, Co-Founder and Greenhouse Director of Lufa Farms. "But we did what made sense to us as technologists and problem solvers. Today, we understand that successful urban agriculture requires not only advanced greenhouse technology, but also direct-to-client distribution, and working together with local, sustainable farmers and food artisans. The sum of all the parts, working together, is greater than the whole."

The future of Lufa Farms

Founded in 2009 by Mohamed Hage, Lauren Rathmell, Kurt Lynn, and Yahya Badran, Lufa Farms now has acombined urban growing space of 138,000 square feet. The company plans to continue the expansion of its urban farm projects in Quebec urban centres, and also in select New England locations in the U.S.

For more information about Lufa Farms click here. For images of Lufa Farms and the Prime Minister's visit, see the Flickr album.

SOURCE LUFA FARMS

Related Links

Olive Trunk Farm Seizes the Opportunity To Feed Texas Town

It took a bout of food poisoning to convince Scott Rowdon to grow his own food, but now the Texas farmer has his eyes set on growing fresh, healthy food for everyone around him

Olive Trunk Farm Seizes The Opportunity To Feed Texas Town

Posted by Eve Newman on March 24, 2017

Food poisoning spurs local food conversion

It took a bout of food poisoning to convince Scott Rowdon to grow his own food, but now the Texas farmer has his eyes set on growing fresh, healthy food for everyone around him.

Rowdon’s foray into farming began with an emergency room visit following dinner at a local burger joint near his home in Little Elm, Texas, about two years ago. “It came about kind of on accident,” he said.

After his recovery, Rowdon decided he wanted to grow more of his own food. But like much of Texas, Little Elm — which sits on the northern side of the Dallas/Fort Worth metro area — isn’t celebrated for its soils.

“Down here in Texas, we have horrible clay soil,” Rowdon said. “It is horrible. But I thought, there had to be a way to be able to grow.”

He began exploring aquaponics and built his first system using a 55-gallon drum and a stock tank with catfish, all indoors. Then he came across Bright Agrotech’s hydroponic technology and purchased a ZipGrow Tower system, which soon became a second system, then a wall, then 25 Towers.

“It just continued to grow,” he said.

