Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Garden going up: Work begins to turn old MFA mill into high-tech indoor farm

For decades, the landmark MFA logo towered over downtown. The colorful sign on the tall white grain elevator served as a nod to our farming heritage. This week, workers rolled out a new banner highlighting the building's new tenant, Vertical Innovations, LLC.

SPRINGFIELD, Mo. For decades, the landmark MFA logo towered over downtown. The colorful sign on the tall white grain elevator served as a nod to our farming heritage. Now, after 65 years, it is gone. In its place is a sign announcing something new to come.

This week, workers rolled out a new banner highlighting the building's new tenant, Vertical Innovations, LLC.

"It was about a six hour project," stated David Geisler, Manager and General Counsel of Vertical Innovations. "That is a lot of work to fasten a banner 200 feet in the air," he laughed.

Vertical Innovations is turning the long-vacant Missouri Farmers Association grain silo complex into a massive indoor vegetable farm. The structure, which has been vacant for years, is owned by Missouri State University, and is being leased to Vertical Innovations for the project.

Geisler explained, "If it works, we are going to be able to supply a large amount of food for the people of Springfield that we know is safe, it is traceable. They are going to be able to say, this is hours old. It is going to be fresh."

There's obviously no sunlight in the tall tubes. So, artificial light and other technologies will help the garden grow. Several new employees will be brought on board to tend the crops and facility.

"Essentially, we are going to be a true vertical farm. We will be a farm using some new ideas we have that nobody else has done before," Geisler said.

As you can imagine, there are not a lot of companies left that build grain elevators. So, for this project, the developer had to hire the modern incarnation of the company that built this place back in 1955. Borton Contractors & Engineers, based in South Hutchinson, KS, is now busy retrofitting the structure for its new purpose.

Geisler said, "I think that is part of the beauty of the project is it allows us to take these icons of our agricultural heritage and reuse them in the 21st century environment. It is refreshing."

Developers and supporters have high hopes for the future of farming in urban environments. Though a grand opening is still months away, Geisler believes this project could be the first of many.

"I think we will provide a model, a blueprint if you will, for how we can use abandoned grain elevators in other cities. But, Springfield will always be first."

As for the old MFA signs, Geisler says the one removed from the north side of the headhouse has been saved for preservation. The emblem facing south, which remains in place, will likely also be taken down and preserved.

By Michael Landis

Startup That Grows Crops in Shipping Containers Unveils Sleek, New Design

At first glance, the tall metal box on the Greenway looks somewhat innocuous. But open the doors and there’s a salad disco happening inside

At first glance, the tall metal box on the Greenway looks somewhat innocuous. But open the doors and there’s a salad disco happening inside.

The large white container, which will be situated in the park all day Friday at the corner of High and Purchase streets, is the latest product from Freight Farms, the local startup that enables would-be farmers to grow produce anywhere using its tricked-out shipping containers.

The company, which has raised nearly $5 million in funding, has become somewhat of a darling to the startup set. Google is using one of its hydroponic containers to feed its 20,000 employees in Palo Alto, and last month Freight Farms partnered with Elon Musk’s chef brother, Kimbal, to help launch his urban farming accelerator, Square Roots.

Since launching in 2010, the company has sold 100 of its signature device, the Leafy Green Machine, said its president, Jon Friedman.

The prototype is a slightly smaller version of the modular growing system. He dubbed it the Leafy Green C (the C stands for community, or compact ... they haven’t decided yet). It’s about one quarter the size of a typical shipping container, clocking in at about 10 feet long, 9 feet high, and 8 feet wide. And it can grow 200 heads of lettuce each week.

Inside is where the fun starts.

Farmers plug their seedlings into six-foot tall, gutter-like “towers” that act as a growing medium for the young shoots. Each tower is then hung from the ceiling and lit with blue and red LED lights, which can be tweaked to emulate the sun as it cycles through the day.

Imagine dozens of vertical spinning towers of lettuce. The entire system gives off a very disco-like feel.

The original containers, which each cost $85,000, are now in nine countries, six islands, 25 states, and 12 schools. But Friedman said the system’s new design has a different customer in mind. It will be half as expensive as the original model (the exact price is not yet set, he said). He’s hoping to attract restaurants, communities and perhaps even individuals who are excited about the idea of container farming but don’t necessarily need nearly an acres worth of produce a week. The company will begin taking preorders in November.

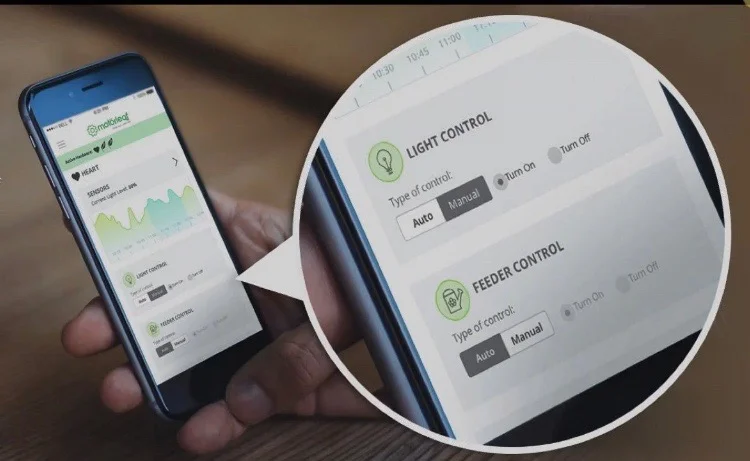

Part of the draw, said Kyle Seaman, the company’s farm technology director, is the newly-designed app called Farmhand that allows the owner of the unit to control all aspects of the container from a smartphone, adjusting the light, heat, nutrients, and water.

“The app informs the farmer if something goes wrong,” said Seamen.

Should their lettuce need some love, they’ll get a ping on their phone. Now, if they can just make it connect to Spotify, they’ll be in business.

Janelle Nanos can be reached at janelle.nanos@globe.com. Follow her on Twitter @janellenanos.

The Growroom is a spherical farm pod that brings agriculture to city streets

With a rapidly increasing population, food demands are skyrocketing, but current factory farming methods are hardly sustainable. Space10 wants to address that problem with brilliant solutions like The Growroom.

Space10 and Danish architects Mads-Ulrik Husum & Sine Lindholm created an innovative, beautiful urban farm dome that shows how we can bring nature and food farming back to our cities. With a rapidly increasing population, food demands are skyrocketing, but current factory farming methods are hardly sustainable. Space10 wants to address that problem with brilliant solutions like The Growroom.

The Growroom was exhibited first at the CHART ART FAIR in Copenhagen, a fair that exhibits exceptional design from the Nordic region. According to Space10, the Growroom is meant to “spark conversations about how we can bring nature back into our cities, grow our own food and tackle the rapidly increasing demand for significantly more food in the future.”

The Growroom is filled from floor to ceiling, end to end, with vegetables, herbs and other edible plants, with a cozy space in the center to reflect and relax. It is a beautiful way to explore how we can bring more food to our cities in a self-sustaining eco system that can supply hyper-local food that is seasonal, fresh and high quality. Growroom gives us “food that tastes better, is healthier for us, more nutritional and doesn’t put massive pressure on our dwindling supplies of fresh water nor our environment,” says Space10.

Earlier this month, people were able to step into the “farm” and experience the Growroom with every sense – from the smell of the plants to the light filtering in between the garden spaces. It’s easy to imagine how such a space could become a feature of every neighborhood, providing a green escape from city life that also provides nourishment. “We’re inviting [people] to step inside the growing green haven, smell and taste the abundance of herbs and plants, and hopefully it will spark passion about growing your own food in the future,” said Carla Cammilla Hjort, Director of Space10.

