Welcome to iGrow News, Your Source for the World of Indoor Vertical Farming

Could The Future of Farming Come From Thinking Inside the Box?

Could The Future of Farming Come From Thinking Inside the Box?

11/02/2015 10:42 am ET | Updated Nov 02, 2016

Cari E. Guittard Principal, Global Engagement Partners; Professor of Global Management, Corporate Diplomacy & Women’s Leadership, Hult International Business School

Recently, the first of many Farm from a Box to launch globally, landed in Sonoma county. Nestled among the vineyards of Shone Farm, “Adam” - a fully functioning farm emerged from a modified shipping container - was soft launched surrounded by a small group of supporters, advisors and several pioneering partners, to include those companies that manufacture all the necessary component parts from pumps and irrigation systems, to solar panels, weather tracking devices and batteries. The effort to disrupt the current thinking and approach to farming in rural communities was conceived by founders Brandi DeCarli and Scott Thompson who are taking the concept of ‘Teach a man to fish and feed him for a lifetime’ to a whole new level.

Food Aid Reinvented - The ‘Swiss Army Knife’ of Sustainable Farming

Having spent much of their careers overseas and working in various development and non-profit efforts, when Brandi and Scott see a need they dive in. Farm from a Box, which has been 3 years in the making, came from their personal passion to find a different and sustainable way to reinvent food aid particularly in areas where natural resources, infrastructure and technology are scarce. “Farm from a Box is the Swiss Army knife of sustainable farming,” said Brandi DeCarli. “We found that rural communities often lack the resources needed to access nutritious food. We developed a toolkit that contains all of the core components needed to grow your own food, on a two acre plot of land, without the need for an existing grid. Imagine the good it can do by growing local, organic food for a school, or helping jumpstart food production after a disaster. Farm from a Box enables and empowers communities to provide for themselves.”

Working with renowned agroecology Professor, Dr. Miguel Altieri, at UC Berkeley, who says that it is possible if land, labor, compost and seeds are available, a 2 acre diversified and self-sufficient agroecological farm can be up and running in a week’s time, managed by people locally. “I support the idea of Farm from a Box as it can provide basic resources for rural communities to create farms that don’t require external inputs,”advised Dr. Miguel, “allowing them to reach yields that will deliver sufficient food for themselves, with a surplus that can be sold in local markets.”

Farm from a Box plans to address the three keys areas that surround the global food crisis as noted by the World Resources Institute and underscored by the UN Sustainable Development Goals, ratified last month:

Global Food Crisis

1. Closing the Food Gap - Feeding 9.6 billion people by 2050

2. Supporting Economic Development by Training & Employing People in Agriculture Related Fields

3. Reduce Environmental Impact with Sustainable Technology and Practices

In early 2016 the second Farm from a Box, “Lucy,” will land in the community of Ziway, in the Rift Valley, Ethiopia and be run by a local women’s cooperative, the Rift Valley Women’s and Children’s Development Organization. The Ethiopian Government, showing remarkable leadership and entrepreneurial spirit, in 2011 established the Ethiopian Agricultural Transformation Agency (EATA) and initiated a massive growth and transformation plan to look at these issues holistically. Their goal, “focus on enhancing productivity and production of smallholder farmers and pastoralists, strengthening market systems, improving participation and engagement of the private sector, expanding the amount of land under irrigation, and reducing the number of chronically food insecure households.” Working closely with partners from the government, NGO and private sector will be key in ensuring that Farm from a Box sees long term success. As Scott shared at the recent groundbreaking,“Women play a vital role in global food security. While Ethiopia has historically struggled with food insecurity, the country is investing heavily in strengthening rural agriculture and building the capacity of smallholders. We chose to pilot “Lucy” in Ethiopia because we know that significant growth is occurring there and giving women access to tools is an investment that will yield tremendous results over the long term.”

Urban Cultivator Indoor Herb Growing Kitchen Appliance

The residential Urban Cultivator provides the means to an opulent herb growing garden right in your kitchen. Eliminate all the dilemma’s that can damage your outdoor garden, including: weather, insects and rodents

Urban Cultivator Indoor Herb Growing Kitchen Appliance

OCTOBER 29, 2015 HEALTHY LIVING KITCHEN APPLIANCES ORGANIC

The residential Urban Cultivator provides the means to an opulent herb growing garden right in your kitchen. Eliminate all the dilemma’s that can damage your outdoor garden, including: weather, insects and rodents.

Our seeds are non-GMO, and no sprays or chemicals are added in the growing process. You’re getting 100% organic, healthy food.

Enjoy true freshness and clean herbs instantly with an endless array of ingredients for your next meal: Aromatic Marjoram, Bold Swiss Chard, Bright Basil, Citrus Dill, Crimson Beet Tops, Crisp Lettuce, Crunchy Cabbage, Delicate Chervil, Earthy Komatsuna, Fragrant, Cilantro, Fresh Parsley, Hearty Sunflower, Indigo Radish, Malt Amaranth, Maple Fenugreek, Mighty Broccoli, Mild Chives, Minty Thyme, Nutty Flax, Pepper Arugula, Power Kale, Robust Lentils, Sharp Mustard, Spicy Radish, Sugar Pea, Sweet Wheatgrass, Tangy Lemon Balm, Tart Sorrel, Umami Savory, Wasabi Nasturtium, Wild Oregano, Woodsy Sage, and Zesty Peppercress.

Fits in the same space as a wine cooler or bar fridge. Or, just have it free standing with the optional butcher block top.

Quick Installation Overview:

1. City Water In Connection

Use the vacuum breaker & braided City Hose to connect to your city water connection. The hose comes with a standard ⅜” compression fitting.

2. City Drain Out Connection

Connect the City Drain Hose (1/2” to 3/4“ hose connection) to your city drain which should be no further than 6’ from the Cultivator and 2’ up from the floor.

3. Power Connection

Connect the Cultivator to a standard 110/240V power outlet. The electricity plug should be no further than 2’ away from the unit and should run out on the same side as the water and drain hose. The wall receptacle is non-replaceable.

4. Hole Size For All Connections

Use a 4” hole saw and remove part of the bottom shelf of the cabinet adjacent to the Cultivator where all the connections run from.

5. Adjustable Feet

Twist the Cultivators feet to adjust its overall height from 34¼” to 34 ½”.

To see the complete installation involvement, check out the appropriate Urban Cultivator support video.

Self-Sustaining Islands, the Future of Farming?

As nautical ways of living catch on, triple decker farms might start supplying a region near you.

Charlie Stephens

The future of oceanic farming is being shaped by a group of Spanish designers. Smart Floating Farms is a floating island of fish farms, hydroponic gardens and solar panels – all of which will help future farmers bypass the inefficiencies of traditional agriculture.

Created by Barcelona design firm Forward Thinking Architecture, Smart Floating Farms (SFF) are modular, self-regulating, and multi-dimensional ocean barges. The 656 x 1,150 ft. rectangular plots provide 2.2 million square feet of farming space, and can be linked or separated according to what is needed.

The main bottom is made up of a fish farm and slaughterhouse, which are maintained by manual labor and an encompassing wave protector. The bottom floor also holds the main storage facility and desalination plant for the hydroponic farm on the story above.

Since hydroponically grown food doesn’t need soil, the floating farm makes practical sense. Production management becomes simplified as well – data is collected from the aeroponic walls and processed through an IoT system that regulates growing conditions such as climate, and eliminates the need for harmful pesticides.

The result is a self-sustaining cycle where waste from the second floor can be used as food for the first, and vice versa. Energy for the farm is sourced from the third story, where high-energy photovoltaic panels and skylights would be located.

Like the designers behind Smart Floating Farms, other entrepreneurs are venturing into unchartered waters. Blueseed is a vision for an ocean-based community of entrepreneurs who live together on an anchored ship, working and creating alongside one another in a collaborative system. While SFF could be floated offshore to any country around the world, Blueseed offers working permits for people regardless of their home citizenship.

We are also seeing new uses of shipping containers, both as living spaces in cities and also as urban farms on college campuses. Traditionally, ships have needed to be compact and efficient to get from place to place, and this maritime model of living and producing appears to be transversing industrial boundaries.

While SFF is not a ship in the exact sense, the idea is still the same – the way we work is being affected by our environmental resources. As we try to bring food production to underserved areas and seek space for making this possible, methods of production are literally changing form.