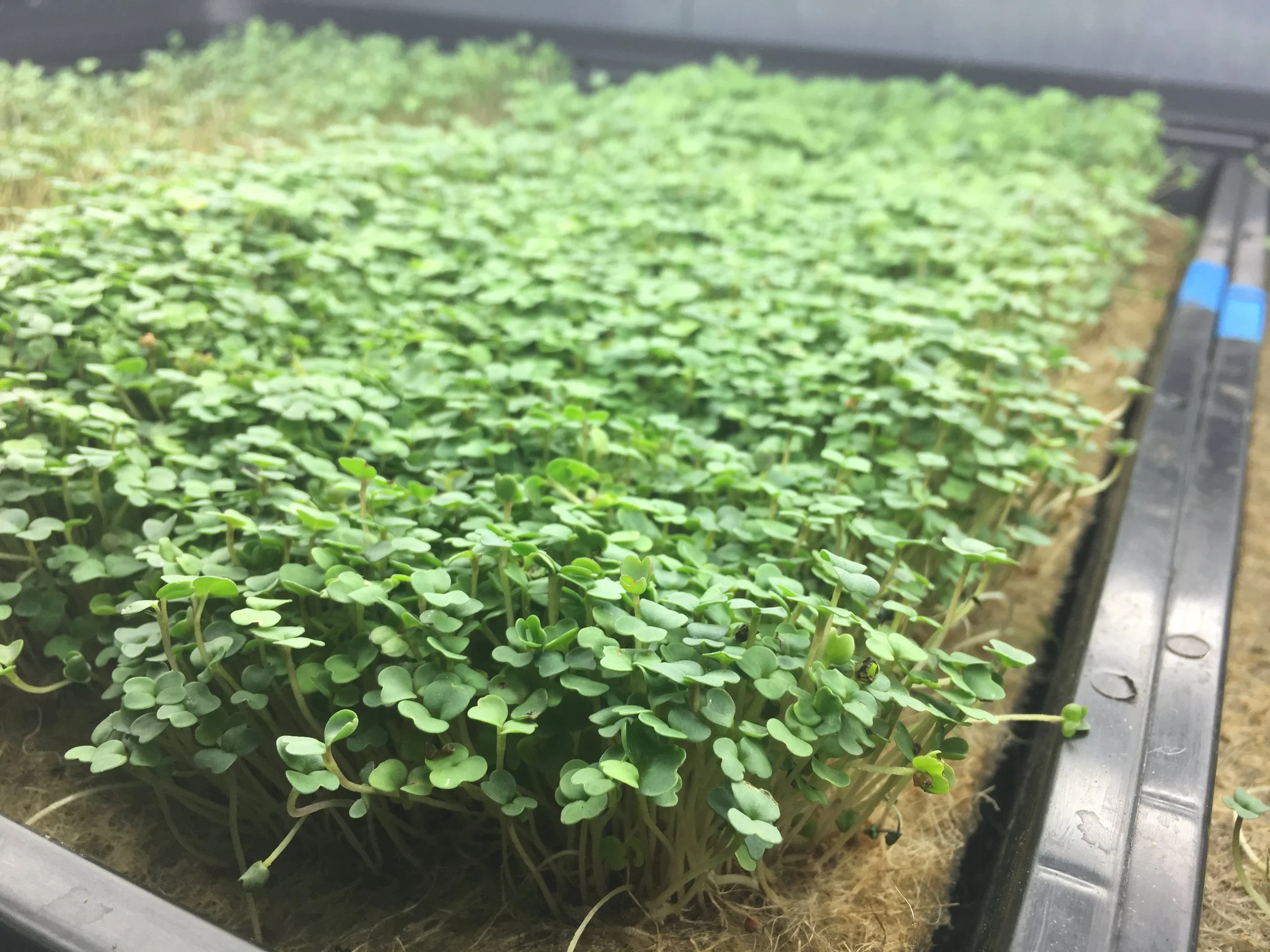

Rowdon began growing microgreens and herbs for himself, family members and friends. Then he started selling them at farmers’ markets about a year ago, and Olive Trunk Farms was born.

Microgreens are especially exciting, and Rowdon uses their vivid colors and bright flavors as selling points.

“Whatever I have at the market that day, I have samples for,” he said.

For customers who don’t want to eat full-grown kale or broccoli, Rowdon presents tiny shoots packed with nutrition and flavor, grown locally, harvested that day and fresh as can be.

One repeat customer, who has been purchasing Olive Trunk Farms sunflower shoots for the last year, said she had trouble maintaining healthy vitamin levels because of medication she takes. But after adding microgreens to her daily meals, her most recent blood work came back great even without supplements.

“[Microgreen sales are] going to be all about education and what you can do with microgreens,” Rowdon said. (Learn about microgreens for yourself here.)

He’s planning to take his greens to Earth Day Texas in Dallas in April, which is touted as the world’s largest Earth Day festival. More than 130,000 people attended last year’s three-day event to learn about the latest technologies and innovations shaping the world.

In June, Olive Trunk Farms will have a booth at the new Frisco Fresh Market, a daily market to be open year-round. The indoor/outdoor market will bring together farmers, foodies and chefs to 30 acres in central Texas to share their love for local produce, and Olive Trunk Farms figures to be right in the mix.

Rowdon is also looking ahead to moving Olive Trunk Farms from its current urban location to a spot with more space for indoor and outdoor growing, where he can power his operation using solar and wind. Already he’s working on ways to recycle and conserve water, such as running a dehumidifier with the microgreens and storing the excess water, which cuts into his water usage.

“My hope is to have an extremely small footprint, but yet very productive,” he said.

As a self-proclaimed technical person with a background working for a financial institution, Rowdon is still surprised about becoming an accidental farmer. But now he’s looking forward to working with his hands, digging into soil and building a business.

“Watching everything I grow from seed to harvest is just absolutely amazing,” he said. “It never ceases to amaze me watching all of this happen and the changes every single day. It’s never a dull moment and it’s never the same day twice,” he said.

He’s also enjoying being part of the growing community of local food producers bringing healthy produce to their friends and neighbors. “It’s healthy, it’s fresh, it’s local, and we want healthy people,” he said.

Interested In Becoming A Farmer Like Scott?

The Upstart Farmers are the modern farmers responsible for hundreds of indoor local farms around the world. Though from a variety of backgrounds and unexpected skill sets, the Upstart Farmers find themselves unified in their vision to feed healthy food to their communities and overcome the limits of traditional ag with innovative farms.

Upstart University trains new farmers to find markets, build farms, and gow incredible crops. Join Upstart U for a free week today to explore your potential as a farmer.

More Speakers Confirmed For GFIA Future Farming Theatre

Already many experts have been confirmed to speak about smart farming at the Proagrica Future Farming theatre at the Global Forum for Innovations in Agriculture (GFIA).

24 Mar 2017

More Speakers Confirmed For GFIA Future Farming Theatre

Already many experts have been confirmed to speak about smart farming at the Proagrica Future Farming theatre at the Global Forum for Innovations in Agriculture (GFIA).

The GFIA will be held from 9-10 May 2017 at the Jaarbeurs Expo Centre in Utrecht, the Netherlands. The event will focus on practical applications and knowledge on Future Farming in horticulture, crops and livestock. The event is organised by Turret Media in cooperation with Proagrica (publisher of All About Feed, Farmers Weekly, Boerderij amongst others)

Proagrica will have its Future Farming Proagrica Theatre, held over 2 days, at the exhibition ground. At this theatre, new ideas, future farming insights will be shared in the fields of dairy, pig and poultry farming, horticulture and arable farming, each having 3 focus topics. The editors of Proagrica brands will moderate the sessions. Each session will have an independent speaker and 2 sponsored speakers. We are proud to confirm some of the speakers to you.