Space10 co-created ‘The Growroom’ together with architects Mads-Ulrik Husum & Sine Lindholm, interaction designer Thomas Sandahl Christensen and gardener Sebastian Dragelykke, Tradium and Raaschou. Hjort says, “At Space10, we envision a future where we grow much more food inside our cities. Food producing architecture could enable us to do so.”

By Kristine Lofgren

Modular Farms Newsletter #3

Toronto & Modular Farm!

Now that the dog days of summer have passed, we figured it was once again time to get you all formally updated on our whereabouts. Amidst the record-breaking heatwave that has been plaguing Toronto for the last few weeks, we have managed to keep cool by doing what we do best - working away in our climate-controlled Modular Farm!

The moment we have all been anticipating has finally arrived. The technicians have finished their work, our initial run of Modular Farm raised Kale has been harvested, and our first sets of Collard and Lettuce seedlings have been transplanted. Also, as you can see from the above photo, we've begun experimenting with the various colourful spectrums our Intravision Spectra Blade LED lights have to offer. If all proceeds as planned, expect to receive a formal invitation to our official unveiling very soon.

On the R&D side, our team has been very busy designing the new line of secondary modules. With the Primary Module almost complete, we've turned our attention to developing the Vestibule, Off-Grid and Macro Farm modules next, as we consider them to be the most vital secondary modules. Once completed, those who have already purchased a Primary Module will be able to easily scale up their production capabilities, have an active climate and pest barrier, and have the ability to power their farms even in the most remote locations.

Every Thursday afternoon for the past month and a half we've had the pleasure of being a part of the #FarmFreshTO pop-up farmer's market at the Bay Adelaide Centre. Unlike other farmers markets around the city, which tend to be more focused on simply buying and selling produce, the main mission of #FarmFreshTO has been to raise awareness of urban vertical farming practices and sustainable living.

We've greatly enjoyed engaging with, and educating, the public on the benefits and applications of our technology; we can't thank Usful enough for giving us such an amazing opportunity. If you're in the area we highly recommend coming down to Arnell Plaza on a Thursday to say hi, treat yourself to some samples, and get a hands-on look at our technology. Just be sure to do it soon, as the final day of the market is September 15th.

Ending the food insecurity issue in Canada has always been, and will always be, the main reason for our existence. While this may seem like a daunting task, we've already seen great strides being made across the country by passionate, like-minded people who have been utilizing ZipGrow technology to feed themselves, their families, and communities in a sustainable fashion. We currently have Modular Farms scheduled for delivery from coast to coast in the next 12 months, however, there are so many Canadians still in desperate need of our help, and we need your help to get them properly fed. Contact us today to find out if a Modular Farm is a good fit for your family and community.

Stay tuned for the next installment of our newsletter!

IES Launched Full Range Of LED Horticulture Grow Lighting Products

IES is one of the leading global developers of greenhouse and indoor farming and gardening LED lights solution.

IES is one of the leading global developers of greenhouse and indoor farming and gardening LED lights solution. With an international team of agriculture experts and researchers, IES focuses on driving innovation and development in their industry which has earned them the status of being a global leading light in the field of supplemental lighting. Recently,

Technological advancements have paved the way to more unconventional methods of cultivating plants, growing and caring for them which include indoor farming and gardening. IES is directed by their desire to generate and cultivate innovative and hi-tech LED Horticulture Lighting technology. Their main point of focus is to satisfy their customers through their high standards of quality in both their products and their customer services. The company spokesperson said: Our Horticulture LED Solutions develops light systems to condition any crop in growth. We do not only provide mere lighting, but we provide the best possible care to increase profit for the grower, we call this custom made plan a ‘light recipe’.”

The range of products has been created to cater to the needs of contemporary indoor and greenhouse farming and gardening lighting needs, the comprehensive range of products includes LED lights specially designed for a greenhouse, hydroponics, aeroponics, home garden, farm, vegetable shed, botanic garden, flower exhibitions, horticulture, hydroponics, hemp cultivations, medical plants cultivations, etc. the spokesperson continued: “Our light recipes are suitable for different segments within horticulture, e.g. vegetable production, tissue culture and young plant production, cut flowers, seedlings and nurseries. Horticulture LED Solutions is offering knowledge of LED Plant lighting around the world to you.”

Consistent global standards of quality and various certifications are the testament to the company's commitment towards maintaining the highest levels of superiority. The company takes a lot of pride in the fact that they maintain a large worldwide customer based with clients in every part of the world including Europe, America, the Middle East and Southeast Asia, their product are available for sale on all major online marketplaces and the complete details of each product is available on the IES horticulture lighting website.

The company looks forward to expanding their global customer base to become a major LED grow lighting manufacturer globally and continue serving their esteemed clients with top of the range products.

About:

IES Lighting Co., Ltd is a horticulture and agriculture LED light producer based in China.

For more information please visit: http://www.grow-lighting.com/

Contact: Jessie

info@grow-lighting.com

Shenzhen,China

Media Contact

Company Name: IES Lighting Co., Ltd

Contact Person: Jessie

Email: info@grow-lighting.com

Country: China

Website: http://www.grow-lighting.com/

2 Acres of Farming In A Shipping Container

With the increasing demand for agricultural products, it has become necessary to practice alternative methods for bringing up the supply levels

2 Acres of Farming in a Shipping Container

Anna Domanska , September 13, 2016 / 2153 0

With the increasing demand for agricultural products, it has become necessary to practice alternative methods for bringing up the supply levels. It has to be taken into consideration that land simply cannot be cleared off to make space for more farms. With this in mind, the technique of vertical farming proves to be beneficial. To explain this further, vertical farming is a technique in which plant cultivation will take place inside skyscraper greenhouses. A specific environment is created using solar or wind turbine energy which is suitable to the plant growth. Furthermore, this type of farming can be done year-round.

The Vertical Farming Accelerator called Square Roots

In order to take this technique further into the agricultural market, entrepreneur Kimbal Musk along with Tobias Peggs is planning to launch a new urban farming incubator program, called Square Roots. Under this program, vertical farming will take place in the Pfizer factory situated in Brooklyn, New York. These vertical farms will be created inside 10 steel containers 320-square-foot each. Each of these containers will be managed by a young agricultural entrepreneur for one year. These entrepreneurs will be given hands-on training in running a vertical farm business by Square Roots. They will have full access to their respective farms at any time they want. In this case, the entrepreneurs can choose to grow anything they like. The entrepreneurs who are interested are supposed to pitch their start-up concept in front of Square Roots.

Such containers will contain rows of organic herbs and these plants will be monitored for watering and proper nutrient content. Due to constant monitoring, many plant diseases and spoilage could be discovered before it starts spreading further. Such farms are located in or around the city. Due to this, the consumer will acquire fresh food products which are a major benefit of vertical farming. The technology used will be developed by vertical farming start-ups Freight Farms and ZipGrow. The plants grown in such containers will be rooted in water instead of soil and cultivated under LED lights. The team of experts has decided to grow green crops inside these containers. This is because such crops are small enough for the entrepreneurs to understand vertical farming thoroughly. One such container is efficient enough to grow crops equivalent to 2 acres of farmland.

Benefits of Vertical Farming

Musk and Peggs strongly believe that urban farming has a number of advantages over traditional farming. Significantly, vertical farms expend 80% less water than outdoor farms and require much less space. On the other hand, Square Roots aims to help young farmers understand this technology better so that it can be implemented efficiently. Such entrepreneurs will be trained under the best mentors provided by Square Roots. The most important advantage of vertical farming is that it’s healthier than the products of industrial farming. The food produced through industrial farming is high-calorie, low nutrient and processed thousands of miles away. Whereas vertical farming does not compromise with the nutritional value.

Kimbal Musk and his ventures within the Agricultural Industry

Kimbal Musk is an American entrepreneur, known for his investments in several technology and food companies. He is an environmentalist who has introduced technological ideas which help in the sustainable growth of society. Musk co-founded The Kitchen which is a chain of restaurants which stocks up its food sources from local farmers. He has also co-founded a venture called The Kitchen Community, which is a non-profit organization. The Kitchen Community builds learning garden in schools around the USA. This organization has already planted vegetable gardens at more than 200 schools nationwide.