The vast expanses of rural farms are being supplanted by the vertical farming, and hydroponics are constantly being improved and adapted around the world in place of soil-dependent techniques. Now, food can be brought from farm to table in just four hours, and unused urban spaces are being transformed into agricultural powerhouses.

Smart Floating Farms is yet another one of these innovative models for producing and delivering fresh, abundant food to areas in need around the globe.

This Giant Floating Farm Could Produce Almost 10 Tonnes of Food Each Year

This giant floating farm could produce almost 10 tonnes of food each year

Fruits, vegetables and fish!

This giant floating farm could produce almost 10 tonnes of food each year

Fruits, vegetables and fish!

FIONA MACDONALD

7 SEP 2015

Architects in Spain have designed a three-storey floating farm that would help produce nearly 10 tonnes of extra food for Earth's growing population each year, without taking up any land or fresh water.

The solar-powered farm would include massive hydroponic farms, watered by desalinated seawater, and a fish farm below, making the entire system self-sustaining and capable of producing most items in a healthy diet.

Of course, the farm is still very much conceptual and no prototype has been made just yet, so it's hard to know how successful their plans would be when put into practice. But the blueprint is based on existing technology, so there's no reason why it couldn't be built.

"This is not science fiction. It is a serious and viable solution," the architect team behind the concept at Forward Thinking Architecture write on their site. "It is not meant to 'solve' all of humanity’s hunger problems or to replace existing traditional agriculture; this is not the idea at all. The driver behind the project is to open a new initiative which can be complementary and compatible with other existing production methods in order to help reduce food risk associated problems in different areas of the globe."

This isn't the first time a floating farm has been proposed - last year a separate group of Spanish architects proposed a taller version of a floating farm, and in Japan and India engineers are building floating solar farms to harness electricity.

What's different about this design is that it contains its own mini-ecosystem that, in theory, would be capable of producing all of the following items:

According to the plans, the top level of the farm would be covered in solar panels and skylights, to allow sunlight to be harvested for electricity, and also to filter through to the plants below.

The second level would contain the hydroponic vegetables and crops. The waste products from these crops would be used to feed the fish in the level below, and the waste from these fish would then be used to fertilise the crops, creating a self-sustaining system.

Forward Thinking Architecture predict that the farm would be able to produce 1.7 tonnes of fish annually and 8.1 tonnes of fruit and vegetables.

Altogether the farm would take up a massive 200 m by 350 m area, or 204,000 square metres - which on land would be pretty impractical, but on the ocean wouldn't be much of a problem given the vast amount of space available.

The farm would also contain wind turbines and wave energy converters, to make the most of the natural energy available to it. And there would be a desalination plant and an on-board slaughterhouse and processing and packaging area, so that products could be sent straight to shops or consumers, reducing the food miles and carbon footprint of each product.

What's even better is that the farm is mostly automatic, using sensor systems to regulate watering processes and position itself in the most efficient spot each day.

Obviously there are some big hurdles to overcome with any type of structure of this kind - the biggest we can think of is the tumultuous nature of Earth's oceans. We currently struggle to keep wave energy generators safe from storm surges, so it would be hard to find safe spots to moor these beauties.

But with an abundance of harbours and lakes around the world, it wouldn't be impossible. And even though this is all just a pipe dream for now, if we could find a way to grow food sustainably in currently unused areas, it would be a big step towards feeding the soon-to-be 7.5 billion mouths on Earth.

H/T: Tech.Mic

This New Site Seeks to Strengthen the Boston Food Industry

The way Branchfood sees it, Boston has the potential to be one of the strongest food systems in the country. Already, Branchfood boasts info on more than 150 local producers, distributors, advocacy groups, funders, startups and composters.

This New Site Seeks to Strengthen the Boston Food Industry

Already, Branchfood boasts info on more than 150 local producers, distributors, advocacy groups, funders, startups and composters.

Rebecca Strong - Staff Writer

8/20/15 @11:21am in Tech

"Eat local."

It’s a phrase we’ve been hearing more and more in recent years, as awareness rises around the nutritional benefits of consuming produce that hasn’t traveled thousands of miles and interest in supporting the local agriculture economy increases. Now, there’s even a term for the people who practice this motto: locavores, who tend only to consume food grown within about 100 miles of its point of purchase. Branchfood launched in 2013 as a platform to promote local food innovation, while connecting like-minded people to share their growth-stage food product and food tech companies. The coworking and events startup, which is based at the CIC on Milk Street, recently realized the lack of a go-to source for learning more about the local food ecosystem—so they decided to build one.

Empowering the industry with information

Lauren Abda

Founder Lauren Abda says her inspiration for the Boston Food Network was this Techscene map. The idea was to aggregate information about all the various entities that make up Boston’s food scene, and bring all that data online so that it’s easily accessible and searchable. Currently, the site includes information about over 150 local food producers, distributors, advocacy groups, funders, startups, composters and more. And it’s already receiving national recognition: The Boston Food Network will be featured at the upcoming International Economic Development Council’s annual conference in Anchorage, Alaska—the world's largest annual gathering of economic developers. This new initiative will also be a topic of conversation at the upcoming Branchfood Community Table gathering Sept. 3.

Abda noted that the site will serve a wide range of people in the Boston community, bringing consumer awareness to local businesses while simultaneously helping those who value local food find out about local players.

“It’s the only site where one can gain a holistic understanding of the local food ecosystem,” she said.

For example, the Support Network section will give entrepreneurs an avenue for finding food focused venture funds, consulting services, or potential business partners. Consumers looking to find locally grown producer will find links to existing resources on farms, farmer’s markets and CSAs serving the Greater Boston area. Busy professionals, meanwhile, have access to a list of food/beverage delivery services on the site, and CPG companies can locate farmers markets and retail outlets that may be interested to carry their products. Chefs, of course, will reap rewards from the resource as well: They can use it to find catering companies to work with, as well as food waste and food recovery organizations available for food pickup or drop off.

The way Branchfood sees it, Boston has the potential to be one of the strongest food systems in the country.

“The strength lies at the intersection of Boston’s proximity to local food from New England farms, patronage for supporting local, and emerging entrepreneurial initiatives dedicated to improving access, cost, health, taste, and distance to our food,” explained Abda.

But in order to get there, it will be crucial for more people in the Boston food industry to connect and collaborate—which is where the new site comes in.

Boosting the network's value

During the first stage of pulling this together, Abda says her team received feedback from about 10 local food experts, enthusiasts, and Web design/development specialists on how to improve it. They are aiming to add more functionality in the future, including sorting and filtering entries, featuring new companies and organizations that want to increase their visibility, and providing further information on each organization such business partnerships or how long they have been active. Down the road, they’re also looking at incorporate this resource organically within other existing databases, like the data available on the City of Boston Office of Food Initiatives website.

Above all, Abda emphasized that The Boston Food Network is an evolving resource. Anyone can submit suggestions to add to these lists of food startups, producers, incubators, funders and distributors. She added that Branchfood is also considering ways to incorporate suggestions a la Wikipedia, with users submitting content edits, and Branchfood reviewing/approving. Already, they’ve added Local Food Jobs section based solely on initial feedback.

“We want this resource to continue to grow and be molded by community feedback and suggestions,” she told BostInno. “This is version 1.0.”

A top priority right now, according to Abda, is working with entities like the Office of Food Initiatives to find the best ways to make this information as easily available to the public and the area's stakeholders as possible, while simultaneously enhancing the technical aspects of the site for improved user experience and interest.

Ushering In The Future

Why thermal management is critical to the evolution of LED grow lighting

Ushering in the future

Why thermal management is critical to the evolution of LED grow lighting.