Future Farming Poultry: Feeding, animal management, big data

Poultry breeding has become precision agriculture and a fine art. Sergio Guerra from Aviagen will talk about the use of big data in poultry breeding and how this can be used by the whole production chain and what are the latest insights?

Ron Cramer from Xiant Technologies (XTI) will speak about innovative lighting in poultry barns. XTI has created a highly differentiated approach to agricultural lighting for both poultry and plants. XTI uses light as a primary controller of biological function by targeting specific photoreceptors in a variety of living species.

Future Farming Pigs: Genetics and breeding, gestation and lactation, grow/finishing

Jurgen van Geyte from the Belgium research institute ILVO has done research in the use of big data in pig production systems. ILVO is part of the project IOF2020, a large scale pilot focused on implementation of Internet of things. How does this apply to pigs? Van Geyte will delve more into that.

Dirk Coucke from DLV Mas in Belgium will speak about an innovative pricing/market advisory service/tool for pig farmers who buy their own raw materials and complete feed. A smart way of doing business is smart purchasing of feed.

Future Farming Dairy: Robotic milking, hygiene, young stock

Calves are the basis for a successful dairy farm. More insights have been gained on smart feeding/housing for calves. Expert Siert-Jan Boersema from Jongvee Coach in the Netherlands will present the latest insights on smart ways to get the most out of young stock.

Future Farming Horti: Precision farming, track and trace, robotics

Marc Kreuger, global head of innovation at the company Here, There and Everywhere. This company designs and builds turnkey indoor farming projects, supplies long term technical and growing support and is actively involved in starting up new businesses and supply chain models that include indoor farming solutions. He will update the audience on the latest insights and developments in this field.

Future Farming Arable: More efficient harvesting, control of pests, use of big data

Sjaak Wolfert from Wageningen UR in the Netherlands will give a short overview of smart farming in agriculture / outdoor cropping systems and how big data is used to boost efficiency and production.

Jérémie Wainstain, CEO of The Green Data will speak about how to extract value from your data. The Green Data Factory is a suite of services dedicated to agridata analysis to give you the power to optimise performance and adoption by your experts.

Want to pitch your idea/product/concept? Companies can still be part of this exciting and innovative theatre for one slot or as sponsor of the whole theatre (including slots for presentations)! Do you want to share your knowledge and practical insights in a 20 minute practical talk and share this directly with the farmers and international experts in the audience? For more information, please contact our dedicated team of account managers to tell you more about the possibilities.

Emmy Koeleman

Editor: All About Feed & Dairy Global

Impression of the Proagrica Future Farming Theatre at the GFIA. An exciting place where 5 seminars will be held about smart farming, with a practical ‘How To’ approach. Photo: Proagrica

McNamara: “The Future Is So Much More Complex Than We Could Have Imagined”

Brad McNamara, CEO and co-founder of Freight Farms, is speaking at the inaugural Boston Food Tank Summit, “Investing in Discovery,” which will be held in collaboration with Tufts University and Oxfam America on April 1, 2017

McNamara: “The Future Is So Much More Complex Than We Could Have Imagined”

Brad McNamara, CEO and co-founder of Freight Farms, is speaking at the inaugural Boston Food Tank Summit, “Investing in Discovery,” which will be held in collaboration with Tufts University and Oxfam America on April 1, 2017.

Freight Farms is an agriculture technology company that provides physical and digital solutions for creating local produce ecosystems on a global scale. Brad and his co-founder, Jon Friedman, developed the company’s flagship product, the Leafy Green Machine, to allow any business to grow a high-volume of fresh produce in any environment regardless of the climate. His hope is for Freight Farms to be scattered across the globe making a dramatic impact on how food is produced.

Food Tank had the chance to speak to Brad about his work developing Freight Farms and his vision for the future of our food system.

Brad McNamara, CEO and co-founder of Freight Farms, is speaking at the inaugural Boston Food Tank Summit, “Investing in Discovery.”

Food Tank (FT): What originally inspired you to get involved in your work?

Brad McNamara (BM): It was a coming together of many different factors. My co-founder, Jon, and I had worked together in the past, and we were both intrigued by the food system and how we could make a difference. Around 2009, Jon was focused on food systems and system design, and I was passionate about the purity of food and the increasing trend towards food awareness. When the two of us first reconnected over a cup of coffee (and then a beer), we got to talking about the complexity of the food system and what we could do to combine our interests. With backgrounds in design and environmental science, our goal was to research methods to allow urban agriculture to emerge as a competitive industry in food production. We mainly focused on rooftop development, then determined the criteria for success and scale to be outside the realm of possibility with agricultural installations that were already in existence. When costs and logistics soared, we turned to shipping containers (there’s Jon’s design background coming into play), and the idea for Freight Farms took off with the goal to build farms in areas that couldn’t support more traditional methods.