The technique of vertical farming is a progressive step towards the sustainable development on a global scale. As this technique requires minimum resources, it gives an output as good as the traditional farming method. Also, it helps in solving the problem of cutting down vegetation to meet the increasing demand of food.

Growing in the Air

A Newark-based AeroFarms seeks to transform agriculture through aeroponics technology that grows greens soil-free and indoors.

Forget sunshine and soil to grow leafy greens and fresh vegetables for health-conscious consumers. A US venture firm is leading a new wave of future agriculture by adopting the latest technology to produce something more fresh, safe and environmentally conscious at the heart of urban spaces.

Instead of growing crops on land with the use of pesticide and water, a Newark-based AeroFarms is running high-tech greenhouses to produce high quantities of nutritious and quality fresh food all year round. Indoor vertical farming -- a concept invented by Dickson Despommier, an ecologist and an emeritus professor of Columbia University -- is what the firm has been promoting.

The firm grows massive amounts of edible greens in stacked rows that reach to the ceiling in a controlled-environment where the temperature, nutrients and lighting are constantly monitored and adjusted. At AeroFarms, plants grow under light-emitting diodes on permeable micro fleece cloth irrigated with a nutrient-infused mist. It uses 95 percent less water, about 50 percent less fertilizers and zero pesticides.

An illustrated image of AeroFarms' vertical farming (AeroFarms)

The US firm is also working on turning an old steel mill in Newark, New Jersey into the world’s largest indoor vertical farm.

In the 6,503 square-meter space, the firm aims to produce up to 907,184 kilograms of baby greens per year, said Marc Oshima, the co-founder and chief marketng officer of AeroFarms in an email interview with The Korea Herald.

Indoor farming can ease growing concerns about climate change, population growth and fast urbanization, he said. Not only is vertical farming sustainable and socially responsible, it is a promising business as it produces greens that are tasty, rich and more nutritious, he added.

Vertical farming, in particular, can be a solution for tech-savvy South Korea that has millions of people living in congested city areas, as it offers a greater level of control to consistently grow high quality food, he said. Korean municipalities have been investing in local startups to conduct research and development in indoor farming. But there has not been many local companies involved in such business so far, according to local experts, citing the lack of economic feasibility and efforts in securing the market.

The following are the questions and answers of the interview.

1. What inspired you to start a high-tech farming business?

We are committed to building, owning, and operating indoor vertical farms that grow delicious, safe, healthy food in a sustainable and socially responsible way all over the world.

We build our farms in repurposed spaces benefitting communities and creating local jobs. Our R&D facility was once a night club and one of our farms is a former paintball/laser tag arena. We are currently building the world’s largest indoor vertical farm in an old steel mill in Newark, New Jersey. It will be 70,000 square feet (6,503 square meters) and have the capacity up to 2 million pounds (907,184 kilograms) of produce per year.

2. What are the benefits of vertical farming for customers, businesses and communities?

Our way of farming mitigates food safety risks: no soil, completely insulated from neighboring operations, no pesticides ever, and we can track a package of greens down to the exact square foot of growing. Most of the common food safety risks simply are not an issue with our system. In addition, all of our farmers and staff go through rigorous food safety training, and we are certified with United States Department of Agriculture Good Agricultural Practices.

Food-borne illnesses from vegetables are mainly a product of the practices needed to sustain large-scale commercial agriculture. Overuse of antibiotics in factory farming of livestock have created resistant bacteria, which are then sold to farmers in the form of manure or fertilizer.

Also, all of our farms have been in repurposed spaces. Our technology can really fit anywhere, but we have been focusing on dormant warehouse space that is close to existing retailers and food service distributors. A big part of our mission is to decrease food miles and travel time so that our greens are as fresh as possible when you eat them. That is why we focus on urban warehouse space specifically. But also, it’s gratifying to breathe some new life into areas that may have lost manufacturing businesses decades ago. The communities we enter are so ready for us to come in and start growing and hiring.

3. What differentiates AeroFarms’ greens from other greens produced through conventional farming methods and mass production?

Just because the supermarket shelves are stocked doesn’t mean that all is well. Food in the US travels thousands of miles and is often up to two weeks old when it reaches consumers.

That’s why distribution is a huge part of our thought process when opening new facilities. AeroFarms builds farms on major routes and near distribution centers so that our greens spend minimal time in transit. That means longer a shelf life, less shrink, better taste and also better nutrition. The second a leaf is harvested the nutrition starts to degrade, so when we can cut transit time down by growing locally we give consumers an even healthier product. So not only do our greens reach the store with more of their original nutrition, our precise control of every aspect of the nutrients, water and environment our plants use to grow means we can create the perfect conditions to optimize for flavor, taste, color, and yield to have a truly sustainable business. Our products are available to the consumer at the exact same price as field grown produce while delivering superior value.

4. Will high-tech vertical farming be the future of farming?

Vertical Farming is growing as quickly as it is because the relief of pressure on our natural resources currently caused by industrial farming is striking a chord. Traditional farming will always be an important part of the food supply, but we would like to see vertical farming become a substantial percentage of overall production. From a food security point of view it’s just smart, but also from a biodiversity and flavor point of view.

5. Who does your business mainly target?

Our greens are incredibly tasty and tend to convert even people who don’t think they like to eat leafy greens -- so there’s really no one in America who is not a potential customer. Our goal is to democratize access to good, healthy food that is responsibly grown.

6. Do you think that vertical farming could be a good business opportunity in Korea?

Absolutely. Vertical Farming is a great solution for dense urban areas because fresh food often has to travel long distances from rural areas to these cities. More importantly, vertical farming offers a far greater level of control to be able to consistently high quality food.

7. What are the challenges you have faced so far? Has there been any opposition from local farmers?

The biggest challenge for us so far has been getting to market fast enough. We have more demand from retailers than we can supply, which is why we’re working hard to bring new farms on line as quickly as possible. We don’t really see ourselves in competition with local farmers. What we’re looking to disrupt is the giant industrial farms in California and Arizona, which have energy and water needs that are vast and generally unreported. Plus, with 20 crop turns a year, we can provide fresh local green in February, when we’re really not competing with anyone.

Marc Oshima, co-founder and chief marking officer of AeroFarms

8. What kind of advice do you have for Korean start-ups or government-funded entities interested in vertical farming?

Growing indoors is not easy to do and we really want to underscore the importance of food safety. At the end, we recommend that experts like AeroFarms get engaged to help in the process.

9. What are your future strategies?

We are looking to build 25 farms over the next five years, and that is a very conservative number given the demand. We currently have farms in development in four different continents including Asia.

By Cho Chung-un (christory@heraldcorp.com)

Agrilyst Reports Indoor Agriculture Over 4k Times More Productive Than Outdoor Commodity Crop Production

The opportunity to harvest more times a year and higher retail prices are making indoor farming more productive than conventional outdoor operations.

Better yields, the opportunity to harvest more times a year and higher retail prices are making indoor farming more productive than conventional outdoor operations, according to a new report from data software company Agrilyst.

The State of Indoor Farming details the results of a survey of over 150 indoor growers in the US, representing around 9% of the country’s current indoor farming market.

While unable to make a 100% like-for-like comparison to outdoor operations for all types of produce, the report builds a comparison between outdoor farms and indoor operations using historical USDA and other public data.

According to the report, indoor horticulture operations stand to make $2.2 million an acre each year compared to an outdoor lettuce operation which makes $12.4k an acre and an outdoor tomato operation, which makes $13k an acre.