November 10, 2016

John Cafferkey

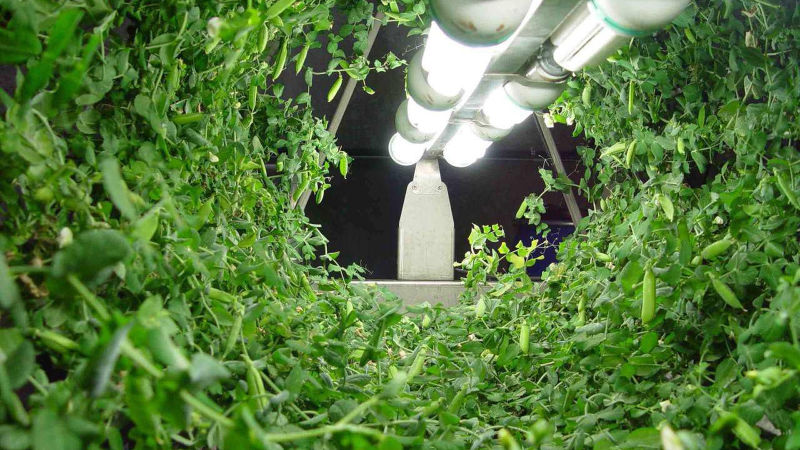

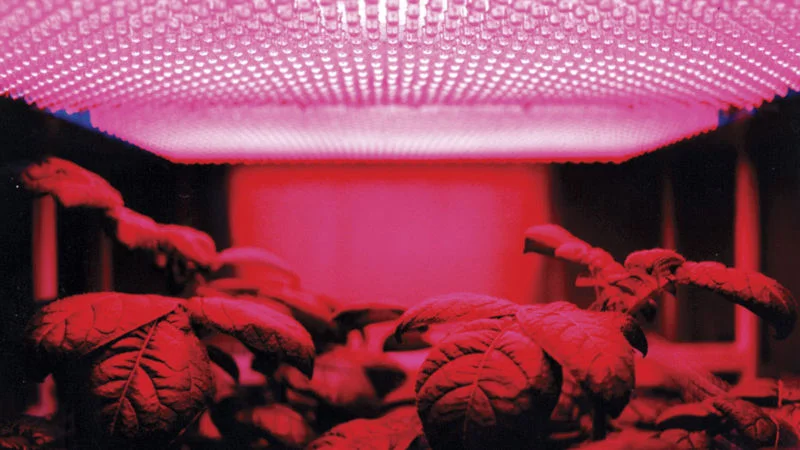

The world is undergoing a revolution in horticultural lighting that will have wide-ranging implications in terms of how and where we grow, and what crops we consume. The move from high-intensity discharge (HID) lighting to LEDs is slashing electric bills for indoor farmers. Alongside cost, the reliability and longevity have both improved, reducing maintenance requirements.

The “instant on-and-off” aspect of LEDs makes them easily integrated into automated growing cycles to maximize plant growth. And with wavelengths optimized for different crops, power usage can be reduced further. The lower heat output of LEDs means plants can be grown closer to light sources, allowing for better use of space.

Analysts LED Inside predicts the market will reach USD $500m by 2017, while WinterGreen Research sees it reaching $1.8 billion by 2021.

LED technology is likely to transform the horticultural industry

The argument for LED grow lighting is increasingly one of economy. The reduced running costs of LEDs has moved the market from high-value crops like cannabis, to lower-value fruit and vegetables, which is having a transformative effect on the industry.

LEDs allow affordable cultivation in previously inaccessible places such as tower blocks in city centres, extreme climates or areas lacking natural light such as the Arctic Circle in winter. Innovations like vertical farming, where plants are tightly stacked on floor to ceiling shelving with closely positioned LED lights, make enormous crop yields from a small footprint possible. Such techniques improve the consistency and standardization of crops while reducing pesticide use. And locating farms close to consumers cuts transport and storage costs.

The societal implications are enormous. In enabling the affordable growth of a diverse range of crops, LED technology has the potential to improve worldwide nutrition, as well as to offset food inflation as populations increase. By enabling crops to be grown close to consumers, LED technology could offset ecological and ethical issues associated with the over-farming of high-value crops (such as avocados and quinoa) within highly localized regions.

Thermal management is a critical factor in the further evolution of LED grow lights

However, LEDs do have one issue: thermal management.

The type of LEDs generally used in horticultural lighting are high-brightness LEDs (HB LEDs), between 1–5W. Although massively more thermally efficient than HIDs, most HB LEDs are still only around 40 percent efficient, so 60 percent of the energy comes out as heat rather than light. Horticultural LED modules often have hundreds of HB LEDs mounted onto a printed circuit board (PCB), creating a considerable thermal challenge. If heat isn’t removed effectively it can have a negative impact on the LEDs, reducing lifetime and light quality and ultimately leading to the LED’s failure, and the plants themselves.Another factor to improve thermal management is growers’ desire to place plants closer to the light source without heat affecting the crop, thus allowing for tighter spacing and greater economies of scale.

There are two fundamental types of thermal management — active and passive. Active thermal management uses fans and pumps to push air or liquid through the LED module. Heat is conducted into this medium (air or water) and drawn away from the LEDs where it is radiated out into the atmosphere or used to warm soil. Passive thermal management uses materials to conduct the heat away. A heatsink is a good example.

Most designers are familiar with active cooling systems. However, heat must be removed at the level of the LED chip itself. If heat is not effectively conducted away from the LED chip, the whole system will fail.

How LED heat extraction works (at the chip and board level)

An LED module will, depending on the device, generally feature either “packaged” or bare HB LED dies mounted on a PCB. To keep this simple, let’s assume the use of packaged LEDs.

A packaged HB LED cannot radiate heat directly into the air due to the surrounding encapsulant. Heat must be conducted through the bottom of the LED, - usually via a ceramic mount that is part of the HB LED ”package” – through the PCB and then out to the thermal management system.

Traditional PCBs, such as FR4, are not sufficiently thermally conductive for HB LEDs. Instead, HB LEDs are mounted onto metal-clad PCBs (MCPCBs), a PCB that incorporates a metal heat spreader. Critically, this MCPCB must also feature a dielectric (electrically isolating) layer that sits between the metal board and the circuit layer to prevent the LED shorting. This dielectric layer must be sufficiently thermally conductive to conduct heat effectively to the metal layer beneath it.

Traditionally, MCPCBs use a layer of epoxy resin between the metal base and the copper circuit as the dielectric. As resins are poor thermal conductors, the epoxy is usually laced with grains of ceramic to improve its performance. However, ceramic-loaded epoxy resin cannot achieve really good thermal conductivity because individual ceramic grains must be separated from each other by epoxy to hold the material together. As the need to remove heat increases, existing MCPCB solutions are unable to meet the challenge.

A new approach is required — one that enables MCPCBs to reach a significantly higher level of thermal conductivity.

Nanoceramics — a new approach to MCPCBs

A new approach to MCPCBs has been developed that delivers thermal performance suited to the demanding needs of horticultural lighting. This approach uses a patented electro-chemical oxidation process to convert the surface of aluminium into a nano-grain alumina (nanoceramic) dielectric layer.

The thinness of this alumina layer (10–30 microns) is critical as it creates an extremely short, uninterrupted thermal path which the heat can move quickly. This gives nanoceramic a composite thermal performance of 115 W/mK. This is much higher than anything else available.

This performance enables horticultural grow light designers to push the limits of lumen density, squeezing more light out of smaller modules. Indoor farms can be built to a higher density helping to achieve higher yields on the same footprint, ultimately driving the economies of scale that are the critical factor for this new wave of farming to fulfil its potential.

John Cafferkey is Marketing Manager at Cambridge Nanotherm, an innovative company employing nanotech for the thermal management of LEDs headquartered in Haverhill just outside of Cambridge. John is responsible for developing and communicating Cambridge Nanotherm’s proposition to global LED manufacturers and designers.

Vertical Farming: What Is It, And What’s Fueling Its Growth?

80% of the earth’s population will live in urban areas by the year 2050.

Vertical farming, or urban farming, is becoming more prevalent in the agribusiness sector. Experts predict that almost 80% of the earth’s population will live in urban areas by the year 2050, so developing and maintaining sustainable supplies of fresh food in large cities is increasingly important–and profitable.

By cultivating plants inside a skyscraper greenhouse, utilizing natural sunlight and artificial lighting, vertical farmers are able to produce fresh food while minimizing land usage and transportation costs. Droughts, floods and other weather-related issues are a thing of the past, and a controlled indoor climate carefully regulates ideal growing conditions year-round.

Curious about opportunities in vertical farming? Here are 10 things you need to know about this growing industry.

History of Vertical Farming

1. Vertical farming is regarded as a fairly new concept, but the idea has been around for a long time. In 1915, American geologist Gilbert Ellis Bailey wrote a book called Vertical Farming, and while it mostly dealt with using particular types of soils to grow crops, the idea for today’s vertical farm was born from his theory.

2. The first practical example of a vertical farm dates back to the 1950s, with an attempt at growing cress indoors at a large scale.

3. In 1999, students in a university classroom were discussing the idea of rooftop farming to produce rice. Dr. Dickson Despommier then took the discussion to the next level: what if crops were grown inside buildings?