FT: What makes you continue to want to be involved in this kind of work?

BM: Our world and our climate are changing, and it is so apparent that there is more work to be done. According to the U.N., food production needs to increase 70 percent by 2050, to feed an ever-urbanizing population. Land and water scarcity take on even more pressing importance, as does urban agriculture. The future is so much bigger and more complex than we could have ever imagined. Over the past few years, we’ve gotten to witness the emergence of a new industry of agriculture technology, and it’s poised to make a dramatic impact on the food system. One of the most amazing things we’ve been able to watch is how many are interested in joining the movement towards a better future. Our network of freight farmers are making dramatic impacts on their local food systems every day, drastically improving food security in their community. They inspire all of us to continue this work.

FT: Can you share a story about a food hero who has inspired you?

BM: My food hero is a customer of ours. His name is Ted Katsiroubas, and he runs Katsiroubas Bros. Fruit and Produce, a wholesale produce distribution company located in the heart of the city of Boston. The business is over 100 years old and was handed down from generations before. I admire how Ted has innovated in the face of a dramatically changing food landscape. As the demand for local, fresh produce has risen, the company expanded to begin working with local farms in the region to meet demand. For those familiar with wholesale distribution, sourcing locally can be a difficult task especially when you are restricted by the growing seasons and volume constraints of small local farmers. That’s why traditionally wholesale distributors rely on shipping produce long distances from warmer climates. But Ted brings a fresh approach to an old school industry. He continues to push the envelope and propel the industry to stay on top of the latest technology through collaboration with other distributors. If anyone were to fall into the category of my food hero, it would be Ted because of his willingness to look to the future and go against the conventional wisdom of how the food industry tells him to conform.

FT: What do you see as the biggest opportunity for fix the food system?

BM: I think the biggest opportunity to fix the food system is to bring it back into the hands of the people. By transitioning to a more decentralized food system, and minimizing the gap between consumers and producers, we will take a critical step towards an environmentally and economically sustainable food system. I think all the various types of technology, the hardware, the software, and the social awareness, all point in the direction to empower the individual. So the real opportunity to fix the system is to utilize what we know to be true—when you give opportunity and power to regular people from all walks of life, that’s when you can change a whole system.

FT: What would you say is the most pressing issue in food and agriculture that you would like to see solved?

BM: There are so many people advocating for a better food system, and we all must be better at communicating and cooperating if we want to make an organized effort to challenge the way things operate currently. From small farmers and producers to organizations and companies. What has become incredibly apparent in the past couple decades is that there is no one size fits all solution. Whether it’s urban or indoor agriculture, hydroponics, aeroponics, aquaponics, or traditional soil-based farming, we all play an important role. We need to have a more holistic view of the food system and how each method can contribute to a better future. If we don’t all work together, it’s going to be difficult to disrupt BigAg. I think taking a broader view is key. There has been so much progress made in agriculture, but we still have a long way to go to create a food system that will serve future generations. It is important to continue working with and connecting with each other to empower and support the next generation of farmers.

FT: What is one small change everyone can make in their daily lives to make a difference?

BM: Maybe it is a bit cliché, but the notion of voting with your dollars. I’m sure others have said it, but it is so important. If every consumer changed 5 percent of their food shopping habits by buying more seasonal and local produce, the impact would be enormous in changing the landscape of the local grocery store.

FT: What advice can you give to President Trump and the U.S. Congress on food and agriculture?

BM: My advice is to be conscious of all the complexities present within the food and agriculture system. There are so many moving pieces that small shifts in the workforce, water use, and the climate have a massive impact throughout the entire system. It is essential to keep a holistic understanding of the relationships between all the components in our food and agricultural system and to consider the ripple effect policy decisions will have on the smaller players involved.

Click here to purchase tickets to Food Tank’s inaugural Boston Summit.

How Urban Farming Took Root Everywhere

HOW URBAN FARMING TOOK ROOT EVERYWHERE

Published On 03/22/2017

Chicago’s Back of the Yards neighborhood was once one of the most industrialized areas in America, where stockyards and factories were manned by thousands of working-class immigrants. It’s the setting of Upton Sinclair’s The Jungle. But today, inside a 93,500-square foot former meatpacking plant there, kale, swiss chard, tomatillos, and oregano grow in vertically stacked trays, nourished by water from a nearby tank of tilapia. There are two additional hydroponic farms growing greens, plus a brewery, bakery, a mushroom farm, an artisan cheesemaker, honeybees on the roof, and a fresh flower farm. In total, there are 12 food-producing tenants in the gigantic, industrial space.

Unlike the neighborhood’s original pork-based economy, this new microscale ecosystem is working towards conducting business without letting a single item go to waste.

“IT IS MUCH MORE THAN AN URBAN FARM. IT’S KIND OF LIKE A MOVEMENT, OR A WEIRD EXPERIMENT.”