Indoor greens growers surveyed reported an average of 340k pounds per acre annually, compared to about 30k pounds per acre reported by the USDA for lettuce under conventional outdoor production. That’s an 11x increase in yield. The majority of this is down to the increase in the number of harvests per year; outdoor lettuce growers harvest four to fives times a year compared to the potential for indoor growers to harvest 18 times a year due to a shorter growing period under controlled conditions.

But even without this cyclicality benefit, indoor growers can produce 2.8x more annually on yield increases alone, according to the report.

There were similar productivity gains for tomato growers, according to the report.

Adding to these harvest and yield figures, the price of indoor-grown produce is also much greater than outdoor-grown produce.

According to the report, indoor greens farmers are getting 10x more, and indoor tomato growers are getting 2.5x more than their outdoor counterparts. A large reason for this is the distribution channels of these growers: direct to consumer or restaurant sales.

Likely a result of this positive trend, 86% of the indoor growers surveyed plan to expand their operations in the next five years. For all respondents, even the minimum planned expansion is 4.7x larger than their current farm size, which suggests significant market growth in the coming years.

They also want to invest in technology. On average, growers have an annual budget of $12 per square foot to invest in technology for both increasing plant yields and managing operations more efficiently. They also have an annual budget of $15 per square foot to invest in technology to improve crop quality.

Topping the list of new technologies, 39% of growers are interested in purchasing a farm management system in the next year, with 90% of all growers surveyed believing that they can increase their crop yields with data analytics. In addition, 28% of growers are interested in purchasing post-harvest automation systems, 28% are interested in purchasing LED lighting, and 27% are interested in purchasing climate control systems. The lowest priority item listed was organic nutrients.

But it is not plain-sailing for indoor agriculture. There are many challenges for the sector to overcome to be truly efficient and sustainable.

Keeping operating costs down is the biggest challenge, according to survey respondents, followed by the difficulty in predicting and stabilizing operating costs. Labor costs are one of the biggest and the report delves into the average workforce dependent on the size of the farm, and type of crop.

The report also touches on the issue of organic certification, which we covered in a post here last week.

To find out more about the make-up of the survey respondents, how exactly they plan to spend, and more in-depth analysis of the challenges they face, download the report here.

Green Sense Farms Reaches Crowdfunding Goal on Day 1

Green Sense Farms, an indoor farm company based in Portage, has raised more than $120,000 in a crowdfunding campaign.

Green Sense Farms, an indoor farm company based in Portage, has raised more than $120,000 in a crowdfunding campaign on startengine.com.

The market-leading company, which raked in $788,000 in revenue last year and just opened its first farm in China, reached its minimum goal of $100,000 on the first day but hopes to raise up to $1 million to build a network of indoor vertical farms. These would be built at perishable food distribution centers owned by large grocery stores and institutional campuses that serve a lot of food daily, such as at hospital cafeterias.

“We’re not subject to rain or drought," Founder and CEO of Green Sense Farms Robert Colangelo said. "We precisely control the indoor environment, to create the perfect conditions for our plants to grow year-round, every single day.”

Last year, the U.S. Securities and Exchange Commission adopted rules that allow companies to sell securities through crowdfunding, which SEC Chairwoman Mary Jo White said would give smaller companies a more innovative way to raise capital while protecting investors.

Companies can go online to raise up to $1 million through crowdfunding over a 12-month period. They're required to disclose independently audited financial information, including from tax returns, and the crowdfunding platforms have to provide investors with disclosures and educational materials.

Green Sense Farms, which reports having $2.6 million in assets, grows GMO-free leafy green vegetables indoors, using less water and land than traditional agriculture. The company says more sustainable farming practices are needed because climate change is reducing the amount of arable land and the world's population is projected to reach 9.7 billion by 2050.

"Green Sense Farms has been the fortunate recipient of numerous stories about our exciting innovative indoor vertical farming technology," Colangelo said. "All this press has generated many inquiries from individuals asking how they can invest in our sustainable farm. We’re pleased to announce that the recently released crowdfunding regulations now allow for individuals to make direct equity investments in growth companies like ours."

The company, which started with a 20,000-square-foot farm in Portage, is seeking investments of at least $100 to fund R&D for new farm designs and to expand its network. It's eyeing indoor farms near colleges, hospitals, military bases and corporate campuses, including abroad in Canada, Scandinavia and China.

"Just as Green Sense Farms has disrupted produce distribution and cut out the middleman, the new crowdfunding regulations have democratized the capital markets, allowing individuals the opportunity to take advantage of public offerings without the use of traditional stock brokers," Colangelo said.

For more information, visit www.startengine.com/startup/green-sense-farms-llc.

15 Ways Urban Farming Can Revitalize a Neighborhood—And Help Farmers Too

What if farms and food production were integrated into every aspect of urban living?

15 Ways Urban Farming Can Revitalize a Neighborhood—and Help Farmers Too

What if farms and food production were integrated into every aspect of urban living?

By Michael Ableman / Chelsea Green Publishing

September 8, 2016

Friendly team harvesting fresh vegetables from the rooftop greenhouse garden and planning harvest season on a digital tablet

Photo Credit: LUMOimages/Shutterstock

[Editor's note: What if farms and food production were integrated into every aspect of urban living—from special assessments to create new farms and food businesses to teaching people how to grow fruits and vegetables so farmers can focus on staple crops? That’s the crux of Michael Ableman’s Urban Food Manifesto, which has been ten years in the making and is spelled out in his new book, Street Farm. The book tells the story of Sole Food Street Farms, and the role it has played in revitalizing not only a neighborhood, but the lives of its individual farmers. The urban farming manifesto below—as told through Street Farm—is a story of recovery, of land and food, of people, and of the power of farming and nourishing others as a way to heal our world and ourselves. You can also check out this Q&A with Ableman, where he describes in more detail the promise of urban farming.]

I have been developing the following 15-point Urban Food Manifesto over the last ten years.

Some of the ideas may sound radical; others will likely seem terribly obvious.

Some are practical, some more ideological, but either way they are focused on the municipal and on individual ways to address what I consider to be some of the most prominent challenges in how we feed ourselves.

1. Every municipality should establish publicly supported agricultural training centers in central and accessible locations. I’m not talking about think tanks or demonstration gardens. I’m talking about working urban farms that model not only the social, cultural, and ecological benefits of farming in the city, but the economic benefits as well. We can talk about all of the wonderful reasons to farm in urban areas, but until we can demonstrate that it’s possible to make a decent living doing it, it’s going to be a tough sell.

2. Regular folks are now so removed from the work of farming that they need to literally see what’s possible. They need access to those who have maintained this knowledge and those who are serious and active practitioners. Every city should have teams of trained farm advisers in numbers proportionate to the population devoted to urban food production. Those agents should operate out of their local urban agriculture centers to run training workshops and classes; they should also venture out into the community to provide on-site technical support in production, in marketing, and in food processing and preparation.

3. The nutrient cycle that once tied farms with those they supplied has been interrupted. We need a full-cycle food system that allows for the return of organic waste via central regional composting facilities that can support the nutrient needs of both urban farms and farms on the fringes of our urban centers. Every community could be composting all its cardboard, paper, old clothing, shoes, restaurant and grocery store waste, and on and on. We need to reduce what comes into our communities from elsewhere, but we also need to reduce what leaves those communities, especially if it has nutritional or soil conditioning values for our land.

4.My fields at Foxglove Farm have as many rocks as grains of soil. Removing those rocks represents a huge amount of work for me, but each one of those rocks also represents an enormous amount of embodied energy, if I could just release it. Every community should own a portable rock grinder that could be taken to farms and used to grind rocks in and around fields that contain essential minerals now being mined elsewhere at great ecological cost. There are huge holes in the world, entire mountains removed, to supply minerals such as gypsum and lime and rock phosphate to our farms. We cannot talk about a sustainable agriculture unless we address where the minerals—especially phosphorous—are going to come from.