How Vertical Farming Works

4. Using Manhattan as an example, Dr. Despommier’s class estimated that one 30-story vertical farm could produce enough food for more than 50,000 people, and 160 such farms could feed the entirety of New York City.

5. The plants that thrive best in vertical farms are nutritious types of produce, like green veggies and tomatoes. Crops like wheat and rice will be more difficult to grow in a vertical farming environment because of the amount of biomass required for them to thrive.

6. Vertically farmed crops can be grown hydroponically or aquaponically (in water) or aeroponically (in the air), without any soil. The biggest need is for a light source throughout the farm. Typically, prototype vertical farms use a combination of natural and artificial light for photosynthesis.

7. Because vertically farmed crops are produced indoors, in a controlled environment, people would have access to locally grown fresh produce year round – no need to purchase imported fruits and vegetables or prepared or frozen foods during the winter months, when those crops typically aren’t in season.

8. Another benefit to vertical farming? Produce grown indoors is organic and chemical-free, as no herbicides or pesticides are required.

The Future of Vertical Farming

9. By 2050, the world’s population is estimated to swell to 9 billion people, and experts guestimate that 80 percent of them will reside in urban areas. As the population grows, there will be less land mass available for farmland and growing food.

10. The world’s largest vertical farm is scheduled to open in Newark, NJ, this year. Set up in an old steel factory, it’s estimated to be 75 times more productive than a traditional farm of a similar size, and it requires no soil and 95 percent less water.

USA Subterranean Farm

About two years ago, before I was really ready, I proposed the development of a subterranean indoor farm in a major metropolitan area in the mid-western United States

USA Subterranean Farm

- Published on July 6, 2015

Glenn Behrman

FollowingUnfollowGlenn Behrman

CEA Advisors,GreenTech Agro LLC, Developers of The Growtainer™ & Growrack™. Indoor Farming Experienced Professional

About two years ago, before I was really ready, I proposed the development of a subterranean indoor farm in a major metropolitan area in the mid-western United States.With a population of 2.75 million, access to four major highways and a food deficit over 2 billion dollars per year, this was and still is an excellent opportunity.

Although I've been in the horticulture industry for almost 45 years, two years ago I was still connecting the dots and certainly didn't know then what I know now about indoor farming, controlled environment agriculture and technology based production but my proposal was well received by the local and state government officials that I came in contact with and they were behind the project 100%. The city and state offered substantial assistance, including access to various economic incentives, a preferred "local grown" purchasing initiative and assistance with developing strategic relationships with C level executives at local Fortune 500 businesses, local hospitals and universities, non-profits, schools, etc.

Since that time I've developed and nurtured relationships with the right people, further evaluated the site that I have in mind, met with the leasing people and found a subterranean site that is affordable, has a great infrastructure in place and is guaranteed to be front page news for a number of reasons.

Fast forward to today: Now I've spent the past four years laser focused on indoor farming, learning a lot from a lot of really qualified people. I've designed, built and operate two successful container based indoor farms, picked the brains of the most knowledgeable people in the industry, established a network of experts in every necessary component and facet of indoor production, spent 1000's of hours focused on site design, automation, production, technology and economics and now I'm ready to pull the trigger on the development of the most unique state of the art indoor farm in the world.

Fast Forward to November 2016. I'll be in Kansas City next week for the kick off of this fantastic project. Watch as it unfolds.... gb@cea-advisors.com

Five Vertical Farms that Capture the Imagination and Profit

Vertical farms: the idea captures our imagination.

May 17, 2015 | Rose Egelhoff

Vertical farms: the idea captures our imagination. We envision their upward-twisting frames nestled between the steel and chrome skyscrapers of the big city. Each floor overflows with fruits and vegetables brought to life by hydroponic or aquaponic growing systems, bringing local food and a breath of fresh air to cities with a footprint smaller than any “horizontal” farm.

Harvesters Alejandra Martinez (front), Steve Rodriguez, and Marquita Twidell cut basil grown in an aquaponic system at FarmedHere, a vertical farming operation based in Bedford Park, Illinois. Image courtesy of FarmedHere.

While setup and electrical costs remain expensive, a wave of vertical farmers around the world has been finding new ways to cut costs and streamline systems to make vertical farming a reality. They may not be ‘farmscrapers’, but these five vertical farms achieve production rates up to 100 times more efficient per square foot than traditional farming while bringing year-round local produce to their communities.

FarmedHere

FarmedHere’s huge, 90,000 square foot facility features an aquaponic setup lit by specially designed magenta and blue LEDs, developed through a partnership with the LED lighting manufacturer Illumitex, Inc. The lights emit only the frequencies of light that plants utilize, reducing energy costs. Roots dangle in trays of water fertilized with waste from tanks of tilapia and closed, soil-free systems minimize exposure to pests and disease, making their organic certification an easy achievement.

FarmedHere grows microgreens, basil and mint—staple crops for vertical farmers because they can be ready in as little as 14 days (that’s 26 harvests every year!). They sell to the big names, including more than 50 Whole Foods Markets and many other Chicago grocery stores.

This Singapore farming company exemplifies the potential for vertical farming to thrive in urban spaces. Real estate prices are sky-high on the densely-populated island, and access to fresh food is limited. Singapore imports most of its produce from China, Malaysia or the U.S.

Jack Ng saw the potential demand for fresh, local produce and created Sky Farms. He designed a growing system called A-Go-Gro. Thirty-foot A-frame towers rotate plant troughs up and down on a hydraulically powered belt to provide equal exposure to sunlight. Though Sky Greens grows hydroponically, these systems can also be adapted to soil growing.

Sky Greens currently produce ten varieties of greens including bok choi, lettuce, kang kong (water spinach) and bayam (amaranth). The product ends up costing about 10% more than imported greens but according to Permaculture News, Sky Greens’ extra- fresh veggies are “flying off the shelves.”

Another Chicago enterprise, the Plant describes itself as “part vertical farm, part food business incubator, part research and education space.”

Ten local food businesses, including several vertical farming operations, a sustainable prawn grower and a bakery, are located inside The Plant. The building is an abandoned pork packing facility in Chicago’s Back of the Yards neighborhood, retrofitted by crews of volunteers to fit the needs of local food producers. One business uses the roof space for good old soil farming while indoor operations employ hydroponics and artificial light. Plans for a shared kitchen are in the works, and The Plant eventually hopes to achieve net-zero energy use by harvesting biogas from their anaerobic digester, eliminating the high electricity costs that plague vertical farmers.

In Japan, the aftermath of the Fukushima crisis left in its wake both abandoned buildings and farmland devastated by radioactive contamination. Vertical farms like Mirai (“future” in Japanese) helped replace the lost food production capacity. Shigeharu Shimamuru, plant physiologist and president of Mirai, collaborated with GE Japan to design a state-of-the-art LED hydroponic system with carefully controlled wavelengths and dark periods. This means plants can photosynthesize at maximum capacity during the day and rest or “breathe” at night.

The combination makes for both fast-growing plants, and efficient resource use. Compared to conventional farming, the setup cuts produce waste by 50 percent, reduces water use by 99 percent and is 100 times more productive per square foot. The system operates in 12 locations around Japan, including a 25,000 square foot farm in the Miyagi prefecture just north of Fukushima, which can produce 10,000 heads of lettuce a day at full capacity. Mirai has recently begun another project in Korea.

Instead of growing in water, Aerofarms takes things another step away from conventional soil farming and grows plants in the air. Seeds germinate in a reusable fabric layer and suspended in stacked trays. The roots are sprayed with water and nutrients and LED lights fuel photosynthesis. Ed Harwood, a former Cornell professor who founded Aerofarms with his partners Marc Oshima and David Rosenberg in 2004, designed the system.

Aerofarms started off producing greens and herbs for farmers’ markets in upstate New York, including the prestigious Ithaca Farmers’ Market. They also sell their technology to other indoor farmers. Though not yet profitable, they are planning to expand. The project: a 69,000 square foot custom-built vertical farm in Newark, NJ. The $39 million development project, which is scheduled for completion in 2016, is being financed primarily by Goldman Sachs’ Urban Investment Group. Additional funds from Prudential Financial and the city of Newark supplement Goldman Sachs’ investment.

City of Vancouver Still Paying for Failed Urban Farm

A failed urban farm located in a downtown Vancouver parkade continues to be a costly headache to the City of Vancouver.

According to documents filed in a continuing lawsuit against the city, a greenhouse and equipment from the farm is still located in the parkade, over a year after the company operating the farm went bankrupt.