The Plant, as the facility is known, is considered a “collaborative community of food producing businesses” that work together inside the former meatpacking plant to not only grow and produce food -- but to create a “closed loop” system for energy, waste, and materials. Meaning that everything is reused: spent grains from the brewery are formed into briquettes to fuel the bakery ovens, coffee grounds from the roastery inside are used to help nourish the mushroom soil. At The Plant, that closed loop system is managed by not-for-profit group Plant Chicago.

Plant Chicago staff also teach the public about this closed loop, circular economy through tours, education programs, and a year-round farmer’s market.

“It is much more than an urban farm,” Kassandra Hinrichsen, education and outreach manager for Plant Chicago says. “It’s kind of like a movement, or a weird experiment.”

It’s not just about providing fresh vegetables

The Food and Agricultural Organization of the United Nations reports that 800 million people practice some form of urban agriculture worldwide, even though it’s illegal in several countries. The USDA doesn’t keep formal stats on urban farming in the United States, but in 2016 it funded about a dozen urban farms, the largest in the agency’s history, according to Business Insider. Even more loans and grants are expected to be given out to urban farmers in the United States this year.

But urban farming isn’t a new phenomenon for America’s cities. In the 1970s, community gardens sprang up in vacant lots in New York City, Chicago, Detroit, and San Francisco -- providing not only a place to grow fresh vegetables, but also a way for urban communities to organize. In 1993, Will Allen purchased a piece of land in Milwaukee so he could sell vegetables from his nearby farm to people in the North Side neighborhood. He then started farming food right in the city -- a project that would become Growing Power, one of the first urban farm projects in the country. In 2009, the Eagle Street Rooftop Farm in Greenpoint opened, becoming New York City’s first commercial rooftop farm. But in the eight years since, as more people have a desire to eat local foods within urban areas, the trend has stretched far beyond Brooklyn.

An increasing number of farms are taking on innovative projects that do much more than just provide food. Like Plant Chicago, for instance, which is charged with researching ways to reduce waste and reuse it at the farm, as well as conducting outreach with the neighboring community.

One of the largest endeavors, which is the brainchild of The Plant’s founder, John Edel, will be to use an anaerobic digester tank to heat the entire facility, rather than electricity or gas. Once it’s online, the energy system will be able to process 30 tons of food waste a day in the same way a human stomach does. It will break down the waste into liquid, biogas, and a high-nutrient solid. The solid and liquid will be sold to soil companies as a compost, while the biogas will be used to heat the building.

Plant Chicago staff and volunteers are also responsible for maintaining the aquaponics farm at The Plant -- a system where plants grow in water and receive the nutrients they would normally get from soil via waste created by fish. The plants, in turn, filter the water for the fish. This sort of farming has become increasingly popular in Chicago, with several for-profit and non-profit farms popping up around the city, in everything from warehouses to classrooms.

“In Chicago in the last couple of years, there has been a crazy bump in indoor farming, like hydroponics and aquaponics facilities,” Hinrichsen says. “Hopefully, indoor farming and those kinds of systems are becoming more accessible to folks, because the point of Plant Chicago is to be open sourced as well, and to show that you don’t necessarily have to have a bunch of money and crazy investors and a business degree to start something like this.”

Farm-to-table is eating better, which is the best way of living better. Fresh food will revitalize your spirits as well as your body -- even in the heart of a city. To reward yourself for living so well, open a bottle of Strongbow cider, and let the crisp and refreshing orchard taste come to you.

What we can grow in cities, and how we use it, is changing

Elsewhere, in Chicago, another company looks to turn the city’s world-famous architecture green.

Thanks to the laughably high prices of land in some cities, urban farmers looked to city roof tops as a potential growing site for their farms early on. But, while they may be more affordable, growing edible crops on a roof comes with it’s own set of problems.

“If you’re trying to grow food in a completely foreign environment, where you don’t have nutritious substates, when you don’t have reliable water, when you have extreme temperatures -- extreme cold and extreme heat -- that’s like Mars, and that’s pretty much what it’s like to grow on a rooftop,” says Molly Meyer, the CEO and founder of Omni Ecosystems, a green roof company based in Chicago.

Meyer’s company developed a green roof system that could allow plants to thrive, despite the harsh conditions. Their green roof technology supporting edible crops is not only lightweight, but includes intuitive irrigation systems. Automated watering systems are linked up to weather stations or rain sensors, to make sure the crops aren’t being watered when rain is in the forecast.

Meyer founded Omni Ecosystems in 2009, but she had worked with green roofs for years previously, and installed her first green roof in 2006 atop True Nature Foods in Chicago. She continued studying green roof tech in Germany as a Robert Bosch Fellow. Germany implemented green roof technology decades back, so Meyer’s experience there amply prepared her to start a company in the United States.