5. We’ve all heard about peak oil; we need to prepare for peak water and peak phosphorous. We can grow food without oil, but we cannot grow it without phosphorous and water. Phosphorous is a mined mineral, which now has limited reserves, most of which are located in China, Morocco, and the Western Sahara. Some scientists believe that at the rate we now use it, remaining reserves will be depleted within fifty to one hundred years.

6. Let’s get over our phobia around human waste, stop spending billions of dollars to flush it away and pollute our rivers and oceans, and start recycling it onto our farms and gardens. Urine is the best local source of phosphorous, and we need to figure out creative ways to recycle it.

7. Every community should support the construction and funding of a permanent covered year-round farmers market space in a dominant central location. Providing this type of physical space is just as important to our civic health, if not more, as the public swimming pool, the sports fields, schools, churches, and libraries.

8. Every new permit for a housing development should be contingent on inclusion of an approved food-production component on a scale relative to the number of people who will live in the development. And every new office or retail building should be engineered for a full-scale rooftop food production component, including greenhouses warmed by the spent heat vented from the building.

9. Every neighborhood, school, and church should be required to restructure existing institutional-kitchen facilities to accommodate cooperative canning, freezing, and dehydrating services for their neighborhoods during non-peak hours.

10. Every real estate transaction should include a small urban farmland preservation tax from which lands could be purchased specifically for the production of food, and those lands could have protective easements that require agricultural use in perpetuity.

11. A great deal of privately owned arable land currently lies fallow. This land could be made available to new farmers under long-term leases. We need to recognize that there is not necessarily any relationship between landownership and land stewardship. The only requirement for landownership in our society is access to capital. That’s not enough. I believe that ownership of land should come with a set of responsibilities.

12. Building inspections are common practice prior to many real estate transactions; we should require land inspections, including ecological assessments and baseline documentation, on every piece of land over five acres. Every land purchaser should be required to attend a stewardship and restoration training course based on the particularities of that piece of land. This will help move land away from its status as commodity and bring some sense of stewardship into ownership.

13.When I was in school my favorite classes were wood shop, metal shop, mechanics, and home economics, which included cooking and sewing. Those subjects were well respected. I looked forward to shop class far more than math or science or English. It was a time when I could make something real and tangible. (Every wood shop teacher I’ve known was missing a finger or two, and I am sure that was a requirement for those positions. I made the connection very quickly between those missing fingers and the machines we worked with.) Life skills classes are coming back into schools, but we need to give farming and cooking and mechanics and plumbing and carpentry the same status and attention as math or English or the sciences.

14. It sounds radical, but in the future full-time professional farmers may no longer have the luxury of raising fruits and vegetables. This should become the responsibility of individuals and families to grow for themselves in their front and backyards, on their balconies and rooftops, and in community garden plots. We could probably survive without another carrot or tomato, but we cannot live without grains and beans and protein sources.

15. Every municipality should initiate a phase-out of all home lawns—effective immediately—but they must also provide neighborhood training programs and technical support for home- and building owners to replace those lawns with food production.

It may be that along with growing food, the real work of farmers in the future should be seen as the sequestration of water and carbon. Anyone who has land, or is managing land, has a huge opportunity and a responsibility to address two of our greatest global challenges—water and climate.

Slowing and spreading surface water and allowing it to percolate and not run off, along with learning to use land and improve soils to store and hold carbon, are urgent and essential roles that farmers need to play now and into the future.

Michael Ableman is the cofounder and director of Sole Food Street Farm and an early proponent of the urban agriculture movement. He has created urban farms in Watts, California; Goleta, California; and Vancouver, British Columbia. Ableman has also worked on and advised dozens of similar projects throughout North America and the Caribbean, and he is the founder of the nonprofit Center for Urban Agriculture. He is the subject of the award-winning PBS film Beyond Organic narrated by Meryl Streep. His previous books include From the Good Earth, On Good Land, and Fields of Plenty. Ableman lives and farms at the 120-acre Foxglove Farm on Salt Spring Island in British Columbia.

How to Grow Crops Without Sun, Soil or Water

A massive new indoor farm is about to open in New Jersey

How to Grow Crops Without Sun, Soil or Water

By Gillie Houston Posted September 08, 2016

A massive new indoor farm is about to open in New Jersey.

When you think farm, you might imagine sun-drenched fields of fertile soil. You probably don't imagine a very large building in Newark, New Jersey. But AeroFarms, a startup that's developed technology allowing plants to grow without sunlight or dirt (and with very little water), might be about to change that.

Related

- Elon Musk's Brother Launches "Urban Farming Accelerator" in Brooklyn

- Do Farm Subsidies Cause Diabetes?

- Funiture Giant IKEA Wants to Help Restaurants Build Their Own Indoor Farms

According to CNN, the company's first 69,000-square-foot farm is slated to open in Newark, New Jersey this September and will produce leafy greens and herbs, like kale and basil. If this sounds a bit dystopian, consider that this approach could have major environmental benefits: AeroFarms says its new structure will require 95 percent less water than the average outdoor farm.

The farm's technological design was inspired by the aeroponic farming techniques already used by astronauts at the International Space Station. At the AeroFarms facility, humidity, temperature, and light are all strictly controlled to create the most growth-friendly environment possible—free of seasons, days or nights. Each of the plant beds, which will cycle through 22-30 harvests every year, grows on a cloth made of recycled materials, under which their roots are misted with a nutrient solution. LED lights replace the sun and shine at the optimal wavelength for each plant.

AeroFarms founder David Rosenberg says the company anticipates the large-scale vertical farm will produce 2 million pounds of greens a year, setting a precedent for the potential of urban indoor farming. The tech entrepreneur, whose ambitions extend far beyond the farmers market, hopes that the technology his company is pioneering will soon be able to help feed the 54 percent of the world's population who live in urban areas, where growing fresh ingredients is difficult. "We are building this company to be wildly impactful. Not just to build a few farms, but to change the world," Rosenberg says.

Though the lack of soil usage in the growing process means AeroFarms crops aren't eligible for organic certification, all of the plants grown in the facility are free of pesticides, herbicides, and fungicides, and use non-GMO seeds. The company also collects extensive data from their plants in order to improve their growth algorithms and future crops. "We build our own software, which take images of leaves to understand height, width, length, stem ratio, curving, color, spotting and tearing," says Rosenberg of the farming method.

Co-founder Marc Oshima, says their crop beds—which the company currently sells exclusively to local markets, shops, and restaurants—are highly computerized, but still require human touch. "We think of ourselves as plant whisperers, listening and observing everything we can do to optimize our plants," he says. "Our growing approach is really leading the way, marrying biology, engineering, and data science."

Spanish Pharmaceutical Giant Puts Growtainer into Operation

After installing the first international Growtainer in the UK last year, GreenTech Agro is expanding its presence in Europe with the recent installation of another Growtainer at Spanish biotechnological giant Bioibérica.

The Growtainer is the brainchild of Glenn Behrman, founder of GreenTech Agro and CEA Advisors. Two years after introducing his first Growtainers for sale in 2014, Behrman has now installed another EU Growtainer at the factory of leading Spanish pharmaceutical company Bioibérica in Pallafols, outside of Barcelona. Their enthusiasm for the Growtainer and vertical production has been driven by their interest in new, modern and sustainable indoor farming practices. They will use the Growtainer to produce leafy greens, herbs and vegetables for their canteen at the factory site, in order to gain more hands on experience with indoor growing.

"Bioibérica is a forward thinking company that is committed to discovering new technologies and industries", said Behrman. "They are open to new innovations and other industry angles that have a potential for capitalization.”

For the Bioibérica project, Behrman collaborated with Dutch horticultural installer Stolze, whose team transformed the used shipping container, outfitted by RCC Container Trading, into a vertical farm. After the installation at the Port of Rotterdam, the Growtainer was shipped to Spain where Behrman and an expert crew from Stolze completed the delivery with a final installation last week.