In a counterclaim filed April 20, EasyPark, a non-profit authority that manages parkades owned or leased by the city, claims it has been unable to use the roof of the parkade or make any income from the space.

EasyPark alleges the greenhouse is a safety risk because it could collapse in a heavy snowfall, and it continues to pay for security and maintenance related to the greenhouse, according to court documents.

EasyPark is asking for an injunction requiring the farm’s current owners to either remove the greenhouse from the roof of the parkade, or permit EasyPark to remove and dispose of the structure.

The counterclaim follows an initial lawsuit filed by Clay Haeber and a numbered company on March 3. In that claim, Haeber alleges the City of Vancouver’s refusal to transfer a licence to operate the farm in the parkade to his company is breach of contract.

Meanwhile, Donovan Woollard, one of the proponents of the high-profile vertical farm that went bankrupt in 2014, says he still believes in the concept and is now working with an Australian company on a new project.

Home of the lettuce-eaters

In 2012, Alterrus, a company trading on the Canadian Securities Exchange (CSE), signed a licence agreement with the City of Vancouver and EasyPark to use space in the parkade at 535 Richards Street.

Alterrus and its subsidiary, Local Garden Vancouver, operated the vertical farm in the parkade. It used a system involving stacked trays that moved automatically “to maximize exposure to natural light,” according to court documents.

The business model for the farm involved selling pesticide-free greens and herbs to high-end restaurants. Local Garden hired people with barriers to employment and planned to deliver by bicycle, according to media reports from 2012.

Alterrus' vertical farm on the top floor of a parkade at 535 Richards Street in 2012 |Dan Toulgoet, Vancouver Courier

At the time of its launch, Vancouver Mayor Gregor Robertson said the project showed “the innovative spirit in our city’s booming clean tech sector,” according to Business in Vancouver’s sister paper, the Vancouver Courier.

Public filings for Alterrus show the company tried several business ideas from the time it was incorporated in 1996, from bicycle rentals for hotels to online dating to skin care. By 2007, the company was focused on vertical farming, and in June 2012, changed its name from Valcent to Alterrus.

Alterrus’ 2012 annual financial statement showed an accumulated deficit of $52 million.

In 2014, both Alterrus and Local Garden Vancouver went bankrupt. The companies owed over $4 million, including $1.2 million to the largest creditor, Vancity Credit Union, and were behind on rent payments to EasyPark.

As the owner of sustainable business consulting company Transom Enterprises, Woollard partnered with Alterrus to launch Local Garden.

Woollard is also director of Radius Ventures, a socialenterprise program at Simon Fraser Univerity’s Beedie School of Business.

“For various reasons which I’d rather not get into, Alterrus as a company went bankrupt,” Woollard said. “At the end of the day there were a number of creditors of which I was one. I am hopeful for the space and [I] continue to do work in the vertical farming space and would love to see that facility open up again.”

Woollard is working with a potential business partner in Australia on another vertical farming project, although the venture is in a preliminary stage, he said. It’s possible the project may be based in Vancouver.

Strawberries, not marijuana

Haeber was appointed to Alterrus’ board in November 2013. In his lawsuit, Haeber claims he incorporated a numbered company because he wanted the vertical farming operation to continue and he was “keenly interested in the urban gardening concept.”

Haeber did not respond to interview requests from BIV.

Haeber is currently head of information technology for Kit and Ace, a clothing firm started by the son and wife of Lululemon (NASDAQ:LULU) founder Chip Wilson. According to his LinkedIn profile, Haeber worked at Lululemon between 2007 and 2013.

Haeber’s numbered company purchased the loans owed by Alterrus and Local Garden and became owner of the farm in July 2014, but still had to negotiate with the City of Vancouver and EasyPark for a licence to operate.

Haeber claims he told the city that once he got the licence, he would sell all his shares in the numbered company to Affinor Growers Inc., a company with experience growing medical marijuana in a vertical farming format. Like Alterrus, Affinor trades on the CSE, an exchange with simpler reporting requirements and lower fees than the Toronto Stock Exchange or the TSX Venture.

According to Haeber’s claim, Affinor confirmed to the city in writing that it would only grow vegetables such as strawberries in the parkade, not marijuana.

Affinor is not a party in the lawsuit.

Haeber alleges that both EasyPark and the city, along with Alterrus and Local Garden’s bankruptcy trustee, agreed to the terms of the licence agreement, prompting Haeber and Affinor to ink a $1.4 million deal for the operation, which included $500,000 in cash and the rest in Affinor stock.

The city’s refusal to grant the licence meant Haeber lost $1.4 million, he alleges. Haeber is now searching for a new buyer.

In a response, the City of Vancouver claims that city solicitor Heidi Granger made it clear to Haeber that final authority to sign a licence agreement rested with either the city’s director of legal services or city council.

The city alleges that while Haeber advised them he planned to sell the business to a third party in April 2014, he didn’t tell the city the identity of the buyer until the following August.

When the city did due diligence on Affinor, the response claims, it learned the company was in the business of growing medical marijuana. Affinor’s financial statements “raised concerns with respect to Affinor’s financial circumstances,” according to court documents.

“Ultimately, the City rejected the plaintiff’s proposal that Affinor be substituted in place of Haeber,” states the city’s response.

Now Affinor is considering launching its own lawsuit, said Nick Brusatore, the company’s chairman. He said his company lost $210,000 when the deal fell through.

“I feel borderline discriminated against,” he said.

Affinor has several projects in the works for both vegetable and medical marijuana production, Brusatore said. None of the farms is yet operational.

Brusatore doesn’t believe a vertical farm in the downtown parkade is viable as a business. His aim was to use the farm as a demonstration project to “have something pretty for the city so we could brag about what we did.”

The City of Vancouver declined, and EasyPark did not respond to, interview requests for this story.

With files from the Vancouver Courier

jstdenis@biv.com

@jenstden

5 Ways Vertical Farms Are Changing the Way We Grow Food

No soil? No problem. Vertical farms are sprouting around the world.

No soil? No problem. From Japan to Jackson, Wyoming, plucking fresh lettuce is as easy as looking up. Vertical farms have been sprouting around the world, growing crops in places where traditional agriculture would have been impossible.

Vertical farms are multiple stories, often have a hydroponic system and some contain artificial lights to mimic the sun. These green hubs are attractive in a variety of ways since food can be produced with less water (since it just recirculates), creates less waste and takes up less space than traditional farming, ultimately leaving a smaller footprint on the environment.

Additionally, the United Nations projects that the world's population will reach 9.6 billion people by 2050, 86 percent of whom will live in cities. For swelling cities, these urban farms give city dwellers greater access to fresh, nutritious food-year round, reducing the distance it has to travel to get to forks. Here are five more reaons why the sky's the limit with vertical farms.

1. Vertical farms can defy any weather: In perpetually wintry Jackson, Wyoming, residents will soon be able to find fresh tomatoes, lettuce and other produce that's not hauled in by delivery trucks. The Vertical Harvest farm is a three-story 13,500 square foot hydroponic greenhouse that will sit on a mere 30 by 150-foot plot adjacent to a parking lot. Utilizing both natural and artificial lighting (especially since the area is blanketed in snow most of the year), three stories of plant trays will revolve inside the building as well as the ceiling in a carousel-like system to maximize light exposure. The company aims to supply 100,000 pounds of year-round produce that's pesticide-free, and will use 90 percent less water than conventional farming because it recycles its water.

Construction of the $3.7 million greenhouse kicked off last November and has already pre sold crops to restaurants, grocery stores and a hospital. In the video below, E/Ye Design architects and Vertical Harvest co-founders Penny McBride and Nona Yehia talk about their innovative building and their mission to hire adults with developmental disabilities to spur local employment.

2. Vertical farms are a great response to climate change: Urban farming has been touted by many as a solution to increasingly extreme weather caused by warmer global temperatures. In very parched California, the Ouroboros Farms in Pescadero employs an unusual group of farmers: Catfish. The farm uses an "aquaponics" system, where 800 catfish swim and dine on organic feed, and as they create waste, the crops above suck up this nitrogen-rich fertilizer. All this means no soil, pesticides or other toxins are required for the stunning variety of vegetables that are produced at the farm, from spicy greens to root vegetables. In case you're wondering, nothing goes to waste; these fish are also sold as food. The farm also saves 90 percent less water than traditional farming.