Omni has installed dozens of green roofs from Boston to San Francisco, as well as the vertical gardens known as “living walls” and subterranean barriers so that crops may be planted safely above contaminated earth. It also manufactures its own soil. But at first, Meyer says the trend was slow moving -- thanks in part to how long it takes for buildings to be designed and constructed.

“The construction industry, and the building industry in general, is very slow industry to change,” she says. “It takes maybe a year to design a building, and a year to build a building. And so, you have a couple years just for one site to change over. Now, we’re really starting to get a clip going. We’re starting to see some snowballing effects. People have seen the technology now, they are recommending and referring it, and applying it.”

Most of their edible crop rooftop farms produce the usual stuff: leafy greens, tomatoes, peppers, etc. But, just last year they were able to grow an entire wheat field in the middle of downtown Chicago -- and it was practically unintentional.

Omni was hired to build a native wildflower meadow on top of the Studio Gang Architects’ rooftop on Division Street. But the construction schedule was pushed into the fall, forcing them to grow a hardy annual plant that could protect the soil. They chose winter wheat, with no intention of harvesting an entire rooftop of the stuff.

“Then, we came back in the spring and lo and behold, there was a wheat field in the middle of downtown Chicago,” Meyer said. “I don’t think any of us were expecting to see a wheat field 40 feet up from one of the busiest intersections in Chicago.”

They enlisted Omni’s sister company, the Roof Crop (which Meyer also co-founded), as well as student volunteers, to harvest the 3,000 square feet of wheat by hand. A nearby miller donated his time and milled the harvested wheat into about 60 pounds of high-grade pastry flour. (He even rewarded the students with cookies.)

But besides the experience, Meyers was able to walk away with a clear ratio for how much wheat can be produced on a rooftop: for every 50 square feet of green roof that’s harvested, they’ll get about a pound of flour.

“Now that we have that metric, we can start looking at cities in completely different ways,” she said. “When building owners need just another incentive to do the thing that is great for a city -- bringing plants to a city -- this is one that can now be measured. We can say, ‘well, actually, if you chose to do wheat, and you harvested it for 20 years, every year you would get X pounds of flour, which could turn into X loaves of bread, or X bottles of beer."

Urban farming extends to food deserts... and real deserts

In South Phoenix, there isn’t a regular farmer’s market, and getting to a grocery store can mean a serious trek. That means the 4,711 residents in this part of town don’t have access to fresh fruit, vegetables, and other healthful whole foods. The area is officially designated a food desert by the USDA, but one project, called Spaces of Opportunity, is planning to change that.

With the help of several area nonprofits known as Cultivate South Phoenix, the Desert Botanical Garden, and a local elementary school, 18 vacant acres in the region are set to become working farmland and a community center for arts and healthy living programming.

“The whole point of the project is to keep as much healthy produce in the community as we possibly can,” says Nicolas de la Fuente, the project’s manager.

Eighteen acres is roughly the size of two New York City blocks, and 9.5 acres will be divided into “incubator farms.” Those spaces will be used as production farming space for people who want to make a serious living off the food they grow. Then, there’s 1.5 acres of community garden space, with plots that are about 4ft x 50ft.

“It’s funny when I say ‘community gardening,’” de la Fuente says. “At 1.5 acres it’s almost rural farming, it’s not like the boxes you see in other cities.”

There are currently four incubator farmers growing and selling winter vegetables, like spinach, collard greens, and kale, in the space. In the next few months, they will switch over to summer season crops: squash, peppers, tomatoes, and watermelons.

To water the crops, de la Fuente says they are planning to install a drip irrigation system. That will help the farmers conserve water, as well as substantially increase their output. Despite the desert conditions, the area was also once rich farmland, known for growing citrus and flowers. The Hohokam Canal system, which was one of the world’s largest canal systems, ran through the area, too.

“It’s actually a super rich agricultural center, that’s just been little by little developed with infill,” de la Fuente says. “So we aren’t necessarily doing anything new. We’re just essentially trying to bring back what was there and embrace the roots of the community.”

Spaces of Opportunity just received enough funding to fully connect to water and power, and their next endeavor is to build out the farmer’s market -- which will be the first in South Phoenix.

There’s still more work to do

Annie Novak has been the farm manager at Greenpoint’s Eagle Street Rooftop Farm in Brooklyn, NY since 2010, and she planted the first seeds on the farm with Ben Flanner in 2009. Since she became farm manager, she’s taught 100 people through an apprenticeship program who are looking to start an agriculture project of their own -- be it starting a small garden on top of their restaurant, or raising grass fed cattle in Texas.

“There’s a lot going on around the country, and internationally,” Novak says. “I feel like New York City leads with press, but I don’t know if we lead with acreage or initiative. Chicago, Detroit, San Francisco, LA to a degree, Milwaukee, Austin -- these are all places that have really successful urban farming programs. So we definitely are not alone.”