Proprietary technology

Inside Bioibérica's Growtainer there are a total of 12 Growracks divided into two separate production chambers. Ten of the Growracks have 4 layers and will be used for regular cultivation, and two racks with 5 layers each will be used for propagation.

Besides having a dedicated proprietary technology for ebb and flow irrigation installed, the Growracks are equipped with Philips GreenPower LED Generation 2 production modules, which are specifically designed for multilayer cultivation in conditioned environments with no daylight. The LED modules ensure a uniform light distribution across the shelves, which means that every plant receives the same level and quality of light.

The irrigation in the Growtainer is divided into six separate zones in order to provide flexibility and allow a wide variety of production of crops at various growth stages. Behrman worked closely with Stolze's engineers to design a sophisticated control system to manage the irrigation, climate, humidity and CO2 levels inside the Growtainer. The entire climate and crop control can be managed remotely via a computer or mobile phone.

Canteen & Research

Bioibérica will grow several crops inside the Growtainer, in the first place to supply their nearby canteen with everyday fresh and safely grown veggies. "They will use it to feed their employees first and gain indoor farming experience with it. While this is an important objective of the installation, Bioiberica is laser focused on the potential advances in their Bio stimulant products. They are excited to incorporate the Growtainer’s state of the art technology based production capacity for further research within their existing business models."

Behrman, who has a long term background in horticulture, has gained a lot of experience with technology based production and container farms over the past few years. "Thanks to the close cooperation with Stolze, VK Pro and RCC Containers, the Holland built Growtainers have become a real state of the art, completely proprietary system. While there are currently many other individuals in the US that offer shipping container farm systems, none of them is as flexible or sophisticated as this one, because this Growtainer version has focused on and tried to improve everything everybody else is trying to do."

Financing and substantial support

At the moment Behrman is continuing to improve the Growracks and building more Growtainers for clients in the United States. "But we have many other exciting plans to announce soon", said Behrman, not only referring to the several new installations in process. "We are almost ready to announce a more manageable crop specific Growtainer for the beginning farmer, with financing and a substantial support system in place, an onsite production initiative with a major US Supermarket Chain and other projects which focus on the highest and best economic use for this exciting and evolving technology.”

For more information:

CEA Advisors - GreenTech Agro

Glenn Behrman (e-mail)

www.growtainers.com

Publication date: 9/7/2016

Author: Boy de Nijs

Copyright: www.hortidaily.com

The Farm that Runs Without Sun, Soil or Water

(CNN) What do you get if you cross a tech entrepreneur with a farmer?

(CNN) What do you get if you cross a tech entrepreneur with a farmer?

The world's largest, and possibly most sophisticated indoor farm -- where greens grow without sun, soil or water.

Well, almost no water. AeroFarms, the company behind the venture, say they will use 95% less water than a conventional outdoor farm.

Set to open in September in Newark, New Jersey, the 69,000-square-foot farm will be hosted in a converted steel factory. It combines a technique called "aeroponics" - like hydroponics, but with air instead of water - with rigorous data collection, which will help these modern farmers figure out optimal conditions for growth.

The goal? To produce tall, handsome, tasty baby greens and herbs such as kale, watercress and basil.

Fighting a looming food crisis

This will be the largest farm of its kind in the world in terms of production capacity: 2 million pounds of greens a year, according to Aerofarms founder David Rosenberg.

But the company's ambitions go beyond selling vast amounts of veg. They also hope to provide an answer to a looming food crisis.

The world's population will hit 8.5 billion by 2030, according to UN estimates, meaning many more mouths to feed.

Most people now live in cities, with 54% of the world's population already living in urban areas.

Rosenberg says innovation is urgently needed to feed everyone, and urban farming might be part of the solution.

"We are building this company to be wildly impactful. Not just to build a few farms, but to change the world."

How it works

Inside the farm, there are no natural seasons, nights or days. Light, air humidity and temperature are all tightly controlled.

As soon as one harvest is in, another begins -- each plant is expected to yield between 22 and 30 harvests a year.

Long rows of LED tubes shed light at the exact wavelength each plant needs to thrive. Instead of soil, the plants are grown on a cloth made from recycled materials, and their roots are misted with a solution of nutrients.

The company says their method is superior to more commonly used indoor farming techniques like aquaponics and hydroponics, which require much more water, and that the plants taste the same, or even better, than their conventionally grown counterparts.

Aeroponic farming techniques have been used before. NASA astronauts use it to grow food at the International Space Station, for example, and home-grow DIY kits can be ordered from a number of companies online.

Farming with algorithms

To make sure the greens have everything they need, the company collects data from the plants to create algorithms for growth.

"We built our own software which take images of leaves to understand height, width, length, stem ratio, curving, color, spotting and tearing," says Rosenberg.

The light is altered to fit each plant

The long rows of so-called growing towers are more like computers than farms, with sensors everywhere observing the process. Every now and then, one of the farmers does an inspection to ensure all is well, explains co-founder Marc Oshima.

"We think of ourselves as plant whisperers, listening and observing everything we can do to optimize our plants. Our growing approach is really leading the way, marrying biology, engineering, and data science."

Their farms are partly run on renewables such as solar power, but what really gets the carbon footprint down is bypassing extensive transportation of the produce by only selling the greens to local markets, shops and restaurants.

Staying local is part of the philosophy. "We have had some request to go nationwide. It's tempting, but seems counter to our mission of locally produced food," Rosenberg says.

Beyond organic?

In addition to ultra-low water usage, not using any soil further reduces the environmental impact.

The crops are currently sold at a 20% premium, similar to organic and locally produced food, but because no soil is involved, they cannot get an organic certification, although some retailers consider them to be beyond organic, Rosenberg explains.

The closed-loop system uses only non-GMO seeds and no pesticides, herbicides or fungicides, and so it reduces the harmful agricultural run-off into the environment, says Rosenberg.

"I think we are going to have a bigger and bigger impact on leafy greens and other crops in the future. And the future is going to be very different, in large part because of data."

By Sophie Morlin-Yron

Motorleaf Is Nest Meets Lego For Next-Gen Agriculture

The world of agricultural technology, or Agtech, is rapidly evolving.

Motorleaf Is Nest Meets Lego For Next-Gen Agriculture

The world of agricultural technology, or Agtech, is rapidly evolving.

It’s automating laborious tasks and providing farmers and growers with greater knowledge and insight into their crops than ever before. As technology evolves so does the needs of the farmer and the growing environment. Around 20% of the world’s food production is grown within cities rather rural areas and inherent in this is the multi-billion dollar industry of indoor growing and hydroponics.

The industry includes $5 billion in urban farming in the US and $5.7 billion for legal cannabis production.

Agtech company motorleaf have released the world’s first wireless monitoring, motion detection and automated growing system for hobby and industrial growers. I spoke to CEO and co-founder Ally Monk to learn more.

According to Monk, the idea originated when as a keen indoor hobby gardener, motorleaf’s co-founder and CTO Ramen Dutta wanted to go on holidays and needed a system to take care of his plants in his absence:

“Ramen was going on vacation, but he had the problem of what would happen to his plants in his absence. He looked at the market and assumed there would be something like a smart home system akin to google Nest but there was nothing. So he started making a HUB that could monitor what was going on and automate a range of appliances such as the water chiller and water level, air temperature, webcam, heating, and cooling. He soon realized that other indoor farmers were interested."

How motorleaf works

The Heart

Motorleaf has created a system that can automate and monitor an indoor growth area with up to 5 acre coverage. Their hardware, described by some as “Nest meets Lego for agriculture” is designed to be plug-and-play, and the grower decides which part of their plant operation they control/monitor and automate. It consists of four modular units:

- The Heart collects Air Temp, Humidity, & Light Level data. Users can connect any lighting hardware, and feeder pump- and start automating their operation in seconds.