"I honestly believe [aquaponics] is the evolution of farming," Ken Armstrong, the founder of Ouroboros Farms, said in the video below, "because of its ability to grow faster and more densely with fewer resources it will be the methodology of growing in the future."

3. Vertical farms adapt to disaster: We previously featured Japanese plant physiologist Shigeharu Shimamura, who converted an abandoned, semiconductor factory into the world’s biggest indoor farm, Mirai. Shimamura built the farm in 2011 in response to the food shortages caused by the Tohoku earthquake and tsunami that devastated Japan, and sparked the Fukushima nuclear disaster which irradiated much of the region's farmland.

At 25,000 square feet, the farm can yield up to 10,000 heads of lettuce a day. That’s 100 times more per square foot than traditional methods, and uses 99 percent less water usage than outdoor fields.

A press release said that the building is powered by special General Electric LEDs that “generate light in wavelengths adapted to plant growth. While reducing electric power consumption by 40 percent compared to fluorescent lighting, the facility has succeeded in increasing harvest yields by 50 percent,” and meant that Mirai was able to offset the cost of pricy LEDs. Watch how it all works:

4. Vertical farms are becoming more advanced: It's only the beginning for vertical farms in terms of technology. At the New Buffalo, Michigan branch of Green Spirit Farms, some plants grow under pink-tinted LED lights which "provide the correct blue and red wavelengths for photosynthesis," according to Harbor Country News. It's so efficient, the farm can currently grow 10 tons of lettuce in only 500 square feet of space. Green Spirit Farms president Milan Kluko also told New Scientist that he and his colleagues are developing a smartphone or tablet app that can adjust nutrient levels or soil pH balance, or sound an alarm when a water pump is malfunctioning, for example. "So if I'm over in London, where we're looking for a future vertical farm site to serve restaurants, I'll still be able to adjust the process in Michigan or Pennsylvania," he said.

Farm Manager Mike Kennedy making sure our fresh & local veggies (kale) are on the right time zone - they are now! pic.twitter.com/V4sNEzd6HR— Green Spirit Farms (@greenspiritfarm) March 8, 2015

5. Vertical farms are saving lives: Vertical farms are being used beyond food. In fact, they're being used to aid human health. Caliber Biotherapeutics in Bryan, Texas is home to the world's largest plant-made pharmaceutical facility. This 18-story, 150,000 square foot facility contains a staggering 2.2 million tobacco-like plants stacked 50-feet high, that will be used for making new drugs and vaccines. Because the indoor farm is so carefully monitored and tightly controlled by technicians, these expensive plants are shielded from possible diseases and contamination from the outside world.

Barry Holtz, the CEO of Caliber, told NPR that the facility is also efficient when it comes to water and electricity: "We've done some calculations, and we lose less water in one day than a KFC restaurant uses, because we recycle all of it."

Plants at Caliber Biotherapeutics grow in a "pink house" under blue and red LED lights. The tobacco-like plants will be used for making new drugs and vaccines. Photo Credit: Caliber Biotherapeutics

This vertical farm will provide Wyoming residents with 100,000 lbs of fresh produce each year

Not only will the Vertical Harvest provide fresh produce for Jackson, it will also serve as an educational facility, with a “small but functional ‘living classroom’” and access for visitors to view the growing areas without contaminating the crops

A 30 foot by 150 foot sliver of land located next to a parking lot in Jackson, Wyoming is set to be transformed into a vertical farm that will produce up to 100,000 lbs of produce each year. Using 90 percent less water than conventional farming, and absolutely no pesticides, the three-story Vertical Harvest greenhouse will enable the cold, land-locked city to provide locally-grown produce for its residents all year round.

The Vertical Harvest farm is designed by E/Ye Design and utilizes a 30 by 150-foot plot of unused city land that sits next to a parking lot in Jackson, Wyoming. Through an efficient building design, and the use of hydroponic farming techniques, the 4,500 sq ft footprint will have 18,000 sq ft of growing area. Within this area, the farm will produce over 37,000 pounds of greens, 4,400 pounds of herbs, and 44,000 pounds of tomatoes.

This is a significant amount of fresh produce for the town of 9,577, and provides residents with a locally-grown alternative thatJackson’s climate previously prevented. Located one mile above sea level, the town is blanketed in snow for months on end, and is therefore forced to import much of its food. In addition, the developers behind the farm have been careful to plan to grow only produce that is currently imported—thereby not competing with local farms, but rather bolstering local businesses by saving on transportation costs.

The 150-foot-long greenhouse facade of the building optimizes the potential for natural light, which both improves photosynthesis and cuts down on energy costs for the facility. There will be times when artificial light is required—for instance, it is impossible to grow tomatoes during a frozen winter on natural light alone—and so grow lights will be installed in order to ensure that the farm meets production goals.

Although the grow lights will require a certain amount of energy, Vertical Harvest founders Nona Yehia and Penny McBride have stated that it still constitutes net energy savings over imported produce, and while HPS (High Pressure Sodium) bulbs will be used for the tomatoes, LEDs will be utilized for the “lettuce varietals, microgreen and propagation areas.”

Not only will the Vertical Harvest provide fresh produce for Jackson, it will also serve as an educational facility, with a “small but functional ‘living classroom’” and access for visitors to view the growing areas without contaminating the crops. Vertical Harvest recently broke ground, and growing will commence later this year.

Vertical farms: "Making Nature Better"

The entire operation is indoors, and it's a trend that could turn urban areas into agricultural hotbed

By DEAN REYNOLDS CBS NEWS December 27, 2014, 7:04 PM

Vertical farms: "Making Nature Better"

- PORTAGE, Indiana -- Do not be confused by the drab facade of the warehouse in this Northwest Indiana industrial park. It's a farm... and it could well be the future. They're called "vertical farms" -- The entire operation is indoors, and it's a trend that could turn urban areas into agricultural hotbeds.

You'll find arugula and parsley, basil, kale and other greens that grace our plates.

"We are growing nine varieties of lettuces,'' said Robert Colangelo, the founder of Green Sense Farms.

Or you could call him Mr. Salad.

"I guess. I'll take that. I could be called worse," says Colangelo.

This is how he does it, with a pink light from a light-emitting diode, or LED

"It gives you a very concentrated amount of light and burns much cooler. And it's much more energy efficient," says Colangelo.

No sun? No problem.

Researchers believe plants respond best to the blue and red colors of the spectrum, so the densely-packed plants are bathed in a pink and purple haze. They're moistened by recycled water; bolstered by nutrients; and anchored in a special mix of ground Sri Lankan coconut husks.

"We take weather out of the equation," says Colangelo. "We can grow year round and we can harvest year-round."

This abundance keeps the prices consistent year-round at local groceries.

Scott Hinkle, a local chef, says the sunless harvest tastes great. Hinkle shows off a "blossom salad" he serves which can include watercress, micro-arugula or kale.

With less water and fertilizer, fewer workers and no gasoline, it's more economical to grow greens this way than on a traditional farm.

Since there are no bugs, there's no need for pesticides. No weeds, so no need for herbicides.

And Colangelo really knows his plants. He says workers play classical music to create happy vibes for the flora.

Is there a composer the plants prefer? If it's Metallica, we don't want to eat it.

As to whether he's cheating nature...

"We're making nature better," says Colangelo.

There's no need for insecticides or herbicides inside the warehouse.

CBS NEWS

© 2014 CBS Interactive Inc. All Rights Reserved.

Urban Farms Build Resilience Within Singapore's Fragile Food System

"For every 2.5 acres, we should be able to produce 1,000 tons of vegetables per year — or about 1 percent of Singapore's needs for leafy green vegetables

Urban Farms Build Resilience Within Singapore's Fragile Food System

August 20, 20147:17 AM ET

At a local FairPrice Supermarket in central Singapore, you'll find baby carrots grown in Bakersfield, Calif. — the same ones for sale at my local grocery store in Washington, D.C.

Such well-traveled vegetables aren't unusual in the tiny island state, which imports more than 90 percent of its food from some 35 countries. Singapore may be one of the most affluent countries in the world, but it depends heavily on others for basic foodstuffs.

A new crop of farmers is trying to change that. Just as property developers build up when they can't build out, so, too, are these agricultural pioneers. Vertical farming is taking hold across Singapore — not only in greenhouses in the vanishing countryside but also on rooftops in the heart of the city, amid soaring skyscrapers and housing blocks. The goal is to farm as efficiently as possible and maximize the remaining land — as well as abandoned and under-utilized spaces — and improve Singapore's ability to provide more of its own food.