While farming is clearly a hard job, Novak says operating a farm in a city provides a lot of opportunities. They are close enough to their markets to meet buyers face to face. There are several restaurants seeking out fresh produce, and there are minimal transportation costs.

Besides the expansion of urban farming, one of the most vital changes she’s seen is that cities, and even the USDA, are beginning to support these initiatives. Urban farms are also getting included in conversations about the importance of green spaces in cities, and in particular how to protect them.

“There always seems to be an ebb and flow in the way cities embrace urban agriculture,” she says. “So I’m just trying to think ahead. What happens when everyone who started a rooftop farm when they were 22 decides they want to know what’s next?”

To protect the work that’s already been done, Novak hopes that cities like New York will start zoning some urban farms as agricultural property, which would ensure that the area remains a space for farming. In New York, there’s only one agriculturally zoned property: The Queens County Farm Museum, and it’s been a working farm since before New York City even existed.

“Why has nobody ever turned Central Park into a condo?” Novak asks from her bike, which is her sole form of transportation around the city. “Well, there are legal reasons why. But we could do the same thing for farms.”

Detroit Turned Blighted Properties Into Urban Farming

Image: Pixabay

Recovery Park is providing a place for ex-offenders, recovering addicts and others with barriers to employment a chance to gain work experience.

Editor’s Note: As of February 2017, the project continues:

By Mary Velan

EfficientGov – Originally posted November 3, 2015

The city of Detroit is teaming up with RecoveryPark to transform a blighted 22-acre area on the city’s lower east side into a center of urban agriculture. The goal of the project is to provide a place for ex-offenders, recovering addicts and others with significant barriers to employment with an opportunity to gain valuable work experience.

The Project

The 60-acre project – which includes more than 35 acres (406 parcels) of city land – is designed to revitalized one of Detroit’s blighted neighborhoods by repurposing vacant land. The city is collaborating with RecoveryPark, a nonprofit organization working to create jobs for people who struggle to get hired.

“RecoveryPark isn’t just about transforming this land. It’s about transforming lives,” Mayor Duggan said. “The city of Detroit is proud to support the work Gary Wozniak and his team are doing to put this vacant land back to productive use and to help ex-offenders and others with barriers to employment rebuild their lives.”

The project is expected to employ 128 individuals within three years, 60 percent of who will be Detroit residents. Consistent with its mission, most of RecoveryPark’s workers will be ex-offenders, veterans and recovering addicts.

The RecoveryPark project wants to leverage Detroit’s underutilized assets while developing a for-profit food business – RecoveryPark Farms – in the local community. To help the project take root and grow, the city is allocated $15 million to the initiative.

Veterans, returning citizens, challenged workers, those in recovery and other marginalized citizens struggle daily for the ability to care for themselves and their families. Recovery Parkwill provide them the opportunity for a meaningful job, to earn a decent wage, own their own business and restore personal dignity, Wozniak said.

Under the $15 million project, which is expected to take five years to bring to fruition, RecoveryPark will replace blighted, vacant lots with dozens of massive greenhouses and hoop houses to grow produce. The fruits and vegetables grown in these facilities will be sold to local restaurants, retailers and wholesalers. Among the local businesses that already purchase produce from RecoveryPark Farms, includes the restaurants Cuisine and Wright & Co. (Detroit), Bacco Ristorante (Southfield) and Streetside Seafood and The Stand (Birmingham).

The City will lease the land to RecoveryPark for $105 per acre per year. In exchange, RecoveryPark must secure or demolish all vacant, blighted structures within its boundaries within the first year. Here are the terms of the deal:

- Within 120 days of possession, RecoveryPark is required to maintain the entirety of the leased footprint, mowing at least once every three weeks, and trimming trees. This remains continues for the entirety of the lease.

- Within 12 months of a signed term sheet, RecoveryPark will re-locate its Waterford, Michigan operations, to the City of Detroit’s negotiated footprint.

- Within 12 months of a signed term sheet 51% of employees will be Detroit based for the first 36 months. After 36 months, Detroit employment must increase to 60%.

- Within the first 12 months of a signed term sheet, RecoveryPark must secure or demolish any blighted / vacant structure within the boundaries. All demolitions will be in accordance with the City of Detroit’s demolition policy. Recovery Park must also present a plan to the City of Detroit for future use of all structures.

- Within 24 months of possession, RecoveryPark will operate at least 3 acres of greenhouses or hoop houses.

- Within 36 months of possession, RecoveryPark will operate at least 6 acres of greenhouses or hoop houses.

- Within 48 months of possession, RecoveryPark will operate at least 9 acres of greenhouses or hoop houses.

- Right of Reverter – The City of Detroit has the right to take back purchased land without greenhouses or hoop-houses if RecoveryPark defaults or does not meet terms.

“Commercial agriculture in Detroit is an important addition to Detroit’s expanding business portfolio,” sad Gary Wozniak, RecoveryPark CEO. “Mayor Duggan’s economic development team has move boldly and swiftly to align city resources with our company’s expansion needs.”