- The Power Leaf connects wirelessly to the Heart which tells them when to turn on and off, based upon pre-set times or sensor readings from the Heart and Droplet.

- The Droplet monitors everything that’s connected to a grower’s water reservoir. Every 4 seconds The Droplet wirelessly sends data to The Heart, information on water level, temperature, PH level, and nutrient levels.

- The Driplet allows growers to automate the delivery of PH and Nutrients, again based upon timer setting or actual live grow conditions.

The system is agnostic, retails for about $1,500 and contains free software which facilitates custom settings, so the motorleaf hardware will automate the grower’s equipment and adjust to their crop’s needs. It’s available online and offline as many growers do not have WiFi in their crop space. It also alerts the grower to any problems that need attending to.

More importantly, it also involves intuitive efforts in predicting and anticipating the needs of the plants. Monk says:

“We’ve never been able to speak to plants but now through technology we can listen to them through their data, we can then understand what they need and feedback instructions to the equipment that’s looking after them so we can best serve their crops.

He also notes the many people’s depiction of the farmer outdoor engaged in manual labour as not entirely actually noting “The farmer of the future looks after his farm through his mobile phone and tablet.”1 He adds that indoor growers in particular have needs which can be more complex than traditional farming:

“When you start growing indoors you have to mimic nature, they have worry bout all the things they have to control indoors such as PH; nutrients, humidity, light, air temperature. How are they controlling it? Switches, controllers, some software and in many cases people are still using pen and paper. Urban farming is on the rise but the technology that looks after this is really lagging behind.”

Motorleaf is well-timed to respond to an emerging market. They receive receives 40,000 data points per customer per week and therefore can start predicting a crop’s needs, solving potential problems before they exist. Also, the start-up plans to use its network of data and growers to connect users to each other – on an opt-in basis – to share data, plant recipes and knowledge.

With the growth in indoor agriculture, hobby farmers and small to medium enterprises will soon benefit from effective IoT technology that enables smart crops and smart farming.

By Cate Lawrence

This Indoor Farm Can Bring Fresh Produce to Food Deserts

This Indoor Farm Can Bring Fresh Produce to Food Deserts!

Almonds got the brunt of the bad press, but they hardly deserve all the blame for California’s water woes. Sure, it’s worth considering how to minimize your water footprint, and forgoing your daily handful of almonds in solidarity with the parched earth couldn’t hurt. But considering how widespread the water crisis is, and the fact that agriculture is responsible for 80 percent of the country’s water consumption, the more crucial question to be asking now—particularly on Earth Day—is what can be done to fundamentally change the way our food gets made?

Mattias Lepp says at least part of the answer involves making it easier for anyone—even city dwellers—to farm their own food. That’s why Lepp, founder of the Estonian startup Click & Grow, has developed what he calls a Smart Farm, an indoor farming system that requires 95 percent less water than traditional agriculture.

You may remember Click & Grow from their uber-successful Smart Herb Garden Kickstarter campaign a few years back. That product let people easily grow herbs in their homes with minimal maintenance. The Smart Farm is similar, but on a much larger scale. The system, which Lepp spent years developing in partnership with universities across Estonia, France, and Russia, can hold 50 to 250 plants at a time, making it a viable option for urban areas that don’t have access to fresh produce—areas the US government calls food deserts. Ideally, a shift to urban farming could drastically reduce the distance between where food is grown and where it is consumed.

The market for these indoor farms, or so-called vertical farms, is already fast-growing, driven by the growing realization that the current water-chugging agricultural system is unsustainable. On one end of the spectrum, countless DIY indoor farming enthusiasts are growing small gardens in their homes. On the other are professional outfits like Green Sense Farms out of Chicago, which grows leafy greens indoors and sells them at local stores. Even tech giants like Panasonic and Toshiba have begun developing gigantic de facto farms of their own in Asia, where there is a severe shortage of agricultural land.

And yet, the majority of these larger farms use hydroponic farming, a process that involves growing plants in mineral solutions instead of soil. They save anywhere from 70 to 80 percent of the water required for traditional agriculture, but they’re complex and can cost tens of thousands of dollars. For most of us, it wouldn’t be economically practical for you or me to grow a full-scale farm at home.

With the Smart Farm, which costs just $1,500, Lepp says it can be. “People all over the world have worked intensively the last 10 or 20 years on bringing food production closer to cities and finding ways to grow it more efficiently,” he says. “But today they all are using hydroponics, and that is unfortunately expensive and messy. We see how we can change this.”

Rather than relying on hydroponics, the Smart Farm uses a new type of soil called Smart Soil, which Lepp developed in partnership with academic advisors. The soil itself is spongey, allowing air and nutrients to flow through. Meanwhile, the nutrients are covered in a special coating that responds to soil moisture. The hardware, which looks like a glass refrigerator, consists of trays for each plant equipped with LED lights and sensors that detect when the moisture levels are off balance. The “farmer” can use an app to adjust the water levels in the system, which triggers more nutrients to be released.

This process cuts down on the amount of water required to grow the plants, Lepp says, because no wastewater is produced. At the same time, the time people have to spend actually tending to the plants is minimized.

“Click & Grow can give the plant the perfect conditions to grow, because air, water, and nutrients are dosed perfectly without any obstacles,” says Uno Mäeorg, a professor at the University of Tartu in Estonia, who worked with Lepp on the development of Smart Soil “And since those conditions are perfect for the plant, it provides us healthier plants.”

Be that as it may, the Smart Farm is still a long way from accomplishing Lepp’s eventual dream of putting a full-scale farm in every urban neighborhood. For starters, the system only supports a limited number of plants today, including strawberries, tomatoes, lettuce, and other herbs, though Lepp says that will change with time. Also, for now the Smart Farm is only available on a built-to-order basis. While the company already has orders coming in and pilot projects with universities, it won’t begin full-scale retail distribution until 2016.

Then there’s the simple fact that we’re all just plain used to buying food from a store. The dream of distributed farming may always be limited to the number of consumers who care enough to try it out.

Still, according to Dr. Dickson Despommier, a professor of public health and microbiology at Columbia University and author of the book The Vertical Farm, that number is growing steadily. And as more people become willing to give indoor farming a try, he says it’s critically important that they have tools, like the Smart Farm, to ease the effort.

“I think it could make a dent in the commercial side of things,” Despommier says of indoor farming’s potential to impact mainstream agriculture. “And if you look at what’s happening in California, there may not be a commercial side of things for much longer.”

Issie Lapowski

Kimbal Musk's New Accelerator In Brooklyn Will Train Vertical Farmers

Square Roots hopes to sprout urban farming entrepreneurs all over the country.

Kimbal Musk's New Accelerator In Brooklyn Will Train Vertical Farmers

When it opens this fall in Brooklyn, a new urban farm will grow a new crop: farmers. The Square Roots campus, co-founded by entrepreneurs Kimbal Musk and Tobias Peggs, will train new vertical farmers in a year-long accelerator program.

"Young people contact me all the time to articulate issues with the industrial food system but they are frustrated by their perceived inability to do anything about it," says Musk. "It's relatively easy to set up a tech company, join an accelerator, and progress down a pathway towards success. It's more complex to do that with food. Seeing this frustration—and pent-up energy—was a big part of the original inspiration for co-founding Square Roots."

The campus will use technology from Freight Farms, a company that repurposes used shipping containers for indoor farming, and ZipGrow, which produces indoor towers for plants. Inside a space smaller than some studio apartments—320 square feet—each module can yield the same amount of food as two acres of outdoor farmland in a year. Like other indoor farming technology, it also saves water and gives city-dwellers immediate access to local food.

New urban farmers will learn specific skills from mentors—how to grow plants hydroponically, or how to sell at farmer's markets (though hopefully it will be a little more advanced than the level of the very funny rendering Square Roots sent us, which you can see in the slideshow above)—and they'll also collaborate on new ideas. "The idea of 'the campus' came from watching magic happen at tech accelerators, like Techstars, where I've been a long time mentor," says Peggs, who will be CEO of the new accelerator. "The aim with the campus is to create an environment where entrepreneurial electricity can flow."