In the 1960s, farms occupied about 10 percent of Singapore's 280 square miles, says Ngiam Tong Tau, a former government official who now is chairman of Sky Greens, one of Singapore's vertical farms.

Today, it has shrunk to less than 1 percent to make way for housing and industry.

Not only is land in short supply, but water is, too. Singapore imports an estimated 30 to 40 percent of its water from neighbor Malaysia.

All this means that these new rooftop and vertical farms could make a big difference for Singapore, helping to insulate it from both natural and man-made threats to its food supply that result in periodic food shortages and price spikes.

"In times of emergencies or food shortages around the world, [if] our neighbors ... don't want to export to us, we still have some food left for certain short periods of time until the food emergencies subside," Ngiam says.

Farming High In The Heart Of The City

Once lined with plantations, Singapore's Orchard Road is now a sort of Asian Rodeo Drive. But overlooking the commercial mecca is a different kind of oasis: 6,000 square feet of vegetable and fish gardens.

The aquaponic garden features mint, basil and leafy greens growing in clay pellets in rows on vertical A-frames that draw water from tanks filled with fish. The waste from the fish fertilizes the plants; eventually, the tilapia will become another crop — to be sold or donated to charity.

It's an economical system, says Allan Lim, one of the founders of ComCrop, the startup that built this garden. It costs about $1.60 a day to pump the water through the 10-foot-tall frames, which go for about $1,000 each.

This closed-loop irrigation system makes sense in tropical Singapore since it uses less water and loses less of it to evaporation and runoff than traditional soil farming. Still, for now, ComCrop relies on roughly two-thirds tap water — versus harvested rainwater — to replenish what's lost to evaporation.

Electricity costs are fairly low, too, and ComCrop's central location means it doesn't have to spend much to distribute its food to clients. Its vertical system yields eight to 10 times more crops than conventional, soil-based farming, according to Keith Loh, another one of the company's founders.

ComCrop sells its herbs wholesale to a local distributor that supplies high-end bars and restaurants. But one of the macro problems that these entrepreneurs are addressing is how to help Singapore's food supply withstand external disruptions like drought, flooding or trade restrictions due to regional public health issues — for example, when Malaysia halted poultry exports during the country's 2004 outbreak of avian flu.

Next year, they hope to scale up the farm by 10 times at another building that houses 80 food-processing companies, with a goal of producing 23 tons of food per month.

"Our goal is that when a time of need comes, the rooftop farm can convert into something important," Lim says.

From Ghost Town Garage To Showcase Garden

Atop the mostly empty garage of the People's Park Complex, a massive housing and commercial development in Chinatown, is a pop-up boutique, spare with a minimalist color palette and lots of reclaimed wood. It wouldn't look out of place in Brooklyn.

It's an outpost of Edible Gardens, a design firm founded two years ago by Briton Rob Pearce and Singaporean Bjorn Low that does foodscaping and landscaping for hotels and restaurants.

"Space in Singapore has to work really hard," says Pearce, who comes from a family of farmers in Somerset, England. "People see what we're doing, so it has to be beautiful."

The next beautification project is turning half of the garage's 60,000-square-foot roof into a farm. Pearce sees rooftop gardens that use otherwise abandoned or underutilized spaces as a win-win solution for developers and urban farmers.

Reaching Higher In The Countryside

Singapore's vanishing countryside — accessible via a 40-minute ride on the immaculate and ultra-punctual MRT train — is home to Sky Greens, one of the world's first commercial vertical farms.

Though Sky Greens has put down roots on 8.6 acres, its crops grow in greenhouses on 30-foot-high vertical frames with hydraulic rotating troughs that bring the plants down to water and then up to the sun.

This kind of farming, says Ngiam, Sky Greens' chairman, yields five times more food than conventional farming.

"For every [2.5 acres], we should be able to produce 1,000 tons of vegetables per year — or about 1 percent of Singapore's needs for leafy green vegetables," Ngiam says.

With about half of the farm developed, Sky Greens is already producing 1.5 to 2 percent of Singapore's demand for leafy green vegetables such as baby bok choy, Chinese water spinach and Chinese broccoli, he says. Eventually, the farm will have 2,000 A-frames, which cost about $12,000 each.

Like other urban farms in Singapore, one of Sky Greens' advantages is how little water it uses, relying primarily on collected and recycled rainwater. And its system of hydraulic-powered rotating troughs means less spent on electricity, and even less water is wasted.

"The troughs come down and go into the water and go up. So there's no leaching of the water," Ngiam explains. "If you are planting on the soil, what the farmer does is pour a lot of water, and then it just leaches out. For us, every drop is used by the plant."

Another advantage is that Sky Greens products can go from harvest to market within the same day. By comparison, vegetables from Malaysia travel one to two days to market.

Sky Greens vegetables do cost more: up to $2 per 3.5-ounce package, or about 10 percent more than vegetables from Malaysia. But Ngiam thinks some middle- and upper-income Singaporeans are willing to pay that premium.

Despite the challenges — of scale, pricing and sustainability — for each of these vertical and rooftop farms, the trend toward quality and the push toward self-sufficiency all point in one direction: up.

This Vertical Farm Skyscraper May Change Our Cities Forever

The Hive-Inn farm would seriously re-vamp the way urbanites eat, by providing very local produce

The Hive-Inn farm would seriously re-vamp the way urbanites eat, by providing very local produce.

Imagine a future where you could pick fresh produce in downtown Manhattan just by visiting a vertical farm right down the block, or where restaurants could use local ingredients from that same quirky-looking farm skyscraper. That future may be nearer than you think. Meet the Hive-Inn farm by OVA Studio in Hong Kong, a concept that is still just in sketch form, but could be changing the way urbanites eat as soon as the next several years.

The Hive-Inn farm resembles a small skyscraper, and is essentially a vertical farm made up of individual containers, or farming modules. Each unit would play a role either in producing food, harvesting energy from the sun and rain, or recycling waste. Essentially, the whole “green building” would be a living ecosystem. The Hive-Inn farm would produce fruits and vegetables that could be used by downtown Manhattan residents and businesses.

See More Urban Farming News

- World’s First Underground Farm to Open This Fall in London

- Explorations in Urban Farming

- The Case for Connection: Urban Farming Takes Root in Upper West Chicago

- Urban Farming Takes Off in Tokyo

- Changing Lives – Urban Farmers of Nairobi

We spoke with Slimane Ouahes, the director at OVA Studio about the future of the project, and what it could mean for New York. Right now, he said, OVA does not have a client, and the idea is still in the planning stages.

“As [the farm] is local, there is nothing to hide, you can see your food growing, rebuild trust between the food production and your appetite, and it will be an attraction for visitors,” explained Ouahes. “Local restaurants would also produce their veggies in these containers and have much more control over the quality.”

Indoor Farm Taps Technology To Grow Leafy Greens

The indoor operation consists of 10 individual farms, each about the size of a parking space that a Toyota Prius would occupy

Drawing from his background as an electrical engineer, Steve Fambro, founder and chief executive officer of Oceanside, Calif.-based Famgro Farms, has tried to eliminate as much variability in leafy green production as possible.

Steve Fambro has drawn from his electrical engineering background to take a systems approach to producing leafy greens indoors

The result is an indoor technological platform that optimizes crop production by trying to provide all of the plants’ needs in terms of lighting, nutrition, humidity, air flow and moisture.

“It uses hydroponics that we have developed and patented and it uses LEDs that we manufacture and patented, but those are just parts of the story,” Fambro said. “I don’t consider this vertical farming. Our goal is so much more.”

Instead, he thinks of it as a systems approach that meshes with his personal philosophy of providing affordable, locally grown produce.

The indoor operation consists of 10 individual farms, each about the size of a parking space that a Toyota Prius would occupy. Together, they produce leafy green yields equivalent to those from 5 to 10 acres of open fields, Fambro said.

The farm grows myriad leafy greens, ranging from its signature sweet kale to microgreens and herbs.

The kale, marketed under Famgro Farms' own label, is touted as having a buttery texture that eats more like lettuce.

“It’s not unlike Kobe beef,” Fambro said of its tenderness.

Although the operation does produce kale microgreens, its forte is full-grown leaves.

“The reason for that is chefs like the savoy, bumpy leaves and they can plate it in different ways,” he said.

For each crop, the company has developed a specific production system that caters to that plant’s individual needs.

The kale crop, for example, spends just 15 days as seedlings and another 15 days in the farm under intense lighting before harvest.