A New Type of Farm is Letting Us Grow 100 Times More Food

Farming has been a cornerstone of civilization for a long time — even before sewer systems. As humans have evolved, so has farming. Thanks to drones, CRISPR/Cas9 gene editing, and a host of other innovations, we have come farther than we would have ever thought possible — including reaching new heights with vertical farming

A New Type of Farm is Letting Us Grow 100 Times More Food

Farming has been a cornerstone of civilization for a long time — even before sewer systems. As humans have evolved, so has farming. Thanks to drones, CRISPR/Cas9 gene editing, and a host of other innovations, we have come farther than we would have ever thought possible — including reaching new heights with vertical farming.

The pinnacle of modern agriculture can be found in Kearney, New Jersey at Bowery farms. The farming company claims it has the capacity to grow 100 times more per square foot than average industrial farms. This might be because the vertical farm calibrates “synthetic” parameters for its produce. Thanks to indoor LEDs that mimic natural sunlight, and nutrient-rich waterbeds that are easy to stack from floor to ceiling, Bowery is able to grow over 80 different types of produce. Bowery will begin selling its organic produce, — including popular salad fixings such as kale and arugula — in NYC come March 6th, at around $3.99 per five-ounce package.

Click to View Full Infographic

THE FUTURE OF FARMING

What’s so remarkable about Bowery is that it underscores the next generation of agriculture. While traditional farming is unlikely to disappear anytime soon, vertical farming showcases increased automation, reduced emissions, and all-around reduced costs.

Automated machines efficiently move water around the plants using a proprietary software known as FarmOS. The unique operating system adapts to new data, adjusting environmental conditions to the warehouse. Trays are optimally stacked to the ceiling and crops are produced year round, increasing the overall efficiency of the process.

Traditional farming reduces soil productivity, wastes water, can foster the growth of pesticide-resistant insects, and increases levels of greenhouse gases. The practice itself is quickly becoming unsustainable, as there’s less land available for farming: since the 1970s, almost 30 million acres have been lost to urbanization.

While traditional agricultural methods may endure, it might be prudent to acknowledge the global and local benefits of vertical farming with so many new companies cropping up.

Garden Spaces Join The Sharing Economy

Alfrea, a company based in Linwood, New Jersey, is trying to extend the sharing economy to garden spaces.

Garden Spaces Join The Sharing Economy

Alfrea, a company based in Linwood, New Jersey, is trying to extend the sharing economy to garden spaces. The company was founded in 2016 as an online marketplace for renting land and finding farm hands for hire. Alfrea has since expanded to Philadelphia, Pennsylvania, and Frederick, Maryland. The company has plans to expand nationwide. The website also has as a farmers’ market platform which allows farmers to sell produce at any time.

For those who live in cities and want to grow food, but lack land, Alfrea facilitates relationships with people who have available plots of land and those who have surplus crops can also sell them on the website. There are three types of Alfrea memberships to use these services, ranging from free to US$15 per month. Visitors to the site can also learn how to grow food in environmentally sustainable ways.

Food Tank had the opportunity to ask David Wagstaff, the company’s founder, about Alfrea’s past, present, and future in the sustainable food movement. This startup wants to give all people access to local, sustainably grown food.

Food Tank (FT): What motivated you to start Alfrea and advocate for locally grown, sustainable food?

David Wagstaff (DW): My parents own a 30-acre farm, but at 92 and 86 years old, it is hard for them to manage. As they have aged, I have taken a more active role in managing the farm, as well as their financial affairs and health decisions. I began to ponder my parents’ health, and in turn, my own. In early 2015, I immersed myself in research on how to have high-quality senior years. I read multiple books, watched several movies, met with various health experts, and even hired a fitness coach. All the research pointed to the importance of eating fruits and vegetables and reducing processed foods. The standard American diet has been tied to common health problems such as heart disease, dementia, Type-2 Diabetes, and some forms of cancer. Further, food purchased at grocery stores is often processed with high sugar, fat, and severely lacking vital phytonutrients.

Surprisingly, as I conducted research, I found that agriculture is linked to environmental degradation and climate change. Food production produces 14 percent of the world’s greenhouse gasses. Methane, a byproduct of many agricultural processes, has a heat trapping index 23-times higher than carbon dioxide and food travels an average of over 1,500 miles from farm to table.

During this time, I was trying to find people that would be willing to grow food on my parents’ land or lease out a portion of it, but it was harder than I thought. When I attempted to grow food in my own yard, the same problems persisted. Even when I turned to farmer’s markets, they were usually only open one day a week during the growing season and not always at convenient times.

Through my experiences, I discovered the sustainable food movement has no central hub for people to participate. Overall, the idea for Alfrea arose from my desire to eat healthily, protect the environment, and unify others who think like me.

FT: Has connecting gardeners and eaters with land, help, and food producers been easier or harder than anticipated?