It's intended for early-stage entrepreneurs. "We're here to help them become future leaders in food," says Musk, who also runs a network of school gardens and a chain of restaurants that aim to source as much local food as possible.

After building out the Brooklyn campus, they plan to expand to other cities, likely starting with cities where Musk also runs his other projects—Memphis, Chicago, Denver, Los Angeles, Indianapolis, and Pittsburgh. Each location will have 10 to 100 of the shipping container farms; Brooklyn will start with 10.

"We have a lot to prove in Brooklyn but our aim to replicate the model in every community as soon as we can," says Musk.

The accelerator is looking for its first class of applicants now, and taking applications on its website.

[Photos: via Square Roots]

Can Kimbal Musk Do for Farms What Elon Has Done for Cars?

“1,000s of millennials to join the real food revolution”

For more than 150 years, Pfizer manufactured pharmaceuticals in its 660,000-square-foot factory on Flushing Avenue in South Williamsburg, Brooklyn, New York. The pharma giant shut down operations in 2008, and since 2011, a host of food start-ups have taken up residence in the building’s cavernous halls. Starting next year, the bakeries and distilleries and kimchi companies will be joined by a venture called Square Roots. Founded by Kimbal Musk and Tobias Peggs, the urban farming accelerator aims to empower “1,000s of millennials to join the real food revolution,” as Musk (Elon’s brother) wrote in a Medium post announcing the venture last week.

“Our goal is to enable a whole new generation of real food entrepreneurs, ready to build thriving, responsible businesses,” Musk continued. “The opportunities in front of them will be endless.”

Square Roots’ real-food revolution will be built around container farming: shipping containers retrofitted into self-contained, highly efficient hydroponic mini farms. Beginning next fall, 10 ag-tech entrepreneurs will each develop an urban farming business in their own 350-square-foot shipping container housed in the Pfizer building. The containers will be able to produce the equivalent yield of two acres’ worth of farmland annually, with 80 percent less water than a conventional farm, according to Musk.

Brooklyn will be just the beginning: “Square Roots creates campuses of climate-controlled, indoor, hydroponic vertical farms, right in the hearts of our biggest cities,” Musk wrote on Medium. “On these campuses, we train young entrepreneurs to grow non-GMO, fresh, tasty, real food all year round, and sell locally. And we coach them to create forward-thinking companies that—like The Kitchen [Musk’s chain of eco-friendly restaurants]—strengthen communities by bringing local, real food to everyone.”

Square Roots joins the growing ranks of high-tech indoor-farming operations that are cropping up in old industrial sectors of major cities across the country—from Newark’s AeroFarms to Chicago’s FarmedHere—that are seeking to both shorten the food-supply chain and fundamentally reimagine the American farm as a high-tech, urban, factory-like operation.

If Square Roots and its contemporaries succeed, the country will be awash in locally grown lettuce, kale, and herbs. But the question is, how much locally grown lettuce, kale, and herbs do we need beyond what is already being produced? Is growing greens and herbs in shipping containers or old factories better—in terms of resources, emissions, and the environment—than growing them on farms in the Southwest? A container-farm entrepreneur can grow lettuce with less space and water than a farmer in California and Arizona, where the bulk of American lettuce is grown. But the question of sustainability isn’t answered quite so easily—and a greens revolution in agriculture can only do so much to address the problems the industry faces.

“I don’t think these big sweeping urban agriculture ideas are going to happen anytime soon,” Raychel Santo, a program coordinator at the Johns Hopkins’ Center for a Livable Future and a coauthor of a report on the potential of urban agriculture, told TakePart in May. Instead of supplanting traditional, rural agriculture, she sees urban farming’s potential in education, conservation, and as a means of fostering a connection between city residents and the food they eat—even if only on a small scale.

Start-ups like Square Roots tout the nearby nature of container farms: Produce can be grown on the outskirts of town instead of in the Arizona desert or California’s Central Valley. That’s part of the sustainability pitch: Container farming cuts down on emissions from transportation. But the great white lie of the local food movement is that the carbon emissions from trucking foods from there to here represent a small slice of agriculture’s overall climate footprint. The Environmental Protection Agency put ag at 9 percent of the nation’s overall emissions in 2014, with livestock and farmland management two of the major contributors.

With their highly efficient use of space, container gardens can do the work of a lot of farmland in exceptionally few square feet. According to Musk’s announcement, one shipping container can produce the same amount of greens or herbs as two acres of farmland—land that, if taken out of production, could be used to capture carbon rather than emitting it.

While container farms are highly efficient when it comes to space, the same cannot be said for their energy use. A 2015 study published in the International Journal of Environmental Research and Public Health sought to determine whether hydroponics were “a suitable and more sustainable alternative” to conventional lettuce farming in Yuma, Arizona, which today is better known for romaine than for train robberies. While the researchers found that hydroponics outperformed traditional field-grown lettuce production in terms of land and water use, the same could not be said for energy use. Between cooling in the summer, heating in the winter, and the energy required for 24-hour lighting, hydroponic operations have high electricity demands. As the authors of the paper concluded, “Due to the high energy demands, at this time, commercial hydroponics is not a suitable alternative to conventional lettuce production in Yuma, Arizona.”

The Johns Hopkins report on urban farming, which reviewed prior research on various types of city-based ag, found similar evidence, and the authors wrote that “producing food in urban settings may increase GHG emissions and water use if plants are grown in energy- and resource-intensive operations, such as indoor/vertical farming, greenhouses, hydroponics (soilless crop production), or aquaculture (the cultivation of aquatic animals or plants for food) facilities in cold or water-scarce regions.”

Both geography and technology could mitigate the energy problem of indoor ag, as the authors noted. Renewable energy could help to offset the energy demand for heating and cooling. Building hydroponics infrastructure in a milder climate could limit the amount of cooling and heating needed throughout the year. Even if the energy issue presents a problem with indoor farming as it exists today, the researchers pointed out that the technology “provides promising concepts that could lead to more sustainable food production.”

Technology could also help to make conventional lettuce farms more efficient from a water-use standpoint. The paper noted that hydroponics are able to use less water than field-grown lettuce not because each plant needs less water when grown indoors but because highly controlled indoor farms can outperform inefficient irrigation technology. Lettuce has shallow roots “but is primarily irrigated through flood furrow irrigation in southwestern Arizona,” the authors wrote, which is also the case in California. “Water not quickly absorbed by the roots is lost to percolation. Increases in the use of low-flow and more-targeted irrigation techniques could lower the overall water use of conventional farming.”

Would a venture capitalist plow money into improving existing ag technologies? It seems unlikely during an era when the tech industry fetishizes so-called disruptive companies. Why make a better irrigation system—or invest in one—when there are more innovative ideas like shrinking down the outmoded American farm, stuffing it in a repurposed shipping container, and dropping it in an old factory in gentrified Brooklyn? CNBC does not write about irrigation companies as a “hot new area for investors,” that’s for sure.

There’s the question of what can be grown in container farms too. AeroFarms grows greens and herbs; FarmedHere grows greens and herbs. Square Roots will grow greens and herbs. Spread, a Japanese indoor-farming company that promises to go fully robotic next year, will increase its daily yield to 50,000 heads of lettuce a day, thanks to its robot workforce.

Square Roots is working with two indoor-farming start-ups, Freight Farms and ZipGrow, for the incubator farms. Freight Farms will supply the shipping containers; ZipGrow will provide the vertical-farming towers. Freight Farms calls its farm-in-a-box containers Leafy Green Machines and recommends growing lettuces, herbs, and brassicas such as kale, chard, and arugula. ZipGrow’s “recommended go-to-market crops” are greens, herbs, and flowers.