All of the crops are grown in an enclosed building designed to exclude insects, weeds and diseases. Sanitary procedures along the way help to minimize pathogens.

As a result, Fambro said they don’t use any pesticides.

In addition, he uses no animal-based nutrients.

Under the National Organic Program, producers can use 37 different pesticides, bone meal, fish emulsions and manure-based composts while maintaining their organic certification.

Famgro’s crops are not certified organic, partly because portions of the program conflict with his philosophy and partly because of food safety concerns.

Take fish emulsions, for example.

“We have no idea if it’s old-growth fish that are brimming with mercury,” he said. “There are no standards of any kind of how those fish are acquired or rendered into fish emulsions.”

Using animal-based products also introduces a second life form into the plant production system, complicating food safety, Fambro said.

In addition, using a vegan-based production system allows the company to market to consumers who for personal or religious reasons oppose killing animals.

As with every crop grown, each step along the way is entered into the computer and tied to a batch number. Not only does this provide for traceability, but it also allows the operation to improve the growing process, Fambro said.

If a propagator, for example, isn’t doing his or her job and yields suffer, the cause can be traced back.

Having all of the data at the touch of a computer also allows the company to schedule production just in time to meet customers’ orders.

Famgro sells to individual local retailers, Whole Foods in Southern California and foodservice as well as through wholesaler LA & SF Specialty, Los Angeles

14 High-Tech Farms Where Veggies Grow Indoors

Farming is moving indoors!

In the 21st century, a significant change is underway in the food industry: farming is moving indoors. The perfect crop field could be inside a windowless building with controlled light, temperature, humidity, air quality and nutrition. It could be in the basement of a Tokyo high-rise, in an old warehouse in Illinois, or even in space. Just look at our collection of awesome indoor farms, where the sun never shines, the rainfall is irrelevant, and the climate is always perfect.

Basil, arugula and microgreens.

A worker checks crops at the FarmedHere indoor vertical farm, in Bedford Park, Illinois, on February 20, 2013. The farm, in an old warehouse, has crops that include basil, arugula and microgreens, sold at grocery stores in Chicago and its suburbs.

Photo: Heather Aitken/AP

Your endive grows in total darkness.

Red endives at the California Vegetable Specialties indoor farm in Rio Vista, California (April 20, 2006). The growing process is long and fragile, with the endives' roots grown outside first and then moved in, where they are left for up to 11 months to grow into mature endives in total darkness.

Photo: Jeff Chiu/AP

Under fluorescent lights.

Toshihiro Sakuma checks the condition of plants under fluorescent lights at a greenhouse built inside a Tokyo building on July 1, 2005.

Photo: Shizuo Kambayashi/AP

Sunless farming.

Fittonia plants are seen as they grow in a special darkened room illuminated by blue and red LEDs at PlantLab, a private research facility, in Den Bosch, central Netherlands, March 28, 2011.

Photo: Peter Dejong/AP

Medical cannabis growing operation.

This facility can be found in Oakland, California. The electricity bill is over $4,000/month.

Illegal cannabis growing operation.

This indoor marijuana farm in California was raided by police.

Photo: Arcata Police Department/AP

Legal cannabis growing operation.

In the Netherlands it was legal to grow hemp for a long time. This is what cultivating the world’s finest indoor marijuana looked like a few years ago.

Photo: World Of Seeds

Japanese indoor greenhouse.

Flowers grow under fluorescent lights in greehouse named "Pasona O2" in the basement of a highrise office building in Tokyo. The new style of greenhouse, built by the human resources service company Pasona Inc. in 2005 at the center of Tokyo's business district, is a facility to train aspiring farmers with high-tech methods involving hydroponics and light-emitting diodes (LED).

Photo: Yohei Yamashita

Rice plants at an indoor paddy field in "Pasona O2". Pasona hopes this greenhouse can help promote the pleasure of agriculture to businessmen and businesswomen, and inspire a new generation of farmers.

Photo: Yohei Yamashita

Tomatoes grown by hydroponics cultivation in "Pasona O2."

Photo: Katsumi Kasahara/Ap

A staff of "Pasona O2" checks vegetables grown under fluorescent lights.

Photo: Katsumi Kasahara/Ap

Hydroponics gardening for the masses.

"The Volksgarden brings simple, clean, and amazingly effective hydroponics gardening to the comforts of your own home," says the company Urban Led Growth. This unit allows to grow up to 80 plants at once. Herbs, vegetables, fruits, and grains can be harvested easily and continuously thanks to the rotating cylinder housing.

Photo: Urban Led Growth

Put an AeroGarden into your kitchen.

This dirt-free indoor garden planter uses aeroponics: vegetables, salad greens, herbs or flowers grow in this pod while being both slightly exposed to air and slightly submerged in the nutrient solution. The AeroGarden has built-in lights and a “Smart Garden” alert button to tell you when your plants need more nutrients or water.

Photo: timmycorkery

An automated, hydroponic, recirculating vertical farming unit.

This is one of the four indoor, climate controlled, automated, hydroponic, recirculating vertical farming units at Green Farms A&M. Green Farms Agronomics & Mycology is located in Valparaiso, Indiana, and was founded in the fall of 2010.

Photo: GreenFarms

Chicago urban garden.

The first "Aeroponic Garden at Any Airport in the World." In 2011, the CDA and HMS Host Corporation collaborated to install a garden in the mezzanine level of the O'Hare Rotunda Building. In this garden, plants' roots are suspended in 26 towers that house over 1,100 planting spots. A nutrient solution is regularly cycled through the towers using pumps so that no water evaporates or is wasted, making the process self-sustaining. No fertilizers or chemicals are used.

Photo: Gkkfea

Astroculture.

A view inside the "Astroculture" plant growth unit, during Space Shuttle mission STS-73, in 1995. Quantum Devices Inc., of Barneveld, Wisconsin, builds the light-emitting diodes used in medical devices and for growing plants, like potatoes, inside the plant growth unit developed for use on the Space Shuttle by the Wisconsin Center for Space Automation and Robotics (WCSAR). The astroculture facility has flown on eight Space Shuttle missions since, including this one in 1995 in which potatoes were grown in space.

Soybean growth aboard ISS.

Expedition Five crewmember and flight engineer Peggy Whitson displays the progress of soybeans growing in the Advanced Astroculture (ADVASC) Experiment aboard the International Space Station (ISS), in 2002. The ADVASC experiment was one of the several new experiments and science facilities delivered to the ISS by Expedition Five aboard the Space Shuttle Orbiter Endeavor STS-111 mission. An agricultural seed company will grow soybeans using the ADVASC hardware, to determine whether soybean plants can produce seeds in a microgravity environment. Secondary objectives include determination of the chemical characteristics of the seed in space and any microgravity impact on the plant growth cycle.

Top photo: Yellow peppers under blue and red Light Emitting Diode (LED) lights at PlantLab, a private research facility, in Den Bosch, central Netherlands, March 28, 2011. Photo: Peter Dejong/AP

By Attila Nagy

Sky-High Vegetables: Vertical Farming Sprouts In Singapore

Singapore is taking local farming to the next level, literally, with the opening of its first commercial vertical farm

Sky-High Vegetables: Vertical Farming Sprouts In Singapore

November 9, 20123:31 PM ET

Singapore is taking local farming to the next level, literally, with the opening of its first commercial vertical farm.

Entrepreneur Jack Ng says he can produce five times as many vegetables as regular farming looking up instead of out. Half a ton of his Sky Greens bok choy and Chinese cabbages, grown inside 120 slender 30-foot towers, are already finding their way into Singapore's grocery stores.

The idea behind vertical farming is simple: Think of skyscrapers with vegetables climbing along the windows. Or a library-sized greenhouse with racks of cascading vegetables instead of books.

Ng's technology is called "A-Go-Gro," and it looks a lot like a 30-foot tall Ferris wheel for plants. Trays of Chinese vegetables are stacked inside an aluminum A-frame, and a belt rotates them so that the plants receive equal light, good air flow and irrigation. The whole system has a footprint of only about 60 square feet, or the size of an average bathroom.

Advocates, whose ranks are growing in cities from New York City to Sweden, say vertical farming has a handful of advantages over other forms of urban horticulture. More plants can squeeze into tight city spaces, and fresh produce can grow right next to grocery stores, potentially reducing transportation costs, carbon dioxide emissions and risk of spoilage. Plus, most vertical farms are indoors, so plants are sheltered from shifting weather and damaging pests.